Escolar Documentos

Profissional Documentos

Cultura Documentos

Flame Scanner

Enviado por

Ravi Sankar MuthuDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Flame Scanner

Enviado por

Ravi Sankar MuthuDireitos autorais:

Formatos disponíveis

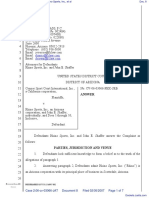

FLAME SCANNER AND COOLING AIR FAN SYSTEM For 4360MW UCCHPINDA THERMAL POWER PLANT CONTRACT BETWEEN

MIPP INTERNATIONAL LTD AND BEIJING EASTERN TRANSIT CONTROL TECHNOLOGY Co, LTD.

VOLUME 2 OF 2

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360MW UCCHPINDA THERMAL POWER PLANT CONTRACT BETWEEN MIPP INTERNATIONAL LTD AND BEIJING EASTERN TRANSIT CONTROL TECHNOLOGY Co, LTD. .

CONTRACT NO. MIPP/PES/10/013

VOLUME 2 OF 2

Page2of4

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

VOLUME - 2 TECHNICAL AGREEMENT

SAMPLE OF INITIALS: S. Nandakumar (Employer) Yu Haisheng (Contractor) Menglili (NEPDI)

NEPDI Northeast Electric Power Design Institute

Page3of4

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

PART-2 TECHNICAL AGREEMENT

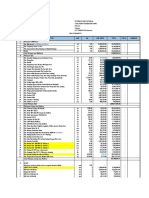

CONTENTS VOLUME 2 TECHNICAL AGREEMENT Table of Contents: Volume 2

Total No. of Pages SECTION AFLAME SCANNER AND COOLING AIR FAN SYSTEM S.19 SECTION B SECTION C SECTION D SECTION E SECTION F SECTION G SECTION H SECTION I SECTION J SECTION K SECTION L TESTS ............................................................................................................... 8 SCHEDULE OF GUARANTEES ....................................................................... 3 DELIVERY SCHEDULE .................................................................................... 6 PACKING AND TRANSPORTATION ................................................................ 6 DRAWINGS AND DOCUMENTS ...................................................................... 7 INSPECTION AND QUALITY .......................................................................... 5 LIAISON MEETINGS ........................................................................................ 6 TRAINING .......................................................................................................... 3 SITE SERVICES (NOT APPLICABLE) .............................................................. 1 SITE DATA ........................................................................................................ 3 ANNEXURES FOR TECHNICAL ....................................................................... 2

Page4of4

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION A

FLAME SCANNER AND COOLING AIR FAN SYSTEM

CONTENTS

1.0 2.0 3.0 4.0

Project Summary Scope of Agreement Design, Technical and Operational Requirements Scope of Supply and Services

ABBREVIATIONS

CCR DCS

Centralized Control Room Distributed Control System

SECTION A Page 1 of 17

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

FLAME SCANNER AND COOLING AIR FAN SYSTEM 1. Project Summary R.K.M Powergen Private Limited (RKMPPL), Chennai, India has proposed to construct and operate a 4x360MW Coal based Power Plant at Ucchpinda in Janjgir Champa District in Chhattisgarh, India. This Technical Agreement covers the supply of Flame Scanner and Cooling Air Fan System and its accessories for the project. R.K.M Powergen Private Limited (RKMPPL) hereinafter referred to as 'Owner', has retained the services of M/s. MIPP INTERNATIONAL LTD (hereinafter referred to as "MIPPIL") incorporated under the laws of the Republic of Mauritius and having its registered office at 3rd Floor, Raffles Tower, 19, Cyber City, Ebene, Republic of Mauritius; and having its branch office at No. 32, 2nd Floor, Block D, Lim Eng Ming Building, Spg. 88, Kg. Kiulap, Bandar Seri Begawan BE1518, Negara Brunei Darussalam (hereinafter called the "Employer") to source the required equipment for this project. Beijing Eastern Transit Control Technology Co, Ltd having registered office at Suite 12 G, Building No 3, No 12 Xiaoying Road, Yayun Garden, Chaoyang District, and Beijing 100101 (hereinafter referred to as The Contractor has agreed to supply and provide supervision and commissioning assistance for the Flame Scanner and Cooling Air Fan System for the project. The Owner has retained the services of M/s Fichtner Consulting Engineers Pvt Ltd,

CONTRACT NO.: MIPP/PES/10/021

Chennai as their engineers, hereinafter called 'Owner's Engineer'. The Employer has retained the services of Northeast Electric Power Design Institute, Changchun, China as their engineers, hereinafter called 'Employer's Engineer'. This Technical Agreement covers the supply of Flame Scanner and Cooling Air Fan System and its accessories for the project.

SECTION A Page 2 of 17

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

2 Scope of Agreement

2.1 The scope of this Agreement covers

a.

Design, manufacture, shop assembly, shop inspection and testing, and supply of Flame Scanner and Cooling Air Fan System Special Tools, Recommended Spares and consumable spares for the project.

b. c.

Remedy and defects therein; and Train the employers Representatives at Contractor /Subcontractors facilities.

2.2 Flame Scanner and Cooling Air Fan System and its accessories, Special Tools, Recommended Spares and Consumable Spares shall be utilized for the Project of 4x360 MW coal fired power plant in Ucchpinda, Janjgir Champa District, Chhattisgarh state, India. This has reference to the discussions had at Changchun on January 20th, 2011 and the subsequent emails exchanged between us and Forney Coporation and Beijing Eastern Transit Control Technology Co, Ltd., dated January 25th, February 14th, February 16th, March 25th, March 26th, April 1st, and April 7th 2011 on the subject. 2.3 The technical specifications of this Agreement shall be the minimum technical requirements, and do not cover all the technical details. The Contractor shall ensure all necessary technical specification to supply the latest industry standard products.

3 Project Related Information boilers to ensure the safe operation and forms a part of FSSS (Furnace Safety Supervision System). Based on the physical property of flame, the Scanner carries out a real-time detection on combustion situation. Once the flame combustion cannot meet the required conditions or flame is extinguished, the Scanner will give a signal as the judging condition for fault alarm to FSSS. According to the signal, the users can stop supplying the fuel into the boiler timely if the flame is extinguished, so that the boilers can be prevented from explosion resulting from accumulation of flammable materials in furnace.

SECTION A Page 3 of 17

CONTRACT NO.: MIPP/PES/10/021

Flame Scanner System is essential equipment for coal-fired, gas-fired and oil-fired

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

4 Design, Technical and Operational Requirements a. Criterion and Standards for equipment design and manufacture. Standards and codes National Fire Protection Association (NFP) ANSI / NFPA70 National Electrical Code

ANSI / NFPA8502 Internal combustion and outer explosion prevention of boiler furnace with multiple burners ANSI / NFPA85F Installation and operation of coal- fired system National Electrical Manufactures Association (NEMA) ANSI / NEMA ICS4 Industrial control equipment and terminal blocks of system ANSI / NEMA ICS6 Industrial control equipment and casing of system Underwriters' Laboratories (UL) UL 44 Safety standards for rubber wires and cables

SECTION A Page 4 of 17

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

1. The Standards and regulations above only give the basic technical requirements.

The

Contractor can adopt more economical and rational design, material, and manufacturing process such that the supplies shall meet the requirements of the Contract, and ensure continuous safe operation. 2. Within the period of manufacturing of Flame Scanner and Cooling Air Fan System, if standards or regulations have any modification or change, Employer has the right to ask for implementing them, and Contractor shall conform to these requirements.

3. Contractor shall provide Quality Management and Quality Assurance Plans as well as relevant standards and regulations to the Employer, before start manufacturing. 4. The power plant uses KKS coding system. The Contractor shall use KKS coding system for

CONTRACT NO.: MIPP/PES/10/021

all the equipment covered in this Contract.

SECTION A Page 5 of 17

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

5 Technical Requirements

5.1Designrequirements

Equipment name: Flame Scanner and Cooling Air Fan System Quantity of coal burners: 24 per unit Quantity of oil burners: 12 per unit Input /output signals: The International standard signal system shall be adopted to connect signals between the system and DCS system, etc. The switching value is passive dry contact, 220V AC 2A, 24V DC 2A.The transmitter shall be two- wire system with 4~20mA output. 5.2 Design conditions and ambient conditions Technical parameters of the boiler Type of the boiler: subcritical steam drum boiler with natural circulation Maximum continuous evaporation rating of the boiler: 1223 t/h Distribution of burners: Contains six elevations of coal burners and three elevations of oil burners. Being tangential Fired boiler, there are 24 coal burners and 12 oil burners per boiler. So in total there shall be 36 flame scanners, 24 to detect coal flame and 12 to detect Oil flame. Top two Oil burner elevations are for firing Heavy oil. In bottom oil elevations, viz., AB, both heavy and light oil can be used as fuel for oil guns. There shall be 6 coal mills catering pulverized coal to coal burners in 6 elevations. 5 mills shall be in operation and one mill shall be kept as Stand by. Quantity of boilers: Four 5.3 General requirements 5.3.1 The Contractor shall provide complete integrated intelligent flame detection system and flame Scanner cooling air system for all the four units.

SECTION A Page 6 of 17

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

5.3.2 The flame scanner shall be capable of clearly distinguishing flames of coal combustion and oil combustion and must have reliable measures for preventing erroneous detection. 5.3.3 The flame scanners shall work on an amplitude and frequency (Flame flicker) principle providing the best tuning control for high discrimination. The appropriate flicker frequency and amplitude gain shall be automatically configurable in the Auto Tune mode and can be manually adjusted via the Edit mode 5.3.4 The Integrated intelligent flame scanner shall be able to efficiently monitor and identify flames of various grades of coal and oil and various flame conditions in order to avoid error in detection. The Sensitivity of the burner flame detection loop shall have enough response to low luminosity. The installation position of Scanners obtained from precise theoretical calculation shall be capable of minimizing interferences from adjacent flame, flame from background in opposite corner, and background radiation from red hot furnace walls.

5.3.5 The flame scanner shall have electronic self- diagnostic feature for their fail proof operation. During health check up, the flame out condition shall be simulated and the scanner

SECTION A Page 7 of 17

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

has to detect no flame. However the logic circuits shall be designed in such a way to prevent burner trip during this self diagnostic checks. The diagnostics results shall be displayed via eight character alphanumeric LED display. The scanner should not have mechanical shutter that increases maintenance costs. 5.3.6. Flame Scanners of every burner shall have 4~20mA signal output to express intensity of flame. The flame on signals and dry contact signals of self detection and fault shall also be provided correspondingly. 5.3.7 The flame scanner shall use optical fibre. The optical fibre shall aim at the combustion zone and read the light signal of flame from the burners to realize continuous and stable detection. 5.3.8 Flame Scanners shall be integrated type and the electric elements of flame Scanners shall be reliable when they are operated under harsh environment (e.g. high temperature, humidity and dust) and shall run safely and stably. The products provided by the Contractor shall meet requirements of the technical agreement. All signals of flame Scanners shall be connected to DCS via hard wiring for interlock purpose. 5.3.9 Special cables shall be adopted to connect flame Scanners and on-site junction boxes. 5.3.10 All probes of oil and coal flame Scanners shall be provided with flexible optical fibre components. 5.3.11 The flame scanners shall have built in intelligence and they shall have the following basic functions: Selection of flicker frequency Threshold value adjustment of flame on/off Gain control; Fault diagnosis;

CONTRACT NO.: MIPP/PES/10/021

SECTION A Page 8 of 17

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

Display all parameters, including alarms and statuses of flame Scanners; Can set, debug/run and display remotely. Fully electronic self- inspection function, automatic learning function, flames on/ off learning and then recommend parameters: gain, flame flicker frequency and threshold, etc.

AUTOMATIC AND MANUAL ADJUSTMENT of the flame relay on and off

thresholds OPTICALLY ISOLATED 4-20MA flame signal output for remote signal indication. SPST FLAME RELAY for BMS safety interlock and independent SPST alarm

relay. FOUR SELECTABLE PROGRAM FILES capable of storing separate set points

based on fuel, load or process conditions. REMOTE RS485 COMMUNICATIONS via Windows 95/98/NT user software for

tuning and flame analysis. SAFE 24 VDC OPERATION to ensure safe working environment for the plant. 5.3.12 The Contractor shall provide two cooling air fans and motors /boiler (total eight) each with a capacity of 100%. The fans are standby for each other and switched on automatically to meet requirement of every flame scanner. Requirement for motors of the cooling air fans:

CONTRACT NO.: MIPP/PES/10/021

Blower Specification Type HP Fan Static Pressure Blower Capacity Volts

SECTION A Page 9 of 17

2510 A 20 HP(15KW) >8.5 KPA 1766 SCFM 415 VAC 50 Hz 3 PH

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

Amps R.P.M Class Capability Static Efficiency Noise

40 A 2900 F 100% 85% 80 db

415VAC 3 phase 4 wire power supply shall be adopted for motors of the cooling air fans. Power of the motor is 50Hz, 15kW and insulation protection grade is grade F. 5.3.13 Cooling air fans efficiency 85%, noise 80db. 5.3.14 A filter must be mounted at the inlet of the cooling air from atmosphere. This is to prevent dust particle from entering into the scanner air circuit. An on-site weather proof control box shall be provided to facilitate local startup and stop control of two cooling air fans and also shall have the facility for remote operation from DCS. 5.3.15. The system shall also provide DCS with dry contact signals such as operation status, fault, trip of both fans, high and low pressure of cooling air, and field/ remote of each scanner air fan. 5.3.16 The system shall be capable of receiving remote startup and stop instructions (dry contacts) from DCS. Interlock and protection logic functions of scanner air fans are programmed in the DCS. 5.3.17 When scanner air header pressure is low or on failure of the fan in operation, the standby scanner air fan shall start automatically meeting all interlocking protections. 5.3.18 The on-site control box of cooling air fans shall be capable of terminating two power supplies of 415V/230V AC, which can be automatically switched over during failure of one power supply. 5.3.19 The Degrees of protection provided by enclosure (IP code) of on-site control box of the cooling air fans shall be IP65 and insulation class of motors of the cooling air fans should be F. The cooling air fans shall continuously run under the ambient temperature of -25~65.

SECTION A Page 10 of 17

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

5.3.20 The diverter baffle plate at the outlet of two cooling air fans of flame scanners shall be automatically switched to ensure the normal running of cooling air fans. 5.3.21 The Contractor shall liaison with manufacturer of the boiler and shall responsible for deciding the installation positions based on the factors like interfaces of flame Scanners on boiler burners, checking effective visual angle range of the flame Scanners with respect to burners., etc. 5.3.22 The Contractor shall provide all sockets and fixing installation components. 5.3.23 The 415 VAC 3 phase 4 wire power supply shall be provided by the Employer. The Contractor shall provide power supply solutions of the flame detection system. The cabinet of the flame detection system shall be capable of receiving two 240V AC 50HZ simultaneously one is from the emergency power supply and the other is from UPS power supply. The Contractor is responsible for converting the two power supply into other voltage levels (including direct current) used for the flame detection systems. If there is an interruption in the main power supply, the power cabinet shall give an alarm and the redundant power supply should serve continuously for the flame Scanners. 5.3.24 The power supply cabinet and on-site control box of cooling air fans shall have bottom cable entries. 5.3.25 The power supply devices shall be provided with Exhaust fans and internal circulating fans for ventilation.

CONTRACT NO.: MIPP/PES/10/021

5.3.26 The Terminal block inside the on-site control box shall be placed convenient for wiring. The place shall be minimum 300mm from bottom of the cabinet and minimum 150mm from top of the cabinet. 5.3.27 Terminal block and terminal in the power supply cabinet and on-site control box of cooling air fans should be marked with clear labels/ferrule according to the drawings and documents.

SECTION A Page 11 of 17

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

5.3.28 The Terminal block, cable clamp and cable trough inside the power supply cabinet and on-site control box of cooling air fan shall be made of non-combustible material. 5.4 Basic requirements of instruments and electric elements 5.4.1 The Contractor shall use standardized components and equipment assemblies from optimizing the spares and consumables. 5.4.2 The International standard signal system shall be adopted to connect signals between the system and DCS system, etc. The switching value is passive dry contact, 220V AC 2A, 24V DC 2A.The transmitter shall be two- wire system with 4~20mA output. 6 SCOPE OF SUPPLY 6. 1 General requirement 6.1.1 This attachment sets forth scope of supply for the contracted equipment. The Contractor shall ensure that the equipment provided is completely new, advanced, mature, complete, safe and reliable. The technical economic performances should be higher than requirements in attachment 1. 6.1.2 The Contractor shall provide detailed lists including type, quantity, place of origin and manufacturer information, etc. 6.1.3 The Contractor shall provide detailed lists of spare parts.. 6.1.4 The Contractor shall provide lists of special tools and instruments.

CONTRACT NO.: MIPP/PES/10/021

SECTION A Page 12 of 17

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

6.2 Scope of supply 6.2.1 Scope of supply of the flame detection and cooling air fan system

Part No. Item Description Unit Number Qty.

Manufa cturer

Coal Flame Scanner

401111-21

Set

24

FORNEY

Oil Flame Scanner External duct assembly of flame

401111-21

Set

12

FORNEY

Scanner

95

set

36

BET

Internal duct assembly of flame 4 Scanner 95 set 36 FORNEY

Cable assembly, 10m length, 12-core

Junction Box

Pieces

36

BET

Redundant power supply

Pieces

BET

II

Cooling air system

SECTION A

Page 13 of 17

CONTRACT NO.: MIPP/PES/10/021

10m

set

36

FORNEY

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

Cooling air fan and motor

11.0KW

set

Air filters 8

Pieces

Base of air fans Y- type pipe, wind door, switching baffle and so on Air fan control box On -off Pressure of cooling air conduit switch On -off Pressure difference Cooling air pipe, 1.5m Technical Drawing and Data 1.5m

Pieces set

FORNEY

set

Pieces

SOR

10 11 12

Pieces Pieces Set

2 36 10 BET BET

Listsofsupply(forsingleunit)

Forney Flame Scanner Specification

CONTRACT NO.: MIPP/PES/10/021

Housing Material: Shipping Weight: Mounting Flange: Input Power: Electrical Connection:

Cast aluminum with gray polyester powder coat finish 0.71bs. (0.32Kg) 1" NPT female pipe mount 24 Vdc, +10%, -15% supply current: 0.35 A, 8.5 VA 12-pin quarter-turn quick-disconnect.

Page 14 of 17

SECTION A

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

Temperature Rating: Humidity: Environmental:

-40F to + 150F (-40C to +65C) 0% to 95% relative humidity, non-condensing NEMA 4X, IP66 FLAME RELAY, SPST (N.O.) Relay Output: FAULT RELAY, SPST (N.C.) Minimum: 10 mA @ 5 Vdc Maximum: 2 A @ 30 Vdc Contact Rating: 2 A @ 50 Vac 2 A @ 240 Vac Analog Output: 4-20 mA dc current, referenced to 24Vdc common. Status Indication: Eight (8) character alpha-numeric LED display (scrolling capability) Operator Interface: Four (4) pushbutton style keys UV Sensor / Wavelength: Super Blue Silicone / 295-320nm IR Sensor / Wavelength: Indium Gallium Arsenide (In Ga As) / 700-1700nm

6.2.2 The Contractor shall provide flame Scanners (including cooling air pipes), special cables and sockets, detailed lists of supply. Type test specification, manufacturer information and lists of spare parts should also be provided by the Contractor. 6.2.3 The Contractor shall provide installation pipes of flame Scanners and fixing installation components. 6.2.4 The Contractor shall provide the following equipment for each unit for debugging: Portable computer used for debugging Original Software for debugging with special software tools 6.2.5 The Contractor shall provide cooling air fans and motors, Y-type pipe, switching baffle, air filtering device, cooling air hose of flame Scanner probe at the front of burner, on-site control box of cooling air fan and detailed lists of supply. Type test specification, manufacturer information and lists of spare parts should also be provided by the Contractor. 6.2.5 The Contractor shall provide the instrument which can detect the air pressure of cooling air manifold and can give an alarm. 6.2.7 The Contractor shall be responsible for integrity of the system provided by him.

SECTION A Page 15 of 17

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

6.3 Special tools and instruments Special tools (for single unit) Part Item Description Number

No.

Unit

Qty.

Manufacturer

Appropriative software,

FS95OW-1

set

FORNEY

2 3 4

Laptop Commutator Join cables.

DELL RS485/232 600m

set Piece Piece

1 1 1

DELL FORNEY FORNEY

6.4 Cabinet: shall be of Rittal make. 6.4.1 Control cabinets internal and external surfaces should be smooth and clean, without any soldering, rivets or bolts. 6.4.2 Control cabinet shall be of sufficient strength to withstand handling, installation and

CONTRACT NO.: MIPP/PES/10/021

operation of electrical short circuits during the production of all accidental stress 6.4.3 Control cabinet shall have internal cooling fans to ensure the internal temperature does not exceed the temperature limit of the internal components. 6.4.4 The control cabinet shall be provided with the lighting and 240V AC power receptacle for maintenance purpose. 6.4.5 Control Cabinet colour shall be RAL 7035.

SECTION A Page 16 of 17

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

6.5 Spare parts The spare parts for commissioning as well as mandatory spares shall be supplied. 6.6 Specified tools The special tools if any, shall be specified and supplied.

(END OF SECTION)

SECTION A Page 17 of 17

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION B TESTS

SECTION B

Page 1 of 8

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

TABLE OF CONTENTS

1. 2. 3. 4. 5. 6. 7. 8. GENERAL ...............................................................................................................................................3 . FAT (FACTORY ACCEPTANCE TEST)................................................................................................3 PRE-COMMISSIONING CHECKS AND SITE CALIBRATION............................................................3 SAT (SITE ACCEPTANCE TEST).........................................................................................................3 GENERAL PROCEDURES FOR TESTS...............................................................................................6 SPECIFIC SITE CONDITIONS...............................................................................................................7 TEST UNCERTAINTIES.........................................................................................................................7 MEASURING EQUIPMENT....................................................................................................................8

SECTION B

Page 2 of 8

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

1.

General Detailed procedure for the FAT (Factory Acceptance Test), Pre-commissioning Checks and Site Calibration Procedures, and SAT (Site Acceptance Test), shall be submitted by the Contractor during the Liaison Meetings and shall get them approved by the Employer. All Tests at Contractors works and at Site shall be witnessed by the Employers Representatives.

2.

FAT (Factory Acceptance Test) Materials used for the main components of the Flame Scanner and Cooling Air Fan System shall be tested and/or inspected in accordance with applicable specifications in the factory. In order to achieve all functional requirements specified for the Flame Scanner and Cooling Air Fan System, needed debugging of the configuration shall be done at factory. Wiring test (point to point), and Signalization and Visualization test shall be done. Simulating the input / output signals, loops shall be tested and demonstrated to ensure that all functions meet the requirement of this specification. The entire system will be tested in line with the approved FAT procedures. This is the pre-requisite for the dispatch.

3.

Pre-Commissioning Checks and Site Calibration All equipments / instruments / accessories shall be calibrated by the contractor /

CONTRACT NO.: MIPP/PES/10/021

employer at site prior to installation. The calibration procedure for each instrument shall be furnished by the contractor.

4.

SAT (Site Acceptance Test) Actual plant inputs and outputs shall be used as they become available. The Contractor shall verify that all systems and documentation are up to date and are ready for availability test. The system shall be accepted upon satisfactory completion of the site availability test described herein.

SECTION B

Page 3 of 8

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

The Contractor shall guarantee 99 % availability for the system and demonstrate all the performance specified in this specification during the availability test. The test shall begin upon completion of the final commissioning of the Flame Scanner and Cooling Air Fan System. The SAT start date shall be mutually consulted with and determined upon by the Owner and the Contractor. The availability denotes the characteristic of a repairable device or system expressed by probability to perform its required function at a stated period of time. I. Definitions a. Uptime Uptime shall be the period of time from beginning of the test until the end of the test, excluding dead time, less the downtime occurred during the time period. b. Downtime Downtime shall be the period of time any device or subsystem supplied by the Contractor is unavailable for service during the test. Total downtime for the availability test shall be calculated by adding the downtime occurred by individual device or subsystem failures during the test period with device or subsystem downtime for concurrent failures being additive. In no case shall chargeable downtime be longer than actual elapsed time. Chargeable downtime = Actual elapsed downtime

CONTRACT NO.: MIPP/PES/10/021

c. Dead time Dead time resulted of the following occurrences shall be declared by mutual agreement between the Owner and the Contractor: Failure of unit or auxiliary Improper operation by the Owner personnel Failure of Owners sensors Loss of environment conditions

SECTION B

Page 4 of 8

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

Irresistible reason Failure of power supplied by the Owner

d. Availability Availability shall be at least value (99 %) specified in this specification for the test period as calculated below: Actual test period - Downtime Availability (%) = Actual test period Actual test period in the equation above is whole test period subtract dead time. II. Owner Participation The responsibility for the conduct of the availability test shall rest with the Owner. The test must be conducted using the operation and maintenance procedures described in the approved the Contractors documentation. The Owners personnel shall operate and maintain the Flame Scanner and Cooling Air Fan System and shall maintain the availability test logs and records. The Contractor shall support the maintenance effort on an on-call basis by providing consultation or on-site assistance as required. If the Contractor is notified by the Owner of the necessity for on-site maintenance support, the Contractors service personnel shall arrive on the site within 96 hours of notification. III. Availability Test Rules Time shall be calculated in hours and tenths of hours and recorded in a log book at the site. The site log shall be considered the official log of the availability test. Copies of the log shall be sent to the Contractor monthly to check for discrepancies. The Contractor shall be notified immediately when any problem occurs in test period. No modification to systems or hardware shall be permitted unless it is deemed necessary mutually by the Owner and Contractor. Prior to start of the availability test, the Owner shall have purchased and have onsite all mandatory spare parts mutually agreed upon by the Owner and Contractor

CONTRACT NO.: MIPP/PES/10/021

X 100%

SECTION B

Page 5 of 8

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

as necessary for the Flame Scanner and Cooling Air Fan System. During the commissioning and the SAT period, any parts borrowed from the Owners spare parts stock must be replaced by the Contractor at no cost to the Owner. In the event of delays in completing repairs due to lack of the Contractor recommended spare parts in the Owners stock, down time shall be charged. Any parts required to complete the commissioning and the availability test successfully shall be provided by the Contractor within 48 hours. In order to verify that all failures have been satisfactorily repaired, no downtime shall have occurred within 240 hours of the conclusion of the availability test. The time limit of the test shall be extended, if necessary for this requirement. After the system availability test is completed successfully, a certificate of availability test shall be signed mutually by the Owner and the Contractor. IV. Guarantee Period a. The Contractor shall agree that the guarantee period of Flame Scanner and Cooling Air Fan System shall be 12 months from the certificate of availability test being signed or 18 months from the delivery of the Flame Scanner and Cooling Air Fan System at site, whichever is earlier. b. During the guarantee period, the Contractor shall assure to change or repair any defect or failure not caused by informal operation of Owners personnel in time without cost to the Owner.

5.

General Procedures for Tests The procedure of FAT and SAT shall include the following for each Test or group of Tests: 1. 2. 3. 4. The sequence of the Tests to be conducted. The time duration of each test. The number of test runs A list of instruments that will be used for each Test. The list shall define which

SECTION B

Page 6 of 8

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

instruments are: a. b. c. d. e. 5. special test instruments certified instruments to be calibrated before and after each test check instruments station supply instruments

A schematic diagram showing all test points, isolation during Tests and cross referenced to the instrument list.

6.

All formulae, calculations, conversion factors, curves, correction curves etc., to be used in conducting the Tests and calculations of the Test results.

7.

Sample Test Reports and all specific result sheet forms that will be used for the Tests.

8. 9. 10.

Written procedure and description for conducting the Test. Data logging through satellite communication is not permitted. For each of the Performance & Guarantee Tests, the Employer / Contractor shall evaluate the Test figures and within Seven (7) days of the completion of the relevant Test, prepare a complete analysis of the Test Results.

11.

Test Reports for each Tests after Completion in which the methods followed, instrument readings, graphs, observations, and final results obtained etc., shall be recorded and reported.

12.

Employer / Contractor shall examine and sign the reports and certificates of all Tests. The Employer shall review and comment on all test protocol and procedures, reports and certificates.

6.

SPECIFIC SITE CONDITIONS The conditions are given in SECTION K SITE DATA of this Technical Agreement

7.

TEST UNCERTAINTIES No tolerance will be allowed over the indicated Guaranteed Values listed under SECTION C SCHEDULE OF GUARANTEE of this TECHNICAL AGREEMENT.

SECTION B

Page 7 of 8

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

8.

MEASURING EQUIPMENT All the instruments shall be calibrated by a certified body before and after the Tests. (END OF SECTION)

SECTION B

Page 8 of 8

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION C SCHEDULE OF GUARANTEES

SECTION C

Page 1 of 3

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

TABLE OF CONTENTS

1. 1.1 1.2

Performance Guarantee ............................................................................................................... 3 Performance Guarantee Value ..................................................................................................... 3 Compulsory correction if the guaranteed values are not met .................................................. 3

SECTION C

Page 2 of 3

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

1.

1.1

Performance Guarantee Performance Guarantee Value

Contractor shall guarantee that the Flame Scanner and Cooling Air Fan System and accessories are complete and reliable relative to the Contractor's scope of supply. The Contractor shall do Power-up, start-up and debug, until the Flame Scanner and Cooling Air Fan System shall satisfactorily control unit operation in a variety of conditions and achieve full function requirements and ensure availability not less than 99%.

1.2

Compulsory correction if the guaranteed values are not met For safe and economic operation of Flame Scanner and Cooling Air Fan System and accessories and to meet the guaranty criteria, any parts/items not mentioned by Employer but required, shall be supplied by Contractor unconditionally free of cost.

(END OF SECTION)

SECTION C

Page 3 of 3

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION D DELIVERY SCHEDULE

SECTION D

Page 1 of 9

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

TABLE OF CONTENTS

1.0 2.0 3.0 4.0 DELIVERY SCHEDULE FOR UNIT-I SUPPLY ................................................................................ 3 DELIVERY SCHEDULE FOR UNIT-II SUPPLY ............................................................................... 4 DELIVERY SCHEDULE FOR UNIT-III SUPPLY .............................................................................. 6 DELIVERY SCHEDULE FOR UNIT- IV SUPPLY ............................................................................. 8

CONTRACT NO.: MIPP/PES/10/021

SECTION D

Page 2 of 9

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

1.0

DELIVERY SCHEDULE FOR UNIT- I SUPPLY

No. Description Delivery Schedule from Commencement Date of Unit-I (in Months) 1 2

Coal Flame Scanner Oil Flame Scanner External duct assembly of flame Scanner Internal duct assembly of flame detector, Cable assembly, 10m length, 12core

6 6

6 7 II

Junction Box Redundant power supply Cooling air system Cooling air fan and motor Air filters Base of air fans Y- type pipe, wind door, switching baffle and so on Air fan control box

6 6 6 6 6 6

CONTRACT NO.: MIPP/PES/10/021

6 6

On -Off Pressure of cooling air

SECTION D

Page 3 of 9

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

No.

Description

Delivery Schedule from Commencement Date of Unit-I (in Months)

conduit switch

10 11 12 13 14 15 16

On -Off Pressure difference Cooling air pipe, 1.5m Technical Drawing and Data Appropriative software Portable computer Commutator Interconnection cables.

6 6 6 6 6 6 6

The Delivery Schedule is based on FOB Shanghai Seaport basis (INCOTERMS 2000)

2.0

DELIVERY SCHEDULE FOR UNIT-II SUPPLY

Delivery Schedule shall be from the Commencement Date of Unit-II, OR, from the Commencement Date of Unit-I as indicated below; whichever is later No. Description From the Commencement Date of Unit-II (in Months) 1 2 3 From the Commencement Date of Unit-I (In Months) 9 9 9

CONTRACT NO.: MIPP/PES/10/021

Coal Flame Scanner Oil Flame Scanner External duct assembly of

6 6 6

SECTION D

Page 4 of 9

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

No.

Description

Delivery Schedule shall be from the Commencement Date of Unit-II, OR, from the Commencement Date of Unit-I as indicated below; whichever is later

flame Scanner Internal duct assembly of flame detector, Cable assembly, 10m length, 12-core

6 7 II

Junction Box Redundant power supply Cooling air system Cooling air fan and motor Air filters Base of air fans Y- type pipe, wind door, switching baffle and so on Air fan control box On -Off Pressure of cooling air conduit switch

6 6 6 6 6 6

9 9 9 9 9 9

10 11

On -Off Pressure difference Cooling air pipe, 1.5m

6 6

9 9

SECTION D

Page 5 of 9

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

No.

Description

Delivery Schedule shall be from the Commencement Date of Unit-II, OR, from the Commencement Date of Unit-I as indicated below; whichever is later 6 6 6 6 6 9 9 9 9 9

12 13 14 15 16

Technical Drawing and Data Appropriative software Portable computer. Commutator Interconnection cables.

The Delivery Schedule is based on FOB Shanghai Seaport basis (INCOTERMS 2000)

3.0

DELIVERY SCHEDULE FOR UNIT-III SUPPLY

Delivery Schedule shall be from the Commencement Date of Unit-III, OR, from the Commencement Date of Unit-I as indicated below; whichever is later No. Description From the Commencement Date of Unit-III (in Months) 1 2 From the Commencement Date of Unit-I (In Months) 12 12

Coal Flame Scanner Oil Flame Scanner External duct assembly of flame Scanner Internal duct assembly of flame detector, Cable assembly, 10m length, 12-core

6 6

12

CONTRACT NO.: MIPP/PES/10/021

12

12

SECTION D

Page 6 of 9

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

No.

Description

Delivery Schedule shall be from the Commencement Date of Unit-III, OR, from the Commencement Date of Unit-I as indicated below; whichever is later 6 6 6 6 6 6 12 12 12 12 12 12

6 7 II

Junction Box Redundant power supply Cooling air system Cooling air fan and motor Air filters Base of air fans Y- type pipe, wind door, switching baffle and so on Air fan control box On -Off Pressure of cooling air conduit switch

12

12

12

10 11 12 13 14 15 16

On -Off Pressure difference Cooling air pipe, 1.5m Technical Drawing and Data Appropriative software Portable computer. Commutator Interconnection cables.

6 6 6 6 6 6 6

12 12 12 12 12 12 12

CONTRACT NO.: MIPP/PES/10/021

SECTION D

Page 7 of 9

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA The Delivery Schedule is based on FOB Shanghai Seaport basis (INCOTERMS 2000)

4.0 DELIVERY SCHEDULE FOR UNIT IV SUPPLY

Delivery Schedule shall be from the Commencement Date of Unit-IV, OR, from the Commencement Date of Unit-I as indicated below; whichever is later No. Description From the Commencement Date of Unit-IV (in Months) 1 2 From the Commencement Date of Unit-I (In Months) 15 15

Coal Flame Scanner Oil Flame Scanner External duct assembly of flame Scanner Internal duct assembly of flame detector, Cable assembly, 10m length, 12-core

6 6

15

15

15

6 7 II

Junction Box Redundant power supply Cooling air system Cooling air fan and motor

6 6 6 6 6

15 15 15 15 15

CONTRACT NO.: MIPP/PES/10/021

Air filters

SECTION D

Page 8 of 9

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

No.

Description

Delivery Schedule shall be from the Commencement Date of Unit-IV, OR, from the Commencement Date of Unit-I as indicated below; whichever is later 6 15

Base of air fans Y- type pipe, wind door, switching baffle and so on Air fan control box On -Off Pressure of cooling air conduit switch

10 11 12 13 14 13 14

15

15

15

On -Off Pressure difference Cooling air pipe, 1.5m Technical Drawing and Data Appropriative software Portable computer. Commutator Interconnection cables.

6 6 6 6 6 6 6

15 15 15 15 15 15 15

The Delivery Schedule is based on FOB Shanghai Seaport basis (INCOTERMS 2000)

CONTRACT NO.: MIPP/PES/10/021

(END OF SECTION)

SECTION D

Page 9 of 9

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION E PACKING AND TRANSPORTATION

SECTION E

Page 1 of 6

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

TABLE OF CONTENTS

1. 2. 3. 4. TRANSPORT OF GOODS.................................................................................................................... 3 DOCUMENTS REQUIRED BEFORE SHIPMENT ............................................................................... 5 ADVICE BEFORE SHIPMENT ............................................................................................................. 5 DOCUMENTS REQUIRED AFTER SHIPMENT .................................................................................. 5

SECTION E

Page 2 of 6

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

1.

Transport of Goods

a. The package and transport of devices shall comply with GB/T13384. b. All Goods shall be suitably packed in sea and road worthy packing for transport under the tropical conditions. All instruments, electrical drives shall be packed in wooden / steel packing cases. c. All delicate surfaces of any part of the Unit should be carefully protected and painted with protective paint / compound and wrapped to prevent rusting and damage. d. All mechanical and electrical equipment and other heavy articles of any part of the Unit should be securely fastened and shall be blocked and braced to prevent movement. All threaded fittings and pipes should be greased and provided with plastic caps. e. Attachments, spare parts and all small pieces of any part of the Unit shall be packed separately in wooden cases with adequate protection inside the case. Each item shall be tagged with part number and reference number so as to identify it with the Flame Scanner and Cooling Air Fan System. f. All protrusions shall be suitably protected and openings shall be blocked by wooden covers / plastic / steel caps etc. g. Where required, equipment / materials shall be packed in polyethylene bags. Silica gel or similar dehydrating compound shall be put inside the bags to protect them. h. Pipe / Tubes made of stainless steel, copper etc., shall be packed in wooden / steel cases as far as possible i. The printed circuit boards and surface mount devices shipped loose should be packed with dry packing to protect them from harmful moisture, electromagnetic

CONTRACT NO.: MIPP/PES/10/021

interface, static discharge and triboelectric charging. j. Instruments shall be packed in molded thermocole packings, placed in corrugated boxes. k. The electronic control cubicles will be covered with polythene bubble sheet and with water proof bituminous sheet and finally boxed in wooden crate / case. l. Corrosion inhibitors/ desiccant agents should be kept in the instrument cubicles and cartons.

SECTION E

Page 3 of 6

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

m. The Contractor shall be held liable for all damages or breakage to the Goods due to defective or insufficient packing as well as for corrosion due to insufficient protection. n. Three (3) copies of Detailed Packing List in water proof envelope shall be inserted in each package. One (1) copy of Detailed Packing List shall be fastened outside each package in water proof envelope and covered by metal cover where possible. o. Marking Location of the external signs and lifting shall comply with GB19190. Each package shall be marked on Three (3) sides as far as possible, with paint / indelible waterproof ink as follows:

SHIPPERS NAME : _________________ CONSIGNEE (office) : R.K.M POWERGEN PRIVATE LIMITED No.14, Dr. Giriappa Road, T.Nagar, Chennai-600 017, Tamilnadu, India Tel : +91-44-66291000 Fax : +91-44-66291100 e-mail : rkmpowergen@gmail.com Project Site: Ucchpinda, Janjgir Champa District, Chhattisgargh State, India Contract No. : NET WT.: . . . . . . . kgs./MT. MIPP/PES/10/0 GROSS WT.: . . . . . . .kgs./MT.

proper

DIMENSIONS: . . . . . . . . . . . . . . . . . . . . . . centimeters. PACKAGE NO.: (Package _of Total _of Packages) TAG / ITEM NO.: . . . . . . . . COUNTRY OF ORIGIN: . . . . . . .

Additional marking such as HANDLE WITH CARE, THIS SIDE UP, FRAGILE or any other additional indications for protection and safe handling shall be added depending on the type of Goods. All cases will bear warning signs on the outside denoting Center of Gravity and Sling Marks. Control cubicle cases shall be marked FRONT and REAR and also the Unit Number and the Cubicle Name.

SECTION E

Page 4 of 6

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

The numeric and alphabet figures, marks etc. used for marking shall be stencil printed. Hand writing should be avoided as far as possible. The size of the figures shall be optimum for each package dimensions. In case of bundles or other packages wherever marking cannot be stenciled, the same shall be embossed on metal or similar tag and wired securely at minimum Two (2) convenient points. p. Documentation All documents shall be in English Language.

2.

Documents required before shipment Thirty (30) days before the expected delivery date at site, preliminary packing lists and sketches of over dimensioned Goods shall be e-mailed /couriered to the Employer. Over dimensioned Goods shall mean any package exceeding any of the following limits: WEIGHT > 20 Metric Tonne (MT) LENGTH > 13.716 meters WIDTH > 2.997 meters

HEIGHT > 2.763 meters

3.

Advice before Shipment The Contractor shall, at least Fifteen (15) days before the expected delivery date at site, advice the Employer by fax / e-mail of the contract number, name of commodity, quantity, total amount, number of packages, total weight and volume as estimated, name and contact details of the transporting agent and the estimated date when the Goods will arrive at site.

CONTRACT NO.: MIPP/PES/10/021

4.

Documents required after Shipment The Contractor shall courier photocopies of the following shipping documents within Three (3) days from the date of shipping.

SECTION E

Page 5 of 6

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

Commercial Invoices - Four (4) Copies Detailed Packing List - Four (4) Copies Test / Analysis Certificate Three (3) Copies Catalogue and / or drawing Two (2) Copies as applicable Pre-shipment certificate issued by Contractor and counter signed by Employers Representative Three (3) Copies (END OF SECTION)

SECTION E

Page 6 of 6

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION F DRAWINGS AND DOCUMENTS

SECTION F

Page 1 of 6

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

TABLE OF CONTENTS

1. 2. 3. 4. 5. CONTRACTORS DOCUMENTS...........................................................................................................3 DOCUMENTATION SCHEDULE............................................................................................................3 PLANT IDENTIFICATION AND TAGGING KKS SYSTEM....................................................................4 INFORMATION AND DRAWINGS NEEDED DURING THE POWER PLANT DESIGN......................5 TECHNICAL DOCUMENT AND DRAWINGS TO BE SUBMITTED TO THE EMPLOYER BY THE CONTRACTOR.......................................................................................................................................6

SECTION F

Page 2 of 6

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

1.

CONTRACTORS DOCUMENTS

The "Contractor's Documents" are defined as the documents which the Contractor must submit to the EMPLOYERS ENGINEER / Employer, as specified elsewhere in the Contract, which will not necessarily include (for example) all the technical documents which the Contractor's Personnel will need in order to execute the Work.

2.

DOCUMENTATION SCHEDULE Documents, Drawings and Technical Information Distribution Schedule EMPLOYERS DESCRIPTION CORRESPONDENCE EMPLOYER TO CONTRACTOR CONTRACTOR TO EMPLOYER EMPLOYERS ENGINEER TO CONTRACTOR CONTRACTOR TO EMPLOYERS ENGINEER DRAWINGS FOR APPROVAL FIRST ISSUE COMMENTS ON DRAWINGS FINAL APPROVED DRAWINGS FOR INFORMATION FIRST ISSUE COMMENTS ON DRAWINGS, IF ANY FINAL DRAWING SC + 2P S SC + 3P SC + 1P SC SC + 2P S SC + 1P S SC + 2P S SC + 3P SC + 2P SC + 1P SC + 2P S SC + 1P S

CONTRACT NO.: MIPP/PES/10/021

EMPLOYER ENGINEER

CONTRACTOR

X O 1 1

1 1 x O

O X O X

SECTION F

Page 3 of 6

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

EMPLOYERS DESCRIPTION AS BUILT DRAWINGS MANUFACTURING INSPECTION & TEST PLAN INSTRUCTION MANUALS - PRELIMINARY - FINAL 4 SC + 5P 2 SC S S O+1 1 S EMPLOYER ENGINEER SC + 6P SC + 2P S CONTRACTOR

LEGEND O ORIGINAL OF DOCUMENT S SOURCE OF DOCUMENT P PRINTED DOCUMENT SC SOFT COPY (CD / DVD) First issue shall be DWG file Final approved PDF file

3.

PLANT IDENTIFICATION AND TAGGING KKS SYSTEM The Contractor shall follow KKS tagging system, for the Flame Scanner And Cooling Air Fan System and accessories, facilities and systems showing the name and number of

CONTRACT NO.: MIPP/PES/10/021

each item and its respective drawing number etc. to fully identify the plant. The structure of the designations shall be developed in such a way that the symbols used can be handled by electronic data processing equipment. The identification system must be used by all subcontractors. Each item of Flame Scanner and Cooling Air Fan System and accessories shall be separately designed with a reference number, which shall be used consistently on the

SECTION F

Page 4 of 6

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

drawings, in the documents and on the catalogues as well as on the equipment items themselves.

4.

INFORMATION AND DRAWINGS NEEDED DURING THE POWER PLANT DESIGN a. English language is to be used for all design documents, drawings and technical information, as well as for all the operation, testing, inspection, maintenance and installation manuals. Standard International Units System (SI) shall be used. b. The Contractor shall provide the design documents as well as drawings and technical information. c. The associated documents (including technical information) and drawings for preliminary design shall be provided. d. Drawings and associated documents required for installation and maintenance shall be provided. A reproducible copy (in pdf version) shall be provided for each drawing and documents. e. After completion of the Work, the Contractor shall provide complete and correct As built drawings. f. The Contractor shall provide the Employer with CD / DVD of the complete design documents, drawings (including As built drawings), and other associated technical information (except codes and standards) used as design basis. g. The Contractor shall ensure that the drawings and documents supplied are complete without any item missing or overlooked, and can meet the demands of plant operation, maintenance, construction and commissioning etc. h. The Contractor shall provide the detailed lists for spare parts and easy wearing parts. i. j. Operation Manuals shall be provided by the Contractor. Maintenance Manuals shall be provided by the Contractor.

CONTRACT NO.: MIPP/PES/10/021

SECTION F

Page 5 of 6

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

5.

5.1

TECHNICAL

DOCUMENT

AND

DRAWINGS

TO

BE

SUBMITTED

TO

THE

EMPLOYER BY THE CONTRACTOR

The Contractor shall provide the following documents and drawings before shipment: a. Equipment and spare parts management information and document including shipment and packing detailed information of equipment and spare parts, storage technical requirement of equipment and spare parts, draft packing list and outline drawing of overweight transportation and over dimensional equipment parts. b. Detailed quality dossier containing quality documents as per approved QAP including material quality, material check, welding, heat treatment, fabrication quality, outline dimension, hydrostatic test, calibration reports etc.

5.2 5.3

The Contractor shall provide spare parts list and wear parts list. The Contractor shall provide the following documents: 5.3.1 Detailed specifications covering construction and materials used for Flame

Scanner and Cooling Air Fan System and Accessories. 5.3.2 Illustrations showing the general arrangement and principal dimensions of the

Flame Scanner and Cooling Air Fan System and Accessories, clearly indicating the accessories. 5.3.3 5.3.4 5.3.5 5.3.6 Inspection and test documentation (language: English) Cable list Single line diagram Cable connection diagram All documents are supplied in PDF format in English language.

5.4

Drawings The Contractor shall provide all drawings information (in English, and with the soft copy), as well as other information requested by the owners including construction design, installation, operation and maintenance, the system secondary development and on-site guidance

SECTION F

Page 6 of 6

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION G INSPECTION AND QUALITY

SECTION G

Page 1 of 5

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

TABLE OF CONTENTS

1. 2. 3. 4. 5. INSPECTION AND EXPEDITING ......................................................................................................... 3 INSPECTION REQUISITES ................................................................................................................. 4 INSPECTION AND TEST PLAN (ITP) .................................................................................................. 4 QUALITY ASSURANCE PLAN (QAP) .................................................................................................. 5 PRE-SHIPMENT CERTIFICATION ...................................................................................................... 5

SECTION G

Page 2 of 5

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

1.

1.1

INSPECTION AND EXPEDITING

All inspections and tests shall be made as per approved Quality Assurance Plan (QAP) which includes Welding Procedure Specifications (WPS) and Product Quality Report (PQR). Goods and / or materials shall be subject to inspection by Employer / Employers Representatives as per the approved QAP. Such tests and / or inspections by Employer may be held in conjunction with the representatives of the Contractor. The Contractor shall advise the Employer, in writing, as the circumstances warrant, at least seven (7) days in advance of the date of the final tests and / or inspection.

1.2

The Employers inspector shall be the authorized inspection spokesman and all matters including the Employers requirements regarding QAP shall be handled with the Contractor directly. Such inspection or failure to inspect on the part of Employer shall in no way relieve the Contractor of any responsibility or liability with respect to such, materials nor prejudice the right of Employer to reject unsuitable material after arrival at the destination. Unless specifically stated contrary in the Contract, all expenses relevant to the preparation and performance of testing, inspection and expediting and the preparation of any test reports or certificates at the Contractors / Subcontractors manufacturing facility shall be borne by the Contractor except for the salaries, fees, traveling, lodging and boarding expenses of Employers Representatives.

1.3

When deemed advisable by Employer, the Contractor and his Subcontractor shall be subject to personal expediting by Employers Representatives. Such expediting shall in no way relieve the Contractor of the time or delivery obligations under the terms of the Contract. At all reasonable times and places, before, during and after manufacture, the Contractor shall grant and provide access to Employer / Employers Representatives to

CONTRACT NO.: MIPP/PES/10/021

all parts of the Contractors works and its Subcontractor works involved in the manufacture or processing of the goods or materials. The Employer will give at least three (3) days notice in advance to the Contractor prior to undertaking the inspection visits at Subcontractors works.

SECTION G

Page 3 of 5

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

2.

2.1

INSPECTION REQUISITES

Within one (1) month from the effective date of Contract, the Contractor shall provide the Employer with inspection standards, procedure of design and manufacture for equipment and materials supplied. At the same time an outline of inspection, proof test and test of equipment shall be furnished.

2.2

When the Goods supplied by Contractor are shipped, the check record, test report and certificate of products shall be handed over to Employer, for inspection and test items with Employer's participation; The Contractor shall also provide Employer's

Representatives with signing or joint signing reports.

2.3

The inspection and test items enumerated in this section are only partial, the Contractor shall provide equipment inspection and test plans for Employers review and approval within One (1) month from the effective date of the Contract.

2.4

During manufacture of the Flame Scanner and Cooling Air Fan System in the Contractors works, the Employer shall dispatch Employers personnel to the Contractors works. They will observe / witness the manufacture including the test and inspection before shipment. All of these cannot replace or decrease the Contractors responsibility to product quality.

3.

3.1

Inspection and Test Plan (ITP)

The ITP shall be finalized, after discussions, to cover items which have to be witnessed either via documentation or witnessing of an activity in the contractors facilities, and Customer Hold Point activities.

3.2

The ITP shall detail the roles of the Contractor, the Employer and the Employers

CONTRACT NO.: MIPP/PES/10/021

Representative as applicable.

3.3

The Employer shall have the right to increase or decrease the scope of the ITP. This shall be discussed and agreed with the Contractor during detailed engineering.

SECTION G

Page 4 of 5

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

4.

4.1

Quality Assurance Plan (QAP)

The QAP shall be finalized to cover from source of raw materials right through to the packing and transportation of the finished product.

4.2 4.3

The QAP shall detail the roles of various Contractor personnel involved. The Employer shall have the right to increase or decrease the scope of the QAP. This shall be discussed and agreed with the Contractor during detailed engineering.

5.

Pre-shipment Certification

A pre-shipment certificate shall be issued by the Contractor for each shipment with the signature of the Employers Representative as soon as the Goods are ready for dispatch. However, for certain shipments to be made directly from bought out manufacturers works on the instruction of the Employers Representative; the preshipment certificate shall be signed by the Employers Representative without direct inspection. (END OF SECTION)

SECTION G

Page 5 of 5

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION H LIAISON MEETINGS

SECTION H

Page 1 of 5

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

TABLE OF CONTENTS

1. 1.1

LIAISON MEETINGS...........................................................................................................................3 FIRST LIAISON MEETING (KICK OFF MEETING)...........................................................................3

MEETING AGENDA..................................................................................................................................................... 3 1.2 SECOND LIAISON MEETING............................................................................................................4

MEETING AGENDA: ................................................................................................................................................... . 4 1.3 THIRD LIAISON MEETING.................................................................................................................5

MEETING AGENDA..................................................................................................................................................... 5

SECTION H

Page 2 of 5

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

1.

LIAISON MEETINGS

Liaison meetings shall be held in order to ensure that the Works will proceed smoothly, and also to coordinate and timely resolution of technical problem, if any. During the first liaison meeting (Kick Off Meeting), it shall be discussed and decided the requirement of subsequent liaison meetings and their schedule.

1.1

FIRST LIAISON MEETING (KICK OFF MEETING) Time Place Participants : : : Within 2 weeks after signing of contract Contractors works / Employers office in India / China Approximately 3 people

Meeting Agenda Technical coordination for preliminary design The Contractor shall provide the Employer, One (1) week prior to the meeting, with the overall preliminary design (fundamental design) planning, technical information and potential technical problems which need to be coordinated with the Employer Technical coordination on the terminal points Battery limit clarifications shall be sorted out to enable the Contractor to produce the first set of construction drawings. Overall completion schedule for Engineering, Procurement, Manufacture, Inspection, Testing and Supply. Drawing and document numbering system Drawing title block Format and schedule for monthly progress reporting Preliminary Quality Assurance Plan (QAP) Inspection and Test Plan (ITP) Preliminary list of Sub-Vendors Coordination on the relevant codes and standards. The Contractor shall organize for Employer to visit and inspect: a) Contractors reference plant (360 MW or higher capacity thermal power station which is under operation)

CONTRACT NO.: MIPP/PES/10/021

SECTION H

Page 3 of 5

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

b) Sub-equipment manufacturers c) A construction site of where similar product / system is getting implemented. 1.2 Adoption of general requirement list given by Employer

SECOND LIAISON MEETING Time Place Participants : : : Six (6) weeks after effective date of contract Contractors works / Employers office in India / China Approximately 3 people

Meeting Agenda: The technical inputs required by the Contractor as discussed during the first liaison meeting shall be made available to the Contractor as per the schedule agreed. In case the inputs are delayed then the schedule for the second liaison meeting shall be mutually agreed between the Employer and Contractor. The Contractor shall introduce his overall preliminary design (concept design). The Employer will review and confirm the preliminary design (fundamental design). Contractor's introduction of the work plan and technical criteria of detailed construction drawings and coordination on the details of construction drawings and status of their delivery schedule. The Employer shall confirm the list of selected vendors of auxiliary equipment by Contractor. Contractor shall submit the list of Sub-Vendors for Employers review and approval.

CONTRACT NO.: MIPP/PES/10/021

If necessary, designers of both parties may work together for a certain period of time. Signing of agreement for preliminary designs (concept design). Detailed Quality Assurance Plan (QAP) FAT, SAT and Pre commissioning calibration procedures shall be submitted and approved by the employer. Explanation of the relevant inspection standards and codes for equipment in the inspection items, and, coordination on the procedure, items and method of the

SECTION H

Page 4 of 5

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

equipment inspection. 1.3 THIRD LIAISON MEETING Time Place Participants : : : To be decided during the second Liaison meeting Contractors works / Employers office in India / China Approximately 3 people

Meeting Agenda Technical coordination and determination of construction schemes of the major project items. Painting procedure and schedule Employer shall review the progress of equipment and materials procurement and where necessary, shall visit and investigate the manufacturing, inspection and test facility of Contractor / Subcontractor for main and auxiliary equipment. Discussion on erection procedures schemes and check list proposed by the erection company for erection completion of each individual equipment.

Discussion on commissioning procedures and check list for commissioning completion as well as Performance Guarantee Test of each individual equipment.

In each liaison meeting, both Parties shall sign the relevant minutes of meeting and agreement. . (END OF SECTION)

SECTION H

Page 5 of 5

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION I TRAINING

SECTION I

Page 1 of 3

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION I

TRAINING

1.1 The Contractor is responsible to provide training for the Employers technical personnel at Contractor's / Sub-Contractors facility. Contractor shall provide necessary administrative assistance for the trainees, but the Employer shall pay for expenses towards transportation and living. 1.2 The training schedule shall be arranged by Contractor so that the trainees can participate in similar plant construction, commissioning and operation. Such training shall be arranged by the Contractor as far as practicable. 1.3 Contractor shall provide the Employers trainees with necessary technical information, drawings, facilities, tools, instruments and safety protection devices etc so that they shall gain enough expertise to operate, maintain, modify and debug Flame Scanner And Cooling Air Fan System. The Contractor shall allow the trainees to take along with him the notes and technical information obtained during the training. 1.4 Contractor shall assign persons to be responsible for instructing the trainees to grasp the essentials of the training program, give guidance for utilizing factory owned technical materials, answer questions encountered in the training course and provide trainees with specifications, standards and test methods which shall have to be grasped, so that comprehensive knowledge about the design philosophy, characteristics and

performance requirements of equipments to be implemented during operation and maintenance can be acquired by trainees in the predetermined time. 1.5 Class room training programme, shall be arranged by Contractor for Employers trainees, so that the work ability of the trainees shall be increased and optimized. The

CONTRACT NO.: MIPP/PES/10/021

broad outline of training contents are as follows: (1) Principle of operation (2) Design, construction and operation features. (3) Trouble shooting, analysis and rectification of system abnormalities (4) Operation guidance. (5) Visit to a power station to see the equipment/system in operation.

SECTION I

Page 2 of 3

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

Contractor may propose the detailed contents for class room training, and this shall be finalized during Liaison meeting. 1.6 At the end of training, Contractor shall conduct an evaluation of the trainees to assess the effectiveness of the training course. The assessment records shall be submitted to the Employer. 1.7 The suggested number of trainees and time schedule of trainees are as below. The final figures shall be arrived after discussion between Employer and Contractor 6 man days of training for three C&I Engineers at your facility in China/India, followed by plant visit.

(END OF SECTION)

SECTION I

Page 3 of 3

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION J SITE SERVICES (NOT APPLICABLE)

SECTION J

Page 1 of 1

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION K SITE DATA

SECTION K

Page 1 of 3

CONTRACT NO.: MIPP/PES/10/021

CONTRACT FOR FLAME SCANNER AND COOLING AIR FAN SYSTEM FOR 4360 MW UCCHPINDA THERMAL POWER PLANT IN CHHATTISGARH STATE, INDIA

SECTION K

SITE DATA

No. 1 DESCRIPTION Project Title DETAILS 4 x 360 MW UCCHHPINDA THERMAL POWER PROJECT R.K.M POWERGEN PRIVATE LIMITED No.14, Dr. Giriappa Road, T.Nagar, Chennai-600 17, Tamilnadu, India Tel : +91-44-66291000 Fax : +91-44-66291100 e-mail : rkmpowergen@gmail.com MIPP INTERNATIONAL LTD. No.32, 2nd floor, Block D, Lim Eng Ming Building, Spg. 88,Kg. Kiulap, Bandar Seri Begawan BE1518, Negara Brunei Darussalam Tel.: +673 -8950224 (Brunei) Fax: +673 -2232880 (Brunei) E-mail: nandakumar.mipp@gmail.com FICHTNER Consulting Engineers India Private Limited Ganesh Chambers 64, Eldams Road Chennai 600 018 Tel : +91 44 24359158 Fax : +91 44 24344579 e-mail : mail@chn.fichtner.co.in Northeast Electric Power Design Institute 4368, Ren Min Street, Changchun, 130021, China Tel : +86-431-85798922 Fax : +86-431-85643157 e-mail : wangheng@nepdi.net 11 km from Kharsia Longitude : 83 07 41E Latitude : 21 53 57 N Kharsia at a distance of 11 km from Site

Owner

Employer

Owners Engineer

Employers Engineer

4 5