Escolar Documentos

Profissional Documentos

Cultura Documentos

Cupola Furnace

Enviado por

Sumit DhallDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cupola Furnace

Enviado por

Sumit DhallDireitos autorais:

Formatos disponíveis

Cupola Furnace

A cupola furnace is a vertical cylindrical furnace used for melting only cast iron. Although other furnaces are capable of melting cast iron, the largest tonnage of cast iron is melted in Cupola furnace.

The cupola showing the general inputs and outputs.

Construction of Cupola Furnace

* The cupola furnace consists of a cylindrical steel shell lined with a refractory material like firebrick and clay. * The height of the Cupola Furnace may range from 20 - 35 feet, while its diameter ranges from 10 - 15 inch. * The Cupola Furnace is open at the both its top and bottom. * At the bottom of the Cupola Furnace, hinged insulated doors are provided, so that after melting is completed, the contents left inside the cupola furnace can be dropped down by opening the hinged doors. * A coarse refractory sand and clay are rammed slightly on the bottom doors of cupola furnace. The sand is rammed in a tapered manner to allow the flow of molten metal easily through the tapping spout. * Opposite to the tapping spout and little higher is a slag hole through which the slag is removed. *Slightly above the slag hole is the wind box and tuyeres. The tuyeres are small openings (covered by wind box) through which air under pressure is forced into the furnace from the wind box, via a pipe from the blowing equipment. * At the top end of the shell, a charging door is provided through which the charge is fed into the Cupola Furnace.

Working of Cupola Furnace

1. Starting The Cupola Furnace

Initially, soft and dry wooden pieces are placed on the sand bottom after which coke is charged up to the tuyeres lever. The wooden pieces are ignited through the tap hole and sufficient air is passed through the tuyeres for proper combustion of coke.

2. Charging Cupola Furnace

The charge used in cupola furnace consists of alternate layers of coke, flux and metal (iron). These three components are continuously built into the cupola furnace. The most commonly used iron - to - coke ratio is 8:1. The flux may be limestone (CaCO3), fluorspar, sodium carbonate or calcium carbide. Limestone is the commonly employed flux. The total weight of the flux will be approximately 1/5th the weight of the coke chare.

3. Melting in Cupola Furnace

Cupola furnace works on the counter current principle. As the combustion takes place, the charge materials (coke, flux and metal) will be descending downwards, while the hot gases due to combustion will be ascending upwards. Heat exchange takes place between the rising hot gases and the descending charge thereby melting the metal. The liquid metal drops down, while the coke floats up on top of it. The flux also melts and reacts with the impurities of the molten metal forming a slag. The slag floats on the surface of the molten metal thereby preventing oxidation of the metal.

4. Tapping slag and molten metal in Cupola Furnace When sufficient liquid metal is collected in the reservoir, the slag door is opened and the slag floating on the surface of the molten metal is tapped and disposed off. Immediately the tapping spout which was closed with a bott ( a clay plug ) is opened and the liquid metal is tapped into ladles. The tapping spout is again closed with the bott. The liquid metal from the ladle is poured into the moulds.

5. Dropping Down The Bottom in Cupola Furnace

When melting is complete and no more liquid is required, the charging of cupola furnace is stopped. The prop under the bottom door is knocked down and the bottom door is swung out of the way allowing the contents in the cupola to drop down. The un-melted charge is collected and used during the next melting. Note:- The operation of dropping down the bottom is very dangerous and has to be done by a trained person.

Zones Of Cupola Furnace

1. 2.

Well zone in Cupola Furnace Combustion Zone in Cupola Furnace

3.

4. 5.

Reducing Zone in Cupola Furnace

Melting Zone in Cupola Furnace Preheating zone in Cupola Furnace

1. Well zone in Cupola Furnace:Well zone in the portion situated between the rammed sand bottom and just below the bottom edge of the tuyeres. The molten metal is occupied in this zone.

2. Combustion Zone in Cupola Furnace

The combustion zone or oxidizing zone is situated normally 15-30 cm from the bottom edge of the tuyeres. It is in this zone where rapid combustion of coke takes place due to which a lot of heat is generated in the furnace. The combustion is rapid due to the supply of blast air through the tuyeres. Oxidation of manganese and silicon evolve still more heat. The reactions which take place in this zone are: C+O2 (from air) CO2+heat 2Mn+O2 2 MnO + heat Si+O2 SiO2 + heat The temperature in this zone varies from 1550C - 1850C.

3. Reducing Zone in Cupola Furnace

Reducing zone or protection zone is the portion located from the top of the combustion zone to the top of the coke bed. In this zone, some of the hot CO2 gas moving upward through the hot coke gets reduced to CO. In other words, reduction of CO2 to CO occurs in this zone. Due to the reducing atmosphere, the charge is protected from oxidation. The reaction taking place in this zone is given by. CO2+C (coke) = 2CO - Heat Due to the reduction, the temperature reduces to around 1200 C in this zone.

4. Melting Zone in Cupola Furnace

The portion located just above the coke bed to the top of the metal (iron) is called the melting zone. The metal starts melting in this zone and trickles down through the coke bed to the well zone. The molten iron while passing down through the reducing zone picks up carbon and the reaction is given by: 3Fe + 2CO = Fe3C+ CO2

5. Preheating zone in Cupola Furnace

The portion occupied from the top surface of the melting zone to the charging door is called Preheating zone. The hot gases rising upwards from the combustion and reducing zone gives its heat to the charge before passing out of the furnace. Thus, the charge is preheated before descending downwards

Você também pode gostar

- Boxer EngineDocumento84 páginasBoxer EngineTOONGA100% (7)

- Metal Casting Full Lecture NotesDocumento51 páginasMetal Casting Full Lecture Notesumarnasar_1987105074% (19)

- Design and Construction of An Induction Furnace (Cooling SysDocumento143 páginasDesign and Construction of An Induction Furnace (Cooling SysKalyanHalder100% (10)

- Digital Image ProcessingDocumento156 páginasDigital Image ProcessingAnushka BajpaiAinda não há avaliações

- The Cupola Furnace 1000205809Documento431 páginasThe Cupola Furnace 1000205809bakhar100% (1)

- Course Syllabus SHS General Physics 1 (Stem, MELC) SY 2021-2022Documento14 páginasCourse Syllabus SHS General Physics 1 (Stem, MELC) SY 2021-2022Eushane Chiya SyAinda não há avaliações

- Heat Treatment Process: By: Jagdish PampaniaDocumento67 páginasHeat Treatment Process: By: Jagdish PampaniabassamAinda não há avaliações

- Understanding Medium Frequency Induction Melting Furnace and Its ComponentsDocumento10 páginasUnderstanding Medium Frequency Induction Melting Furnace and Its Componentsdarwin_huaAinda não há avaliações

- Foundry PracticeDocumento58 páginasFoundry PracticetrishAinda não há avaliações

- Cupola Furnance, Sand Casting, CO2 CastingDocumento14 páginasCupola Furnance, Sand Casting, CO2 CastingshubhamAinda não há avaliações

- Walmart A Case Study Implementation of Rfid in Supply2091Documento23 páginasWalmart A Case Study Implementation of Rfid in Supply2091Majestyking100% (1)

- Induction Furnace KarakteristikDocumento58 páginasInduction Furnace KarakteristikyanuarAinda não há avaliações

- R134a HXWC Series Water Cooled Screw Flooded Chillers Cooling Capacity 200 To 740 Tons 703 To 2603 KW Products That Perform PDFDocumento16 páginasR134a HXWC Series Water Cooled Screw Flooded Chillers Cooling Capacity 200 To 740 Tons 703 To 2603 KW Products That Perform PDFmohamad chaudhariAinda não há avaliações

- Cupola Design, Operation and ControlDocumento75 páginasCupola Design, Operation and ControlGamini Hettiarachchi100% (14)

- Blast FurnaceDocumento91 páginasBlast FurnaceSarbajitManna100% (1)

- Iron MakingDocumento135 páginasIron MakingSandeep Bandyopadhyay50% (2)

- Designand Construtionofthe Coreless Induction FurnaceDocumento91 páginasDesignand Construtionofthe Coreless Induction FurnaceUma Koduri100% (1)

- Training Presentation On Induction FurnaceDocumento15 páginasTraining Presentation On Induction FurnaceAaradhya Poddar0% (1)

- Sy Katz, Ph.D. S. Katz Associates, Inc. 4388 Knightsbridge Lane W. Bloomfield, MI 48323Documento64 páginasSy Katz, Ph.D. S. Katz Associates, Inc. 4388 Knightsbridge Lane W. Bloomfield, MI 48323shribalajicAinda não há avaliações

- Cupola Furnace-Iron MakingDocumento32 páginasCupola Furnace-Iron MakingSameer MdAinda não há avaliações

- Induction FurnaceDocumento33 páginasInduction Furnacesing_r100% (2)

- Cupola FurnaceDocumento27 páginasCupola FurnaceVijay Ganapathy50% (2)

- What Is Furnace ?Documento18 páginasWhat Is Furnace ?BARUN BIKASH DEAinda não há avaliações

- Cupola Furnace A Practical Treatise On The Construction and Management of Foundry Cupolas .. (1899)Documento430 páginasCupola Furnace A Practical Treatise On The Construction and Management of Foundry Cupolas .. (1899)SPYDERSKILL89% (9)

- Induction FurnaceDocumento16 páginasInduction FurnaceDeepak VishwakarmaAinda não há avaliações

- A TextBook of Fluid Mechanics and Hydraulic Machines - Dr. R. K. Bansal PDFDocumento287 páginasA TextBook of Fluid Mechanics and Hydraulic Machines - Dr. R. K. Bansal PDFPullavartisrikanthChowdaryAinda não há avaliações

- SM TupkaryDocumento666 páginasSM TupkaryElio100% (5)

- Cupola and Blast FurnaceDocumento26 páginasCupola and Blast FurnaceGurjinder SinghAinda não há avaliações

- Unit I Foundry AllDocumento58 páginasUnit I Foundry AllvelavansuAinda não há avaliações

- Blast Furnace Cooling Water Monitoring and Control SystemDocumento27 páginasBlast Furnace Cooling Water Monitoring and Control SystemAnil MistryAinda não há avaliações

- Induction FurnaceDocumento5 páginasInduction FurnaceOmar MushtaqAinda não há avaliações

- Energy Optimizing FurnaceDocumento4 páginasEnergy Optimizing Furnacesourajpatel100% (1)

- Types of Furnaces Used in CastingDocumento29 páginasTypes of Furnaces Used in CastingMurali100% (1)

- Cast IronDocumento21 páginasCast Irondellibabu509Ainda não há avaliações

- Cupola FurnaceDocumento32 páginasCupola Furnaceadelina ednandaAinda não há avaliações

- Physics As Level Book (2022-2023)Documento492 páginasPhysics As Level Book (2022-2023)AMNA MOAZZAMAinda não há avaliações

- Billets ProcessDocumento5 páginasBillets ProcessWewey NuestroAinda não há avaliações

- Induction FurnaceDocumento4 páginasInduction FurnaceMuhammad Noman100% (1)

- Some Ironfounding Cupola Furnace in Asia and EuropeDocumento4 páginasSome Ironfounding Cupola Furnace in Asia and EuropeKhin Aung ShweAinda não há avaliações

- The Melt Shop ProcessDocumento38 páginasThe Melt Shop ProcessAmr Tarek100% (3)

- Furnace TheoriesDocumento78 páginasFurnace TheoriesPushkar KhannaAinda não há avaliações

- Melting Furnaces: Cupola FurnaceDocumento5 páginasMelting Furnaces: Cupola FurnaceAly RamadanAinda não há avaliações

- Repot On SMS-2 JSPL, Raigarh FinalDocumento45 páginasRepot On SMS-2 JSPL, Raigarh FinalRahul Pandey100% (1)

- Present Indian Steel Making Practice and Its Scenario: Introduction: WHAT IS STEEL?Documento10 páginasPresent Indian Steel Making Practice and Its Scenario: Introduction: WHAT IS STEEL?SarbajitManna100% (1)

- 2.1.2 Pseudocode PDFDocumento13 páginas2.1.2 Pseudocode PDFBlessed Endibye KanyembaAinda não há avaliações

- Meltingfurnace 170728094222Documento31 páginasMeltingfurnace 170728094222Ninfa LansangAinda não há avaliações

- Sintering Plant at A GlanceDocumento72 páginasSintering Plant at A Glanceskt9560Ainda não há avaliações

- Melting of Metals: Cupola FurnaceDocumento13 páginasMelting of Metals: Cupola FurnaceRahul RaiAinda não há avaliações

- Guidelines For Proper Coreless Furnace Maintenance.Documento7 páginasGuidelines For Proper Coreless Furnace Maintenance.iowafurnace83100% (2)

- CupolaDocumento5 páginasCupolaRajan Goyal100% (2)

- What Is Furnace ?Documento21 páginasWhat Is Furnace ?BARUN BIKASH DEAinda não há avaliações

- Induction FurnaceDocumento7 páginasInduction FurnaceDeepak Velusamy100% (2)

- Induction HeatingDocumento5 páginasInduction HeatingPavan KumarAinda não há avaliações

- Cupola FurnaceDocumento23 páginasCupola Furnacesayan halderAinda não há avaliações

- A Modular IGBT Converter System For High Frequency Induction Heating ApplicationsDocumento3 páginasA Modular IGBT Converter System For High Frequency Induction Heating Applicationsimosaba322Ainda não há avaliações

- Melting FurnacesDocumento11 páginasMelting Furnacesabhishek_m_more0% (1)

- Crucible Furnace Some MoreDocumento2 páginasCrucible Furnace Some MorePrashanth BnAinda não há avaliações

- Cupola Furnace Mechanical EngineeringDocumento8 páginasCupola Furnace Mechanical EngineeringMujahid Raza NooriAinda não há avaliações

- Iron MakingDocumento26 páginasIron Makingsumit ranjanAinda não há avaliações

- What Is Furnace ?Documento18 páginasWhat Is Furnace ?BARUN BIKASH DEAinda não há avaliações

- Cupola FurnaceDocumento6 páginasCupola FurnaceAyushAinda não há avaliações

- CupolafurnacaDocumento23 páginasCupolafurnacaSourav SumanAinda não há avaliações

- Study of CUPOLA Aim: To Study of CupolaDocumento5 páginasStudy of CUPOLA Aim: To Study of CupolaSUPERSTITIOUS TECHNICAL WORLDAinda não há avaliações

- Unit 3 NotesDocumento12 páginasUnit 3 NotesarunkumarnoolaAinda não há avaliações

- Gating System and CupolaDocumento18 páginasGating System and CupolaArya PrakashAinda não há avaliações

- Scanned by CamscannerDocumento20 páginasScanned by CamscannerSumit DhallAinda não há avaliações

- How To Make A Straight Line Fit Using Excel?Documento4 páginasHow To Make A Straight Line Fit Using Excel?waelAinda não há avaliações

- 1 s2.0 S1878029616301578 MainDocumento9 páginas1 s2.0 S1878029616301578 MainoliviaAinda não há avaliações

- Xat2016 Paper PDFDocumento29 páginasXat2016 Paper PDFSumit DhallAinda não há avaliações

- How To Make A Straight Line Fit Using Excel?Documento4 páginasHow To Make A Straight Line Fit Using Excel?waelAinda não há avaliações

- How To Make A Straight Line Fit Using Excel?Documento4 páginasHow To Make A Straight Line Fit Using Excel?waelAinda não há avaliações

- Class10 Science Unit11 NCERT TextBook English EditionDocumento12 páginasClass10 Science Unit11 NCERT TextBook English Editionshraddha0603Ainda não há avaliações

- Motion EconomyDocumento15 páginasMotion EconomySumit DhallAinda não há avaliações

- Mixed Integer PROGRAMMINGDocumento11 páginasMixed Integer PROGRAMMINGSumit DhallAinda não há avaliações

- Gdpi Kit2018 Iisc DomsDocumento8 páginasGdpi Kit2018 Iisc DomsSumit DhallAinda não há avaliações

- CAT 2017 AdvertisementDocumento1 páginaCAT 2017 AdvertisementSumit DhallAinda não há avaliações

- Motion EconomyDocumento15 páginasMotion EconomySumit DhallAinda não há avaliações

- NCERT Book Psychology XIIDocumento211 páginasNCERT Book Psychology XIIKanishkaVKhatri100% (11)

- Txt.13 - Std'11 - Sociology - Introducing SociologyDocumento104 páginasTxt.13 - Std'11 - Sociology - Introducing SociologyKavish Bhardwaj100% (1)

- Barrons 333 High Freq Words With Meanings PDFDocumento8 páginasBarrons 333 High Freq Words With Meanings PDFahmedhussien1Ainda não há avaliações

- Supply Chain Analysis Into The Construction Industry Report For The Construction Industrial StrategyDocumento127 páginasSupply Chain Analysis Into The Construction Industry Report For The Construction Industrial StrategyWaqas Ashraf KhanAinda não há avaliações

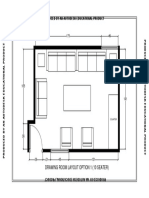

- Produced by An Autodesk Educational Product: Drawing Room Layout Option 1 (10 Seater)Documento1 páginaProduced by An Autodesk Educational Product: Drawing Room Layout Option 1 (10 Seater)Sumit DhallAinda não há avaliações

- 123Documento24 páginas123Sumit DhallAinda não há avaliações

- Construction SCMDocumento40 páginasConstruction SCMcsrajmohan2924Ainda não há avaliações

- 123Documento24 páginas123Sumit DhallAinda não há avaliações

- Duct AssemDocumento1 páginaDuct AssemSumit DhallAinda não há avaliações

- N P T E L (Nptel) : Ational Rogramme On Echnology Nhanced EarningDocumento67 páginasN P T E L (Nptel) : Ational Rogramme On Echnology Nhanced EarningKarthik V KalyaniAinda não há avaliações

- G107 G46 Admit CardDocumento1 páginaG107 G46 Admit CardSumit DhallAinda não há avaliações

- 2013 - 14 Class Schedule Weekend Batches: Electronics Engineering Weekend - NW (Noida)Documento2 páginas2013 - 14 Class Schedule Weekend Batches: Electronics Engineering Weekend - NW (Noida)Sumit DhallAinda não há avaliações

- Through GATE Way: Recruitment of Management Trainees (Tech) - 2014Documento1 páginaThrough GATE Way: Recruitment of Management Trainees (Tech) - 2014sujendra38Ainda não há avaliações

- SmartPlant 3D IntergraphDocumento2 páginasSmartPlant 3D IntergraphSumit DhallAinda não há avaliações

- Duct AssemDocumento1 páginaDuct AssemSumit DhallAinda não há avaliações

- GATE ME Solved Question Paper 2006Documento10 páginasGATE ME Solved Question Paper 2006Sumit DhallAinda não há avaliações

- HD 70 CDocumento101 páginasHD 70 CPhamVanGiangAinda não há avaliações

- Installation Guide VAMP 221-MCSet - V4Documento16 páginasInstallation Guide VAMP 221-MCSet - V4cokicisneAinda não há avaliações

- Three Way Conference Template 2019Documento4 páginasThree Way Conference Template 2019api-313701922Ainda não há avaliações

- DI CaseletesDocumento9 páginasDI Caseletessprem4353Ainda não há avaliações

- Third Periodic TestDocumento4 páginasThird Periodic TestCrizelda AmarentoAinda não há avaliações

- Ee 494 ADocumento43 páginasEe 494 AGopinath B L NaiduAinda não há avaliações

- Acessórios Cloro Gás - VaccupermDocumento28 páginasAcessórios Cloro Gás - Vaccupermbalzac1910% (1)

- 638 - Servoregler Technical - ManualDocumento123 páginas638 - Servoregler Technical - ManualemfiAinda não há avaliações

- Hook Height With Drawwork SensorDocumento3 páginasHook Height With Drawwork SensorJose PalumboAinda não há avaliações

- PugalenthiDocumento7 páginasPugalenthiTHANI ORUVANAinda não há avaliações

- Ch02HullOFOD9thEdition - EditedDocumento31 páginasCh02HullOFOD9thEdition - EditedHarshvardhan MohataAinda não há avaliações

- MS Excel FunctionsDocumento3 páginasMS Excel FunctionsRocket4Ainda não há avaliações

- Research MethodsDocumento10 páginasResearch MethodsAhimbisibwe BenyaAinda não há avaliações

- Base Tree PropertyDocumento17 páginasBase Tree PropertyMario Jardon SantosAinda não há avaliações

- NewDocumento3 páginasNewShreyanshu KodilkarAinda não há avaliações

- Apm 2014Documento9 páginasApm 2014bubushtarAinda não há avaliações

- Important QuestionsDocumento8 páginasImportant QuestionsdineshbabuAinda não há avaliações

- Janitza-Main catalogue-2015-ENDocumento418 páginasJanitza-Main catalogue-2015-ENOchoa Para La BandaAinda não há avaliações

- DWL-3200AP B1 Manual v2.40 PDFDocumento83 páginasDWL-3200AP B1 Manual v2.40 PDFFrank Erick Soto HuillcaAinda não há avaliações

- Electrical BEE Latest 2022 2023 Quantum Series (Searchable)Documento116 páginasElectrical BEE Latest 2022 2023 Quantum Series (Searchable)ritamlyrisAinda não há avaliações

- Pengaruh Customer Experience Terhadap Kepuasan Pelanggan Dan Loyalitas Pelanggan Survei Pada Pelanggan KFC Kawi MalangDocumento6 páginasPengaruh Customer Experience Terhadap Kepuasan Pelanggan Dan Loyalitas Pelanggan Survei Pada Pelanggan KFC Kawi MalangSatria WijayaAinda não há avaliações

- Worksheet 7-g6 MATHSDocumento2 páginasWorksheet 7-g6 MATHSAhmedAR or main emailAinda não há avaliações

- Enerpac SQD-Series ManualDocumento16 páginasEnerpac SQD-Series ManualTitanplyAinda não há avaliações

- Design of Adaptive Headlights For AutomobilesDocumento5 páginasDesign of Adaptive Headlights For AutomobilesEditor IJRITCCAinda não há avaliações