Escolar Documentos

Profissional Documentos

Cultura Documentos

Carrier Cold Room Calculaton PDF

Enviado por

Mohammad AmerTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Carrier Cold Room Calculaton PDF

Enviado por

Mohammad AmerDireitos autorais:

Formatos disponíveis

REFRIGERATION SELECTION GUIDE

For Condensing Units & Unit Coolers

Todays Solution To Your Total Range Of Refrigeration Needs.

Carrier Corporation 10/91, Rev A 06/03

www.totaline.com

Literature Number: 570-545

REFRIGERATION SELECTION GUIDE

Table of Contents

Introduction: Using The Totaline Refrigeration Condensing Unit Selection Guide .............................................................. 3 Section One: Performing A Job Survey and Determining Refrigeration Load Job Survey ...............................................................................4 Site Conditions .........................................................................4 Refrigeration Load Calculations ............................................... 4 Refrigeration Load Segments ...................................................4 Transmission (Wall Load) .........................................................4 Air Change or Ventilation Load ................................................ 4 The Product Load .................................................................... 5 Other Considerations Specific Heat Latent Heat Heat of Respiration Product Load Formulae Miscellaneous Loads ............................................................... 5 Safety Factor and Other Considerations .................................. 6 Total Load ................................................................................ 6 Load Calculation Forms 8 For rooms below 32F (sample) ....................................... 8 For rooms below 32F (blank) .......................................... 9 For rooms above 32F (blank) ........................................ 10 For rooms above 32F (sample) ......................................11 Section Two: Equipment Selection Considerations Evaporator Coil Selection - System Temperature Difference and Relative Humidity ........................................... 12 Run Time and Defrost Operations ..........................................12 Electric Defrost Hot Gas Defrost Water Defrost General Defrost Considerations Compressor / Condensing Unit Selection .............................. 13 Evaporator Selection ...................................................... 13 - 15 Gravity Fin Coils Gravity Booster Unit Coolers (low air units) Space Coolers Unit Coolers Product Coolers Evaporator Layout ................................................................. 15 Selecting Thermal Expansion Valves ..................................... 15 Selecting A Heat Exchanger ................................................... 15 Section Three: Tables Table 1 - U Values of Various Insulations .......................... 16 Table 2 - Transmission Heat Gain Factors ............................. 16 Table 3 - Average Air Changes Per 24 Hours For Storage Rooms ................................................ 17 Table 4 - Heat Removed In Cooling Air To Storage Room Conditions ...................................... 18 Table 5 - Storage Requirements and Properties of Perishable Products ................................... 19 - 23 Table 6 - Approximate Heat of Respiration Rates at Temperature Indicated ........................................... 24 Table 7 - Heat Equivalent of Electric Motors ......................... 25 Table 8 - Heat Equivalent of Occupancy ............................... 25 Table 9 - Summer Outdoor Design Data ........................25 - 26 Table 10 - Operating Conditions for Fur Storage .....................27 Table 11 - Insulation Requirements for Storage Rooms ......... 27 Table 12 - Suggested Freezer Temperatures F ........................27

REFRIGERATION SELECTION GUIDE

Introduction: Using The Totaline Refrigeration Selection Guide

The Totaline Refrigeration Selection Guide presents data and examples to assist the installing contractor or engineer when preparing actual refrigeration load estimates and selecting refrigeration equipment. Section One of this publication provides a detailed explanation of the factors that determine a refrigeration load. This will be of significant assistance when completing the easy-to-use Load Calculation Forms included in this section. In addition to a perforated blank form for refrigeration applications below and above 32, examples of completed load estimates are presented. Blank forms are also available in pads from your Totaline representative. Once the refrigeration load is determined, proper equipment must be selected. Section Two is a guide to selecting the most appropriate equipment to the particular application. Section Three contains handy refrigeration reference tables that will be most helpful in pinpointing specific needs. Many of the tables in Section Three are referenced in the first two sections and the remainder are included for additional reference. This manual is offered as a general tool for industry use and for anyone designing systems. Certain tabular data has been duplicated in full or part from ASHRAE Handbooks. All other data has been compiled by the Replacement Components Division of Carrier Corporation, Syracuse, NY. Installers, engineers or others using this manual should exercise judgement when specifying refrigeration equipment for specific applications. The Replacement Components Division is not responsible for any use made of this text. Thank you for considering Totaline refrigeration condensing units. Totaline products are engineered and manufactured with the utmost in quality control. The Replacement Components Division of Carrier Corporation is ready to support all your needs with our full range of Totaline Service Parts.

REFRIGERATION SELECTION GUIDE

Section One: Performing A Job Survey & Determining Refrigeration Load

When reading this section refer to Load Calculation Forms starting on page 8. Internal Load - heat produced by internal sources such as lights, electric motors, and people working in the space.

Job Survey

Site Conditions

The calculation of the transmission, product, internal and air change load segments will be discussed in detail. Before the load can be estimated, however, a comprehensive analysis of site conditions must be made to assure an accurate evaluation of the total refrigeration load. This job survey should determine all pertinent job site information including: Design ambient temperatures (see Table 9) Storage area temperature and humidity requirements Storage area dimensions and type of construction, insulation, exposure, etc. Type and amount of stored product Electrical service requirements Any miscellaneous loads including people, lights, appliances, etc. Based on this data, the total heat load of the refrigerated space can be calculated by adding the totals of the four load segments: transmission, product, internal and air change. It is common practice, and recommended, to add a 10% safety factor to the calculated refrigeration load.

Transmission (Wall Load)

The wall or transmission load is the load caused by the refrigerated space being located adjacent to a space at a higher temperature. Heat always travels from the warmer to the cooler atmosphere. The sensible heat gain through walls, floors and ceilings will vary with the following factors: Type and thickness of the insulation Type of construction Outside wall area in square feet Temperature difference between the refrigerated space and the outside ambient, adjusted to allow for solar heat load on any surface exposed to the sun. The following explains the formulae used to calculate the transmission load. Thermal Resistance, R, is defined as the total resistance of a material to heat flow, expressed in (F TD) (sq ft)/Btuh. (TD is temperature difference which is explained in Section Two, page 12.) Coefficient of Heat Transfer, U, is defined as the overall rate of heat transfer through a material, expressed in Btu/(hr) (sq ft) (F TD). The overall heat transfer factors based on the actual wall construction can be calculated by the formula: Q = A x U x TD, where Q = heat load, Btuh A = sq ft area of the wall, roof, etc U = the "U" factor for the wall expressed in F between the inside and outside wall surface. The tabulated heat gain factors, Tables 1 and 2, at intervals of overall temperature differences, can be used to simplify calculations. These factors are expressed in Btu/sq ft/24 hours. Other Considerations For small walk-in coolers and freezers, where there are no unusual requirements, the wall load may be taken as the total outside surface multiplied by the appropriate wall heat gain factor based on the ambient air temperature difference. Latent heat gain due to moisture transmission through walls, floors, and ceilings of modern construction refrigerated facilities is negligible and can be ignored.

Refrigeration Load Calculations Refrigeration Load Segments

The primary function of refrigeration is to maintain conditions of temperature and humidity that are required by a product or process within a given space. To perform this function, equipment of the proper capacity must be installed and controlled on a 24-hour basis. The equipment capacity is determined by the actual instantaneous peak load requirements. Generally, it is impossible to measure the actual peak load within a refrigerated space. These loads must be estimated. The total refrigeration load is the total of the following load segments: Transmission Load - heat gain through walls, floors and ceilings. Air Change Load - heat gain associated with air entering the refrigerated space, either by infiltration or ventilation. Product Load - heat removed from and produced by products brought into and stored in the refrigerated space.

REFRIGERATION SELECTION GUIDE

Air Change or Ventilation Load

Each time a door is opened to a refrigerated room from an adjacent unrefrigerated space, some outside air will enter the room. This untreated warm moist air will impose an additional refrigeration load and must be taken into account in the heat load calculation. Usually, the infiltration air's moisture content is more than that of the refrigerated space. As this air is cooled to the space temperature, the moisture will condense out of the air. This imposes both a sensible and latent heat load in the space which must be removed by the refrigeration equipment. Infiltration air quantities are difficult to determine accurately. Usually, a number of air changes per day are estimated. Table 3 indicates the number of air changes that may be expected in a given size of room over a 24-hour period. The data contained in this table have been determined by experience and may be used with confidence. Please note that the air change factors vary for rooms above and below 32F. For rooms below 0F, some further reduction of the air changes may be considered. There is usually less traffic involved in a 0F room, with less air movement resulting. Having determined the number of air changes to be expected, the room volume is then multiplied by the number of air changes. To obtain the infiltration load, a factor is then obtained from Table 4 and is applied to the total volume of air. The Btu/cubic foot factors in Table 4 are based on the dry bulb temperature and the relative humidity of the infiltration air. Infiltration Air Formula: Infiltration Btu/hr = Room Volume, Cubic Feet x Air Change Factor (Table 3) Latent Heat When the product is cooled to a temperature of 32F or lower, the latent heat load is also a part of the product load. This process is called the latent heat of fusion. The latent heat load is the quantity of heat involved in changing the state of a substance without changing its temperature.

For example, 144 Btus must be removed to freeze a pound of water. In the process, the pound of water at 32F becomes a pound of ice at 32F.

This calculation is applied to all products that must be frozen. The latent heat of fusion of any product is that of water - 144 Btu/lbmultiplied by the percentage of water content of the product. Actual corrected latent heat figures for various products are shown in Table 5. Heat of Respiration Certain food products experience chemical changes after storage. This is true of most fruits and vegetables, and some dairy products. This chemical change results in heat production which must be considered in the load calculation. The heat of respiration occurs at temperatures over 32F and varies depending on the product and the storage temperature. Table 6 indicates the heat of respiration for various products at common storage temperatures. Please note that this heat load increases considerably at higher temperatures. Product Load Formulae Sensible load (Btu/24 Hours) = Specific heat of products (Table 5) x temperature reduction of products F x lbs of product Latent heat of fusion (Btu/24 Hours) = Latent heat of product (Table 5) x lbs of product Heat of respiration (Btu/lbs/24 Hours) = Heat of respiration of product (Table 6) x lbs of product

The Product Load

The heat gain caused by the product must be considered in the total refrigeration load calculation. The product heat gain will include some or all of the following: 1.The load due to the product being placed in the refrigerated space at a higher temperature than the design refrigerated space. 2.The heat removed by freezing or chilling the product. 3.The heat of respiration caused by chemical reactions occurring in the product. Specific Heat A product cooling from its initial temperature requires the removal of sensible heat. Sensible heat is heat that can be detected and recorded on a dry bulb thermometer. The sensible heat to be removed is known as the specific heat which is the amount of heat in Btus that must be removed to reduce the temperature of the product 1F. The specific heat will vary with the type of product and is different above and below 32F. Specific heat figures are listed in Table 5 for various product types.

REFRIGERATION SELECTION GUIDE

Miscellaneous Loads

All electrical energy used by lights, motors, heaters, etc., located in the refrigerated area, must be included in the heat load. To calculate these loads: Lights = Total lighting wattage x hours in use x 3.41 Btu/Watt for incandescent or 4.2 for fluorescent lights. Coolers and freezers = 1 to 1-1/2 Watts per square foot of floor area. Allow up to double this amount for work areas

Total Load

To arrive at the total Btu/24 hr load, total all four main sources of heat gain and add a 10% safety factor as recommended. For system running times and defrost information, see Section Two - Equipment Selection Considerations, page 12. If further assistance is required, please contact your Totaline distributor.

Motors - The heat input from motors vary with the motor size, BHP output, efficiency and whether it is located within, or outside of, the refrigerated space. The heat equivalent of one BHP is 2545 Btu/hr. Motor efficiencies vary from 40% and less for small fan motors to 80% or more for integral horsepower motors. The motor output will be its BHP x 2545 Btu/hr x hours of operation. If the motor is located inside the refrigerated area, divide its output by its efficiency. If the motor is located outside the refrigerated area, its inefficiency will be dissipated outside, then only its output will figure in the room load. If the motor is located in the room and the load is outside, only the inefficiency will be added to the room load. Multiply the output by (1 - efficiency). For motors rated in Watts output, divide by 746 to obtain the heat equivalent horsepower rating. See Table 7, Heat Equivalent of Electric Motors. Occupancy Load - People working in a refrigerated storage area dissipate heat at a rate determined by the room temperature. The heat load added to the room equals the number of people, the hours of occupancy and heat equivalent per person. Multiple occupancies of short duration will carry additional heat into the room. See Table 8, Heat Equivalent of Occupancy.

Safety Factor and Other Considerations

A minimum 10% safety factor is normally added to the total refrigeration load to allow for minor omissions and inaccuracies, but do not assume this is adequate to take care of the evaporator fan load. (Additional safety or reserve capacity may be available from the compressor running time and average loading.) The Total Load with safety factor does not include the evaporator fan or defrost loads, which must be evaluated and added to the basic load to arrive at the total load for the final selection of the refrigerating equipment. Tables and data required for calculating loads are tabulated for quick reference.

REFRIGERATION SELECTION GUIDE

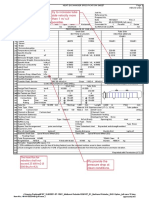

LOAD CALCULATION FORMS

LOAD CALCULATION FORM

Customer Address

For Rooms Below 32F

EXAMPLE #1 S.C.

Date

FREDS FROZEN FISH Job 34 CHARLES ST., PORTLAND, MAINE Estimator

3/30/01

SITE CONDITIONS

1. Describe the application FREEZER - FRESH FISH 20 x (l) 30 2. What are the outside room dimensions (ft.)?(w) x (h) 10 FIBERGLASS 6 3. Describe the insulation Type Thickness inches 6 4. What is the overall wall thickness? inches ROOM 75 5. What is the outside or surrounding air temperature? (Table 9) F -10 6. What is the storage room temperature? F 85 7. What is the temperature reduction? (subtract line 6 from line 5) F 500 8. What is the electrical load watts including lights and motors? watts 0 9. How many people occupy this space? 2000 LBS / DAY 10. What is the total product weight? HADDOCK ARRIVING AT 50F, 11. Product load information:

FACILITY LAYOUT

(Note: Detail all relevant construction features)

LOAD CALCULATION

NO OUTSIDE WALLS

A. Transmission (Wall) Load a. Exterior wall surface 20 30 600 (w)__________ x (l) ___________ = __________ 30 10 300 (l) __________ x (h) __________ = __________ 20 10 200 (w) _________ x (h) __________ = __________ 1100 2200 __________ x 2 = __________ sq ft 142.8 (INTERPOLAYTION) b. Table 2 Btu load/sq ft/24 hours = __________________________ 314,160 2200 142.8 a. ______________________ x b. ______________________ = _______________________ Btu / 24 hours B. Air Change (Infiltration Load) 29 19 9 4959 a. Interior room volume _______ x ______ x _______ = ________ cu ft

(inside room dimensions)

5.6 b. Table 3 air changes per 24 hours = ____________ 2.4 c. Table 4 Btu/cu ft = ____________ 4959 5.6 2.4 a. _____________ x b. _____________ x c. ______________ C. Product Load 1. Product temperature reduction load above freezing 2000 a. Total product weight = _____________ Ibs 18 b. Product temperature reduction to freezing = _______________ F 0.85 c. Table 5 specific heat above freezing = _______________ 2000 18 0.85 a. _____________ x b. _____________ x c. ______________ 2. Latent Heat of Fusion Load 2000 a. Total product weight = _____________Ibs 117 b. Table 5 latent heat of fusion = _____________Btu/lb 2000 117 a. ______________________ x b. ______________________ 3. Product temperature reduction load below freezing 2000 a. Total product weight = __________ Ibs 42 b. Product temperature below freezing = ______________ F 0.44 c. Table 5 specific heat below freezing = ______________ 2000 42 0.44 a. _____________ x b. _____________ x c. ______________ D. Miscellaneous Load 500 a. Electrical load (Watts) __________ x 3.42 x 24 0 -----------b. Number of occupants __________ x (Table 8) __________ x 24 E. Total Load without safety factor (add right column) .............................. F. Safety Factor (add 10% of Btu load per 24 hours) ................................. G. Total Load with safety factor (Add E and F) ........................................... REFRIGERATION Total Btu Per 24 Hours = 795,750 20 LOAD: Compressor Running Time (See page 12) 8

Prepared by

66,649 _______________________ Btu / 24 hours

30,600 _______________________ Btu / 24 hours

234,000 _______________________ Btu / 24 hours

= = = = = =

=

36,960 _______________________ Btu / 24 hours 41,040 _______________________ Btu / 24 hours 0 _______________________ Btu / 24 hours 723,409 _______________________ Btu / 24 hours 72,341 _______________________ Btu / 24 hours 795,750 _______________________ Btu / 24 hours 39,788 BTU / HR LOAD

Date

Load calculation pads are available from your Carrier representative (Literature Number 570-825)

LOAD CALCULATION FORM

Customer Address Job Estimator Date

For Rooms Below 32F

FACILITY LAYOUT

(Note: Detail all relevant construction features)

SITE CONDITIONS

1. Describe the application 2. What are the outside room dimensions (ft.)?(w) x (l) 3. Describe the insulation Type Thickness 4. What is the overall wall thickness? 5. What is the outside or surrounding air temperature? (Table 9) 6. What is the storage room temperature? 7. What is the temperature reduction? (subtract line 6 from line 5) 8. What is the electrical load watts including lights and motors? 9. How many people occupy this space? 10. What is the total product weight? 11. Product load information: x (h) inches inches F F F watts

LOAD CALCULATION

A. Transmission (Wall) Load a. Exterior wall surface (w)__________ x (l) ___________ = __________ (l) __________ x (h) __________ = __________ (w) _________ x (h) __________ = __________ __________ x 2 = __________ sq ft b. Table 2 Btu load/sq ft/24 hours = __________________________ a. ______________________ x b. ______________________ = _______________________ Btu / 24 hours B. Air Change (Infiltration Load) a. Interior room volume _______ x ______ x _______ = ________ cu ft

(inside room dimensions)

b. Table 3 air changes per 24 hours = ____________ c. Table 4 Btu/cu ft = ____________ a. _____________ x b. _____________ x c. ______________ C. Product Load 1. Product temperature reduction load above freezing a. Total product weight = _____________ Ibs b. Product temperature reduction to freezing = ______________ F c. Table 5 specific heat above freezing = ____________ a. _____________ x b. _____________ x c. ______________ 2. Latent Heat of Fusion Load a. Total product weight = _____________Ibs b. Table 5 latent heat of fusion = _____________Btu/lb a. ______________________ x b. ______________________ 3. Product temperature reduction load below freezing a. Total product weight = __________ Ibs b. Product temperature below freezing = ______________ F c. Table 5 specific heat below freezing = ______________ a. _____________ x b. _____________ x c. ______________ D. Miscellaneous Load a. Electrical load (Watts) __________ x 3.42 x 24 b. Number of occupants __________ x (Table 8) __________ x 24 E. Total Load without safety factor (add right column) .............................. F. Safety Factor (add 10% of Btu load per 24 hours) ................................. G. Total Load with safety factor (Add E and F) ........................................... REFRIGERATION Total Btu Per 24 Hours = LOAD: Compressor Running Time (See page 12) Prepared by

_______________________ Btu / 24 hours

_______________________ Btu / 24 hours

_______________________ Btu / 24 hours

= = = = = =

=

_______________________ Btu / 24 hours _______________________ Btu / 24 hours _______________________ Btu / 24 hours _______________________ Btu / 24 hours _______________________ Btu / 24 hours _______________________ Btu / 24 hours BTU / HR LOAD

Date

Load calculation pads are available from your Carrier representative (Literature Number 570-825)

LOAD CALCULATION FORM

Customer Address Job Estimator Date

For Rooms Above 32F

FACILITY LAYOUT

(Note: Detail all relevant construction features)

SITE CONDITIONS

1. Describe the application 2. What are the outside room dimensions (ft.)?(w) x (l) 3. Describe the insulation Type Thickness 4. What is the overall wall thickness? 5. What is the outside or surrounding air temperature? (Table 9) 6. What is the storage room temperature? 7. What is the temperature reduction? (subtract line 6 from line 5) 8. What is the electrical load watts including lights and motors? 9. How many people occupy this space? 10. What is the total product weight? 11. Product load information: x (h) inches inches F F F watts

LOAD CALCULATION

A. Transmission (Wall) Load a. Exterior wall surface (w)__________ x (l) ___________ = __________ (l) __________ x (h) __________ = __________ (w) _________ x (h) __________ = __________ __________ x 2 = __________ sq ft b. Table 2 Btu load/sq ft/24 hours = __________________________ a. ______________________ x b. ______________________ = _______________________ Btu / 24 hours B. Air Change (Infiltration Load) a. Interior room volume _______ x ______ x _______ = ________ cu ft

(inside room dimensions)

b. Table 3 air changes per 24 hours = ____________ c. Table 4 Btu/cu ft = ____________ a. _____________ x b. _____________ x c. ______________ C. Product Load 1. Product temperature reduction load a. Total product weight = _____________ Ibs b. Product temperature reduction to freezing = ______________ F c. Table 5 specific heat above freezing = ____________ a. _____________ x b. _____________ x c. ______________ 2. Respiration Heat Load a. Total product weight = _____________Ibs b. Table 6 respiration heat/lb = _____________Btu/lb a. ______________________ x b. ______________________ D. Miscellaneous Load a. Electrical load (Watts) __________ x 3.42 x 24 b. Number of occupants __________ x (Table 8) __________ x 24 E. Total Load without safety factor (add right column) .............................. F. Safety Factor (add 10% of Btu load per 24 hours) ................................. G. Total Load with safety factor (Add E and F) ...........................................

_______________________ Btu / 24 hours

_______________________ Btu / 24 hours

= = = = = =

=

_______________________ Btu / 24 hours _______________________ Btu / 24 hours _______________________ Btu / 24 hours _______________________ Btu / 24 hours _______________________ Btu / 24 hours _______________________ Btu / 24 hours BTU / HR LOAD

REFRIGERATION Total Btu Per 24 Hours = LOAD: Compressor Running Time (See page 12)

Prepared by

Date

Load calculation pads are available from your Carrier representative (Literature Number 570-878)

10

LOAD CALCULATION FORM

Customer Address

For Rooms Above 32F

EXAMPLE #2 L.S.

Date

JOHN E. APPLESEED 12 CIDER ST., PITTSBURGH, PA

Job Estimator

3/31/01

SITE CONDITIONS

1. Describe the application WALK-IN COOLER (APPLES) 20 x (l) 30 2. What are the outside room dimensions (ft.)?(w) x (h) 10 4 3. Describe the insulation Type POLYURETHANE Thickness inches 6 4. What is the overall wall thickness? inches 90 5. What is the outside or surrounding air temperature? (Table 9) F 35 6. What is the storage room temperature? F 55 7. What is the temperature reduction? (subtract line 6 from line 5) F 8. What is the electrical load watts including lights and motors?1000 (10HR/DAY) watts 2 9. How many people occupy this space? 7000 LBS 10. What is the total product weight? 11. Product load information: FRESH APPLES ARRIVING AT 70F

FACILITY LAYOUT

(Note: Detail all relevant construction features)

LOAD CALCULATION

FROM ORCHARD

A. Transmission (Wall) Load a. Exterior wall surface 20 30 600 (w)__________ x (l) ___________ = __________ 30 10 300 (l) __________ x (h) __________ = __________ 20 10 200 (w) _________ x (h) __________ = __________ 1100 2200 __________ x 2 = __________ sq ft 52.8 (INTERPOLAYTION) b. Table 2 Btu load/sq ft/24 hours = __________________________ 116,160 2200 52.8 a. ______________________ x b. ______________________ = _______________________ Btu / 24 hours B. Air Change (Infiltration Load) 29 19 9 4959 a. Interior room volume _______ x ______ x _______ = ________ cu ft

(inside room dimensions)

7.2 b. Table 3 air changes per 24 hours = ____________ 1.78 c. Table 4 Btu/cu ft = ____________ 4959 7.2 1.78 a. _____________ x b. _____________ x c. ______________ C. Product Load 1. Product temperature reduction load 7000 a. Total product weight = _____________ Ibs 35 b. Product temperature reduction to freezing = _______________ F 0.87 c. Table 5 specific heat above freezing = _______________ 7000 35 0.87 a. _____________ x b. _____________ x c. ______________ 2. Respiration Heat Load 7000 a. Total product weight = _____________Ibs 0.45 b. Table 6 respiration heat/lb = _____________Btu/lb 7000 0.45 a. ______________________ x b. ______________________ D. Miscellaneous Load 10 1000 a. Electrical load (Watts) __________ x 3.42 x 24 X 24 2 895 b. Number of occupants __________ x (Table 8) __________ x 24 E. Total Load without safety factor (add right column) .............................. F. Safety Factor (add 10% of Btu load per 24 hours) ................................. G. Total Load with safety factor (Add E and F) ...........................................

63,555 _______________________ Btu / 24 hours

213,150 _______________________ Btu / 24 hours

= = = = = =

3150 _______________________ Btu / 24 hours 34,200 _______________________ Btu / 24 hours 42,960 _______________________ Btu / 24 hours 473,175 _______________________ Btu / 24 hours 47,318 _______________________ Btu / 24 hours 520,493 _______________________ Btu / 24 hours

REFRIGERATION Total Btu Per 24 Hours = 520,493 = 16 LOAD: Compressor Running Time (See page 12)

32,530

BTU / HR LOAD

Prepared by

Date

Load calculation pads are available from your Carrier representative (Literature Number 570-878)

11

REFRIGERATION SELECTION GUIDE

Section Two: Equipment Selection Considerations

Now that the refrigeration load for a particular job site is calculated, it is time to select the most suitable equipment for the application. Section Two offers information that will help make equipment selection decisions. This information, used together with product data and specifications from manufacturers' literature, will result in an informed selection decision. For suction temperatures below 30F and rooms below 35F, electric defrost, hot gas defrost or water defrost is required. With these positive methods of defrost, equipment selection can be based on longer compressor operation, with 18 to 20 hours most common. However, this depends on the type of equipment used and the latent load in the storage. A modern unit cooler or product cooler in a tight room with average latent load, can be selected on 20 hour operation. The type of defrost used is generally a matter of either contractor or owner preference. Different geographic regions tend to use one particular type of defrost more frequently. As a rule, electric defrost is more common than hot gas, and hot gas more common than water defrost. Electric Defrost Electric defrost is the most common method in use today. Equipment cost is about the same as with hot gas but installed cost can be lower. Operating cost is about 15% higher with electric defrost than with hot gas and a fair amount of heat and moisture is released in the room during defrost. Hot Gas Defrost Hot gas defrost is still the most efficient method of defrosting regardless of storage temperature but, unfortunately, most contractors are reluctant to use it. Defrost is very quick with minimum room temperature rise. Hot gas defrost, however, requires care to ensure that the compressor is protected against liquid slugging. Water Defrost While not very common, water defrost can be used on both medium and low temperature storages. Water must be at least 50F and is sprayed on the coil at a rate of about 3 gpm/square foot of coil for five to 15 minutes, depending on severity of frosting. Water defrost is fast and efficient but some moisture is re-released into the room. These systems also require more maintenance than electric or hot gas systems. General Defrost Considerations Because of high suction pressure (and high load) after defrost, compressor selection must be checked to see that it can operate in a higher range than the actual design point. If not, a crankcase pressure regulator may be required to keep suction pressure down to acceptable values. If this is the case, an accumulator should also be used. This is very important for a blast freezer. On large air defrost systems (gravity coil, for example) it is a good idea to have solenoids in the liquid and suction lines so refrigerant will not migrate during defrost. In addition, large fin coil installations are often split into sections with a thermostat for each section to compensate for uneven room loading. It is also recommended that a pump down system be used for both off-cycle and all defrost periods.

Evaporator Coil Selection System Temperature Difference and Relative Humidity

When selecting an evaporator coil, the temperature difference, or TD, between the room and the saturated suction temperature dictates the relative humidity in the space (assuming the room is properly sealed). The closer the temperature difference between room and suction temperatures in selecting the evaporator, the larger the evaporator and the higher the relative humidity in the room. Conversely, a large system TD reduces the size of the evaporator and causes it to do more drying and therefore lowers the relative humidity. The following table can be used as a guide. Knowing the product relative humidity requirement, select the evaporator as follows:

Relative Humidity % (RH) TD (F)

Over 90 80-90 70-80 50-70

8 10 15 20

Too low relative humidity will result in excessive weight loss in the product as well as surface deterioration. Too high relative humidity speeds the growth of bacteria and surface slime. See Table 5 for recommended relative humidity values for different products. There is a slightly different problem associated with freezers. In order to avoid excessive frost accumulation on the coil, and to prevent product dehydration during long term storage, most evaporators are selected for 10F TD.

Run Time and Defrost Operations

When the design suction temperature is over 30F, a defrost cycle is not normally required, and it is common practice to select equipment on a 20- to 22-hour compressor operation. For suction temperatures below 30F and room temperatures over 35F, off-cycle (air defrost) can generally be used. This involves cycling the compressor off with a time clock while the evaporator fans remain in operation and room air melts the ice on the coil. For every two hours of compressor operation, one hour of air defrost time is needed. Therefore, compressor selection is based on 16 hours per day.

12

REFRIGERATION SELECTION GUIDE

Compressor/Condensing Unit Selection

The four main types of compressors used in commercial refrigeration today are: Open - belt driven (low speed, 500-1750 rpm) Open - direct driven (medium speed, 1160 or 1750 rpm) Semi-hermetic (1750 rpm) Hermetic (welded, 3500 rpm) The compressor type used is often a matter of personal preference but it is important to be aware that compressor life decreases with increased speed and increased condensing temperature. On commercial refrigeration applications, compressors are most commonly used with air-cooled condensers. They are also used with water-cooled condensers and occasionally with evaporative condensers. Water restrictions in recent years and simpler maintenance are the reasons for the popularity of air-cooled systems. The air-cooled condenser may be an integral part of the compressor unit (air-cooled condensing unit) or it may be remotely located (on the roof, for example). Compressor/condensing units are generally classified as high, medium or low temperature. Approximate evaporating temperatures are: High +30F to +50F Medium -10F to +30F Low 40F to -10F A choice of refrigerant, R-12, R-22 and R-502 is available, depending on the application. Knowing the room load, room temperature and desired suction temperature (room temperature - TD = suction temperature), a condensing unit can be selected. As the range of models (capacities) is far more limited in condensing units than in evaporators, it is common practice to select the closest condensing unit size that will do the job, then select the evaporators to balance with the condensing unit selected at the correct TD. When it is possible that the compressor may occasionally be the coldest spot in the system, crankcase heaters should be used. Unloading is seldom (if ever) used on commercial refrigeration systems. Refrigerant receivers are generally used and are sized to hold from 80% to the complete system operating charge. In any critical application, use two completely independent systems. In all cases, every room should be on a separate and independent system.

Evaporator Selection

The spacing of the fins on the evaporator coil must be considered for a particular application. While high fin density (12 fins/inch) gives increased coil capacity, it also increases the problem of dirt and frost collection. In the majority of commercial refrigeration applications, the fin spacings used are 8, 6 and 4 fins/inch. Generally, 8 fins/inch is used down to +32F coil temperature while spacings of 4 and 6 fins/inch are used whenever frost will be present. The closer the fins are together, the more rapidly the coil capacity will fall off as the frost builds up. On most low temperature applications, 6 fins/inch can be used as long as the evaporator capacity is reduced by 15% (x 0.85), when making the selection. This 15% frost reduction is a more accurate representation of the unit capacity averaged over the four to six hours between defrost cycles. For minimum downtime, base selection on a 4 fin/inch coil and its normal capacity reduced by 5% (x 0.95). In most cases, holding freezers are selected with 6 fin/inch coils while blast freezers use 4 fins/inch. Once the space and product loads have been established, select the evaporator type most suitable for the application. This selection will depend on: Storage temperature Relative humidity Air velocity Room size and shape Refer to Table 5 for recommended storage temperature and relative humidity. As most rooms handle more than one product, compromise may be necessary. Next, establish what form (if any) of defrost will be required. The following describes the various types of evaporators that are available and descriptive data on their use. Gravity Fin Coils Outlet velocity about 60 fpm Temperature range = 35F and above Capacity range @ 10FTD = 100-19,000 Btu/hr/unit Air flow range = 0

13

REFRIGERATION SELECTION GUIDE

Gravity fin coils are used in rooms requiring little or no air flow. They are commonly used in meat aging rooms as they produce the best meat surface texture and appearance. They are also used in beef sales coolers since they have no fans and operate silently. Although not very common in current designs, some packing houses and supermarkets still prefer this type of unit. These coils are installed between-the-rails in meat coolers, as well as in poultry storages, cut flower rooms, etc. Most gravity coils are used in high-humidity applications. Gravity Booster Unit Coolers (low air units) Outlet velocity less than 150 fpm Temperature range = 28F and above Capacity range @ 10F TD = 4500-27,000 Btu/hr/unit Air flow range = 200 fpm face velocity or 1200 cfm/ton Unit coolers are the most common type of evaporator in use today. Unit coolers are used at all temperatures, on all types of storages and are available with hot gas or electric defrost. These units handle larger quantities of air than gravity boosters and are able to throw the air 30 to 40 feet with a one foot drop. The most common application is the food store walk-in freezer or general purpose cooler. They are also used in blast freezers and some models are available with low pitch fans for use as gravity boosters. Unit coolers are generally considered the most economical evaporator on a first-cost basis and are adaptable to many applications. Product Coolers Temperature range = 40F and above Capacity range @ 10F TD = 26,000-385,000 Btu/hr/unit Air flow range = 600 fpm face velocity or 1600-2500 cfm/ton Unit Coolers Temperature range = 40F and above Capacity range @ 10F TD = 790-75,000 Btu/hr/unit Air flow range = 500-600 fpm face velocity or 1500-2000 cfm/ton

The application of gravity boosters are similar to gravity fin coil applications. Gravity boosters usually result in a lower first cost to the owner and are, therefore, gradually replacing the fin coil. They are also installed between-the-rails in meat rooms as well as meat cutting and packaging rooms, cut flower boxes, fruit and vegetable storages and ice storages. Gravity booster unit coolers are available with electric defrost for applications in the 28-34F and without defrost for rooms over 34F. The gravity booster has a power operated fan to provide a more positive air flow than the gravity coil. Space Coolers

Temperature range = 28F and above Capacity range @ 10F TD = 9600-46,000 Btu/hr/unit Air flow range = 200-500 fpm face velocity or 1200 cfm/ton

Applications for space coolers are very similar to gravity fin coils and gravity boosters but space coolers are much more versatile. Both air flow and outlet velocity are variable. Units are available with hot gas and electric defrost as well as for ammonia. Other applications include breweries, cheese factories and general storage rooms.

Product coolers are the largest and the most versatile evaporators and are generally found on larger jobs. They are available for all refrigerants and with all types of defrost systems, air quantity, coil rows, fin spacing and coil area. Some models are available as propeller fans (free blow) as well as the standard centrifugal fan version. They are commonly used with duct work and models are available for floor mounting as well as ceiling suspension. While more expensive in first cost than unit coolers, product coolers are often a necessity in larger storages and are commonly found in blast freezers. When using electric defrost, horizontal type product coolers must be used. Vertical type product coolers with electric defrost will result in stack effect. This causes extensive convection currents which adversely affect the defrost operation. After identifying the type of evaporator to use, the actual selection must be made to balance with the condensing unit selection. The condensing unit should be selected first because only a fixed number of condensing units sizes are available, while there is virtually an unlimited selection of evaporators.

14

REFRIGERATION SELECTION GUIDE

When selecting hot gas or electric defrost units, allow for coil frosting and for the capacity rating of the unit to be reduced accordingly. With electric defrost units, where the heaters are internally located in blank tubes, compared to a standard coil, the capacity must be reduced to allow for the loss of surface. Manufacturers usually recommend a rating correction factor for electric defrost coils. It is always good practice with any storage (and particularly with freezers) to have two completely independent systems. In the event of a breakdown of one system, the other unit will slow down the temperature rise in the room until the other system is repaired and placed back into service.

Selecting Thermal Expansion Valves

Selecting and installing thermal expansion valves are of utmost importance for the best coil performance. Valve capacity must be at least equal to the coil load rating but not oversized for the conditions. Any valve which is substantially oversized will tend to be erratic in operation and this will impair both coil performance and rated capacity output. Always install liquid line strainers ahead of all thermal expansion valves

Selecting A Heat Exchanger

Although sometimes controversial in high temperature applications, it is generally agreed that in medium and low temperature refrigeration systems, heat exchangers, when properly applied, contribute the following to overall system performance: 1. Sub-cooling the liquid refrigerant entering the thermal expansion valve reduces the flash gas load of the evaporator inlet. It also increases the enthalpy difference of the refrigerant during its evaporating phase which produces more useful work in the evaporator. 2. In the process of heat exchanger sub-cooling, the heat extracted from the liquid refrigerant is transferred to the suction gas, thereby insuring a dry suction return to the compressor at an entering superheat level. This produces the best possible volumetric efficiencies for the refrigerant used. 3. The increase in suction line temperature will also reduce the possibility of sweating. 4. The use of a heat exchanger permits more open adjustment of the thermal expansion valve without risk of serious flood-back of liquid to the compressor under light or variable load conditions. At the same time, this assures the maximum utilization of evaporator surface. In all low temperature applications, it is most important to correctly size and properly apply heat exchangers. Selections must be based on accurate performance ratings checked out against the calculated design loads involved for each evaporator or otherwise for the entire system. Care must also be taken to insure that both liquid and suction connections are properly sized in order to reduce entrance and exit losses to a minimum. Recommended allowable suction line pressure drops due to the heat exchanger vary from 0.50 psi maximum for +20F evaporator applications to 0.25 psi maximum for -40F evaporator temperatures.

Evaporator Layout

Evaporator layout is much more important than many designers realize. Follow these general, but important, rules: 1. Air pattern must cover the entire room. 2. Never locate evaporators over doors. 3. Know the location of aisles, racks etc. 4. Locate near compressors for minimum pipe runs. 5. Locate near condensate drains for minimum run. The size and shape of the storage generally dictates the type and location of the evaporators. The illustrations below show some typical examples.

15

REFRIGERATION SELECTION GUIDE

Section Three: Tables

Table 1 - "U" Values of Various Insulations

Material Thickness (Inches) "R" "U" Material Thickness (Inches) "R" "U"

Polystyrene Foam Styrofoam "SM" (Blue) Styrofoam Roofmate (Blue) Polyurethane Foam Board

Rigid Glass Fibre Styrofoam Beadboard (White)

1 2 3 4 5 6 8 1 2 3 4 5 6 8 1 1 2 3 4 5 6 8

5.0

6.25

4.0 3.57

0 20 0 10 0 07 0.05 0 04 0.035 0.025 0.16 0.08 0.055 0.04 0.032 0.027 0.02 0.25 0 28 0.14 0.09 0.07 0.055 0.045 0.035

Glass Fibre Batts

Cork

Sawdust Wood Blackjoe Concrete

1 2.5 3.5 6 1 2 3 4 5 6 8 9 10 1 6 1 0.5 1

3.0

3.3

1.68 1.2 1.0 0.1

0.33 0.15 0.1 0.07 0.3 0.18 0.1 0.075 0.07 0.06 0.04 0.02 0.01 0.60 0.1 0.85 0.8 10.00

Table 2 - Transmission Heat Gain Factors (Btu/24Hours/Sq. Foot of Outside Surface)

WALL INSULATION "U" FACTOR

(FROM TABLE 1, ABOVE)

DESIGN TEMP. DIFF. F*

.01 .02 .025 .030 .035 .040 .045 .050 .055 .060 .065 .070 .075 .080 .085 .090 .095 .10 .20 .30 .50 1.00

10 2.4 4.8 6.0 7.2 8.4 9.6 10.8 12.0 13.2 14.4 15.6 16.8 18.0 19.2 20.4 21.6 22.8 24.0 48.0 72.0 120.0 240.0

20 4.8 9.6 12.0 14.4 16.8 19.2 21.6 24.0 26.4 28.8 31.2 33.6 36.0 38.4 40.8 43.2 45.6 48.0 96.0 144.0 240.0 480.0

30 7.2 14.4 18.0 21.6 25.2 28.8 32.4 36.0 39.6 43.2 46.8 50.4 54.0 57.6 61.2 64.8 68.4 72.0 144.0 216.0 360.0 720.0

40 9.6 19.2 24.0 28.8 33.6 38.4 43.2 48.0 52.8 57.6 62.4 67.2 72.0 76.8 81.6 86.4 91.2 96.0 192.0 288.0 480.0 960.0

50 12.0 24.0 30.0 36.0 42.0 48.0 54.0 60.0 66.0 72.0 78.0 84.0 90.0 96.0 102.0 108.0 114.0 120.0 240.0 360.0 600.0 1200.0

60 14.4 28.8 36.0 43.2 50.4 57.6 64.8 72.0 79.2 86.4 93.6 100.8 108.0 115.2 122.4 129.6 136.8 144.0 288.0 432.0 720.0 1440.0

70 16.8 33.6 42.0 50.4 58.8 67.2 75.6 84.0 92.4 100.8 109.2 117.6 126.0 134.4 142.8 151.2 159.6 168.0 336.0 504.0 840.0 1680.0

80 19.2 38.4 48.0 57.6 67.2 76.4 86.4 96.0 105.6 115.2 124.8 134.4 144.0 153.6 163.2 172.8 182.4 192.0 384.0 576.0 960.0 1920.0

90 21.6 43.2 54.0 64.8 75.6 86.4 97.2 108.0 118.8 129.6 139.4 151.2 162.8 172.8 183.6 194.4 205.2 216.0 432.0 648.0 1080.0 2160.0

100 24.0 48.0 60.0 72.0 84.0 96.0 108.0 120.0 132.0 144.0 156.0 168.0 180.0 192.0 204.0 216.0 228.0 240.0 480.0 720.0 1200.0 2400.0

16

* For temperature differences greater than 100F, Btu/sq. ft. factor will be in direct proportion (e.g. for 120F use factor for 60F T.D. and multiply by 2).

REFRIGERATION SELECTION GUIDE

Table 3 - Average Air Changes Per 24 Hours

Storage Rooms Below 32F

Volume Cubic Feet Air Changes Per 24 Hrs. Volume Cubic Feet Air Changes Per 24 Hrs. Volume Cubic Feet

Storage Rooms Above 32F

Air Changes Per 24 Hrs. Volume Cubic Feet Air Changes Per 24 Hrs.

250 300 400 500 600 800 1,000 1,500 2,000 3,000 4,000 5,000

30.0 26.5 23.5 20.0 17.5 15.0 13.5 12.3 11.9 7.8 6.0 5.6

6,000 8,000 10,000 15,000 20,000 25,000 30,000 40,000 50,000 75,000 100,000

5.2 4.5 4.0 2.8 2.5 2.2 2.0 1.8 1.5 1.2 1.0

250 300 400 500 600 800 1,000 1,500 2,000 3,000 4,000 5,000 6,000

38.0 34.5 29.5 26.0 23.0 20.0 17.5 14.0 12.0 9.5 8.2 7.2 6.5

8,000 10,000 15,000 20,000 25,O00 3O,000 4O,000 5O,000 75,000 100,000

5.5 4.9 3.9 3.5 3.0 2.7 2.3 2.0 1.6 1.4

NOTE: For storage rooms with anterooms reduce values by 50%; for heavy usage rooms, increase values by 2. Compiled in part from ASHRAE Handbook of Fundamentals, 1989.

17

REFRIGERATION SELECTION GUIDE

Table 4 - Heat Removed in Cooling Air to Storage Room Conditions (Btu per cu. ft.)

Storage Room Temp F 30 25 20 15 10 5 0 -5 -10 -15 -20 -25 -30 Storage Room Temp F 65 60 55 50 45 40 35 30 50 .18 .27 .39 .59 .76 .93 1.08 70 0.21 0.37 0.52 0.66 0.80 0.92 1.04 1.15 1.26 1.37 1.47 1.57 1.67 In Rooms Below 32F Temperature of Outside Air F 40 80 0.26 0.43 0.58 0.72 0.85 0.97 1.09 1.20 1.31 1.42 1.52 1.62 1.72 70 0.55 0.71 0.86 1.00 1.13 1.25 1.36 1.47 1.58 1.69 1.79 1.89 1.99 50 70 Relative Humidity, Percent 80 50 0.62 1.09 0.78 1.19 0.93 1.39 1.07 1.50 1.20 1.63 1.32 1.74 1.43 1.80 1.55 1.92 1.65 2.05 1.76 2.15 1.86 2.25 1.96 2.35 2.06 2.44 In Rooms Above 32F Temperature of Outside Air F 85 90 Relative Humidity, Percent 60 50 0.52 0.58 0.78 0.83 1.00 1.05 1.21 1.26 1.40 1.45 1.57 1.62 1.74 1.78 2.01 2.05 90 60 1.21 1.36 1.51 1.63 1.75 1.87 1.98 2.05 2.18 2.28 2.38 2.47 2.56 50 2.05 2.20 2.33 2.46 2.58 2.69 2 80 2.90 3.00 3.10 3.19 3.29 3.38 60 2.31 2.46 2.60 2.72 2.84 2.95 3.06 3.16 3.26 3.36 3.46 3.55 3.64

70 60 .18 .27 .51 .72 .89 1.06 1.21 50 0.32 0.58 0.80 1.01 1.20 1.37 1.54 1.78

95 60 0.81 1.06 1.28 1.49 1.68 1.85 2.01 2.31 50 0.85 1.10 1.32 1.53 1.71 1.88 2.04 2.33 60 1.12 1.37 1.59 1.79 1.98 2.15 2.31 2.64

Compiled in part from ASHRAE Handbook of Fundamentals,1989.

18

REFRIGERATION SELECTION GUIDE

Table 5 - Requirements and Properties of Perishable Products

Storage Temperature, F Relative Humidity, % Approximate Water Storage Content. Life % Vegetables 2 weeks 5 months 2 - 3 weeks 7 - 10 days 3 - 5 days 6 - 8 months 4 - 6 months 10 - 14 days 10 - 14 days 3 - 5 weeks 5 - 6 months 4 - 6 weeks 5 - 9 months 2 - 4 weeks 3 - 4 months 1 - 2 months 10 - 14 days 4 - 8 days 10 - 14 days 7 - 10 days 2 - 3 weeks 6 - 12 months 6 - 7 months 10 - 14 days 10 - 12 months 3 - 4 weeks 2 - 4 weeks 1 - 3 months 2 - 3 weeks 3 - 4 days 7 - 10 days 3 - 4 weeks 1 - 8 months 1 - 2 months 4 - 6 months 1 - 3 weeks 6 - 8 months 6 months 2 - 3 weeks 5 - 8 months 4 - 7 months 2 - 3 months 3 - 4 weeks 2 - 4 months 2 - 4 weeks 4 - 6 months 2 - 4 months 10 - 12 months 10 - 14 days 84 80 93 89 67 11 88 31.3 90 85 92 88 88 92 88 94 87 74 96 93 93 61 93 75 87 90 85 95 91 90 89 88 85 79 74 12 12 92 81 78 69 91 95 95 95 89 79 7 - 15 93 Highest Freezing, F Specific Heat above 32F Btu/lb F Specific Heat below 32F Btu/lb F Latent Heat Btu/lb Commodity Artichokes Globe Jerusalem Asparagus Beans Snap or Green Lima Dried Beets Roots Bunch Broccoli Brussels Sprouts Cabbage, late Carrots Topped-immature Topped-mature Cauliflower Celeriac Celery Collards Corn, Sweet Cucumbers Eggplant Endive (Escarole) Frozen Vegetables Garlic, dry Greens, leafy Horseradish Kale Kohlrabi Leeks, green Lettuce, head Mushrooms Okra Onions Green Dry, & onion sets Parsley Parsnips Peas Green Dried Peppers Dried Sweet Potatoes Early Main crop Sweet Pumpkins Radishes Spring Winter Rhubarb Rutabagas Salsify Seed, vegetable Spinach

32 32 32 - 36 40 - 45 37 - 40 50 32 32 32 32 32 32 32 32 32 32 32 32 50 - 55 46 - 54 32 -10 - 0 32 32 30 - 32 32 32 32 32 - 34 32 45 - 55 32 32 32 32 32 50 32 - 50 45 - 50 50 - 55 38 - 50 55 - 61 50 - 55 32 32 32 32 32 32 - 50 32

95 - 100 90 - 95 95 - 100 95 95 70 95 - 100 95 95 - 100 95 - 100 98 - 100 98 - 100 98 - 100 95 95 - 100 98 - 100 95 95 - 98 95 90 - 95 95 - 100 65 - 70 95 - 100 95 - 100 95 95 95 95 - 100 95 90 - 95 95 - 100 65 - 75 95 - 100 98 - 100 95 70 60 - 70 90 - 95 90 90 - 95 85 - 90 50 - 75 95 95 - 100 95 98 - 100 98 - 100 50 - 65 95 - 98

29.9 27.5 30.9 30.7 30.0 0.32 30.4 30.9 30.6 30.4 29.5 29.5 30.6 30.4 31.1 30.6 30.9 31.1 30.6 31.9 30.6 31.5 28.7 31.1 30.2 30.7 31.7 30.4 28.7 30.4 30.6 30.0 30.4 30.9 0.30 0.30 30.7 30.9 30.9 29.7 30.6 30.7 30.7 30.3 30.0 30.0 31.5

0.87 0.83 0.94 0.91 0.73 0.23 0.90 0.92 0.88 0.94 0.90 0.90 0.93 0.91 0.95 0.90 0.79 0.97 0.94 0.94 0.69 0.94 0.78 0.89 0.92 0.88 0.96 0.93 0.92 0.91 0.90 0.88 0.84 0.79 0.24 0.24 0.94 0.85 0.82 0.76 0.92 0.95 0.95 0.95 0.91 0.83 0.29 0.94

0.45 0.44 0.48 0.47 0.40 0.46 0.47 0.46 0.47 0.46 0.46 0.47 0.46 0.48 0.46 0.42 0.49 0.48 0.48 0.40 0.48 0.42 0.46 0.47 0.46 0.48 0.47 0.46 0.47 0.46 0.45 0.44 0.42 17 0.47 0.44 0.43 0.41 0.47 0.48 0.48 0.48 0.47 0.44 0.23 0.48

120 114 133 127 94 126 130 122 132 126 126 132 126 135 125 106 137 133 133 89 133 104 125 129 122 136 130 129 127 126 122 112 106

132 116 111 99 130 134 134 134 127 113 16 133

19

REFRIGERATION SELECTION GUIDE

Table 5 - Requirements and Properties of Perishable Products (continued)

Storage Temperature, F 45 - 50 41 - 50 50 - 55 55 - 70 45 - 50 32 32 32 61 30 - 40 32 - 41 32 40 - 55 31 - 32 31 - 32 36 - 40 31 - 32 30 - 31 45 - 50 36 - 40 31 - 32 0 - 32 31 - 32 32 - 40 31 - 32 -10 - 0 31 - 32 50 - 60 31 - 32 31 41 - 50 45 - 50 32 - 50 48 - 50 55 31 - 32 41 - 50 32 - 48 45 31 - 32 32 - 41 29 - 31 45 - 50 30 45 31 - 32 41 31 - 32 32 - 41 Relative Humidity, % 70 - 75 95 50 - 75 90 - 95 90 - 95 95 95 95 85 - 90 90 - 95 55 - 60 90 - 95 85 - 90 85 - 95 90 - 95 90 - 95 95 90 - 95 90 - 95 85 - 95 90 - 95 90 - 95 75 or less 90 - 95 50 - 60 85 - 90 90 - 95 90 - 95 85 - 90 85 - 90 90 - 95 90 90 - 95 85 - 90 85 - 90 85 - 90 90 85 - 90 85 - 90 85 - 90 90 - 95 55 - 60 90 - 95 90 - 95 90 85 - 90 90 - 95 90 - 95 90 - 95 55 - 60 Approximate Water Storage Content. Life % Vegetables continued 5 - 8 weeks 5 - 14 days 4 - 6 months 1 - 3 weeks 4 - 7 days 30.6 94 85 93 94 Highest Freezing, F Specific Heat above 32F Btu/lb F Specific Heat below 32F Btu/lb F Latent Heat Btu/lb Commodity Squash Acorn Summer Winter Tomatoes Mature green Firm, ripe Turnips Roots Greens Watercress Yams Apples Apples, dried Apricots Avocados Bananas Blackberries Blueberries Cantaloupes Cherries Sour Sweet Casaba Melons Cranberries Currants Dates, cured Dewberries Figs Dried Fresh Frozen fruits Gooseberries Grapefruit Grapes American Vinifera Guavas Honeydew Melons Lemons Limes Mangoes Nectarines Olives, fresh Oranges Papayas Peaches Peaches, dried Pears Persian Melons Persimmons Pineapples, ripe Plums Pomegranates Prunes Fresh Dried

31.1 30.6 31.0 31.1 30.0 31.6 31.4 0.79 30.0 30.0 31.5 30.6 30.6 29.7 29.8 29.0 28.8 30.0 30.4 30.2 3.7 29.7 27.6 30.0 30.0 29.7 28.1 30.4 29.4 29.1 30.4 30.4 29.4 30.6 30.6 30.4 29.2 30.6 28.1 30.2 30.6 26.6 30.5

0.95 0.88 0.94 0.95 0.93 0.92 0.94 0.42 0.87 0.42 0.88 0.72 0.80 0.88 0.86 0.93 0.87 0.84 0.94 0.90 0.88 0.36 0.88 0.39 0.82 0.90 0.90 0.86 0.86 0.86 0.94 0.91 0.89 0.85 0.86 0.80 0.90 0.82 0.91 0.43 0.86 0.94 0.84 0.88 0.88 0.86 0.88 0.46

0.480.45 0.48 0.48 0.47 0.47 0.48 105 0.45 0.27 0.46 0.40 0.42 0.46 0.45 0.48 0.45 0.44 0.48 0.46 0.45 0.26 0.45 0.27 0A3 0.46 0.46 0.45 0.45 0.45 0.48 0.46 0.46 0.44 0.44 0.42 0.46 0.47 0.46 0.28 0.45 0.48 0.48 0.45 0.45 0.44 0.45 0.28

135 122 133 134 132 129 133

4 - 5 months 92 10 - 14 days 90 3 - 4 days 93 3 - 6 months 74 Fruits and Melons 3 - 8 months 84 5 - 8 months 24 1 - 2 weeks 85 2 - 4 weeks 65 75 3 days 85 2 weeks 82 5 - 15 days 92 3 - 7 days 2 - 3 weeks 4 - 6 weeks 2 - 4 months 10 - 14 days 6 - 12 months 3 days 9 - 12 months 7 - 10 days 6 - 12 months 2 - 4 weeks 6 - 10 weeks 2 - 8 weeks 3-6months 2 - 3 weeks 3 - 4 weeks 1 - 6 months 6 - 8 weeks 2 - 3 weeks 2 - 4 weeks 4 - 6 weeks 3 - 12 weeks 1 - 3 weeks 2 - 4 weeks 5 - 8 months 2 - 7 months 2 weeks 3 - 4 months 2 - 4 weeks 2 - 4 weeks 2 - 3 months 2 - 4 weeks 5 - 8 months 84 80 93 87 85 20 85 23 78 89 89 82 82 83 93 89 86 81 82 75 87 91 89 25 83 93 78 85 86 82 86 28

121 122 94 108 122 118 132 121 114 133 124 122 29 122 34 112 127 127 118 118 119 133 127 123 117 118 108 124 130 127 118 133 112 122 123 118 123

20

REFRIGERATION SELECTION GUIDE

Table 5 - Requirements and Properties of Perishable Products (continued)

Storage Temperature, F 31 - 32 31 - 32 31 - 32 31 - 32 40 50 - 60 31-34 32 - 34 31 - 34 32 - 36 32 - 36 32 - 34 34 - 41 31 - 34 32 - 36 -20 to -4 32-34 31 - 34 41-50 32 - 36 41-50 -20 to -4 32 - 34 32 - 39 32 - 34 32 - 34 32 - 34 50 - 59 32 32 - 34 - 10 - 0 32 - 34 32 - 34 32 - 34 32 - 34 32 - 34 - 10 - 0 32 - 34 37 - 41 50 - 59 - 10 - 0 37 - 41 61 - 64 Relative Humidity, % 90 90 - 95 90 - 95 90 - 95 90 - 95 90 95-100 95 - 100 95 - 100 80 - 90 80 - 90 95 - 100 95 - 100 95 - 100 95 - 100 90 - 95 95-100 95 - 100 In sea water 100 95-100 90 - 95 88 - 92 85 - 90 85 85 85 15 90 90 90 - 95 85 - 90 85 - 90 85 85 85 90 - 95 80 - 85 80 - 85 65 - 70 90 - 95 80 - 85 85 Approximate Water Storage Content. Life % Fruits & Melons continued 2 - 3 months 85 18 2 - 3 days 81 2 - 3 days 84 5 - 7 days 90 2 - 4 weeks 87 2 - 3 weeks 93 Seafood (Fish) 12 days 81 10 days 81 18 days 75 10 days 61 10 days 64 6 - 8 days 65 4 - 5 days 62 18 days 64 14 days 70 6 - 12 months Seafood (Shellfish) 12days 80 12 - 14 days 76 Indefinitely 79 5 - 8 days 87 5days 80 3 - 8 months Meat (Beef) 1 - 6 weeks 62 - 77 1 - 3 weeks 49 1 - 3 weeks 45 1 - 3 weeks 56 1 - 3 weeks 67 6 - 8 weeks 48 5 days 70 1 - 7 days 66 6 - 12 months Meat (Pork) 3 - 7 days 32 - 44 3 - 5 days 37 3 - 5 days 30 3 - 7 days 8 3 - 5 days 49 4 - 8 months 3 - 5 days 1 - 2 weeks 3 - 5 months 6 - 8 months 2 - 3 weeks 4 - 6 months 56 57 42 19 13 - 20 Highest Freezing, F 28.4 30.0 30.9 30.6 30.0 31.3 28 28 28 28 28 28 28 28 28 Specific Heat above 32F Btu/lb F 0.88 0.38 0.84 0.87 0.92 0.90 0.97 0.85 0.85 0.80 0.70 0.72 0.73 0.71 0.72 0.77 Specific Heat below 32F Btu/lb F 0.45 0.25 0.44 0.45 0.47 0.46 0.48 0.44 0.44 0.42 0.38 0.39 0.40 0.39 0.39 0.40 Latent Heat Btu/lb 122 117 120 129 122 133 117 117 107 87 92 93 89 92 100 Commodity Quinces Raisins Raspberries Black Red Strawberries Tangerines Watermelons Haddock,Cod.Perch Hake, Whiting Halibut Herring Kippered Smoked Mackerel Menhaden Salmon Tuna Frozen Fish Scallop meat Shrimp Lobster.American Oysters, Clams (meat & liquid) Oyster in shell Frozen shellfish Beef, fresh, average Beef carcass Choice, 60% lean Prime, 54% lean Sirloin cut (choice) Round cut (choice) Dried, chipped Liver Veal, 81% lean Beef, frozen Pork, fresh average Carcass, 47% lean Bellies, 35% lean Backfat, 100% fat Shoulder, 67% lean Pork, frozen Ham 74% lean Light cure Country cure Frozen Bacon Medium fat class Cured, farm style

28 28 28 28 27

0.84 0.81 0.83 0.89 0.84

0.44 0.43 0.44 0.46 0.44

114 109 113 125 115

28 - 29 29 28

0.70 - 0.84 0.61 0.58 0.66 0.50 0.60 0.77 0.74

0.39 - 0.43 0.35 0.34 0.37 0.40 0.34 0.41 0.40

89 - 110 70 64 80 96 69 100 94

29

28 - 29

28 29

0.48 - 0.57 0.52 0.47 0.30 0.61 0.66 0.67 0.56 0.38 0.34 - 0.39

0.30 - 0.33 0.31 0.29 0.22 0.35 0.37 0.37 0.33 0.26 0.24 - 0.26

46 - 63 53 43 70 80 82 60 27 19 - 29

21

REFRIGERATION SELECTION GUIDE

Table 5 - Requirements and Properties of Perishable Products (continued)

Storage Temperature, F 34 - 39 - 10 - 0 32 - 34 32 32 32 32 - 34 32 32 - 10 - 0 28 - 32 28 - 32 28 - 32 28 - 32 - 10 - 0 32 - 34 32 - 10 32 - 34 40 40 40 -20 to -15 32 - 34 70 45 - 70 40 70 40 70 Low Relative Humidity, % 85 90 - 95 85 85 85 85 85 - 90 85 85 90 - 95 95 - 100 95 - 100 95 - 100 95 - 100 90 - 95 90 - 95 75 - 85 70 - 85 65 65 65 65 Approximate Water Storage Content. Life % Meat (Pork) continued 2 - 6 weeks 2 - 4 month 1 - 7 days 38 1 - 3 weeks 50 1 - 3 weeks 56 1 - 3 weeks 54 Meat (Lamb) 5 - 12 days 60 - 70 5 - 12 days 61 5 - 12 days 65 8 - 12 months Meat (Poultry) 1 - 4 weeks 74 1 - 4 weeks 74 1 - 4 weeks 64 1 - 4 weeks 69 12 months Meat (Miscellaneous) 1 - 5 days 68 Dairy Products 1 month 16 12 months 12 months 6 months 12 months 12 months 3 - 23 months 2 - 4 months 6 - 9 months 16 months 24 months 12 months 15 months 12 months Eggs Eggs Shell Shell, farm cooler Frozen Whole Yolk White Whole egg solids Yolk solids 29 - 32 50 - 55 0 0 0 35 - 40 35 - 40 80 - 85 70 - 75 5 - 6 months 2 - 3 weeks 1 year plus 1 year plus 1 year plus 6 - 12 months 6 - 12 months 66 66 74 55 88 2-4 3-5 28 28 0.73 0.73 0.80 0.65 0.90 0.22 0.23 0.40 0.40 0.42 0.36 0.46 0.21 0.21 96 96 106 79 126 4 6 37 37 39 31 63 87 2 3 74 74 27 5 25 29 0.53 0.62 0.66 0.65 0.69 - 0.77 28 0.31 0.35 0.37 0.36 0.38 - 0.41 0.70 0.73 54 72 80 77 86 - 100 0.38 87 0.40 93 Highest Freezing, F Specific Heat above 32F Btu/lb F Specific Heat below 32F Btu/lb F Latent Heat Btu/lb Commodity Bacon continued Cured, packer style Frozen Sausage Links or bulk Country, smoked Frankfurters, average Polish style Fresh, average Choice, 67% 1lean Leg, choice, 83% 1lean Frozen Poultry, fresh, average Chicken, all classes Turkey, all classes Duck Poultry, frozen Rabbits, fresh Butter Butter, frozen Cheese, Cheddar long storage short storage processed grated Ice cream, 10% fat Milk Whole, pasteurized Grade A Dried, whole Dried, nonfat Evaporated Evaporated unsweetened Condensed sweetened Whey, dried

28 - 29

27 27 27 27

0.80 0.80 0.72 0.76

0.42 0.42 0.39 0.41

106 106 92 99

0.75 -4 - 31 8 8 19 21 31 29.5 29.5 5 0.36 0.52 0.52 0.50 0.45 0.70 0.93 0.26 0.26 0.79 0.79 0.42 0.28

0.40 0.25 0.31 0.31 0.31 0.29 0.39 0.46 0.21 0.21 0.42 0.42 0.28 0.22

97 23 53 53 56 44 86 125 28 4 106 106 40 7

Low Low

Low Low

22

REFRIGERATION SELECTION GUIDE

Table 5 - Requirements and Properties of Perishable Products (continued)

Storage Temperature, F Relative Humidity, % Low Low 0 - 34 0 - 34 0 - 34 0 - 34 0 35 - 40 35 - 40 0 32 - 60 32 - 40 32 - 35 35 - 37 34 - 40 50 28 - 32 45 0 32 - 50 70 35 30 - 35 32 - 40 31 - 32 50 - 65 35 - 40 35 - 46 35 - 50 40 40 65 65 70 - 75 65 or below 70 or lower 50 - 70 80 - 85 80 - 85 45 - 55 50 - 60 90-95 90 - 95 65 - 75 1 year plus 60 - 70 85 50 - 65 70 - 85 50 - 55 60 - 65 Approximate Water Storage Content. Life % Eggs continued 1 year plus 12 - 16 5-8 Candy 6 - 12 months 1 1.5 - 6 months 2 5 - 12 months 10 3 - 9 months 17 Miscellaneous 1 year plus 3 - 8 weeks 3 - 6 months 3 - 13 weeks 1 year 1 year plus 1 - 2 months 2 - 4 months Several Years 1 year plus Several months 4-8 months 12 - 14 months 8 - 12 months 0 1 year plus 3 - 6 weeks 4 - 6 weeks 1 year 1 - 2 years 6 months 2 months 90 90 32 - 37 47 10 - 15 17 0 0 33 3-6 16 89 10 71 28 0.70 30.4 1 year plus Highest Freezing, F Specific Heat above 32F Btu/lb F 0.31 0.26 0.25 0.26 0.32 0.37 Specific Heat below 32F Btu/lb F 0.24 0.22 0.20 0.21 0.23 0.25 Latent Heat Btu/lb 20 11 1 3 14 24 Commodity Flake albumen solids Dry spray albumen solids Milk chocolate Peanut brittle Fudge Marshmallows Alfalfa meal Beer Keg Bottles and cans Bread Canned goods Cocoa Coconuts Coffee, green Fur and fabrics Honey Hops Lard (without antioxidant) Maple syrup Nuts Oil,vegetable, salad Oleomargarine Orange juice Popcorn, unpopped Yeast, baker's compressed Tobacco Hogshead Bales Cigarettes Cigars

0.92 0.34 0.58 0.32 - 0.35 0.35

0.47 46 - 53 0.34 0.23 - 0.24 0.26

129

67 14 - 21 26

0.48 0.22 - 0.25 0.32 0.91 0.31 0.77

0.31 0.21 - 0.22 0.25 0.47 0.24 0.41

51 4-8 22 127 19 102

Compiled in part from ASHRAE Refrigeration Handbook,1990.

23

REFRIGERATION SELECTION GUIDE

Table 6 - Approximate Heat of Respiration Rates at Temperature Indicated

Btu/Pound/24 Hours Product Apples Asparagus Beans - Green Beans - Lima Beets Blueberries Broccoli Brussels Sprouts Cabbage Carrots Cauliflower Celery Cherries Corn Cranberries Cucumbers Grapefruit Grapes Lemons Lettuce - Head Lettuce - Leaf Melons - Cantaloupes 32F 0.45 4.70 3.15 1.35 1.35 0.85 3.75 2.9 0.6 1.05 1.95 0.8 0.75 4.65 0.33 0.28 0.35 0.3 0.35 1.15 2.2 0.65 40F 0.8 9.0 5.15 2.6 1.75 7.0 4.4 0.85 1.75 2.25 1.2 1.4 6.0 0.45 0.50 0.6 0.65 1.35 3.2 1.0 60F 2.05 18.5 19.1 12.2 3.6 21.0 10.1 2.05 4.05 5.05 4.1 6.0 19.2 1.55 1.75 1.8 4.0 7.2 4.3 Product Melons - Honeydews Mushrooms Okra Onions Onions - Green Oranges Peaches Pears Peas Peppers - Green Peppers - Sweet Plums Potatoes - Immature Potatoes - Mature Raspberries Spinach Strawberries Sweet Potatoes Tomatoes - Green Tomatoes - Ripe Turnips 32F 3.1 0.45 1.8 0.35 0.6 0.4 4.2 1.35 1.35 0.3 2.4 2.3 1.6 0.9 0.3 0.5 0.95 Btu/Pound/24 Hours 40F 0.5 6.0 0.5 4.9 0.7 0.85 0.85 7.4 2.4 2.4 0.6 1.3 0.8 3.8 5.1 2.7 1.25 0.55 0.65 1.1 60F 1.4 15.8 1.2 9.0 2.2 4.2 5.4 21.0 4.3 4.3 1.3 2.4 1.0 10.1 18.5 9.0 2.7 3.1 2.8 2.65

Compiled in part from ASHRAE Handbook of Fundamentals,1989.

24

REFRIGERATION SELECTION GUIDE

Table 7 - Heat Equivalent of Electric Motors

Btu/Hp/Hr Motor Hp 1/8 - 1/2 1/2 - 3 3 - 20 Connected Load in Refrigerated Space1 Btu/Hr 4,250 3,700 2,950 Watts 1,243 1,081 863 Motor Losses Outside Refrigerated Space2 Btu/Hr 2,545 2,545 2,545 Watts 744 744 744 Connected Load Outside Refrigerated Space3 Btu/Hr 1,700 1,150 400 Watts 497 337 117

1. For use when both useful output and motor losses are dissipated within refrigerated space, motors driving fans for forced circulation unit coolers. 2. For use when motor losses are dissipated outside refrigerated space and useful work of motor is expended within refrigerated space; pump on a circulating brine or chilled water system, fan motor outside refrigerated space driving fan circulating air within refrigerated space.

3. For use when motor heat losses are dissipated within refrigerated space and useful work expended outside of refrigerated space; motor in refrigerated space driving pump or fan located outside of space.

Table 8 - Heat Equivalent of Occupancy

Cooler Temperature F 50 40 30 20 10 0 -10 Heat Equivalent/Person Btu/Hr. 720 840 950 1,050 1,200 1,300 1,400

Table 9 - Summer Outdoor Design Data

(Design dry bulb and wet bulb temperature represents temperature equalled or exceeded during 1% of hours during the four summer months.) Location Alabama Birmingham Mobile Alaska Fairbanks Juneau Arizona Phoenix Tucson Arkansas Fort Smith Little Rock California Bakersfield Blythe Los Angeles San Francisco Sacramento Dr Bulb F 97 96 82 75 108 105 101 99 103 111 94 80 100 Wet Bulb F 79 80 64 66 77 74 79 80 72 78 72 64 72 Location Colorado Denver Connecticut Hartford Delaware Wilmington D.C. Washington Florida Jacksonville Miami Tampa Georgia Atlanta Savannah Hawaii Honolulu Idaho Boise Dr Bulb F 92 90 93 94 96 92 92 95 96 87 96 Wet Bulb F 65 77 79 78 80 80 81 78 81 75 68

25

REFRIGERATION SELECTION GUIDE

Table 9 - Summer Outdoor Design Data continued

(Design dry bulb and wet bulb temperature represents temperature equalled or exceeded during 1% of hours during the four summer months.) Location Illinois Chicago Springfield Indiana Fort Wayne Indianapolis Iowa Des Moines Sioux City Kansas Dodge City Wichita Kentucky Lexington Louisville Louisiana New Orleans Shreveport Maine Portland Maryland Baltimore Massachusetts Boston Worcester Michigan Detroit Grand Rapids Minnesota Duluth Minnesota Mississippi Biloxi Jackson Missouri Kansas City St. Louis Montana Billings Helena Nebraska Omaha Nevada Las Vegas Reno New Hampshire Concord New Jersey Newark Trenton New Mexico Albuquerque Santa Fe New York Albany Buffalo New York North Carolina Charlotte North Dakota Bismark Dr Bulb F 94 95 93 93 95 96 99 102 94 96 93 99 88 94 91 89 92 91 85 92 93 98 100 96 94 90 97 108 95 91 94 92 96 90 91 88 93 96 95 Wet Bulb F 78 79 77 78 79 79 74 77 78 79 81 81 75 79 76 75 76 76 73 77 82 79 79 79 68 65 79 72 64 75 77 78 66 65 76 75 77 78 74 Location Ohio Cincinnati Cleveland Oklahoma Tulsa Oregon Pendleton Portland Pennsylvania Philadelphia Pittsburgh Rhode Island Providence South Carolina Charleston South Dakota Sioux Falls Tennessee Memphis Nashville Texas Dallas El Paso Galveston Houston Utah Salt Lake City Vermont Burlington Virginia Richmond Roanoke Washington Seattle Spokane Yakima West Virginia Charleston Wisconsin Milwaukee Wyoming Cheyenne Canada Alberta Calgary British Columbia Vancouver Manitoba Winnipeg New Brunswick St. John Newfoundland Gander Nova Scotia Halifax Ontario Toronto Quebec Montreal Saskatchewan Regina Yukon Whitehorse Dr Bulb F 94 91 102 97 91 93 90 89 94 95 98 97 101 100 91 96 97 88 96 94 82 93 94 92 90 89 87 80 90 81 85 83 90 88 92 78 Wet Bulb F 78 76 79 66 69 78 75 76 81 77 80 79 79 70 82 80 67 74 79 76 67 66 69 76 77 63 66 68 75 71 69 69 77 76 73 62

26

REFRIGERATION SELECTION GUIDE

Table 10 - Operating Conditions for Storage

Temp. F Humidity Operating T.D. F Designed Running Time For Unit

35 - 40

55% - 65%

20 - 25

18 hours

Table 11 - Insulation Requirements for Storage Rooms

Storage Temperature F Desirable Insulation U Factor

-50 to -25 -25 to 0 O to 25 25 to 40 40 and up

0.01 0.04 0.06 0.075 0.1

Table 12 - Suggested Freezer Temperatures F

Bread Candy 0 0 Vegetables Beef -10 -10

Ice Cream Butter Eggs Fish Shellfish

-15 O to -10 O or lower -10 -20

Lamb Pork Veal Poultry

-10 -10 -10 -20

27

Thank You! The Replacement Components Division (RCD) of Carrier Corporation thanks you for considering Totaline refrigeration products. These products are engineered and manufactured with the utmost in quality control. RCD is ready to support your installation and all other needs with our full range of Totaline Service Parts. Thanks again!

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs and prices without notice and without incurring obligations.

REPLACEMENT COMPONENTS DIVISION CARRIER CORPORATION 10/91, Rev A 06/03

www.totaline.com Literature Number: 570-545

Você também pode gostar

- Carrier Handbook Part 1Documento162 páginasCarrier Handbook Part 1Tanveer100% (3)

- Heating and Cooling Load Calculations: International Series of Monographs In: Heating, Ventilation and RefrigerationNo EverandHeating and Cooling Load Calculations: International Series of Monographs In: Heating, Ventilation and RefrigerationNota: 3.5 de 5 estrelas3.5/5 (6)

- Cold Room Calculation and Component SelectionDocumento18 páginasCold Room Calculation and Component Selectionluis100% (3)

- Carrier VRF 2018 enDocumento116 páginasCarrier VRF 2018 enLD Jr Francis100% (1)

- Induction unit system design manualDocumento35 páginasInduction unit system design manualNahiyan AbdullahAinda não há avaliações

- Calculate Chiller CapacityDocumento2 páginasCalculate Chiller Capacityhima007100% (6)

- A Guide in Practical Psychrometrics for Students and EngineersNo EverandA Guide in Practical Psychrometrics for Students and EngineersAinda não há avaliações

- Heatcraft - Engineering Manual (2008)Documento44 páginasHeatcraft - Engineering Manual (2008)sauro83% (12)

- ABCs of ComfortDocumento71 páginasABCs of ComfortAlex ChinAinda não há avaliações

- HVAC Equations, Data, and Rules of Thumb, Third EditionNo EverandHVAC Equations, Data, and Rules of Thumb, Third EditionAinda não há avaliações

- Quick Calculation ColdroomDocumento1 páginaQuick Calculation Coldroom15690100% (2)

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideAinda não há avaliações

- HVAC Systems Duct DesignDocumento39 páginasHVAC Systems Duct Designsardarmkhan100% (2)

- York Cond Unit Piping GuidelinesDocumento128 páginasYork Cond Unit Piping Guidelinesdokundot100% (1)

- HVAC - Practical Basic Calculation PDFDocumento37 páginasHVAC - Practical Basic Calculation PDFmohdrashid100% (2)

- Industrial Refrigeration Best Practices GuideDocumento25 páginasIndustrial Refrigeration Best Practices Guidepiggott12100% (5)

- Chiller OperationDocumento6 páginasChiller OperationKannan Vellasamy67% (3)

- Carrier Training Materials CatalogDocumento32 páginasCarrier Training Materials Catalogsmith_ra0% (2)

- Designing A Cold Storage and It's Refrigeration SystemDocumento11 páginasDesigning A Cold Storage and It's Refrigeration SystemzhyhhAinda não há avaliações

- Air Vs Water Cooled ChillersDocumento15 páginasAir Vs Water Cooled ChillersVelram ShanmugamAinda não há avaliações

- Ice Plant ProductionDocumento8 páginasIce Plant ProductionTristan Paul Guerra Orodio100% (1)

- Cooling Coil 01Documento15 páginasCooling Coil 01Sam Wang Chern Peng100% (3)

- Daikin AG 31-002 Centrifugal Chiller Fundamentals Guide Vers 2.2Documento33 páginasDaikin AG 31-002 Centrifugal Chiller Fundamentals Guide Vers 2.2usmanafzal246Ainda não há avaliações

- Water Cooled ChillerDocumento7 páginasWater Cooled ChillerKrishna MurariAinda não há avaliações

- Heat Load in Refrigeration SystemsDocumento72 páginasHeat Load in Refrigeration Systemsforeverdiesel100% (8)

- Durrat Island district cooling load estimate based on revised masterplanDocumento1 páginaDurrat Island district cooling load estimate based on revised masterplanAbraham JyothimonAinda não há avaliações

- Chiller SizingDocumento2 páginasChiller SizingwernhowAinda não há avaliações

- Engineering Manual Evaporative CondensersDocumento16 páginasEngineering Manual Evaporative Condenserstulamst100% (2)

- Air Blast FreezerDocumento15 páginasAir Blast FreezerRahul PatilAinda não há avaliações

- ASY (R-134) Series Screw ChillerDocumento51 páginasASY (R-134) Series Screw Chillernafoukh89% (9)

- Chiller Plant CommissioningDocumento38 páginasChiller Plant Commissioningavbsky100% (1)

- All-Air Systems GuideDocumento62 páginasAll-Air Systems GuideradiopascalgeAinda não há avaliações

- Chiller SelectionDocumento3 páginasChiller SelectionSameer Pawar50% (2)

- Duct Design RevDocumento21 páginasDuct Design Revapi-25999517100% (1)

- Cooling Tower Fundamentals PDFDocumento27 páginasCooling Tower Fundamentals PDFDarshan Raghunath100% (3)

- Fundamentals of Duct DesignDocumento71 páginasFundamentals of Duct Designjmdc100% (1)

- 4.14. BuildingsDocumento21 páginas4.14. BuildingsAtul YadavAinda não há avaliações

- Heating, Ventilating, and Air Conditioning Load CalculationsDocumento36 páginasHeating, Ventilating, and Air Conditioning Load CalculationsAbdalhady JoharjiAinda não há avaliações

- HVAC Thermal Load EstimatingDocumento28 páginasHVAC Thermal Load EstimatingIntisar Ali SajjadAinda não há avaliações

- Air Cond Load EstDocumento28 páginasAir Cond Load Estari_aristaAinda não há avaliações

- Feasibility Study For Solar Cooling SystemsDocumento86 páginasFeasibility Study For Solar Cooling SystemsPopa Florin100% (1)

- Cooling Load Estimation For Hibir BoatDocumento10 páginasCooling Load Estimation For Hibir BoatAdi WahyudiAinda não há avaliações

- Heatcraft Engineering ManualDocumento44 páginasHeatcraft Engineering Manualjs_cal77100% (1)

- Load CalculationDocumento4 páginasLoad CalculationVirani BharatAinda não há avaliações

- Designing HVAC systems for residential buildingsDocumento8 páginasDesigning HVAC systems for residential buildingsRise CompanyAinda não há avaliações

- Cooling and heating load principlesDocumento18 páginasCooling and heating load principlesSaif AliAinda não há avaliações

- Carrier - Handbook of Air Conditioning System Design (Part 1)Documento162 páginasCarrier - Handbook of Air Conditioning System Design (Part 1)Jonathan Castro96% (93)

- Glass Unit V Air-Conditioning Load CalculationDocumento26 páginasGlass Unit V Air-Conditioning Load CalculationASWIN KUMAR N SAinda não há avaliações

- Course HV-6011Documento62 páginasCourse HV-6011Hafiz Muhammad MuneebAinda não há avaliações

- Minimize Wall Surface Heat LossesDocumento22 páginasMinimize Wall Surface Heat LossesSamanway DasAinda não há avaliações

- Air-Conditioning Load EstimationDocumento23 páginasAir-Conditioning Load Estimationtkm2004Ainda não há avaliações

- Air Cond Load EstDocumento28 páginasAir Cond Load EstNurul AdawiyahAinda não há avaliações

- Scaleup of Agitated Thin-Film EvaporatorDocumento4 páginasScaleup of Agitated Thin-Film Evaporatorcristian_fram100% (1)

- Heat Load Calculation : J.IlangumaranDocumento70 páginasHeat Load Calculation : J.Ilangumaranapi-25999517Ainda não há avaliações

- Presentation 1Documento51 páginasPresentation 1Cedrick S TanAinda não há avaliações

- Air Purger (CPA-10) - Cool PartnersDocumento3 páginasAir Purger (CPA-10) - Cool PartnersMohammad AmerAinda não há avaliações

- Air Purger (CPA-10) - Cool PartnersDocumento3 páginasAir Purger (CPA-10) - Cool PartnersMohammad AmerAinda não há avaliações

- Cubic Unit Cooler: SKB Semi-Industrial RangeDocumento8 páginasCubic Unit Cooler: SKB Semi-Industrial RangeMohammad AmerAinda não há avaliações

- TylerMSD ISManual LowrezDocumento204 páginasTylerMSD ISManual LowrezMohammad Amer100% (1)

- MYCOM VR Series Screw Compressor Overhaul ManualDocumento51 páginasMYCOM VR Series Screw Compressor Overhaul ManualWai LaiAinda não há avaliações

- Omega TransducersDocumento3 páginasOmega TransducersMohammad AmerAinda não há avaliações