Escolar Documentos

Profissional Documentos

Cultura Documentos

Asme QCM

Enviado por

CaptainToniesTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Asme QCM

Enviado por

CaptainToniesDireitos autorais:

Formatos disponíveis

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY ( ALPHA-ECC )

Address : Lot 9, Dong Xuyen Industrial Zone, Rach Dua Ward, Vung Tau City, Baria Vung Tau Province, Vietnam, 70000 Tel : (84. 64) 3611 200 ; Fax : (84. 64) 3611 788

QUALITY CONTROL MANUAL FOR THE SHOP CONSTRUCTION AND FIELD ASSEMBLY OF POWER BOILERS, PRESSURE VESSELS, PARTS AND POWER PIPING IN ACCORDANCE WITH ASME CODE SECTION I, SECTION VIII DIVISIONS 1 AND 2, B31.1 For ASME CERTIFICATION MARK WITH DESIGNATORS S, U AND U2 AND REPAIRS / ALTERATIONS TO METALLIC PRESSURE RETAINING ITEMS IN ACCORDANCE WITH THE NATIONAL BOARD INSPECTION CODE FOR NB R STAMP

2nd EDITION

CONTROLLED COPY CONTROL No. Holder UNCONTROLLED COPY

Revision Rev. 0 1 2 3 4 Date Prepared by QA/QC Manager Ngo Le Thong Ngo Le Thong Ng L Thng Ng L Thng Ng L Thng Reviewed by QA/QC Dept GM Phan Van Quang Phan Van Quang Phan Vn Qung Phan Vn Qung Phan Vn Qung Approved by Director Vu Van Dao Vu Van Dao L Xun Hng L Xun Hng L Xun Hng Accepted By A.I

21-02-2011 17-01-2012 26-04-2012 03-10-2012 14-11-2012

Responsible: QA/QC Dept Document Title

QUALITY CONTROL

Document format: A4 Document status N/A Document Number AL-QC-ASME.01 MANUAL

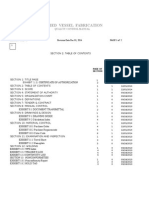

QUALITY CONTROL MANUAL Sec. I Table of Contents

Section Rev. No. Page

I 4 1 of 1

Section Preface I II III 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 14.0 15.0 16.0 Cover Page Table of Contents Statement of Authority Glossary Organization QC Manual Control

Description

Rev 4 4 2 2 3 3 3 2 3 3 3 2 2 3 2 2 2 2 1 3

Date 14-11-2012 14-11-2012 03-10-2012 03-10-2012 14-11-2012 14-11-2012 14-11-2012 03-10-2012 14-11-2012 14-11-2012 03-10-2012 03-10-2012 03-10-2012 14-11-2012 03-10-2012 03-10-2012 03-10-2012 03-10-2012 14-11-2012 14-11-2012

Drawings, Design Calculations, and Specification Control Material Control Examination & Inspection Program Correction of Nonconformities Welding Nondestructive Examination Heat Treatment Calibration of Measurement and Test Equipment Records Retention Authorized Inspector Field Assembly Repairs and Alternations Special Requirements for Section VIII, Div. 2 Index of Sample Forms

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL Sec. II Statement of Authority

Section Rev. No. Page

II 2 1 of 1

This QC Manual will be used for the shop construction and field assembly of Power Boilers, Boiler External Piping and Pressure Vessels and parts in accordance with the ASME Code Section I, ASME Code Section VIII Div.1 & Div.2, and B31.1. Repairs and Alterations to metallic Pressure Retaining 2 Items in accordance with National Board Inspection Code and any applicable jurisdiction requirements, where the item is installed. All Code items will be constructed or field assembled in the full compliance with the Code, this QC Manual. Repairs and Alterations shall be in accordance with National Inspection Code and this QC Manual. No person involved in the implementation of this QC Manual shall deviate from the provisions set forth in this QC Manual. The QA/QC DEPT General Manager has the sufficient and well-defined responsibility, authority and organizational freedom to identify quality problems and to initiate, recommend and provide solutions to those problems. He also has authority to stop work, which in his opinion, further process will result in non-conforming. All review, approval, certification and authorization used in this QC Manual are indicated by initial/ signature and date of responsible personnel. Electronic signatures are not used. In the event that any problem or difference in opinion concerning quality that cannot be resolved within the organization, it shall be brought to my attention for final resolution and this resolution shall be within the limits of Code, NBIC and this QC Manual as applicable.

Le Xuan Hung DIRECTOR

03-10-2012

Date

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. III Glossary Rev. No. Page

III 2 1 of 2

AI AIA AIS ASME BM Code C of C DEPT ALPHA-ECC Hold Point Item PS&M DEPT MDR GM 2 PE / RPE PM P&W DEPT MRF MTR NB or National Board NCR NDE

Authorized Inspector ASME accredited Authorized Inspection Agency Authorized Inspector Supervisor The American Society of Mechanical Engineers Bill of Material ASME Codes Sec.I, Sec.VIII Div.1 & Div. 2, and B31.1 and Sections and standards referenced therein Certificate of Compliance Departments in COMPANY Southern Petroleum Construction Joint Stock Company Hold point is a designated inspection stage where the next operation cannot proceed without sign-off by the party who designate the hold point Raw materials, sub-assemblies and completed products covered in this Manual. Process Skid & Modules Department Manufacturer's Data Report or Manufacturers Partial Data Report General Manager of Departments Professional Engineer / Registered Professional Engineer Project Manager Production & Workshops Department Material Requisition Form Material Test Report or Certificate of Compliance The National Board of Boiler and Pressure Vessel Inspectors Nonconformance Report Nondestructive Examination (RT, UT, MT, PT and VT)

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. III Glossary Rev. No. Page

III 2 2 of 2

PRI PUR DEPT PO PQR QCP WL QC Inspector QA/QC DEPT MRIR Welder

Pressure Retaining Item Purchasing Department Purchase Order Procedure Qualification Record Quality Control Procedure Welder Register List Quality Control Inspector in ALPHA-ECC Quality Assurance/Quality Control Department Receiving Inspection Report Welders or Welding Operators unless otherwise described separately Witness point means a designated inspection stage beyond which the next operation can proceed when the specified partys presence is not available after being notified in advance. The notification shall be documented on the Traveler. Record of Welder or Welding Operator Performance Qualification Welding Procedure Specification Radiographic Examination Ultrasonic Examination Magnetic Particle Examination Liquid Penetrated Examination Visual Examination A Manufacturing step or operation that requires a review of records by AI or Customer. The review activity shall be documented by signature and date on the Traveler and affected document. Quality Control National Board Inspection Code

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Witness point

WPQ WPS RT UT MT PT VT Review QC NBIC

Document Number : AL-QC-ASME.01

Section QUALITY CONTROL MANUAL Sec. 1.0 Organization Rev. No. Page

1.0 3 1 of 4

1.1

This section defines the scope of authorities and responsibilities of key personnel in various departments relating to the implementation and promotion of quality activities in the construction of Code Items. The DIRECTOR is responsible for overall Code construction and NBIC repair/ alteration activities within ALPHA-ECC. The Director will delegate authority to various departments. DEPUTY DIRECTOR reports to the Director. His duties and responsibilities shall include but are not limited to. a) To ensure all requirements of bid documents are fully defined to avoid misinterpretation. b) To determine companys resources and capacity are adequate to fully comply with all requirements of tender prior to submission of bid. c) To identify and resolve all differences, uncertainties or any ambiguous information existing in tender, contract document and request for concession or waiver otherwise.

1.1.1 1.1.2

1.1.3 3

The QA/QC DEPT GM reports to the Deputy Director and responsible for coordinating and controlling inspection activities. The responsibility shall include but not be limited to:

a) Regular review of the applicable ASME Code Edition/ NBIC Edition and Addenda and any consequential update of the Manual, and ensure that only controlled copies of the QC Manual are used. b) Verify compliance and execution of this Quality Control Manual at the shop and field. c) Review of Welding Procedure Specification (WPS) and certify Procedure Qualification Records (PQR), and Welder / Welding Operator Performance Qualification (WPQ). 3 d) Review of Nondestructive Examination (NDE) & Heat Treatment Procedures and NDE personnel certification records. e) Safekeeping of ASME Certification Mark and NB Stamps and proper issuance of the National Board Numbers (on request by client to be registered with the National Board). f) Liaison with the Authorized Inspector for the timely execution of inspections and document reviews. Submitting all supplementary procedures to A.I for his review and acceptance.

g) Control of Nonconformities. h) Certifying MDR

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 1.0 Organization Rev. No. Page

1.0 3 2 of 4

1.1.4

THE QC INSPECTOR / Site QC Inspector reports to QA/QC DEPT GM. The responsibility shall include but not be limited to:

a) Inspection of incoming material as per Section 4.0 b) Inspection of Dished Head for forming accuracy. c) Examining welds by means of visual inspection. d) Routine inspection of welding and fabrication operation to ensure that: I). Qualified welders are employed in the Code work. II). The correct welding procedure is being used. III). Welding consumables are controlled as described in procedure No.: AL-WCP-04 e) Conducting welder qualification test. f) Reporting Non-Conformities as described in Section 6.0. g) Keeping calibration records of measuring and test equipment. h) Conducting Final inspection and tests. i) j) 1.1.5 Preparing Manufacturers Data Report and Stamping. Ensuring that inspection hold points do not progress, until authorized to do so. PROCESS SKID & MODULES DEPT GENERAL MANAGER The PS&M DEPT GM is responsible for: a) the review and approval of design documents, drawings, fabrication procedures, specifications, Traveler and subsequent revisions to these documents; b) the appointment of a Design Engineer to prepare design calculations and material selection from the applicable Code section to which the item is to be constructed. 1.1.6 ENGINEER Engineer is responsible for: (a) (b) (c) (d) (e) 1.1.7 the preparation and issuance of shop drawing, fabrication procedures, specifications, Traveler and other related documents, including their subsequent revisions; ensuring that any interruption resulting from design or material changes are properly identified. providing effective supervision instructions and make all applicable documents available in the working area in the shop. preparing weld joints for NDE work. conducting hydrostatic tests as per Code requirements.

DESIGN ENGINEER The Design Engineer is responsible for: c) the liaison with the client / design sub-contractor to ensure drawings, design calculation and material selection meet Code requirements and Clients Specification. d) Submission to PE/RPE for certification of Manufacturers Design Report.

Document Number : AL-QC-ASME.01 SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 1.0 Organization 1.1.8 Rev. No. Page

1.0 3 3 of 4

PRODUCTION AND WORKSHOPS DEPARTMENT GENERAL MANAGER The P&W DEPT GM reports to Deputy Director and is responsible for the smooth implementation and execution of the Code item fabrication and repairs and alterations at the shop in compliance with the Code requirements. His responsibility shall also include but not limited to: (a) assigning a Foreman to ensure that the production activities be carried out under controlled conditions; (b) controlling shop equipment and devices and maintaining them in proper working conditions; (c) maintaining the proper calibration of shop equipment and measuring devices, and timely updating QA/QC DEPT. with the calibration status.

1.1.9

SITE MANAGER: The Site Manager shall assume the duties of P&W DEPT GM at the field site. The Site QC Inspector designated by the QA/QC DEPT GM takes responsibility for the quality control activity at the site including in-process inspection, control of NDE subcontractor. He shall certify the MDR for fieldwork portion. He is the principal contact with the A.I at field site.

1.1.10 SITE QC INSPECTOR

1.1.11 PURCHASING DEPARTMENT GENERAL MANAGER The PUR DEPT GM reports to Deputy Director and is responsible for preparing purchase orders and the purchase of Code materials. 1.1.12 PURCHASING STAFF The Purchasing Staff is responsible for the implementation of Code material purchases. 1.1.13 MATERIAL CONTROLLER Material Controller reports to QA/QC DEPT GM and is responsible for the handing of the receiving material and prepare for receiving and inspection. 1.1.14 FOREMAN Reports to P&W DEPT GM / Site Manager and is responsible for the assignment of qualified Welder and supervision of fabrication or assembly operation. 1.1.15 STOREMAN The Storeman is authorized to receive incoming materials and welding consumable. The Storeman reports to P&W DEPT GM. He is responsible for the proper identification and storage of stock, incoming materials and welding consumables, and the maintenance of the electrode oven. He will issue material to Welder upon requested. 1.1.16 DOCUMENT CONTROLLER System Document Controller reports to QA/QC DEPT GM and is responsible for the registration and distribution of documents related to this Quality Control Manual (all revisions of this Manual, its associated QCPs, Exhibits, etc.). Project Document Controller reports to PS&M DEPTt GM and is responsible for the registration and distribution of project documents. 1.1.17 ORGANIZATION CHART See Fig. 1.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 1.0 Organization 1.1.18 DELEGATION OF DUTIES Rev. No. Page

1.0 3 4 of 4

Each GM can delegate performance of duties to his qualified subordinates but the responsibility cannot be delegated.

Figure 1. Organizational Chart

DIRECTOR

DEPUTY DIRECTOR

PROCES SKID & MODULES DEPT. GENERAL MANAGER - Engineer - Design Engineer - Project Doc. Controller

PURCHASING DEPT. GENERAL MANAGER - Purchasing Staff

QA/QC DEPT. GENERAL MANAGER - QA/QC Manager - QC Inspector - Welding Engineer - System Doc. Controller - Material Controller - NDE Sub-Contractor

FIELD SITE (See FIG. 2) (See Section 13)

PRODUCTION & WORKSHOPS DEPT. GENERAL MANAGER - Foreman - Storeman

: Administration Line : Communication Line

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL Sec. 2.0 QC Manual Control 2.1 Scope

Section Rev. No. Page

2.0 3 1 of 2

This section describes the applicability and control of the QC Program for CODE/ NBIC activities. 2.2 2.2.1 2.2.2 2.2.3 Applicability of QC Program This QC Manual is the primary documentation of the QC Program. Detailed requirements not covered by this QC Manual will be implemented by the related Quality Control Procedures (QCP) which shall not conflict with this QC Manual. QC Program set forth in this QC Manual shall be applied to the Code/ NBIC activities under ASME Certificates/ NBIC certificate held by ALPHA-ECC. Upon agreement with the customer, the portions of this QC Manual may be applied to the fabrication of Non-Code items where the Code Stamping is not a contractual requirement. Control of QC Manual The QC Manual shall be prepared by the QA/QC Manager in accordance with the Code, reviewed by the QA/QC DEPT GM and approved by the Director. The review and the approval shall be indicated by the QA/QC DEPT GM's and the Director's signature/date on the Cover page. The QC Manual shall be submitted to the AI for review and acceptance prior to implementation. The AI acceptance shall be documented with his signature/date on the Cover page. Distribution 1) 2) The QA/QC DEPT GM is responsible for distribution of the QC Manual. Only controlled copies of the QC Manual shall be distributed by the System Document Controller designated by the QA/QC DEPT GM to the related dept(s) in ALPHA-ECC and shall be available to all the personnel concerned. All the controlled copies of the QC Manual to be issued shall be serialized. The QC Manual and all revisions thereto shall be distributed by hand carry to the related depts. The recipient shall sign and date on the Quality Control Manual Distribution Master List (Exh. AL-ASME-01) except for the recipient of uncontrolled copy. Uncontrolled copy may be issued outside the ALPHA-ECC at the discretion of the QA/QC DEPT GM. Uncontrolled copy shall be current at time of issuance but need not be updated.

2.3 2.3.1 2.3.2 2.3.3 2.3.4

3) 4)

5)

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 2.0 QC Manual Control 2.3.5 1) Revision Control Rev. No. Page

2.0 3 2 of 2

Revisions to the QC Manual may be requested by ALPHA-ECC personnel, by Code change, by organizational change, etc. and the QA/QC DEPT GM shall be responsible for the final decision and preparation of the revision to the QC Manual. The QC Manual shall be revised by each Section except for the Sample Forms which are revised by page. The revised area of the QC Manual except for typographical correction shall be identified by italic font plus isosceles triangle mark with revision level. This also applies to areas of pictorial information. Revision status of each Section and Sample Form shall be shown on the Table of Contents and Index of Sample Form, respectively. Addition of information on Sample Forms will not require a revision to the QC Manual, but shall be available to the AI for review prior to its use and to be included in the next revision of the QC Manual. However, deletion of information on sample forms is considered a revision. Distribution of revised QC Manual shall be controlled in the same manner as the original. For any revision in the QC Manual, whole manual is issued as revised document. Obsolete copies of the QC Manual shall be returned to the QA/QC Manager and destroyed by the QA/QC Manager. One copy of the obsolete QC Manual, marked with VOID, may be retained by the QA/QC DEPT for historical record. Review of Code Edition and Addenda QA/QC DEPT GM will review ASME Code Edition/ NBIC Code Edition and Addenda after issuance but prior to the effective date for possible revisions of QC Manual or program. The review result shall be documented with signature, date and results on copies of the summary of changes page of the respective Code or using separate review sheet When revisions are required due to changes in ASME Code/ NBIC Code Edition and Addenda, they shall be implemented within 6 months of the Edition or Addenda issue date.

2)

3) 4)

5) 6)

2.4

2.5

Quality Control Manual Edition At the discretion of QA/QC DEPT GM, this QC Manual may be issued wih a new Edition during the time of the triennal ASME joint review. All revision level shall be reverted to zero and all previous revision level indicators shall be removed.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL Sec. 3.0 Drawings, Design Calculations, and Specification Control 3.1 Scope

Section Rev. No. Page

3.0 3 1 of 3

This section describes order entry and control of design calculations, drawings and specifications and revisions thereto. 3.2 Order Entry Upon awarding of a contract to the ALPHA-ECC, the DIRECTOR shall issue the Job Number, identify it as ASME job and inform the PS&M DEPT GM, P&W DEPT GM, and the QA/QC DEPT GM with comments / directions, if any. The Job number shall be shown on all project related documents. Documents supplied by Customer shall be transferred to the related DEPT GMs from DIRECTOR. Either US Customary unit, SI unit or local customary units may be used for compliance with all requirements of the Code, but one system shall be used consistently throughout all phases of construction (e. g. material, design, fabrication and report) unless otherwise permitted by the Code. The system to be used shall be designated on the drawing in accordance with the Customer Specification. Units on the name plate and MDR shall be consistent with fabrication drawings. Alternate units can be shown in parenthesis. Material certified to either SI or US Customary units can be used irrespective of the units used in construction. PS&M DEPT GM is responsible selection of units.

3.2.1

3.2.2 3.2.3

3.3

Customer Specification Specifications supplied by customer shall be reviewed by Design Engineer, before being accepted by PS&M DEPT GM, in order to verify compliance with applicable Code requirements. After being accepted by PS&M DEPT GM, the specification shall be sent to DIRECTOR for approval. DIRECTOR is responsible for further communication with the Customer for the requirements that are not clear or not in compliance with the Code.

3.4

Control of Customer Supplied Documents The PS&M DEPT GM is responsible for review of the customer supplied documents to assure Code compliance. Customer supplied drawings and calculations may be used directly for fabrication. They shall be stamped with Customer Supplied and reviewed by Design Engineer for meeting Code requirements and approved for construction by PS&M DEPT GM prior to their use. Acceptance of drawings and calculations shall be evidenced by PS&M DEPT GM's signature/date on the drawings and calculations. Revisions to the Customer Supplied Documents shall be controlled in the same manner as the original. When design is by Sub Contractor, customer-supplied documents (data sheets, specifications, drawings) shall be provided to the design sub-contractor. The design-subcontractor generated drawings, design calculation and material specification shall be reviewed by Design Engineer and approved by PS&M DEPT GM for the Code compliance and then shall be submitted to the AI for his review. Alpha ECC remains responsible for correctness and completeness of all design documents. For parts of piping, design responsibility may be taken by main boiler / vessel manufacturer. In such case, partial data report shall be identified with the design responsibility.

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

3.4.1 3.4.2

3.4.3 3.4.4 3.4.5

3 3.4.6 3.4.7

Document Number : AL-QC-ASME.01

Section QUALITY CONTROL MANUAL Sec. 3.0 Drawings, Design Calculations, and Specification Control 3.5 1) 2) Control of Documents Drawings, Calculations and Specifications Rev. No. Page

3.0 3 2 of 3

3.5.1

General Assembly Drawings, calculations and specifications shall be prepared by the Design Engineer, reviewed and approved for construction by PS&M DEPT GM for Code compliance. Drawings shall contain enough information to ensure proper fabrication. This information will consist of, but not be limited to, design conditions, material specification including grade, type and class, NDE requirements, heat treatment, dimensions, tolerances, Code Section with Edition and Addenda, drawing number etc. Design calculation shall include the evaluation whether the impact test is required or exempted (not require for S), the applicable Code Section and Addenda, calculation methods and calculated thickness etc. Design Engineer shall verify the Code compliance of inspection openings and corrosion allowance according to the applicable Code as required to be described on the MDR. PS&M DEPT GM shall submit the design calculations and drawings to the A.I. for his review prior to the start of fabrication so that the Al may place his inspection points on the TRAVELER in accordance with Section 5.0 of this QC Manual. All design documents shall be registered with and distributed by the Project Document Controller. The Project Document Controller shall keep Document Distribution Master List (Exh : AL-ASME-02) and record the latest revision for each document. The Project Document Controller shall hand deliver new/ revised drawings to the concerned personnel and obtain the signature with date of recipients as record of receipt on the Drawing / Document Distribution List. Computer Aided Design Calculation When computer aided design calculations are used for the design of Code items, the PS&M DEPT GM is responsible for the input of the correct design data and for verifying that the correct output has been obtained and in compliance with Code by alternate methods. The PS&M DEPT GM shall review Code Edition and Addenda to determine whether computer programs are affected or not. All computer program revisions shall be verified in the same manner as the original prior to use. Computer aided calculations shall be made available to the AI. The PS&M DEPT GM provides the A.I with any alternate calculations when requested. Fabrication Documents

3)

4) 5)

6)

3.5.2 1)

2)

3) 3.5.3

1) The PS&M DEPT GM is responsible for issuing the applicable fabrication documents such as work instructions. 2) Fabrication documents with revision level to be used for fabrication shall be listed on the Traveler by the PS&M DEPT GM and distributed to ASME working area. 3) When contractually required, as built drawings shall be prepared by Engineer, approved by PS&M DEPT GM and may be verified by A.I. 3.5.4 Inspection and Test Documents 1) The QA/QC DEPT GM is responsible for issuing the inspection and test documents such as Inspection and Test Procedure, NDE Procedure as described in Section 7.0 and 10.0 of this QC Manual. 2) Inspection and test documents with revision level to be used for fabrication shall be listed on the Traveler.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL Sec. 3.0 Drawings, Design Calculations, and Specification Control 3.5.5

Section Rev. No. Page

3.0 3 3 of 3

Fabrication, inspection and test documents shall be registered with the Project Document Controller and Distributed by hand carry under the responsibility of the Project Document Controller Quality Control Procedure (QCP) QCP shall be prepared by QC Inspector and Approved by the QA/QC DEPT GM. Revisions of Drawings/Documents

3.5.6 3.5.7

1) Revisions of drawings/documents shall be prepared, reviewed, approved and distributed in the same manner as the original. 2) The revised area of drawings/documents except for typographical correction shall be identified with a vertical line on the right hand margin and the area of pictorial information shall be identified with appropriate method such as cloud mark and revision level. 3) Obsolete copies shall be withdrawn from the work area and physically destroyed or if retained for historical purpose identified with the stamping of "VOID" by the recipient. 4) Revised drawings / calculations must be verified by PS&M DEPT GM. 5) For any revision to drawings or customer specifications, PS&M DEPT GM shall review and verify if design calculations need be revised. Design calculations shall reference the revision No. of drawing. Revisions to the design documents shall be distributed to all concerned and to AI for his review. 3.6 Availability of Documents to the AI All the documents related to Code activities shall be made available to the A.I.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 4.0 Material Control 4.1 Scope Rev. No. Page

4.0 2 1 of 4

This section describes procurement, receiving inspection and control of Code materials including welding materials to assure that only intended materials are used in Code construction. 2 4.2 Responsibility Requisition of materials shall be the responsibility of the PS&M DEPT GM. Purchasing of materials will be the responsibility of the PUR DEPT GM in according with approved procedure. Receiving inspection and review of the Purchase Order will be the responsibility of the QA/QC DEPT GM. 2 4.3 Material Requisition Form (MRF) The Material Requisition Form ( Exh : AL-ASME-06) and the Bill of Material (BM) ( Exh : AL-ASME-07) will be prepared by the Engineer for each contract, reviewed and approved by the PS&M DEPT GM. The MRF and BM will be the part of PO. The Bill of Material (BM) will contain the material specification, grade/class, quantity, size. Prior to approval of the MRF and BM, the PS&M DEPT GM shall assure that the MRF/BM includes all the requirements of the Material Specification of ASME Code Section, construction Codes and Customer Specifications, including Material Certification documentation requirements, that the materials are acceptable for Construction and that all the relevant ordering information as required by the Material Specification is indicated. No change or substitution of material shall be made without revision of the MRF and BM, and any other affected documents and the approval of the PS&M DEPT GM as applicable and it shall be made available to the A.I when requested. One copy of MRF and BM shall be forwarded to the PUR DEPT. 4.4 Purchase Order After having received the approved MRF/BM, the Purchasing Staff will prepare the Purchase Order (Exh : AL-ASME-05) using the information as shown on the MRF and BM. The Purchase Order will contain the Job number. Project Name, MRF and BM numbers with revision. The Purchase Order shall be approved by the DIRECTOR and sent to the proper vendor by PUR DEPT GM with the MRF and BM (if applicable) for purchasing the material. All materials will be ordered to SA or SB specification for which allowable stresses are listed in the Section II Part D for the applicable construction Code, and to SFA specification for welding material, or other specifications allowed by the Code. A copy of the approved Purchase Order with MRF and BM will be forwarded to the QA/QC DEPT to be used during receiving inspection. When vessel shell sections, heads or other pressure boundary parts are cold formed by a subcontractor, the required certification for the part shall indicate whether or not the part has been heat treated. QC Inspector shall ensure that thickness and dimension requirements after forming are within the design requirement and the applicable ASME Code requirement.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 4.0 Material Control Rev. No. Page

4.0 2 2 of 4

The coded marking system, if used by the subcontractors of formed shape or the processors of plate and pipe shall be acceptable to QA/QC DEPT GM of ALPHA-ECC and to the AI. This shall be verified at receiving inspection stage. 4.5 Receiving Inspection The PUR DEPT will receive the material and inform QA/QC DEPT for receiving and inspection. All document provided by the material supplier shall be forwarded to QC Inspector for receiving inspection. The QC Inspector will prepare Material Receiving Inspection Record : MRIR (Exh : AL-ASME-08). Using the Purchase Order with MRF and BM and Code as a guide, the QC Inspector shall perform receiving inspection and fill out the MRIR. The MRIR will contain measurement for dimensions, heat no., slab no., Job number, MTR number, material identification marking taken from the materials and all other pertinent information. The QA/QC DEPT GM shall verify the miscellaneous pressure part for which the Partial MDR is not required for Code compliance per UG-11 & PG-11. 4.6 Identification of the accepted Material The QC Inspector will indicate the acceptable material by attaching the "ACCEPTED" Sticker (Exh : AL-ASME-11) on the material. When small parts are received, they may be placed in the bin or tub and the "ACCEPTED" Sticker will be attached on the tub or bin. For the material from which the "ACCEPTED" Sticker can be easily defaced during handling i.e. for plates, pipes, etc. the QC Inspector may indicate the acceptance of the material by writing the Job number or MRIR number with signature on the surface of the material with paint. All material with large size enough to be marked with ASME close to ID marking (by non deleted ink). If the material is found to be non-conforming, a "HOLD" Sticker (Exh : AL-ASME-11) will be placed upon the material and an NCR shall be generated per Section 9. 2 4.7 Material Certification (MTR) The Material Certification, when required, will be reviewed by the QC Inspector for the traceability of identification numbers on the material and for the compliance with the requirements of the ASME Code and Purchase Order. QA/QC DEPT GM shall verify Code compliance and re-certify (Exh : AL-ASME-11) for the ASTM material produced to an edition other than those listed in Acceptable ASTM Editions of ASME Code Section II Part A or B or different from edition and addenda of the construction Code used. QA/QC DEPT GM stamps ACCEPTED with signature and date on the material certificate will evidence review of the Material Certificate. The QA/QC DEPT GM will review the MRIR with the material certification and he is responsible to make them available to the AI when requested. The QA/QC DEPT GM shall approve the MRIR and returns it to the QC Inspector. If further material testing is required to be performed at receiving inspection or during manufacturing operations, the test shall be arranged by the QC Inspector with a PO & testing specification and the result shall be reviewed/approved by the QA/QC DEPT GM and shall be available to the AI using either a NCR or a Traveler. The report will be referenced and attached to the MTR and form part of the material certification.

Document Number : AL-QC-ASME.01 SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL

Section Rev. No.

4.0 2 3 of 4

Sec. 4.0 Material Control 4.8 Issuance of Material

Page

Upon receiving the approved MRIR, the QC Inspector shall distribute the copies of the MRIR to PUR DEPT / P&W DEPT GMs for notification of acceptance. A copy of the MRIR will be sent to the PS&M DEPT GM for withdrawal of the accepted material for fabrication work as described in the Traveler. The Storeman shall release only the material accepted and so identified on the MRIR and material to the Foreman. This shall be documented on the Store Issue Voucher (Exh : AL-ASME-10). 4.9 Storage Storage of Code material in the shop will be in the designated areas. A shop storage area will be in such a location as to prevent damage to the material. Welding material will be stored in accordance with manufacturer's recommendation in a clean and dry area and under the control of the Storeman / Material Controller and in a suitable atmosphere when opened. Welding material shall be stored, issued and controlled in accordance with the Welding Consumable Control Procedure ( AL-WCP-04) 4.10 Customer Supplied Material For customer supplied materials, MTR or C of C as required by the material specification and Code shall be provided and Customer supplied material will receive the same cycle of receiving inspection, identification, certification and control according to the paragraph 4.5 through 4.9. using customer supplied documents, MRF, BM for inspection and Code compliance. 4.11 Stock Material Stock material will receive the same cycle of receiving inspection, identification, certification and control according to the paragraph 4.5 through 4.9, before use, except the BM and MRF. Code and drawings are used in receiving inspection. 4.12 Non-Conforming Material If material is found to be nonconforming, it will be handled in accordance with Section 6.0 of this QC Manual. 4.13 Identification Marking In case the original identification markings are to be cut out or obliterated in subsequent operations, or the material is divided into two or more parts, one set of material identification shall be transferred on to each piece of material prior to cutting to the location where the markings will be visible on the completed vessel, or a Coded Marking Control Procedure (AL-CM-17) shall be used to assure identification of each piece of material during fabrication and subsequent identification of the markings on the completed vessel. When the Coded Marking System is used it shall be traceable to the original required marking and shall be acceptable to the A.I. Heat numbers or material identification markings shall be recorded on the Traveler in the event of machining or other operation causes the identification markings to be removed.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 4.0 Material Control Rev. No. Page

4.0 2 4 of 4

Upon completion of machining or other operation, the markings will be re-stamped or etched back onto the material. This shall be verified by the QC Inspector. For plate materials used in the construction of Section I Boilers, one group of plate manufacturer's stamps, consisting of the manufacturer's name, plate identification number, material specification number with grade, class and type as appropriate shall remain visible on shell plate, furnace sheets and heads, except that heads containing tube holes and butt straps shall have visible at least a sufficient portion of such stamps for identification or the Coded Marking System may be used as described earlier in this paragraph. 4.14 Authorized Inspector All documents for Code material will be made available to the A.I. for review.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 5.0 Examination & Inspection Program 5.1 Scope Rev. No. Page

5.0 3 1 of 3

This section describes the control measures of examination, test and inspection through construction process. 5.2 Responsibility Material processing and handling in the shop will be the responsibility of P&W DEPT GM. The Traveler shall be prepared and implemented under the responsibility of PS&M DEPT GM. The planning and performing of examinations and inspections will be the responsibility of the QA/QC DEPT. 5.3 Traveler The Traveler ( Exh : AL-ASME-21 ) which shall contain all applicable processes such as fit-up, welding, NDE, heat treatment, inspection and test, etc. and all applicable procedures to be used, shall be prepared by the Engineer and approved by the PS&M DEPT GM. The Traveler shall be forwarded to the QA/QC DEPT GM or his designee for review and the designation of QC Hold/Witness points. When entry to the completed vessel is not provided, an inspection stage shall be identified on the Traveler for internal examination prior to setting up the final closure weld. 5.3.3 After designation of QC Hold/Witness points, the QA/QC DEPT GM shall submit the Traveler and drawings and any other documents requested to the AI so that he may assign his Hold/Witness/Review points prior to start of fabrication. The Traveler reviewed by the A.I. with his signature/date shall be given to the Engineer to place in the working area with the applicable drawings and procedures referenced on the Traveler for use during fabrication. The revision to the Traveler shall be prepared, reviewed and approved in the same manner as for the original including A.I. review except that the processed page of Traveler shall remain attached to the revised page. If additional Hold/Witness/Review Points are requested by the AI or Customer, they shall be included. Hold/Witness/Review Points shall not be deleted without approval of the QA/QC DEPT GM, A.I. and/or Customer. Upon the satisfactory completion of the each operation, the Engineer shall sign/date on the applicable column to indicate the completed fabrication operation on the Traveler. The Engineer shall also record the identification of materials used and the ID No. of the Welders who welded the joints on the Traveler.

5.3.1

5.3.2

5.3.4

5.3.5

5.3.6

5.3.7 5.3.8

5.4

In-Process Inspection The QC Inspector will monitor the fabrication, NDE and heat treatment operations, and document inspection results on the Traveler and appropriate report form. The QA/QC DEPT GM shall notify the A.I. of all Hold/Witness Points in reasonable advance. The designated Hold Points shall not be bypassed without consent of the party who designated the inspection point. In the event that the AI consents to allow work to proceed through a specified AI Witness Point which is not mandated by the Code without his presence, the QA/QC DEPT GM shall be responsible for documenting this agreement on the Traveler prior to beginning of the work so affected. AI may designate additional Hold Point in such event.

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

5.4.1 5.4.2 5.4.3

Document Number : AL-QC-ASME.01

Section QUALITY CONTROL MANUAL Sec. 5.0 Examination & Inspection Program 5.4.4 Rev. No. Page

5.0 3 2 of 3

Upon satisfactory completion of the inspection of the QC Inspector / A.I. / Customer's Hold/ Witness/Review Points, they will sign-off on the applicable column of the Traveler to indicate their acceptance. Related report/record number shall be recorded on the Traveler. If any non-conformance is found during inspection, they shall be handled in accordance with Section 6.0 of this QC Manual and QC Inspector shall record the NCR number on the Traveler. Nonconforming conditions found by a person other than QC Inspector will be notified to the QA/QC DEPT GM. Upon the completion of fabrication operations, the completed Traveler and required reports shall be submitted to the QA/QC DEPT GM for review to assure that all the designated inspections and tests have been completed and conform to the applicable drawings, procedures and customer documents. The QA/QC DEPT GM is responsible for assuring that all Code required inspections by the A.I. have been performed and there is no open NCR. When the review is acceptable, the Traveler and associated records shall be handled in accordance with Section 11.0 of this QC Manual.

5.4.5

5.4.6

5.4.7 5.4.8

5.5

Final Testing The Engineer shall be responsible for conducting the final pressure test as per Hydrotest Procedure AL-HT-15 (AL-HT-15-01). The QA/QC DEPT GM or his designee shall be responsible for monitoring the final pressure test of the Code items. The QC Inspector and the A.I. shall witness and make the examination and inspection on the welded joints and connections of Code items during the final pressure test and document the result on the Pressure Test Report ( Exh : AL-ASME-12). A.I. is given an opportunity to sign the Pressure Test Report. Pressure indicating gauges used in testing shall have dials graduated over a range as described in the applicable Code section. In the event of a pneumatic test for Section VIII, Div.1 construction, the NDE requirements of UW-50 shall be followed before the test. For Section I Boiler, hydrostatic test shall be performed to preclude over pressurization so that the membrane stress of any part shall not be greater than 90% of its yield strength. A pressure relief valve may be used and set to the predetermined pressure of 0.9 x Pmax. Permissible test temperature shall be as per Code and specified in the hydrotest procedure AL-HT-15 (AL-HT-15-01).

5.5.1 5.5.2 5.5.3

5.5.4 5.5.5 5.5.6

5.5.7

5.6

Manufacturers Data Reports and Stamping Upon successful completion of the final pressure test, QC Inspector shall provide a complete MDR and the QA/QC DEPT GM will review it for correctness, and certify the MDR. The MDR signed by the QA/QC DEPT GM will be presented to the AI for his review and signature. The QA/QC DEPT GM will distribute the copy of the MDR to the user or his designated agent, AIA and jurisdiction at the location of installation, as required by the Code. When providing parts to be assembled by another ASME Certificate Holder, it is the responsibility of the QA/QC DEPT GM to assure that the Partial MDR has been forwarded, in duplicate, to the manufacturer of the finished item or, for replacement or repair parts, to the user or his designated agent. The scope of the design responsibility shall be indicated in the Remarks of the Partial MDR.

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

5.6.1

5.6.2 5.6.3

Document Number : AL-QC-ASME.01

Section QUALITY CONTROL MANUAL Sec. 5.0 Examination & Inspection Program 5.6.4 Rev. No. Page

5.0 3 3 of 3

Prior to affixing the ASME Certification Mark and/or NB Stamps, the QC Inspector shall check the data on the item or on the Name Plate Marking ( Exh : AL-ASME-14) with the final drawings and related documents to assure all specified requirements have been met. Direct stamping shall not be used on vessels or parts constructed of steel plates less than 1/4 inch (6mm) thickness or of nonferrous plates less than 1/2 inch (13mm) thickness. The ASME Certification Mark and/or NB Stamps shall be applied only with the concurrence of the AI and he will witness the affixing of the ASME Certification Mark and/or NB Stamps. For field assembled boilers and pressure piping, ASME Certification Mark and/or NB Stamps shall be applied in accordance with the requirements of PG-108 and PG-109 respectively by the QA/QC DEPT GM in the concurrence and presence of AI.

5.6.5 5.6.6

5.7

ASME Certification Mark and NB Stamps The QA/QC DEPT GM shall safely keep the Certification Mark and NB Stamps when not in use. When a stamp is requested by the shop, the QA/QC DEPT GM or his designee will hand carry it to the location. Soonest after being used, the ASME Certification Mark and/or NB Stamps shall be returned to the custody of the QA/QC DEPT GM.

5.7.1 5.7.2 3

5.8

Retention of MDR The Manufacturer's Data Report shall be maintained by QA/QC DEPT GM which shows the date issued, type of vessel and manufacturer's serial number. (See Section 11 of this QC Manual for retention).

5.9

Registration with National Board (NB) When the registration of MDR with NB is required, the original MDR shall be sent to NB for registration by the QA/QC DEPT GM within 60 days after signing by the A.I. The MDR shall be the signed and dated with commission number and endorsements of the A.I. holding NB commission. For registration with NB, the serialized NB number shall be assigned by the QA/QC DEPT GM after the completion of the pressure test without prefix or suffix, skips or gaps of unused numbers or duplication of numbers starting with one and shall be recorded in the National Board No. Log (Exh : AL-ASME-18) at the time of completion of final inspection/ pressure test as applicable.

5.10 Authorized Inspector All documents related to Code activities including material certification, examination reports, test records and other fabrication records shall be made available to the Authorized Inspector when requested.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 6.0 Correction of Nonconformities 6.1 Scope Rev. No. Page

6.0 3 1 of 2

This section describes the system for handling of nonconforming items including identification, reporting and disposition in order to prevent their inadvertent use. Nonconformity is any condition which does not comply with the applicable rules of the Code, this QC Manual or other specified requirements. Nonconformity shall be corrected before the item can be considered to comply with Code requirements. 6.2 Identification When nonconforming conditions are found at any stage of fabrication activity, it shall be identified by the QC Inspector by attaching a "Hold" Sticker( Exh : AL-ASME-11 ) to the nonconforming items. Where attaching the Hold Sticker is not practical, it shall be attached to the tub or the bin, and shall be indicated on the Traveler as appropriate. The QC Inspector shall issue a Nonconformance Report ( Exh : AL-ASME-13) The QC Inspector is responsible to record the NCR number on the Traveler or on the Material Receiving Inspection Record (MRIR) for receiving inspection. When an individual other than the QC Inspector detects the nonconforming conditions, the individual shall notify the nonconformance to the QA/QC DEPT so that the activities described above shall be accomplished. Documentation The QC Inspector documents the nonconforming condition on the NCR with the recommended dispositions, if possible. When the NCR is issued it will be recorded on the Non Conformance Report Log (Exh : AL-ASME-22 ) and which is maintained by the QA/QC DEPT GM. 6.4 Segregation The nonconforming items shall be segregated, if practical, from similar acceptable items by the P&W DEPT GM or PUR DEPT GM and further processing shall not be permitted until the final disposition is made. 6.5 Disposition The QA/QC DEPT GM/ PS&M DEPT GM is responsible for providing the final disposition of the nonconforming condition and when needed, the NCR will be sent to the PS&M DEPT GM before the final disposition for the further technical justification or design evaluation. The PS&M DEPT GM is responsible for evaluation of nonconformance and for the development of the recommended disposition of nonconformance in accordance with the requirements of Code and Customer documents. The QA/QC DEPT GM shall review the recommended disposition and make final disposition. A copy of the NCR resulting in a design change shall be distributed to the PS&M DEPT GM for information and use in the reconciliation of the design documents. All NCR's shall be submitted to the A.I. by the QA/QC DEPT GM for his review and concurrence and designation of inspection points (Ref. Para. 6.5.6) prior to the implementation of disposition.

6.2.1

6.2.2 6.2.3 6.2.4

6.3 6.3.1 6.3.2

6.5.1

6.5.2

6.5.3

6.5.4

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL

Section Rev. No.

6.0 3 2 of 2

Sec. 6.0 Correction of Nonconformities 6.5.5

Page

The NCR need not be issued for recurring type welding defects found by NDE or visual inspection during the fabrication process provided the following conditions are met and documented on the appropriate NDE report. a) The welding defects are repaired using the welding repair procedure which has been verified by the AI in advance and impact testing is not the requirement. b) The repair shall be completed before final heat treatment or pressure testing whichever is earlier. c) The repaired area shall be re-inspected/ examined using the original method

6.5.6

When the final disposition is Use As Is, it should be approved by the QA/QC DEPT GM with technical justification and no Code violation, all affected documents shall be revised and approved as the original. When the final disposition is "Repair", the PS&M DEPT GM shall describe the process steps including required inspection for repair work on the NCR or by using the Traveler. It is the responsibility of the P&W DEPT GM to implement the disposition for the In-Process items and of the PUR DEPT GM for the received material. Repaired items shall be examined in accordance with applicable procedures and with the original acceptance criteria unless the alternate acceptance criteria are established on the NCR which meets the Code requirements.

6.5.7 6.5.8 6.5.9

6.5.10 Nonconforming items shall be returned for further fabrication process as described on the original Traveler only after the disposition has been accepted by QA/QC DEPT GM, the AI and /or the Customer. 6.5.11 Upon completion of disposition activity, the QC Inspector shall close it out by confirming with his signature and date, and signature/date of the AI on the NCR. 6.6 Repair of Base Materials When the disposition of a nonconformance requires the repair to base material as defined by the Code, the acceptance by the AI and the customer shall be obtained prior to the start of repair work for the method and extent of repairs. It shall be documented on the NCR. 6.7 Un-Resolved Nonconformity Material or items that cannot be corrected from the nonconforming condition shall be scrapped. 6.8 Authorized Inspector All documents related to the NCR activities will be made available to the AI for his review.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL Sec. 7.0 Welding 7.1 Scope

Section Rev. No. Page

7.0 3 1 of 4

This section describes the control of WPS, PQR, Welder qualification, welding material distribution and welding processes. All Welding Procedure Specification (WPS) and Welders shall be qualified according to the requirements of Section IX of the ASME Code and additional requirements of the applicable Code of construction. 7.2 Responsibility Preparation of all welding procedures and the procedure qualification tests will be the responsibility of the Welding Engineer / QC Inspector. The certification of the PQR and WPQ will be the responsibility of the QA/QC DEPT GM. The P&W DEPT GM is responsible for the control of all welding materials. Actual issuing and storage of welding material will be the responsibility of Storeman. Welding Engineer / QC Inspector is responsible for the full supervision and control of the welding of the test coupons and recording actual data of variables used in the welding for the qualification of welding procedure, welder and welding operator. 3 In addition to the Traveler (see 5.3.1), the Engineer is responsible for the preparation of work instructions for welders and fitters, production weld and NDT maps. It is the responsibility of QC Inspector to monitor and inspect all aspects of production welding, including welding consumables, etc. to ensure full compliance with the Code and WPS. This responsibility shall also include visual inspection of welds (see 8.1), liaison with NDT Sub-contractor for project-specific NDT service, liaison with customers inspector, AI, and other third party (if any) for their hold, witness, review points indicated on the Traveler. 7.3 Welding Procedure Specification The Welding Engineer / QC Inspector will be responsible for the preparation and qualification of Welding Procedure Specifications and revisions to them. When revisions to a WPS are required and the changes are limited to the nonessential variables the existing WPS shall either be revised showing a new revision level and date or a new WPS shall be written. Any changes in essential or supplementary essential variables (only when impact test is required by the applicable construction Code), will require a new qualification test. The Welding Engineer / QC Inspector shall maintain a list of the WPS which have been qualified for ASME Code activities. The WPS designated by the Welding Engineer / QC Inspector and specified on the Traveler or weld map shall be made available to the Welders in the work area. QA/QC Dept General Manager / A.I may request re-qualification of a WPS at any time, when he has reason to question the WPS on making sound welds.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 7.0 Welding 7.4 7.4.1 Welders/Welding Operators (Welder hereafter) Rev. No. Page

7.0 3 2 of 4

The qualification of Welder will be performed under the full supervision and control by the Welding Engineer / QC Inspector in ALPHA-ECC shop. Only qualified Welders shall be assigned to perform Code welding by the Foreman. The Foreman is responsible for assignment and supervision of welders. Each welder will be assigned a unique identifying number upon successful completion of first qualification test by the Welding Engineer / QC Inspector. If a Welder leaves the ALPHA-ECC, unique identifying number shall not be reassigned for at least 1 year. All qualified Welders name, identifying number, qualified position, F-number, pipe diameter, thickness, process and welding date in that process, etc. will be maintained in a Welder Register List (WL) ( Exh : AL-ASME-04) for each project individually. The QC Inspector will update the project-specific WL for any addition or deletion of new Welder or at least every three months. The updated copies of the WL will be given to the Foreman. If the expiration of some Welder's qualification on WL is coming prior to the next update the Foreman shall notify it to the Welding Engineer / QC Inspector to verify the extension of the qualification. Qualified Welder/Welding Operator is listed on Welder Continuity Log ( Exh : AL-ASME-03) which is updated by Welding Engineer / QC Inspector. Welder Continiuty Log shall indicate at least one report of welders activity per month within the every three month period. The weld joint shall be stamped by Foreman with the Welder's unique identification number on base material surface at distance of not more than 3 feet (1 m) of weld which he makes in steel plates 1/4 inch (6mm) and over in thickness and in nonferrous plates 1/2 inch (13mm) and over in thickness, or record Welder's identification number on applicable column of Traveler by Engineer with his signature. For identification of Welders on vessels in which the wall thickness is less than 1/4 inch (6mm) for steel material and less than 1/2 inch (13mm) for nonferrous material, suitable stencil or other surface markings shall be used, or a record of Welder ID shall be indicated on the Traveler by Engineer for each joint, which shall be available to the AI when requested. Documentation of Test Result The results of the qualification test shall be documented on the PQR or the WPQ as applicable. When the testing is performed by an outside laboratory, steps shall be taken to assure that the test is performed on the correct specimen and these test reports shall be documented on the PQR/WPQ by the Welding Engineer / QC Inspector, which are then certified by QA/QC DEPT GM. Test reports provided by the outside source laboratory shall be kept on file by the Welding Engineer / QC Inspector.

7.4.2

7.4.3

7.4.4 3

7.4.5

7.4.6

7.5

7.6

Expiration and Renewal of Qualification The performance qualification of Welder shall be affected when one of the following conditions occurs.

7.6.1

When a Welder has not welded with a process during a period of 6 months or more, his qualifications for that process shall expire; unless, within the six month period, prior to his expiration of qualification. 1) A Welder has welded using manual or semiautomatic welding under the supervision and control of Foreman that will extend his qualification for an additional 6 months. 2) A Welding operator has welded with a machine or automatic welding under the supervision and control of Foreman that will extend his qualification for an additional 6 months.

7.6.2

When there is a specific reason to question his ability to make welds that meet the specification, his qualification which support the welding he is doing shall be revoked. All other qualifications not questioned remain in effect.

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Document Number : AL-QC-ASME.01

Section QUALITY CONTROL MANUAL Sec. 7.0 Welding Rev. No. Page

7.0 3 3 of 4

7.6.3 7.6.4 7.7

The QA/QC DEPT GM or the AI may require re-qualification of the Welder when these reasons are found. Renewal of qualification shall be in accordance with QW-322.2 of the Code Section IX.

Welding Material Distribution

7.7.1 The Storeman will be responsible for issuing and returning of welding material using in accordance with the Welding Consumable Control Procedure ( AL-WCP-04) 7.7.2 Low hydrogen electrodes shall be properly identified and kept in atmosphere controlled storage area under conditions complying with the manufacturer's recommendation. Low hydrogen welding materials shall be dried in the heating oven before being issued for use in the shop according to the manufacturer's recommended time and temperature on the Welding Electrodes Baking and Holding Report (Exh : AL-ASME-16). Electrodes of controlled quantity will be issued to Welders by the Storeman. Remained materials will be returned to the welding material crib at the end of the shift or after the time specified on the Welding Material Issue Record ( Exh : AL-ASME-17) whichever comes earlier. The low hydrogen electrodes once issued and returned will not be used for Code job. 7.7.3 Welding materials not requiring heated storage will be kept in clean and dry storage areas. 7.8 Welding The Foreman shall assign the welder to the job based on WL, WPS and drawings. The Foreman shall maintain the applicable documents to perform the job at the working place of ASME Code job. QC Inspector will record Welder I.D, WPS, Joint No, NDE Method into Welding Summary (Exh : AL-ASME-23) when requested by customer. Engineer will control Traveler based on working assignment. 7.8.1 Tack Weld and preparation for welding Tack welds used to secure alignment shall either be removed completely when they have served their purpose, or their stopping and starting ends shall be properly prepared by grinding or other suitable means so that they may be satisfactorily incorporated into the final weld. Tack welds, whether removed or left in place, shall be made using a qualified WPS. Tack welds to be left in place shall be made by Welders qualified in accordance with Sec. IX and shall be examined visually for defects, and if found to be defective, it shall be removed. The method of base metal preparation used shall leave the welding groove with reasonably smooth surfaces and free from deep notches, striations or irregularities. The surfaces for welding shall be free of all scale, rust, oil, grease or other foreign materials. 7.9 Individual may be contracted by ALPHA-ECC to supply their welding services provided all the following conditions are met. All Code construction shall be the responsibility of the ALPHA-ECC. All welding shall be performed in accordance with the ALPHA-ECCs Welding Procedure Specifications.

7.9.1 7.9.2

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL Sec. 7.0 Welding

Section Rev. No. Page

7.0 3 4 of 4

7.9.3 7.9.4 7.9.5 7.9.6

All Welders shall be qualified by the Welding Engineer/ QC Inspector/Site QC Inspector in accordance with this QC Manual and assigned with an identification number. The P&W DEPT GM has the authority for complete and exclusive administrative supervision of all Welders. The Engineer shall provide technical supervision to the Welders. The Foreman has authority to assign and remove Welders at his discretion without involvement of any other organization. The Director shall be responsible for Code compliance of the vessel or part, including Certification Mark stamping and providing Data Report Forms properly executed and countersigned by the Authorized Inspector. The signature of the AI on the cover page indicates the acceptance of this program on behalf of the AIA of record.

7.9.7

7.10 Authorized Inspector The AI shall have the right at any time to call for and witness tests of welding procedure qualification or of the ability of any Welder. All documentation in this section will be made available to the A.I.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 8.0 Nondestructive Examination 8.1 Scope Rev. No. Page

8.0 2 1 of 2

This section describes the requirements for NDE and documentation of the results as required for Code compliance. When Non-Destructive Examination (RT, UT, MT and PT) is needed, it will be subcontracted. Visual Examination required by the ASME B31.1, Section VIII Division 2 will be performed by qualified QC Inspector. 8.2 2 Responsibility QA/QC DEPT GM has the overall responsibility for successful performance of nondestructive examination as required for Code compliance. Preparation and approval of NDE procedures, calibration of the NDE equipment, qualification of NDE personnel and implementation of NDE for RT, UT, MT and PT will be the responsibility of the subcontractor's NDE Level III who is appointed by the QA/QC DEPT GM as a ALPHA-ECC Level III. The NDE will be conducted by qualified personnel of subcontractor in accordance with the written procedures which shall be reviewed by the QA/QC DEPT GM. QA/QC DEPT GM is responsible for the qualification of VT Examiner and preparation of VT procedure in accordance with AASME B31.1, Section VIII Division 2 (Visual Examination Procedure AL-VS-13). 2 8.3 Appointment of Level III The QA/QC DEPT GM shall review the NDE Subcontractors written practice, qualification and certification records of the intended NDE Level III personnel and, when satisfactory, write a letter to that NDE Level III as ALPHA-ECC appointed NDE Level III examiner. This letter will state the methods (RT, UT, MT and PT) he is appointed for and date of expiration of the appointment. 2 8.4 Documentation for the NDE Personnel The subcontractor will provide the written practice which is in accordance with the Code and using the SNT-TC-1A (Code adopted Edition and Addenda) as guide. The QA/QC DEPT GM will review the qualification and certification records of personnel to assure that they are in accordance with the Code and NDE Subcontractors written practice. 8.5 VT Examiner VT Examiner shall be qualified and certified according to the Procedure : AL-VS-13 8.6 2 NDE Procedures NDE procedures shall be written and qualified in accordance with Code requirements and demonstrated to the satisfaction of the AI, when required by the construction Code. When there is a change in one or more in essential variables, the NDE procedure shall be re-qualified. This demonstration shall be documented with the AI's signature on the cover sheet of the procedure. The QA/QC DEPT GM shall certify applicable NDE procedures in accordance with T-150 of ASME Section V. The NDE procedures shall be made available to the NDE operators in the working area. VT procedure shall be provided by the QA/QC DEPT GM.

Document Number : AL-QC-ASME.01 SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 8.0 Nondestructive Examination 8.7 Nondestructive Examination Rev. No. Page

8.0 2 2 of 2

The extent and method of NDE for Code items will be decided in accordance with the Code and Customer Specification by the Design Engineer and it shall be described on the fabrication drawing. The QA/QC DEPT GM, when needed, prepares NDE map showing NDE requirement for weld joints and materials with assistance of Design Engineer in accordance with the designated NDE requirements on the drawing. Additional NDE may be required considering the fabrication process. The subcontractor shall perform the applicable nondestructive examination based on the drawing and NDE Map and submit the NDE reports and film to the QA/QC DEPT GM. NDE results will be documented on the appropriate subcontractors report forms. The QA/QC DEPT GM or his designee will verify the results of NDE and if a defect is found, he will notify the results to the Engineer. Nonconforming conditions shall be handled according to the Section 6.0 of this QC Manual. 8.8 Equipment Control The appointed NDE Level III is responsible for the calibration and control of the NDE equipment. He will maintain the list of the NDE equipment and calibration records which will be reviewed by the QA/QC DEPT GM. 8.9 2 Authorized Inspector The reports of all nondestructive examinations including film and interpretation sheets will be filed by the QA/QC Inspector and, after review and acceptance of QA/QC DEPT GM, made available to the AI for his review. All documents including written practice, examination procedures, personnel records, calibration records, etc. will be on file by the QA/QC DEPT GM and made available to the A.I. When there is a specific reason to question the qualification of the procedure or the personnel, the A.I. may ask for re-qualification.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL

Section Rev. No.

9.0 2 1 of 1

Sec. 9.0 Heat Treatment

Page

9.1

Scope This section describes the requirements of heat treatment. All heat treatment will be subcontracted.

9.2

Heat Treatment The PS&M DEPT GM is responsible to approve the Design Sub-contractor submitted scope of the heat treatment according to the requirement of Code, standards, and Customer Specifications. The Engineer will provide the heat treatment procedure which shall be as a minimum describing the heating and cooling rate, time and temperature, the location and number of thermocouple, method of thermocouple attachment and removal, and instruction to the Heat Treatment Sub-contractor. The PS&M DEPT GM approves the procedure and instruction. Alternatively, the heat treatment procedure / instruction will be submitted by the Heat Treatment Sub-contractor and it shall be reviewed by the Engineer and approved by the PS&M DEPT GM. The QA/QC DEPT GM or his designee shall assure the proper performance of the heat treatment by witnessing, monitoring and document review i.e. furnace loading, method, heating and cooling rate, time and temperature, the location and number of thermocouple, method of thermocouple attachment and removal calibration equipment used in the heat treatment, etc. Before performing the heat treatment, the QC Inspector shall make examination to check the identification marking, stamping or tagging on the Code item. After completion of the heat treatment, the QC Inspector shall make examination to check the identification marking and to verify that there is no damage or unacceptable deformation on the item.

9.2.1

9.2.2

9.2.3

9.2.4 9.2.5

9.3

Record The QA/QC DEPT GM or his designee shall review the heat treatment record and Time-Temperature Chart for conformance with the requirements of the procedure, specification, Code and Customer Specification. The heat treatment record shall include date, serial number of the equipment used, procedure, and furnace loading (including location and number of thermocouples) as a minimum. All the heat treatment records shall be made available to the A.I for his review.

9.3.1

9.3.2

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 10.0 Calibration of Measurement and Test Equipment 10.1 Scope Rev. No. Page

10.0 3 1 of 2

This Section describes the system for the calibration of examination, measuring and test equipment used in the fulfillment of Code requirements. Calibration will be carried out by the outside agency 10.2 Responsibility

10.2.1 The QA/QC DEPT GM shall have the responsibility to assure that examination, measuring and test equipment used in the fulfillment of Code requirements have been calibrated when required by the Code and are of proper type, range and accuracy to assure the intended quality of the items. 10.2.2 Calibration of NDE equipment is the responsibility of the NDE Level III 10.2.3 Calibration of equipment shall be accomplished by ALPHA-ECC or government accredited calibration agency. 10.3 Calibration Standard and Frequency The measurement and test equipment shall be calibrated and traceable by marked serial number and controlled in accordance with the national standards or the manufacturer's standards. 10.3.1 The calibration frequency shall be decided and designated in the Measuring Instrument List (Exh No.: AL-ASME-20) by the QA/QC DEPT GM based on the national standard, the Code, and the manufacturers standard. 10.3.2 Pressure gauges shall be calibrated against a standard dead weight tester or calibrated master gage. These pressure gauges shall be calibrated at least every 12 months, except 6 months for ASME Section VIII Div. 2 construction. 10.3.3 The measurement or test equipment shall be replaced or recalibrated at any time when there is reason to believe that they are in error or there is a doubt in the accuracy due to dropping or damage. 10.4 Calibration Control

10.4.1 Calibration status of equipment shall be recorded on the Measuring Instrument List : ( Exh. No. : AL-ASME-20 ) which contains the identification number, name, range, date calibrated and date to be expired for calibration, etc. The QC Inspector is responsible to review and maintain the calibration records issued by the external agency. 10.4.2 The equipment ID number shall be recorded on the inspection and test records, MRIR, etc. as appropriate. 10.4.3 The calibrated equipment shall be identified by the calibration records and by the calibration label ( Exh. AL-ASME-11) or outside agencys label which identifies the expiration date. The QC Inspector shall keep all calibration records until the next calibration. 3 10.4.4 When out of calibration equipment is found being used, the QC Inspector shall evaluate all inspection records since the previous equipment calibration. Items affected by the out of calibration condition shall be documented on the NCR for evaluation and disposition and controlled in accordance with Section 6.0 of this QC Manual.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

Section QUALITY CONTROL MANUAL Sec. 10.0 Calibration of Measurement and Test Equipment Rev. No. Page

10.0 3 2 of 2

10.5

NDE Equipment Calibration of NDE equipment shall be done by the NDE Sub-contractor. The QA/QC DEPT GM or his designee shall review and verify these calibration records for Code compliance.

10.6

Authorized Inspector All documents in relation to the calibration will be made available to the A.I. when requested.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL

Section Rev. No.

11.0 2 1 of 2

Sec. 11.0 Records Retention 11.1 11.2 Scope This section describes the requirements for retention of records. 2 Responsibility

Page

Each DEPT GM is responsible for the transfer of the records to the QA/QC DEPT GM. The System Document Controller is responsible for the retention of the records. 2 11.3 Records

11.3.1 Records are retained according with the Table 1 (Records to be retained). 11.3.2 Quality records specified in Table 1 will be kept for a period and at a place as designated by the applicable Dept GM and shall be available to the AI until he signs the Manufacturer's Data Report. 11.3.3 The Customer's specification may require certain documents to be provided with the product. 2 11.4 Records Retention

11.4.1 Records shall be filed and maintained in a manner to be fully identified, protected from deterioration or damage and to allow access by the AI to specific information contained therein at any time during the period of vessel and parts manufacture. 11.4.2 All record shall be identified by pertinent material or item identification numbers. 11.4.3 After AI signs off the Manufacturers Data Report, all documents or records shall be transferred to the QA/QC DEPT GM for maintenance in accordance with Table 1. 11.5 Authorized Inspector

11.5.1 When the MDR is presented to the AI for review and signature, all other pertinent documents will be presented to him as requested. 11.6 Distribution of MDR The QA/QC DEPT GM shall have the responsibility to distribute the copies of the MDR to the Jurisdiction, Authorized Inspection Agency, A.I. and/or Customers as required by the Code or Customer Specification.

11.7

For ASME Section VIII Div. 2, the retained records described in this section of QC Manual shall be made available to the AIS or to the ASME Joint Review Team during the triennial renewal joint review.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL

Section Rev. No.

11.0 2 2 of 2

Sec. 11.0 Records Retention

Page

Table 1 : Records to be retained

No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

Type of Record Design Calculation RT Film RT Reports UT Reports Material Certifications, Material Test Reports and/or Partial Data Reports Heat Treatment Records including PWHT and Test Results Manufacturing Drawings WPS / PQR / Weld Map / Welder Qualification Records for each welder who welded on the vessel NCRs (including the procedures and records of repairs to material,items and assembly) Travelers and inspection records Hydrostatic Test Records with proof test report. Pneumatic Test Records (Sec. VIII, Div. 1, 2) Manufacturers Data Report/ Manufactures Partial Data Report Users Design Specifications Manufacturers Design Reports Tabulation of Material Specification / Manufacturing / NDE Procedures with Qualification Records List of Subcontracted Services and Parts NDE Examiner Certification personnel demonstration Records including

Retention Period (years) Sec I & B31.1 VIII Div.1 3 VIII Div.2 -

5 5 5

3 3 3 3 3 3 3 3 3 3 -

5 -

Inspection, Examination and Test Report Results of Production Test Plates (if applicable) As-Built Drawings ( U2 only)

: Until AI signs off the Manufacturers Data Report. : Three (3) years after Stamping.

Document Number : AL-QC-ASME.01

SOUTHERN PETROLEUM CONSTRUCTION JOINT STOCK COMPANY( ALPHA-ECC )

QUALITY CONTROL MANUAL

Section Rev. No.

12.0 2 1 of 1

Sec. 12.0 Authorized Inspector

Page

12.1

Scope This section covers the interface between Southern Petroleum Construction Joint Stock Company ( ALPHA-ECC) and the Authorized Inspection Agency (AIA).

12.2

Inspection Agreement with AIA ALPHA-ECC shall maintain a written Inspection Agreement to provide Code inspection and audit services with an AIA which is accredited by the ASME in accordance with the requirements of latest version of ASME QAI-1.

12.3