Escolar Documentos

Profissional Documentos

Cultura Documentos

Maquina de Teste Abrasão PDF

Enviado por

ruytguerraTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Maquina de Teste Abrasão PDF

Enviado por

ruytguerraDireitos autorais:

Formatos disponíveis

Date : March, 01 2010 Publication : SA Builder/ Bouer Page Number: 44-45

The abrasion testing machine will assist customers in complying with the new South African Bureau of Standards abrasion requirements for concrete pavers

CMA director, John Cairns

Abrasion testing machine assists in complying with paving regulations

he leading manufacturer of block and brick making machines. Pan Mixers South Africa ;PMSA), in partnership with the Concrete Manufacturers Association (CMA). has manufactured a robust abrasion testing machine to assist customers in complying with the new South African Bureau of Standards (SABS) abrasion requirements for concrete pavers. The new SABS standard, which has been established by the CMA, will make way for concrete pavers that are specified not only in crushing and breaking strength, but in abrasion resistance too. The new standard - SANS 1058 Concrete Paving Blocks - is in its publishing stage, and should be finalised in the next few months. PMSA director, Walter Ebeling. says that once the standard is implemented, the company's abrasion testing machine will allow users to carry out their own testing of this portion of the SABS certification, thus eliminating the need to send products to external laboratories and, in turn, minimising downtime. "In the past, paving has sometimes failed - not because of the paving block strength, but because the abrasion resistance of the pavers was not adequate. The new standard specifies a measurable standard for abrasion resistance,'' explains Ebeling.

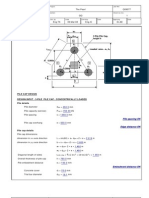

After carrying out extensive research, the CMA determined that the most uniform method of testing abrasion to the new SABS standard would be to use ball bearings. "This technique simulates high-traffic areas such as loading yards, stock yards and intersections whereby abrasion is a problem," adds Ebeling. The abrasion testing machine is a square-shaped drum, onto which four pavers can be bolted to each face of the machine. A small opening allows the surface of the paver to be exposed to the inside of the drum. The steel ball bearings sit inside the drum, while the pavers are clamped onto each of the faces. When the drum turns the bell bearings fall onto and slide across the pavers - thereby simulating abrasion. After a specified number of revolutions, the pavers are weighed and the mass loss is measured against their weight before the test began. CMA director, John Cairns, says that on a set of eight pavers, the average weight loss must not exceed 12 grams. If the weight loss falls below the 12 gram mark, the pavers will be considered abrasion resistant.

44

BUILPER

MARCH 2010

Page 1 / 2 Size=826X299mm Circulation: 1 Readership: n/c

Date : March, 01 , 2010 Publication : SA Builder/ Bouer Page Number: 44-45

Furthermore. Pan Mixers' abrasion testing machine has been built with replaceable liners, as well as safety guarding, which prevents any pan of an operator's body from making contact with, or coming close to dangerous moving parts. In addition, the machine is backed up by PMSA and is built to last many years. All the components are machined on Pan Mixers' inhouse computer numerically controlled (CNC) machine. Cairns adds that alternate methods of testing - such as wire brushing - are inferior, as there are too many variables that could influence the amount of wear on a paving surface. By using steel ball bearings, these variables are covered, and a comprehensive test result is achieved. The current standard does not take abrasion into account. "Prior to conducting research, it was thought that a paver with a higher compressive strength would offer better abrasion resistance properties. This has, however, proved to be incorrect - there is no relationship between compressive strength and abrasion resistance. Our charts show that even a block of 59 MPa can have very poor abrasion resistance, while a block of only 25 MPa can have excellent abrasion resistance," notes Cairns. He says that concrete paving blocks that are manufactured according to the new standard will provide the consumer with the means of being able to compare the performance of the various pavers on the market with more accuracy.

"The new abrasion standard is 'good news all round', as the industry has been pushing for higher standards for many years," maintains Ebeling. Pan Mixers is Africa's largest manufacturer of concrete block, brick and paving machinery, supplier of concrete pumps, planetary pan mixers, concrete pipe machinery, moisture measuring systems, oxide dosing systems, kerbstone machinery, mixing plants and weigh batching plants. The company has the facilities to manufacture high-quality products designed to meet the requirements of both local and international markets.

Page 2 / 2 Size=2S0X299mm Circulation: 1 Readership: n/c

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Stonehell Dungeon - II - Into The Heart of Hell PDFDocumento170 páginasStonehell Dungeon - II - Into The Heart of Hell PDFrcsample67% (3)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Pile Cap Design 1Documento6 páginasPile Cap Design 1kjpatel2100% (2)

- HCM001 Hollow-Core Design Manual - Complete - 03.23.15 PDFDocumento38 páginasHCM001 Hollow-Core Design Manual - Complete - 03.23.15 PDFVatova JarrandAinda não há avaliações

- Moving Wheel Loads AnalysisDocumento1.825 páginasMoving Wheel Loads AnalysisruytguerraAinda não há avaliações

- 150mm 5 Core SlabDocumento1 página150mm 5 Core SlabruytguerraAinda não há avaliações

- 10x48 Elematic 4 Wide Load Table With 2 Structural ToppingDocumento1 página10x48 Elematic 4 Wide Load Table With 2 Structural ToppingruytguerraAinda não há avaliações

- Base Pad Width (Perp. To Sail)Documento1 páginaBase Pad Width (Perp. To Sail)ace1205Ainda não há avaliações

- Isolated Foundation Calculation ACI 318M 95Documento820 páginasIsolated Foundation Calculation ACI 318M 95ruytguerra0% (1)

- Two Way SlabDocumento1 páginaTwo Way SlabKenton SuazoAinda não há avaliações

- Retaining Wall DesignDocumento168 páginasRetaining Wall DesignAlfonso PatuktokAinda não há avaliações

- XL SudokuDocumento15 páginasXL SudokuruytguerraAinda não há avaliações

- Preters ADocumento2 páginasPreters AruytguerraAinda não há avaliações

- Tech Ny ContaDocumento1 páginaTech Ny ContaruytguerraAinda não há avaliações

- Mago Garden 2013Documento36 páginasMago Garden 2013ruytguerraAinda não há avaliações

- BMX TricksDocumento2 páginasBMX TricksruytguerraAinda não há avaliações

- Drunk DrivingDocumento2 páginasDrunk DrivingruytguerraAinda não há avaliações

- Surface Area v13 1Documento6 páginasSurface Area v13 1dicktracy11Ainda não há avaliações

- زلازلDocumento1 páginaزلازلruytguerraAinda não há avaliações

- Concrete Covering BlocksDocumento1 páginaConcrete Covering BlocksruytguerraAinda não há avaliações

- Footing Design (ACI318-02)Documento7 páginasFooting Design (ACI318-02)jjmtzcAinda não há avaliações

- Opening Calculator v1 1Documento4 páginasOpening Calculator v1 1ruytguerraAinda não há avaliações

- Problem Analysis Using Pareto ChartDocumento5 páginasProblem Analysis Using Pareto ChartruytguerraAinda não há avaliações

- WindDocumento1 páginaWindruytguerraAinda não há avaliações

- Control Chart ExampleDocumento9 páginasControl Chart ExampleruytguerraAinda não há avaliações

- Pareto Analysis: (Company Name)Documento1 páginaPareto Analysis: (Company Name)ruytguerraAinda não há avaliações

- زلازلDocumento1 páginaزلازلruytguerraAinda não há avaliações

- Problem Analysis Using Pareto ChartDocumento5 páginasProblem Analysis Using Pareto ChartruytguerraAinda não há avaliações

- WindDocumento1 páginaWindruytguerraAinda não há avaliações

- زلازلDocumento1 páginaزلازلruytguerraAinda não há avaliações

- Tank FootingDocumento3 páginasTank FootingruytguerraAinda não há avaliações

- Preters ADocumento2 páginasPreters AruytguerraAinda não há avaliações

- Tds Igp Duraface 5809whiteline enDocumento2 páginasTds Igp Duraface 5809whiteline enUlysses CarrascoAinda não há avaliações

- Linus Torvalds Biography by The Linux Information ProjectDocumento9 páginasLinus Torvalds Biography by The Linux Information ProjectAmit PatelAinda não há avaliações

- Aki Moilanen Tips and TricksDocumento34 páginasAki Moilanen Tips and Trickssen2natAinda não há avaliações

- Electrical Conduit Supports 01Documento1 páginaElectrical Conduit Supports 01Manoj JaiswalAinda não há avaliações

- Advanced Junos Enterprise Switching: Detailed Lab GuideDocumento152 páginasAdvanced Junos Enterprise Switching: Detailed Lab Guide3gero3100% (1)

- Rwp-Isb AddendumDocumento28 páginasRwp-Isb AddendumMuhammad Tariq Zafar ChishtyAinda não há avaliações

- Roofmate PDFDocumento29 páginasRoofmate PDFFadi HAinda não há avaliações

- Pengaruh Suspender Tipe Vertical Dan Inclined Terhadap Kestabilan Jembatan GantungDocumento10 páginasPengaruh Suspender Tipe Vertical Dan Inclined Terhadap Kestabilan Jembatan GantungMuhammad RidhaAinda não há avaliações

- TR 098 - Amendment 1 PDFDocumento119 páginasTR 098 - Amendment 1 PDFGaurav DograAinda não há avaliações

- ASEE PAPER CHINESE TEMPLE Final 3 27 2015 PDFDocumento23 páginasASEE PAPER CHINESE TEMPLE Final 3 27 2015 PDFQF “QF”Ainda não há avaliações

- Exchange Server 2013 InstallationDocumento38 páginasExchange Server 2013 InstallationMuhammad Atif RamzanAinda não há avaliações

- Businessdistrict Designguidelines: Prepared For The City of Des PlainesDocumento11 páginasBusinessdistrict Designguidelines: Prepared For The City of Des PlainesRabbani K.Ainda não há avaliações

- OrbitX - Remote Assistance Setup PDFDocumento10 páginasOrbitX - Remote Assistance Setup PDFapisituAinda não há avaliações

- Example of Buildings/ StructuresDocumento11 páginasExample of Buildings/ StructuresrylineAinda não há avaliações

- Siemens NX 10 Sheet Metal TutorialDocumento1 páginaSiemens NX 10 Sheet Metal TutorialChokri Atef100% (1)

- Map LondonDocumento1 páginaMap LondonsaukimirzaAinda não há avaliações

- Check List/Self Appraisal of Fire Safety Measures in Educational Buildings Below 6 Meters HeightDocumento4 páginasCheck List/Self Appraisal of Fire Safety Measures in Educational Buildings Below 6 Meters HeightSanjay SinghAinda não há avaliações

- Learning-Practice - Oracle 12C PDFDocumento7 páginasLearning-Practice - Oracle 12C PDFPraveen Bachu100% (1)

- Method Statement For Pile Breaking PDFDocumento3 páginasMethod Statement For Pile Breaking PDFSoe PaingAinda não há avaliações

- Efficient Utilisastion of Hybrid Power Plant Using MPPT Technique and Reducing The Voltage Intrupption by Using DstatcomDocumento17 páginasEfficient Utilisastion of Hybrid Power Plant Using MPPT Technique and Reducing The Voltage Intrupption by Using DstatcomAnuj TripathiAinda não há avaliações

- Site Diary 1Documento7 páginasSite Diary 1Alia KhalidAinda não há avaliações

- Mobile CommunicationDocumento57 páginasMobile CommunicationUrvashi BhardwajAinda não há avaliações

- Building Energy Performance Simulation Tools - A Life-Cycle and Interoperable PerspectiveDocumento49 páginasBuilding Energy Performance Simulation Tools - A Life-Cycle and Interoperable Perspectivehb_scribAinda não há avaliações

- Modulo 6 Semana 2: Actividad Integradora 3. Be My GuestDocumento8 páginasModulo 6 Semana 2: Actividad Integradora 3. Be My Guestmarino1245Ainda não há avaliações

- Export To PDF Using Itext in JavaDocumento2 páginasExport To PDF Using Itext in JavaMichaelAinda não há avaliações

- Montpellier Tourist MapDocumento2 páginasMontpellier Tourist MapHarryM8188Ainda não há avaliações

- Command Scripts IAM Tekno MW3Documento2 páginasCommand Scripts IAM Tekno MW3Faralahy Ulrich0% (1)

- Nmap Cheat SheetDocumento18 páginasNmap Cheat SheetJesse VazquezAinda não há avaliações

- IECDocumento3 páginasIECArun KumarAinda não há avaliações