Escolar Documentos

Profissional Documentos

Cultura Documentos

Is 15622-2006 PDF

Enviado por

ravi03121Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Is 15622-2006 PDF

Enviado por

ravi03121Direitos autorais:

Formatos disponíveis

IS 15622:2006

(Superseding IS 13753:1993, IS 13754:1993, IS 13755:1993 and IS 13756:1993)

nn

Indian Standard

PRESSED CERAMIC TILES SPECIFICATION

ICS 91.100.23

Q BIS 2006 BUREAU OF MANAK BHAVAN, IN II IAN STANDARDS 9 BAHADUR SHAH ZAFAR NEW DELHI 110002 MARG

PriceGroup

Flooring,

Wall Finishing and Roofing Sectional Committee, CED 5

FOREWORD This Indian Standard was adopted by the Bureau of Indian Standards, after the draft finalized by the Flooring, Wall Finishing and Roofing Sectional Committee had been approved by the Civil Engineering Division Council, It was seen that there were four separate specifications of ceramic tiles based on different percentage of water absorption, namely:

IS No. Title

13753:1993 13754:1993 13755:1993 13756:1993

Specification B 111) Specification B H b) Specification B 11a) Specification (Group B 1)

for dust pressed ceramic tiles with water absorption of E > 10% (Group for dust pressed ceramic tiles with water absorption of 6% < Es 10?4.(Group for dust pressed ceramic tiles with water absorption of 3% < E < 6?/. (Group for dust pressed ceramic tiles with low water absorption of E < 3A

In place of separate specification for each category, it was suggested to bring out a general specification for ceramic tiles for different water absorption categories to cover all the important requirements. Accordingly efforts were made to bring out this standard, which supersedes IS 13753, IS 13754, IS 13755 and IS 13756. The following major changes have been incorporated in this standard: a) b) c) Title of the standard has been changed from dust pressed ceramic tiles to pressed ceramic tiles, Requirementsgiven in 1S 13753 to IS 13756 have been clubbed in one volume at the time of preparation of this standard. Category of the ceramic tiles with water absorption less than-3 percent as per the existing IS 13756 have now been changed to two categories, namely, one for the range of water absorption 0.08 to 3 percent and another having range of less than 0.08 percent. Category of the ceramic tiles with water absorption 6 to 10 percent have now been omitted which-were covered as per the existing standard IS 13754. Certain modular preferred sizes as well as non-modular sizes for the tiles having the varying water absorption have been added in the tables. Test requirements for the ceramic tiles having the different water absorption capacity have been modified at number of places to bring in line with latest practice being followed in the country.

d) e) o

In formulation of this standard considerable assistance have been derived from 1S0 13006 Ceramic tiles Definition, classifications, characteristics and marking and 1S0 10545 (Parts 1 to 14) Ceramic tiles Tests. For the purpose of deciding whether a particular requirement of this standard is complied with, the final value, observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with IS 2:1960 Rules for rounding off numerical values (revised. The number of significant places retained in the rounded off value should be the same as that of the specified value in this standard.

IS 15622:2006

Indian Standard

PRESSED CERAMIC TILES SPECIFICATION

1 SCOPE 1.1 This standard specifies &izes, dimensional tolerances, mechanical, physical and chemical requirements, surface quality requirements and marking of ceramic tiles.

f)

Tables 2, 4, 6, and 8 give the most common non-modular sizes.

4.2 Other Sizes

1.2 It is applicable only to pressed ceramic glazed/ unglazed tiles of first quality for use as both floors and walls coverings.

1.3 There is a small production of pressed ceramic unglazed tiles with water absorption greater than 10 percent, that is, not covered by this standard.

For pressed tiles with dimensions other than those given in Tables 1, 3, S, 7 and Tables2, 4, 6, 8, the work size shall be stated by the manufacturer. The relevant requirements for work size and thickness given in the respective tables are applicable.

4.3 Spacer Lug Tiles 4.3.1 Spacer lugs are projections, usually 0;6 mm that are located along certain edges of tiles so that when

2 REFERENCES The standards given at Annex A contain provisions which through reference in this text, constitute provisions of this standard. At the time of publication, the editions indicated were valid. All standards are subject to revision and parties toagreements based-on this standard are encouraged to investigate the possibility of applying the most recent editions of the standards indicated in Annex A. 3 DEFINITIONS 3.1 The definition of pressed ceramic tiles is given in IS 13712. 3.2 The surface of tiles and components belonging to this group can be smooth, profiled, wavy, decorated or finished in some other way. It can be unglazed (UGL), glossy, matt or semi-matt (GL). 3.3 Tiles may have spacer lugs. 4 SHAPES AND SIZES 4.1 For shapes and sizes, see Fig. 1 and Fig. 2 and the following: a) Tables 1 and 2: For tiles with water absorption, E.> 10 percent (Group B III),

two tiles are placed together in line, the lugs on adjacent edges separate the tiles by a distance not less than the specified width of joints (see Fig. 2). Lugs are positioned so that the joint between the tiles may be filled with grout without the Iugs remaining exposed. 4.3.2 Pressed tiles may be made with other spacer lug systems and in such cases the manufacturers work size shall apply. NOTE Some tiles have one or more manufacturing

projections part way along certain edges and smaller than 0.3 mm. These are not intended as spacer lugs and shall not be used to space joints.

4.4 Accessories Dimensions and tolerances of accessories, for example, soap-holder, are not standardized, and these shall be stated by the manufacturer, where appropriate.

5 REQUIREMENTS 5.1 Dimensional and surface quality requirements and physical and chemical properties are given in the following tables:

a) b) c) d)

Table 9: For tiles with water absorption E >10 percent (Group B HI), Table 10: For tiles with water absorption 3 <Es 6 percent (Group B H), Table 11 : For tiles with water absorption 0.08< E <3 percent (Group B I b), and

pmm Table 12: For tiles with water CIU>U1 -L----Es 0.08 percent (Group B Ia).

b) Tables 3 and 4: For tiles with water absorption, 3< E <6 percent (Group B 11), , c) Tables 5 and 6: For tiles with water absorption, 0.08< E <3 percent (Group B I b), d) Tables 7 and 8: For tiles with water absorption, E S 0.08 percent (Group B I a). e) Tables 1,3,5, and 7 give the modular preferred sizes, and 1

5.2 Sampling and basis for acceptance shall be in accordance with IS 13630 (Part 15).

1S 15622:2006

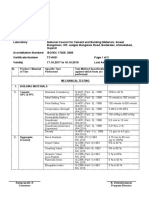

1-

c-+

I l-----v----w-J

Co-Ordinating Size (C) = Work Size (W) + Joint Width (J) Work Size (W) = Dimensions of the Visible Faces a and b Co-Ordinating Size (C) = Work Size (W) + Joint Width (J) Work Size (W) = Dimensions of the Visible Faces a and b

FIG. 1 TILE

FIG. 2 TILEWITH SPACE LUGS

Table 1 Modular Preferred Sizes for Tiles with Water Absorption, E >10 percent (Group B III) (C/ause 4. 1)

Work Size (Wj Thickness@ mm

Coordinating Size (C) cm

Length(a)

mm (2)

Width(b)

mm (3)

(1) M30 x 30 M30x 15 M25 x15 M20 x 20

(4)

The manufacturer shall choose the work size in

M20X15

M20 x 10 M15 x15 MIOX IO

orderto allowa nominal oint widthbetween j

1.5 remand 5 mm

The thicknessshallbe specifiedby the manufacturer. includesthe profile on It

the visible face and on the rear side

IS 15622:2006 Table 2 Non-modular Sizes for Tiles with Water Absorption, E >10 Percent (Group B HI) (Clause 4.1)

Nominal Size (N) cm

Work Size (W)

Thickness

(d)

Length (u) mm

(2)

Width (b)

mm (3)

mm

(1) 4(J x 40 32 32 32

X

(4)

48

x 60 x

40

33 x 33 31,5x42 32

x

32

3r3x 30 30X 15

25

25

21.6 x 10.8 20 x 40 20 x 30 20 x 20 2(3X 15 15.2 x 15.2 15.2 x7.6 15X 15 15 X7.5 10.8 x 10.8 10 x 20

The manufacturer shall choose the work size in such a way that the difference between the work size and the nominal size is not more than ~2 percent and 5 mm For spacer lug tiles, one work size shall apply for each nominal size within the 1imits mentioned above

The thickness shall be specified by the manufacturer. It includes the profile on the visible face and on the rear side

Table 3 Modular Preferred Sizes for Tiles with Water Absorption, 3< E <6 Percent (Group B 11) (Ckzz4se4.1)

Coordinating cm

Size (C)

Work Size (W)

Thickness

(d)

Length (a)

mm

Width (b)

mm

mm

(1) MIO x 10 M15 x 15 M20x 10 M20 x 15 M20 x 20 M30 x 30 M40 x 40 M45 x 45

(2)

(3)

(4)

The manufacturer shall choose the work size in order to allow a nominal joint width between 2 mm and 5 mm

The thickness shall be specified by the manufacturer. It includes the profile on the visible face and on the rear side

IS 15622:2006 Table 4 Non-modular Sizes for Tiles with Water Absorption,

3< E S 6 Percent (Group B II) (Clause 4.1)

Nominal Size (~ cm

Work Size (w)

(1)

lr)x ]()

Length (a) mm (2)

Width (b) mm (3)

Thickness mm

(d)

(4)

15 X7.5 15 x 10 ]5X]5 15.2 x 7.6 15.2 x 15.2 20 x 10 20 x 20 25 x 25 30X 15 30 x 20 30x 3(J 30.6 x 30.6 31.5 X31.5 40 x 30 40 x 40 40.6 x 40.6 The manufacturer shall choose the work size in such a way that the difference between the work size and the nominal size is not more than *2 percent and 5 mm The thickness shall be specified by the manufacturer. It includes the profile on the visible face and on the rear.side

Table 5 Modular Preferred 0.08<

Sizes for Tiles with Water Absorption, (Clause 4.1)

E S 3 Percent (Group B I b)

Coordinating cm

Size (~ Length (a)

Work Size (W)

(1)

M1O x 10 M15 x15 M20 x 10 M20x15 M20 x 20 M30 x 30

mm (2)

Width (b) mm (3)

Thickness mm

(d)

(4)

The manufacturer shall choose the work size in order to allow a nominal joint width between 2 mm and 5 mm

The thickness shall be specified by the manufacturer. H includes the profile on the visible face and on the rear side

IS 15622:2006 Table 6 Non-modular Sizes for Tiles with Water Absorption, 0.08< E <3 Percent (Group B I b) (Clause 4.1)

Nominal Size (N) cm

Work Size (W)

Thickness

(d)

Length (a) mm (2)

Width (b) mm (3)

mm

(1) lox 10 15 X7.5 15 x 10 15X15 15.2 x 7.6 15.2 x 15.2 Xl x 10 20 x 20 25

x

(4)

25

The manufacturer shall choose the work size in such a way that the difference between the work size and the nominalsize is not more than *2 percent and 5 mm

The thicknessshallbe specifiedby the

manufacturer. It includes the profile on the visible face and on the rear side

30 x 15 3(3x 20 30 K3(I 40 x 3(J 45 x 45 60

X 60

Table 7 Modular Preferred Sizes for Tiles with Water Absorption, E S 0.08 Percent (Group B I a) (Clause 4.1)

Coordinating cm

Size (C)

Work Size (W)

Thickness

(d)

Length (a) mm (2)

Width (b) mm (3)

mm

(1) MIO x 10 M15 x 15 M2OX1O M20x 15 M20 x 20 M30 x 30 M45 x 45

(4)

The manufacturer shall choose the work size in order to allow a nominal joint width between 2 mm and 5 mm

The thickness shall be specified by the manufacturer. It includes the profile on the visible face and on the rear side

-*

1S 15622:2006 Table 8 Non-modular Sizes for Tiles with Water Absorption, (Clause 4.1)

E S 0.08 Percent (Group B I a)

Nominal Size (iv) cm Length (a) mm (1)

Work Size (W) Width (b) mm

Thickness-(~ mm

(2)

(3)

(4)

lox 10 15 X7.5 15X ]0 15 x 15 15.2 x 7.6 15.2 x15.2 2(3X 10 2r3x 20 25

x

Themanufacturer choose the work size in such shall

a way that the difference between the work size and the nominal size is not more than *2 percent and 5 mm The thickness shall be specifmd by the manufacturer. It includes the profile on the visible face and on the rear side

25

30 x 15 30x 20 30 x 3(3 40 x 30 60 X 60

(jo X

90

9(3x 90 90 x 12(3

Table 9 Test Requirements for Pressed Tiles with Water Absorption, E >10 Percent (Group B III) (C/ause 5.1 )

Characteristics (1) L) Dimensions and Surface Quality

Requirements (2)

Method of Test,

Refto Part ofIS 13630

(3)

Length and width:

The deviation in percent of the average size of each tile (2 or 4 sides) from the work size (W) Tile with spacer lugs The deviation in percent of the average size of each tile (2 or-4 sides) from the average size of the 10 test specimen (20 or 40 sides) THe with spacer lugs

ii) Thickness:

I< 12 cm : +0.5 ) I >12 cm :+0,2 +0.6 /0,3 ls12cm:+0.4/-O.2

I>12cm:*0.15 *0.25 Part 1

The deviation, in percent of the average thickness of each tile from the work size thickness, a) <250 cmz

q

*3.O

b)> 250 to 500 Cmz c) >5130to 1000 Cmz d)> 1000 cmz

+3.0 *4.O +4.0

IS 15622:2006 Table 9 (Concluded)

Characteristics

Requirements

Method of Test, Ref to Part of IS 13630

(1) iii) Straightness

of sidesz) (Facial sides):

(2)

!

(3)

The maximum deviation from straightness, in percent related to the corresponding work sizes iv) Rectarrgulari@: The maximum deviation from rectangularity in percent related to the corresponding work sizes

q0.15

+0.15

Tilewithspacerlugs v)

SurfaceJatness:

*0.15 Part1

The maximum deviation from flatness, hr percent a) Centre curvature, related to diagonal calculated fromthework sizes

b) c) Edge curvature, related to the corresponding work size Warpage, related to the diagonal calculated from the work sizes.

)

*0,22 *0,22 +0.22

vi) Surface quali~

Minimum 95 percent of tiles shall be free from visible defects that would impair the appearance of a major area of tiles. >10 percent, when the value exceeds 20 percent this shall be indicated by the manufacturer. (Average 10 percent) Average 12 for thickness K 7.5 mm Average 15 for thickness z 7.5 mm 200 fors 7.5 mm thickness, Min

500 for >7.5 mm thickness, Min

) Part 2

1) Physical I%operties i) Water absorption, percent by mass

ii)

Modulus of rupture, in N/mm

iii) Breaking strength, in N iv) Moisture expansion, in mm/m v) Scratch hardness of surface (Mobs) vi) Co-efficient of linear thermal expansion from ambient temperature to 10OC vii) Thermal shock resistance viii) Crazing resistance)

U) Chemical i) Properties

Part 6 } Part 3 Part 13

0.04 3, Min 9 x 10+

K-, J@

Part 4 Part 5

Part 9

10 cycles, Min 4 cycles@ 7.5 bar, Min

Resistance to staining of glazed tiles ii) Resistance to household chemicals and swimming pool water cleansers except to cleansing agents containing hydrofluoric acid and its compounds iii) Resistance to acids and alkalis (with the exceptions of hydrofluoric acid and its compounds)

Class 1, &fin Class AA, Min Part 8 Required if agreed, according to the chemical resistance class indicated by the manufacturer.

1) For tiles having one or more adjacent glazed tiles. 2) Not applicable for tiles having curved shapes. ) Certain decorative effects may have a tendency to craze. These shall be identified by the manufacturer, in which case the crazing test is not applicable.

IS 15622:2006 Table 10 Test Requirements for Pressed Tiles with Water Absorption 3 c Es 6 Percent (Group B H) (C)awe 5.1)

Characteristics

Surface of the Product(s)

SS90 cm (I)

) Dimensions i) and Snrface Quality

90<s< 190 cmz (3)

190<s<410 cm2 (4)

s>41r)

cm2

Method of Test, Ref to Part of

Is 13630 (6)

(2)

(5)

Length and width

a)

The deviation in percent of the average size of each tile (2 or 4 sides) from the work size (W): 1) Unrectified 2) Rectified *lo * 0.5 * 0.75 * 0.3 * 0.4 *041 * 0.4 *0.1

b) The deviation in percent of the average size of each tile (2 or 4 sides) from the average size of the 10 test specimen (20 or 40 sides): 1) Unrectified 2) ii)

Thickness

* 0.6 &0.3 flo

* 0.5 * 0.3 * 10

* 0.4 *0.1 *5

* 7).4 *0.1 *5

Rectified

The deviation, in percent of the average thickness of each tile from the work size thickness iii) Straightness

of sides) (Facial sides)

from deviation maximum The straightness, in percent related to the corresponding work sizes: a) b) Unrectified Rectified * 0.5 + 0.3 * .0.4 * 0,3 * 0.3 fo.1 * 0.3 10.1

iv) Rectangularity) deviation from maximum The rectangularity in percent related to the corresponding work sizes: a) b) v) Unrectified Rectified * 0.8 * 0.3 * 0.4 * 0.3 * 0.3 *0.1 * 0.3 *0.1

Surjacej7atness

The maximum deviation from flatness, in percent a) Centre curvature, related to diagonal calculated from the work sizes Edge curvature, related to the correspondbrg work size Warpage, related to the diagonal calculated from the work-sizes il.o i 0.5 * 0.5 * 0.5

b) c)

+1.0 * 1.0

* 0.5 * 0.5

* 0.5 * 0.5

* 0.5 f 0.5

vi) SurJace quality2)

Minimum 95 percent of tiles shall be free from visible defects that would impair the appearance of a major area of tiles.

Physical Properties i)

Water absorption, pereent by mass

Average 3 <Es 6, Individual mrwimum 6.2 Average 30, Individual 28, A4in

s 7.5 mm thickness :500, Min >7.5 mm thickness : I 000. Min

Part 2

ii) Modulus of rupture, in N/mmz i iii) Breaking strength,n N

Part 6

,}

IS 15622:2006 Table 10 (Concluded)

Characteristics

Surface of the Product(s)

Ss 90 cmz (1) iv) Scra[ch

scale) hardness of surface (Mobs

90<s<

~mz

190

190< s<410

ml

S>41O

~ml

Method of Test, Ref to Part of IS 13630

(2)

(3)

(4)

(5)

(6)

a) b)

Commercial application Home 1) Glazed, and 2) Unglazed tiles

of glazed tiles

7, Min 5, Min

Part 13

v)

Resistance to abrasion Class 1 to V

a) b)

Commercial application Residential applications

IV, Min II, Min 9 x 104, Mox

Part 11

linear thermal vi) Co-efficient of expansion from ambient temperature to 100C (K-) vii) Therrnrd shock resistance viii) Crazing resistance;) glazed tiles ix) Frost resistance

Part4 Part5 Part9 Part10

10 Cycles, Min 4 Cycles at 7.5 Bar, A4in Required, if agreed

;)

Chemical

Properties

i)

Resistance to staining of glazed tiles

Class 1, Min

ii) Resistance to household chemica[s and e swimming pool water cleansers xcept to cleansing agents containing hydrofluoric acid and its compounds Glazed tiles (Unglazed tiles) iii) Resistance to acids and alkalies (with the exceptions of hydrotluoric acid and its compounds) Glazed tiles Class AA, Min Required, if agreed according to the chemical resistance class indicated by the manufacturer

1

Part8

) Not applicable for tiles having curved shapes. 2) Because of tiring, slight variations from the standard eolour are unavoidable. This does not apply to intentional irregularities of colour variation of the face of pressed tiles of low water absorption (wh~chcan be unglazed, glazed or partly glazed) or to the colour variation over a tile are% which is characteristic for this type of tile and desirable. Spots or coloured dots which are introduced for decorative.purposes are not considered a defect. ) Certain decorative effects may have a tendency to craze. These shall be identified by the manufacturer, in which case the crazing test is not applicable.

IS 15622:2006 Table 11 Test Requirements for Pressed Tiles with Water Absorption 0.08< E <3 Percent (Group B I b) (Clause 5.1)

Characteristics

Surface of the Product(s)

S<90 cmz

(1)

90<s<190

cm2 (3)

(2)

190<s<410 cm= (4)

S>41O

~m2

Method of Test, Ref to Part of

1S 13630 (6)

\

(5)

Dimensions

and Surface Quality

i)

Length and wid~h a) The deviation in percent of the average size of each tile (2 or 4 sides) from the work size (W) * 1.0 i 0.75 k 0.2 +0.1

b) The deviation in percent of the average size of each tiIe (2 or 4 sides) from the average size of the 10 test specimen (20 or 40-sides) ii)

Thickness

+ 0.6

i 0,3

* 0.2

+0.1

The deviation, in percent of the average thickness of each tile from the work size thickness iii) Straightness

of sides) (Facial sides)

*5

*5

*4

*4

The maximum deviation from straightness, in percent related to the corresponding work sizes iv) Rectangularityi) from deviation maximum The rectangularity in percent related to the corresponding work sizes v)

Surface Jatness

* 0.5

* 0.4

* 0.3

*().1 Part 1

* 0.8

* &4

* 0.3

+0.1

The maximum deviation from flatness, in (percent): a) b) c) Centre curvature, related to diagonal calculated from the work sizes Edge curvature, related corresponding work size to the * 0.8 + 0,8

q

* 0,4 * 0.4 * 0.4

i 0.3 * 0.3

q

* 0.2 * 0.2 * 0.2

Warpage, related to the diagonal calculated from the work sizes

0.8

0.3

vi) Surface qrialityz)

Minimum 95 percent of tiles shall be free from visible defects that would impair the appearance of a major area of tiles

1 Part 2 Part 6

}

i) Physical Properties

i)

Water absorption, percent by mass Modulus of-rupture, in N/mm2

Average s 3, Individual maximum, 3,3 Average 38, Individual minimum 35 g 7.5 mm thickness :600, &fin >7.5 mm thickness : 1200, A4in 0.02, Max 6, A4in 5, Min

ii)

iii) Breaking strength, in N

iv) v)

Moisture expansion, in mm/m

Scratch hardness of surface (Mobs scale)

Part 3

a) b)

Commercial application Home application

Part 13

vi) Abrasion resistance Resistance to abrasion of glazed tiles Class Itov a) b) Commercial application Home application HI, Min 11,Min Part 11

10

IS 15622:2006 Table 11 (Corrc/ude~

Characteristics

Surface of the Product(s)

(1)

vii) Co-efficient of linear thermal expansion from ambient temperature to 100C (K-) viii) Thermal shock resistance ix) x) Crazing resistonce~)glazed tiles Frost resistance

S<90 cmz (2)

7

x ] 04

90<s< 190 190<SS41CI ~mz cm2 (4) (3)

K-, ~~x

S>41O cmz (5)

Method of Test, Ref to Part of

IS 13630 (6)

Part 4 Part5 Part 9 Part 10

10 Cycles, Min 4 Cycles@ 7.5 bar, Min Required

) Chemical Properties

i) Resistance to staining of glazed tiles Class 1, Min

ii)

Resistance to household chemicals and swimming pool water cleansers except to cleansing agents containing hydrofluoric acid and its compounds Glazed tiles Class AA, A4in Part 8

iii) Resistance to acids and alkalies (with the exceptions of hydrofluoric acid and its compounds) Glazed tiles Required, if agreed according to the chemical resistance class indicated by the manufacturer

I

1)

7.)

3)

Not applicable for tiles having curved shapes. i o Because of firing, slight variations from the standard colour are unavoidable. Thisdoesnotapplyto intentionalrregularitiesf colour variation of the face of pressed tiles of low water absorption (which cars be unglazed, glazed or partly glazed) or to the colour variation over a tile are% which is characteristic for this type of tile and desirable. Spots or coloured dots which are introduced for decorative purposes are not considered a defect. Certain decorative effects may have a tendency to craze. These shall be identified by the manufacturer, in which case the crazing test is not applicable.

11

IS 15622:2006 Table 12 Test Requirements for Pressed Tiles with Water Absorption E S 0.08 Percent (Group B I a) (Clause 5.1)

Characteristics

Surface of the Product(s)

Method of Test,

S<90 ~m2 (1)

I Dimensions and Surface Quality i) Length and widlh: a) .The deviation in percent of the * 1.0 (2)

90<s<190 cm2

(3)

190<s<410 cmz

(4)

S>41O

~m2

Refto Part of Is 13630

(6) \

(5)

* 0.75

0.2

+0.1 +0.1

averagesize of eachtile (2 or 4

sides) from the work size (W) b) The deviation in pcrccnt of the * 0.6 *

0.3

* 0.2

averagesize of eachtile (2 or 4

sides) born the average size of the 10 test specimen (20 or 40 sides) ii) Thickness The deviation, in percent of the average thickness of each tile from the work size thickness iii) S&aiglrbress ofsidesi) (Facial sides) deviation from The maximum straightness, in percent related to the corresponding work sizes iv) Rectangularity) The maximum deviation from * 0.8 * 0.4

q

*5

*5

k4

*4

* 0.5

* 0.4

* 0.3

* 0.1

Part1 0.3 *0.1

i rectangularityn percent related to the corresponding work sizes v)

Surface jlatness

The maximum deviation from flatness, in (percent): a) Cerrtre sizes %) Edge curvature, related to the work corresponding size c) Warpagc, related to the diagonal =$ 0.8 * 0.8 * ().4 * 0.4 * * curvature, related to * 0.8 i 0.4 *

0.3 0.3 0.3

* (.).2 * 0.2 * 0.2

diagonal alculated the work c from

calculated fromthework sizes

vi) Surface quality2) Minimum 95 percent of tiles shall be free from visible defects that would impair the appearance of a major area of tiles

1) Physical Properties

i) ii) Water absorption, percent by mass Modulus of rupture, in N/mmz Averages 0.08, Individual maximum, 1.0 Part 2

Average 47, Individual minimum 44 s 7.5 mm thickness :800, Min >7.5 mm thickness : 1500, A4in

}

iii) Breaking strength, in N

Part6

Part 13

iv) Scratch hardness of surface (Mobs scale) v)

Abrasion resistance

6, A4in

100,

Max

Part 12

Resistance to unglazed tiles in mm~)

deep abrasion of (Removed volume 6

X 104 K-], ~~X

vi) Co-efficient of linear thermal expansion from ambient temperature to 100C (K-)

Part4

12

IS 15622:2006 Table 12 (Concluded)

Characteristics S<9CI

Surface of the Product(s) 90<s<19(

I

cm2 (1) vii) Thermal shock resistance viii) Frost resistance ix) Impact resistance x) Bulk density, in (g/cc) (2) 10 Cycles, A4in Required Required 2.2, A4in

cmz (3)

190<s<41 cm2 (4)

S>41O cm2 (5)

Method of Test, Ref to Part of

IS 13630 (6) Part 5 Part 10 Part 14 Part 2

C) Chemical Properties i) Resistance to household chemicals and swimming pool water cleansers except to agents contrrining cleansing hydrofluoric acid and its compounds: Unglazed tiles ii) Resistance to acids and alkalies (with the exceptions of hydrotlroric acid and its compounds): Unglazed tiles Required3) 1 Required Part 7

1, Not applicable for tiles having curved shapes. z) Because of firing, slight Vmiations from he standard colour are unavoidable, Thk does not apply to intentional irregularities of colourvariation the faceof pressed of tilesof lowwaterabsorption (whichcan be unglazed, glazed or partly glazed) or to the colourvariationover a tile area,whichis characteristic thk type of tile and desirable. Spots or coloured dots which are for introduced for decorative purposes are not considered a defect. 3) If the hue becomes slightly different this is not considered to be chemical attack.

6 MARKING 6.1 Marking

AND DESIGNATION

6.2.1 The use of the Standard Mark is governed by the provisions of the Bureau of Indian Standards Act,

Ceramic tiles and/or their packaging shall be marked as follows: a) b) c) Name and address of the manufacturer andl or trade-mark and the country of origin, Batch number/date of manufacture, and Designation of tiles as per 6.3.

Marking

1986 and the Rules and Regulations made thereunder. The details of conditions under which a licence for use of the Standard Mark may be granted to manufacturers or producers maybe obtained from the Bureau of Indian Standards. 6.3 Designation TiIe shall be specified according to the following examples: pressed tile, GL (W148mm x 148mm) BIIIM15cmx15cm

6.2 BIS Certification

The tiles may also be marked with the Standard Mark.

13

IS 15622:2006

ANNEX

(Clause2)

LIST OF REFERRED

INDIAN STANDARD IS No. Title

Is No.

13630 (Part 1): 2006 (Part 2): 2006 (Part 3): 2006

Title

Ceramic tiles Methods test #lrst revision):

of

(Part 9): 2006

Determination of crazing resistance Glazed tiles (&t

revision)

Determination of dimensions and surface quality (first revision) Determination of water absorption and bulk density first revision) Determination of moisture expansion using boiling water Unglazed tiles @-st revision) Determination of linear thermal expansion @st revision) Determination of resistance to thermal shock @rst revision) Determination of modul~s of rupture and breaking strength (#irst

revision)

(Part 10): 2006

(Part 11) :2006

Determination of frost resistance

(jht revision)

Determination of resistance to surface abrasion Glazed tiles

@st revision)

(Part 12) :2006

(Part 4): 2006 (Part 5): 2006 (Part 6): 2006

Determination of resistance to deep abrasion Unglazed tiles

(jirst revision)

(Part 13) :2006

Determination of-scratch hardness of surface according to Mobs (lhst

revision)

(Part 14) :2006

(Part 7): 2006

Determination of chemical resistance Unglazed tiles (jlrst

revision)

(Part 15) :2006

(Part 8): 2006

Determination of chemical resistance Glazed tiles (jirst

revision)

13712)

Determination of impact resistance by measurement of coefficient of restitution Ceramic tiles Sampling and basis for acceptance (Superseding Is 13711 ; 1993) Ceramic tiles Definitions, classifications, characteristics and marking

1)Under Revision.

14

. Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote harmonious development of the activities of standardization, marking and quality certification of goods and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in any form without the prior permission in writing of BIS. This does not preclude the free use, in the course of implementing the standard, of necessary details, such as symbols and sizes, type or grade designations. Enquiries relating to copyright be addressed to the Director (Publications), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed periodically; a standard along with amendments is.reaffmed when such review indicates that no changes are needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of BIS Catalogue and Standards : Monthly Additions. This Indian Standard has been developed from

DOC : No.

CED 5 (7281).

Amendments

Issued Since Publication

Amend No.

Date of Issue

Text Affected

BUREAU OF INDIAN STANDARDS Headquarters : Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002 Telephones :23230131,23233375,2323 9402 Regional Offices : Central Eastern Northern Southern Western : Manak Bhavan, 9 Bahadur Shah Zafar Marg NEW DELHI 110002 : 1/14 C.I.T. Scheme VII M, V. L P. Road, Kankurgachi KOLKATA 700054 : SCO 335-336, Sector 34-A, CHANDIGARH 160022 : C.I.T. Campus, IV Cross Road, CHENNAI 600113 Manakalaya, E9 MIDC, Marol, Andheri (East) MUMBAI 400093 Telegrams : Manaksanstha (Common to all offices) Telephone 23237617 { 23233841 23378499,23378561 { 23378626,23379120 2603843 { 2609285 f225412 16,22541442 ~ 22542519,22542315 28329295, 28327858 { 28327891,2-8327892

Branches : AHMEDABAD. BANGALORE. BHC)PAL. BHUBANESHWAR. COIMBATORE. FARIDABAD. GHAZIABAD. GUWAHAT1. HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR. NALAGARH. PATNA. PUNE. RAJKOT. THIRUVANANTHAPURAM. VISAKHAPATNAM.

Printed at Frabhat Offset Press, New Delhi-2

Você também pode gostar

- IS 15622 (2006) - Pressed Ceramic TilesDocumento20 páginasIS 15622 (2006) - Pressed Ceramic TilesTAJAMULAinda não há avaliações

- Is 15622-2017Documento17 páginasIs 15622-2017Rohil Julaniya50% (6)

- Is 4457 2007 PDFDocumento27 páginasIs 4457 2007 PDFParameswaran MadhuAinda não há avaliações

- IS 1542 (1992): sand for plasterDocumento8 páginasIS 1542 (1992): sand for plasterkc_nk100% (1)

- Is 383 2016Documento22 páginasIs 383 2016Meena MurmuAinda não há avaliações

- Amendment No. 1 August 2017 TO Is 383: 2016 Coarse and Fine Aggregate For Concrete - SpecificationDocumento1 páginaAmendment No. 1 August 2017 TO Is 383: 2016 Coarse and Fine Aggregate For Concrete - Specificationpapia mandalAinda não há avaliações

- IRC-SP-49-1998 Guidelines For The Use of Dry Lean Concrete As Sub-Base For Rigid PavementDocumento17 páginasIRC-SP-49-1998 Guidelines For The Use of Dry Lean Concrete As Sub-Base For Rigid PavementDarshan Cr50% (2)

- Is:4926 RMCDocumento21 páginasIs:4926 RMCRamesh100% (7)

- Soil - Direct Shear Test (Is 2720 - P 13, 1986, Reaff.2011)Documento10 páginasSoil - Direct Shear Test (Is 2720 - P 13, 1986, Reaff.2011)siddhi jadhav0% (1)

- Is 12894: 1990Documento6 páginasIs 12894: 1990mukaslam100% (7)

- Is 2720 Part-4 Methods of Test For Soils Grain Size Analy.182155414Documento40 páginasIs 2720 Part-4 Methods of Test For Soils Grain Size Analy.182155414krityanand19900% (2)

- D 2041 D 2041M 11Documento4 páginasD 2041 D 2041M 11gadAinda não há avaliações

- Quality Control of Rigid Pavements 1Documento58 páginasQuality Control of Rigid Pavements 1pranjpatil100% (1)

- Coarse and Fine Aggregate ManualDocumento14 páginasCoarse and Fine Aggregate Manualjitender100% (1)

- IS 2185 (Part 1) 1979Documento27 páginasIS 2185 (Part 1) 1979manishparetaAinda não há avaliações

- Material Testing As Per Is CodesDocumento2 páginasMaterial Testing As Per Is Codesadityaratna gangji100% (1)

- Is 16715-2018 UggbsDocumento16 páginasIs 16715-2018 UggbsGayatry Bawane100% (1)

- PDFDocumento23 páginasPDFsaroiitmAinda não há avaliações

- Is 15388 (2003) - Specification For Silica FumeDocumento13 páginasIs 15388 (2003) - Specification For Silica FumeN GANESAMOORTHYAinda não há avaliações

- IS-1121 Part-1 Compressive StrengthDocumento8 páginasIS-1121 Part-1 Compressive StrengthSaurav KumarAinda não há avaliações

- Is 4990 2011 PDFDocumento20 páginasIs 4990 2011 PDFPratik DiyoraAinda não há avaliações

- Is:2386 1Documento22 páginasIs:2386 1Ramesh0% (1)

- Amendment No. 2 November 2019 TO Is 383: 2016 Coarse and Fine Aggregate For Concrete - SpecificationDocumento1 páginaAmendment No. 2 November 2019 TO Is 383: 2016 Coarse and Fine Aggregate For Concrete - Specificationpapia mandal100% (1)

- IRC:19-2005 Water Bound Macadam SpecificationsDocumento24 páginasIRC:19-2005 Water Bound Macadam SpecificationsJitendraceAinda não há avaliações

- DLC-Dry Lean Concrete Sub-base for Cement Concrete PavementDocumento14 páginasDLC-Dry Lean Concrete Sub-base for Cement Concrete PavementvijayAinda não há avaliações

- Is 456 Amendment 5Documento7 páginasIs 456 Amendment 5Shambu NathAinda não há avaliações

- Is 1786 A2Documento1 páginaIs 1786 A2sivaramAinda não há avaliações

- 6 Pavement Quality Concrete PPT by Deepak ThamanDocumento6 páginas6 Pavement Quality Concrete PPT by Deepak ThamanThaman Thaman100% (1)

- IS 15658 Amendment Adds TestsDocumento3 páginasIS 15658 Amendment Adds Testsraviteja036Ainda não há avaliações

- Eiffic/Efuf (T:, RFRDT (FrrtfuDocumento17 páginasEiffic/Efuf (T:, RFRDT (FrrtfuRamasubba RajuAinda não há avaliações

- PW .KR B Èku JK (K&Lhesav B V Fof'Kf"V: HKKJRH EkudDocumento11 páginasPW .KR B Èku JK (K&Lhesav B V Fof'Kf"V: HKKJRH EkudANMSAinda não há avaliações

- Appendix - 1800 - III (Sfgop-Tcipc)Documento8 páginasAppendix - 1800 - III (Sfgop-Tcipc)kvijayasok100% (1)

- 1786 4Documento2 páginas1786 4Indira BanerjeeAinda não há avaliações

- Is 4031 Part 6 - Compressive StrengthDocumento6 páginasIs 4031 Part 6 - Compressive Strengthbhustlero0o75% (4)

- 4031 - 4 Part 4 Determination of Consistency of Standard Cement PasteDocumento3 páginas4031 - 4 Part 4 Determination of Consistency of Standard Cement Pastevelmurug_balaAinda não há avaliações

- 1786 2012 New Ammendments PDFDocumento23 páginas1786 2012 New Ammendments PDFS RamakrishnaAinda não há avaliações

- Is 2547Documento11 páginasIs 2547Vivek GosaviAinda não há avaliações

- Marth 1800 PrestressingDocumento17 páginasMarth 1800 PrestressingRamesh100% (4)

- Paving Bitumen - Specification: Indian StandardDocumento2 páginasPaving Bitumen - Specification: Indian StandardDevela Avinash100% (1)

- Elastic RecoveryDocumento4 páginasElastic RecoverypdbAinda não há avaliações

- 516 2 1Documento16 páginas516 2 1Indira BanerjeeAinda não há avaliações

- IS 16014 - 2012 GabionDocumento13 páginasIS 16014 - 2012 GabionOM BIHARI SINGHAinda não há avaliações

- IS 10086 - 1982 (Reaff 1999)Documento23 páginasIS 10086 - 1982 (Reaff 1999)G.Ramesh100% (3)

- 3812 1 PDFDocumento14 páginas3812 1 PDFइंजि कौस्तुभ पवारAinda não há avaliações

- CPWD Waterproofing Specification PDFDocumento38 páginasCPWD Waterproofing Specification PDFManasAinda não há avaliações

- Is 10262-2019Documento44 páginasIs 10262-2019ਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟ96% (141)

- Casting of Mortar CubesDocumento2 páginasCasting of Mortar Cubeswajid100% (1)

- Is 7861 Part-II Code of Practice For Extreme Weather Concr.182114718Documento26 páginasIs 7861 Part-II Code of Practice For Extreme Weather Concr.182114718Neti N MurtyAinda não há avaliações

- 3495 1Documento8 páginas3495 1Suraj Vishwakarma67% (3)

- Is 15622 2006 PDFDocumento20 páginasIs 15622 2006 PDFPatel SumitAinda não há avaliações

- ÇSLM Fljkfed Vkbysa Fof'kf"v: HKKJRH EkudDocumento17 páginasÇSLM Fljkfed Vkbysa Fof'kf"v: HKKJRH EkudIndira MukherjeeAinda não há avaliações

- Determination of Shrinkage Stresses in CDocumento5 páginasDetermination of Shrinkage Stresses in CHaytham ElsayedAinda não há avaliações

- Is 13712 2006Documento10 páginasIs 13712 2006kavi_prakash6992Ainda não há avaliações

- Is 459Documento10 páginasIs 459AmbrishAinda não há avaliações

- ÇSLM Fljkfed Vkbysa Fof'kf"v: HKKJRH EkudDocumento17 páginasÇSLM Fljkfed Vkbysa Fof'kf"v: HKKJRH EkudAnshu TechAinda não há avaliações

- Is 1077 Common Burnt Clay Building BricksDocumento7 páginasIs 1077 Common Burnt Clay Building BricksKathiravan ManimegalaiAinda não há avaliações

- Is 654 1992 PDFDocumento14 páginasIs 654 1992 PDFmutton moonswamiAinda não há avaliações

- Disclosure To Promote The Right To InformationDocumento27 páginasDisclosure To Promote The Right To InformationBabin SaseendranAinda não há avaliações

- TEK - 01-01E ASTM Specifications For Concrete Masonry Units (7-2007)Documento4 páginasTEK - 01-01E ASTM Specifications For Concrete Masonry Units (7-2007)Ryan KuntzAinda não há avaliações

- Products, Glazing Techniques and Maintenance SECTION4 GGF Datasheet For The Quality of Thermally Toughened Soda Lime Silicate Safety Glass For Building PDFDocumento12 páginasProducts, Glazing Techniques and Maintenance SECTION4 GGF Datasheet For The Quality of Thermally Toughened Soda Lime Silicate Safety Glass For Building PDFgulilero_yoAinda não há avaliações

- Course StructureDocumento28 páginasCourse Structureravi03121Ainda não há avaliações

- Faqs About GST Goods and Services TaxDocumento12 páginasFaqs About GST Goods and Services TaxSachin SainiAinda não há avaliações

- Is.3861.2002 Method of Measurement of Plinth, Carpet and Rentable Areas of BuildingsDocumento10 páginasIs.3861.2002 Method of Measurement of Plinth, Carpet and Rentable Areas of Buildingsvijay2528Ainda não há avaliações

- SP-34-1987 Handbook On Reinforcement and DetailingDocumento286 páginasSP-34-1987 Handbook On Reinforcement and DetailingEr Prabhakara B88% (69)

- Basic Concepts in Nonlinear Dynamics and ChaosDocumento36 páginasBasic Concepts in Nonlinear Dynamics and Chaospperic13Ainda não há avaliações

- Project Profile On Fly Ash Bricks PDFDocumento2 páginasProject Profile On Fly Ash Bricks PDFArooshbabu BabuAinda não há avaliações

- Mangalore TilesDocumento14 páginasMangalore Tilesravi03121Ainda não há avaliações

- SP70Documento58 páginasSP70Pritesh Ramesh BareAinda não há avaliações

- SP16-Design Aid For RC To IS456-1978Documento252 páginasSP16-Design Aid For RC To IS456-1978sateeshsingh90% (20)

- Select Datum SpreadsheetDocumento14 páginasSelect Datum SpreadsheetlsatchithananthanAinda não há avaliações

- 800 KV TL DesignDocumento67 páginas800 KV TL Designravi0312150% (2)

- Lec 1Documento40 páginasLec 1Satyaprakash PrasadAinda não há avaliações

- 33kv Line Estimate & Trans Erec.Documento5 páginas33kv Line Estimate & Trans Erec.ravi03121Ainda não há avaliações

- Batching Plant CalculationDocumento1 páginaBatching Plant Calculationravi03121Ainda não há avaliações

- Land Acquisition Act 1894Documento56 páginasLand Acquisition Act 1894Umar HayatAinda não há avaliações

- Civil EnggDocumento54 páginasCivil Enggசுப.தமிழினியன்Ainda não há avaliações

- Hand Book Revised)Documento311 páginasHand Book Revised)ravi03121Ainda não há avaliações

- Nepal Final Energy Sector ScenarioDocumento51 páginasNepal Final Energy Sector Scenarioravi03121Ainda não há avaliações

- Department of Education Region IV-A Business Plan GuideDocumento4 páginasDepartment of Education Region IV-A Business Plan GuideSEAN DANIEL AGUARESAinda não há avaliações

- QY25K5-I Technical Specifications (SC8DK280Q3)Documento11 páginasQY25K5-I Technical Specifications (SC8DK280Q3)Everton Rai Pereira Feireira100% (1)

- Kevin Chiu - Solving Procrastination v1.1Documento2 páginasKevin Chiu - Solving Procrastination v1.1TêteHauteAinda não há avaliações

- Shadow The Hedgehog (Sonic Boom)Documento11 páginasShadow The Hedgehog (Sonic Boom)Tamajong Tamajong PhilipAinda não há avaliações

- Listening Script 11Documento11 páginasListening Script 11harshkumarbhallaAinda não há avaliações

- Azura Amid (Eds.) - Recombinant Enzymes - From Basic Science To Commercialization-Springer International Publishing (2015) PDFDocumento191 páginasAzura Amid (Eds.) - Recombinant Enzymes - From Basic Science To Commercialization-Springer International Publishing (2015) PDFnurul qAinda não há avaliações

- Chlor Rid SlidesDocumento47 páginasChlor Rid Slidesmohammed goudaAinda não há avaliações

- God in The Quran A Metaphysical StudyDocumento133 páginasGod in The Quran A Metaphysical StudyFaisal Ali Haider LahotiAinda não há avaliações

- Drive Test For BeginnerDocumento88 páginasDrive Test For Beginnerahwaz96100% (1)

- Clinical TeachingDocumento29 páginasClinical TeachingJeonoh Florida100% (2)

- 102DNDocumento2 páginas102DNManuel ZavalaAinda não há avaliações

- Sensor Guide: Standard Triaxial Geophones Specialty Triaxial Geophones Standard Overpressure MicrophonesDocumento1 páginaSensor Guide: Standard Triaxial Geophones Specialty Triaxial Geophones Standard Overpressure MicrophonesDennis Elias TaipeAinda não há avaliações

- Bicycle Repair ManualDocumento162 páginasBicycle Repair Manualrazvancc89% (9)

- GulliverDocumento8 páginasGulliverCris LuAinda não há avaliações

- Analisis Efektivitas Inklusi Keuangan Di BMT Syariah Riyal: PendahuluanDocumento25 páginasAnalisis Efektivitas Inklusi Keuangan Di BMT Syariah Riyal: PendahuluanEma Rina SafitriAinda não há avaliações

- FMBXXX Quick Manual v3.5Documento18 páginasFMBXXX Quick Manual v3.5AMAinda não há avaliações

- Chapter 2 Fanning EquationDocumento9 páginasChapter 2 Fanning EquationFaisal AyyazAinda não há avaliações

- A Study To Assess The Effectiveness of PDocumento9 páginasA Study To Assess The Effectiveness of PKamal JindalAinda não há avaliações

- Computer Vision: Chapter 5. SegmentationDocumento16 páginasComputer Vision: Chapter 5. SegmentationThịi ÁnhhAinda não há avaliações

- Educ 1301 Field Experience 1 ThielenDocumento4 páginasEduc 1301 Field Experience 1 Thielenapi-610903961Ainda não há avaliações

- LADY BroshureDocumento2 páginasLADY BroshureMcGabi GabrielAinda não há avaliações

- Methanol Technical Data Sheet FactsDocumento1 páginaMethanol Technical Data Sheet FactsmkgmotleyAinda não há avaliações

- 611k01 Kicatalog C Ka Us 1Documento8 páginas611k01 Kicatalog C Ka Us 1Ean LeeAinda não há avaliações

- BOQ Sample of Electrical DesignDocumento2 páginasBOQ Sample of Electrical DesignAshik Rahman RifatAinda não há avaliações

- ZSL National Red List of Nepal's Birds Volume 2Documento636 páginasZSL National Red List of Nepal's Birds Volume 2Tushita LamaAinda não há avaliações

- Dayal Bagh: Spircon 2013: Book of AbstractsDocumento202 páginasDayal Bagh: Spircon 2013: Book of AbstractsSant Mat100% (2)

- Carl Rogers, Otto Rank, and "The BeyondDocumento58 páginasCarl Rogers, Otto Rank, and "The BeyondAnca ElenaAinda não há avaliações

- Katja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)Documento383 páginasKatja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)MariaIoanaTelecan100% (1)

- Capacitor BanksDocumento49 páginasCapacitor BanksAmal P RaviAinda não há avaliações

- A Study On Financial Performance of Small and MediumDocumento9 páginasA Study On Financial Performance of Small and Mediumtakele petrosAinda não há avaliações