Escolar Documentos

Profissional Documentos

Cultura Documentos

Beams Tutorial Answers v3

Enviado por

berto2008Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Beams Tutorial Answers v3

Enviado por

berto2008Direitos autorais:

Formatos disponíveis

BEHAVIOUR AND DESIGN OF STRUCTURES 3

Title: Steel Beams Tutorial Solution

Date: 8 Jan 2009 Sheet: 1 Made by: MG

of 3

Checked:

LOADS Assume normal weight concrete Office loading Self-weight of slabs Assume SBs have self-weight of Assume PBs have self-weight of =25kN/m3 =2.5kN/m2 =2kN/m2 =0.5kN/m =0.6kN/m =1.35 =1.5 Table A1 Table NA.3

=25*0.08

Partial safety factor on permanent actions, G Partial safety factor on variable actions, Q Each SB produces a point load on each PB of (1.5*2.5*4*3)+(1.35*2*4*3)+(1.35*3*0.5) Self-weight of PB produces a UDL of (1.35*0.6) Shear transmitted to each column =[(0.81*12)+(2*79.4)]/2 Peak bending moment =84.6*6-79.4*2-6*0.81*3 SF and BM diagrams as below V

84.6kN

Table NA1.2(B)

=79.4kN

=0.81kN/m =84.6kN =334.2kNm

84.6kN

331.9kNm

334.2kNm

331.9kNm

BM

BEHAVIOUR AND DESIGN OF STRUCTURES 3

Title: Steel Beams Tutorial Solution

Date: 8 Jan 2009 Sheet: 2 Made by: MG

of 3

Checked:

Assume S275 steel Required plastic section modulus, Wp, =(334.2*1000*100)/(275*100) Try 406*178*67UB with Wp=1346cm3 SECTION CAPACITY CHECKS Section classification Note: Section data from Steel Designers Manual 1994, data from newer tables may differ a little. Depth of web, cw, Thickness of web, tw, Outstand of flange, cf, Thickness of flange, tf Web classification: Flange classification =(235/275) =178.8/2-8.8/2-10.2 =0.92 =360.4mm =8.8mm =74.8mm =14.3mm Table 5.2 =1215cm3

cw/tw=360.4/8.8 =41 Limit for Class 1 cw/tw<72=66.53 therefore Class 1Table 5.2 cf/tf=74.8/14.3 =5.2 Limit for Class 1 cw/tw<9=8.32 therefore Class 1 Both flange and web Class 1 therefore section Class 1

5.5.2(6)

Bending Capacity Check bending capacity at mid-span m0 p3-34 Section modulus, Wpl Section moment capacity, Mc,Rd =Wplfy/ m0=(1346*275)/(1*1000) Design moment , MEd =1.0 =1346cm3 =370.0kNm =334.2kNm NA. 2.15 Eqn. 6.13 Eqn. 6.12

Mc,Ed/Mc,Rd=0.91 therefore section adequate in bending Shear Capacity Check shear capacity at supports Shear area = for simplicity take 85.5*102-2*178.8*14.3 =3436mm2 Shear capacity, Vpl,Rd =3009*(275/3)/1 =575kN

6.2.6(3)a Eqn. 6.18

BEHAVIOUR AND DESIGN OF STRUCTURES 3

Title: Steel Beams Tutorial Solution

Date: 8 Jan 2009 Sheet: 3 Made by: MG

of 3

Checked:

Design shear, VEd VEd/Vpl,Rd=0.15 therefore section adequate in shear

=82.5kN Eqn. 6.17

Bending and Shear Check combined bending and shear capacity at points where secondary beams join the primary beam Shear force less than half the plastic shear resistance therefore can be neglected. Lateral-Torsional Buckling Assume secondary beams provide lateral restraint at 4m intervals and that the floor system does not provide restraint. Then use 6.3.2.4 to check for L-T buckling. Section modulus, Wy Mc,Rd Mc,Ed I of flange +1/3 web A of flange +1/3 web Radius of gyration of, ifz Correction factor, kc Slenderness limit, c 0 Lc L Comp. flange sness, f Class 1, therefore plastic section modulus As above Mid-span design moment [(360.4/3*8.83)+(14.3*178.83)]/(12*104) [(360.4/3*8.8)+(14.3*178.8)]/102 (I/A) =(681/36) take linear moment in central span conservatively take worst case =1346cm3 6.3.2.4(1)B =370.0kNm =334.2kNm =681cm4 =36cm2 =4.3cm 6.3.2.4(1)B =1 Table 6.6 =0.4 =(E/fy)= =(1*4)/(0.043*86.8) =1.07 =0.4 =4m =86.8 NA2.19 6.3.2.4(1)B

6.2.8(2)

c 0 * Mc,Rd/ Mc,Ed=0.4

Therefore beam fails in buckling.

To prevent this failure use a larger section or provide additional lateral restraint at, say 1.5m intervals, perhaps via the floor system.

Você também pode gostar

- 7 Steps To Developing An Agile Marketing Team Wrike EbookDocumento17 páginas7 Steps To Developing An Agile Marketing Team Wrike Ebookberto2008Ainda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Worked Examples To Eurocode 2Documento165 páginasWorked Examples To Eurocode 2amin6693225097% (30)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- En 15620 Steel Static Storage Systems - Adjustable Pallet Racking - Tolerances, Deformations and ClearancesDocumento76 páginasEn 15620 Steel Static Storage Systems - Adjustable Pallet Racking - Tolerances, Deformations and ClearancesPaul Costan92% (12)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- En 15095-2007+a1 (2008)Documento45 páginasEn 15095-2007+a1 (2008)berto2008Ainda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- En 15629 (2008)Documento35 páginasEn 15629 (2008)berto2008100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Simple Column Design ExampleDocumento5 páginasSimple Column Design Exampleberto2008Ainda não há avaliações

- Connections Tutorial: Behaviour and Design of Structures 3Documento1 páginaConnections Tutorial: Behaviour and Design of Structures 3berto20080% (1)

- Steel Desing To Eurocode 3Documento2 páginasSteel Desing To Eurocode 3Jonp4ul_MiddletonAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Reinforced Concrete Column by Zinab EC2Documento15 páginasReinforced Concrete Column by Zinab EC2berto2008Ainda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Nominal MomentsDocumento2 páginasNominal Momentsberto2008Ainda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- LT Buckling Beam Design - Simple Method - 2upDocumento5 páginasLT Buckling Beam Design - Simple Method - 2upberto2008Ainda não há avaliações

- Steel Beam DesignDocumento39 páginasSteel Beam Designberto2008Ainda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Effective LengthsDocumento8 páginasEffective Lengthsberto2008Ainda não há avaliações

- Columns Tutorial: Behaviour and Design of Structures 3Documento1 páginaColumns Tutorial: Behaviour and Design of Structures 3berto2008Ainda não há avaliações

- Steel Beams TutorialDocumento1 páginaSteel Beams Tutorialberto2008Ainda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Column Sizing Chart PDFDocumento7 páginasColumn Sizing Chart PDFberto2008Ainda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Design Charts For Composite Beams 2upDocumento3 páginasDesign Charts For Composite Beams 2upberto2008Ainda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Outline Steel Design SpreadsheetDocumento22 páginasOutline Steel Design Spreadsheetberto2008Ainda não há avaliações

- Wind Load For CubaDocumento7 páginasWind Load For Cubaberto2008Ainda não há avaliações

- Fatigue Assessment of Concrete Bridges - Euro Norms: Ravindra Kumar GoelDocumento9 páginasFatigue Assessment of Concrete Bridges - Euro Norms: Ravindra Kumar Goelberto2008Ainda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- 528-Volume 2 Part II - MEP SpecificationsDocumento270 páginas528-Volume 2 Part II - MEP SpecificationsSharique BaigAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Shelco 4FOS 5FOS Housings1Documento2 páginasShelco 4FOS 5FOS Housings1ramonmzaAinda não há avaliações

- John and Rebecca Arioto 12-13-17Documento24 páginasJohn and Rebecca Arioto 12-13-17L. A. PatersonAinda não há avaliações

- HF 725 Series: in Line High Pressure FiltersDocumento16 páginasHF 725 Series: in Line High Pressure FilterssitnikovsAinda não há avaliações

- Preliminary Detailed Cost Estimate Checklist1 PDFDocumento5 páginasPreliminary Detailed Cost Estimate Checklist1 PDFRehan HamidAinda não há avaliações

- Plastic Mould SteelDocumento20 páginasPlastic Mould SteeldocumentosvaltierraAinda não há avaliações

- Moment Calculations - CORRECTDocumento5 páginasMoment Calculations - CORRECTBipul PoudelAinda não há avaliações

- Exam MMUP TotalDocumento11 páginasExam MMUP TotalTariq AtiyahAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- LT Gate Globe Check Valves Api 602Documento12 páginasLT Gate Globe Check Valves Api 602Krunal MahidadiaAinda não há avaliações

- Door Sealing Systems: Product CatalogueDocumento184 páginasDoor Sealing Systems: Product CatalogueFábio AndréAinda não há avaliações

- "Fiberglass!", "Why Does It Always Have To Be Fiberglass?": Fiberglass Work in Seven Easy StepsDocumento15 páginas"Fiberglass!", "Why Does It Always Have To Be Fiberglass?": Fiberglass Work in Seven Easy StepsEsnayder Nova CastellanosAinda não há avaliações

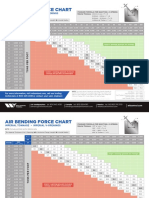

- Air Bend Force ChartDocumento2 páginasAir Bend Force ChartLorenz Joseph PalmaAinda não há avaliações

- CED13 - Building Construction PracticesDocumento5 páginasCED13 - Building Construction PracticesAmanulla KhanAinda não há avaliações

- Development and Characterisation of Multi-Layered Jute Fabric-Reinforced HDPE CompositesDocumento15 páginasDevelopment and Characterisation of Multi-Layered Jute Fabric-Reinforced HDPE Compositesabilio_j_vieiraAinda não há avaliações

- 11-14%Cr IIW Document - Part 2Documento21 páginas11-14%Cr IIW Document - Part 2GagrigoreAinda não há avaliações

- Oguni DomeDocumento5 páginasOguni DomeShubham PatidarAinda não há avaliações

- Home Download Alex Weir Gnuveau - NetworksDocumento9 páginasHome Download Alex Weir Gnuveau - NetworksLungmuaNa RanteAinda não há avaliações

- Composite Deck DesignDocumento16 páginasComposite Deck Designvejanidb100% (1)

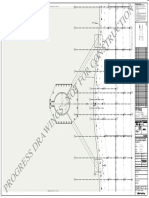

- S-T1-424-F1-2004 - Framing Plan Level B1 Sheet 004Documento1 páginaS-T1-424-F1-2004 - Framing Plan Level B1 Sheet 004Marco ReyesAinda não há avaliações

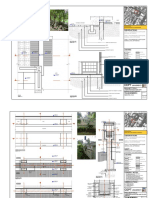

- Observations:: Residential Navyug Society, AhmedabadDocumento5 páginasObservations:: Residential Navyug Society, AhmedabadRavnish BatthAinda não há avaliações

- Emergency Estimate $72,590.61Documento19 páginasEmergency Estimate $72,590.61Corporate OfficeAinda não há avaliações

- Fit-Up Piping B192-5-S2Documento22 páginasFit-Up Piping B192-5-S2Prathamesh OmtechAinda não há avaliações

- Design For NSF by Harry PoulosDocumento7 páginasDesign For NSF by Harry PoulosSantosoAinda não há avaliações

- AE2354 Htm2marksDocumento13 páginasAE2354 Htm2marksrenjithrenjuAinda não há avaliações

- Jabal Al Ka'Aba BOQ ModifiedDocumento81 páginasJabal Al Ka'Aba BOQ ModifiedJaime Manalili Landingin50% (2)

- Foundation Substructure CodeDocumento64 páginasFoundation Substructure CodeDeven PatleAinda não há avaliações

- Final PPT LITRACONDocumento15 páginasFinal PPT LITRACONRAmyaAinda não há avaliações

- HVAC TestDocumento5 páginasHVAC TestFaizal Achmad100% (1)

- PSG Design Data Book Me6503 Design of Machine ElementspdfDocumento30 páginasPSG Design Data Book Me6503 Design of Machine Elementspdfhaseena beeAinda não há avaliações

- Adams Rite 4612-1SCDocumento1 páginaAdams Rite 4612-1SCrodney_massieAinda não há avaliações