Escolar Documentos

Profissional Documentos

Cultura Documentos

(A) Transformer Specification Sheet

Enviado por

Pranay KharbeTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

(A) Transformer Specification Sheet

Enviado por

Pranay KharbeDireitos autorais:

Formatos disponíveis

Transformer Specification Sheet

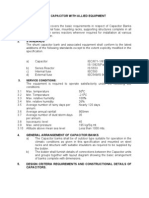

Hermetically sealed, step up transformers for mounting within a Compact Sub Station (which will house the MV & LV switchgear and transformer), with the following specifications.

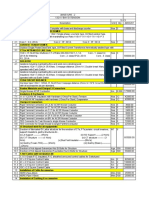

Preliminary Information 1 2 3 4 Name of Manufacturer Service Rating,KVA ONAN Rated no load voltage a) HV,kv b) LV,kv Temperature rise Oil / Winding (over ambient 50oC) Number of phases / Frequency Vector Group reference a) HV connection b) LV connection Insulation Level Impulse / PF withstand HV/LV Terminal arrangement,HV/LV Taps on winding a) Off ckt./ On Load b) Tapping range c) No. of steps Performance figures a) No load loss, KW b) Load loss, KW c)Impedance,% Accessories to be provided Rating & diagram plate Earthing terminals Lifting lugs Bottom filter cum drain valve with plug Top filter valve with plug Pulling lugs Flat rollers Pressure relief device (Spring Operated) Cover lifting lugs Oil level indicator (Prismatic Type) First filling of transformer oil PECON make oil and winding temperature relay (Cat no. TR-7551-C) with RS 485 port for remote monitoring, as well as 4-20mA output. Danish Pvt. Ltd. Hermetically Sealed Indoor type for CSS 1250 20 0.415 50OC/55OC 3 / 50Hz Ynd11 Star Delta 125 / 50 / 3 KV Bare Bushings / Palm Connectors Off circuit +5% To -5% +5%, +2.5%, 0, -2.5%, -5% 2.10KW 12.2KW 5.00

5 6 7

8 9 10

11

12

13

Tests to be carried out on Transformers Measurement of winding resistances Load loss and short circuit impedance measurements Separate source voltage withstand test Transformation ratio measurement and connection checking No load loss and current measurements Induced over voltage withstand test Magnetic balance test

(A) Routine Test Will be carried out on all Transformers and client can witness them, if required , free of charge.

(B)

Type Test Will be carried out in the presence of the Client on one transformer, at extra cost.

Temperature rise test

Note: 1. All parameters like losses, percentage impedance and temperature rise will be subject to IEC tolerances. Transformers which exceed these tolerances will be rejected. 2. The oil used for the transformers will be of SHELL, NYNAS or APAR makes only.

Doc. No:-PKG/CSS-TS/1250/20-0.415KV/001

Você também pode gostar

- Electrical Boq for Sulphuric Handling at EnclosureDocumento2 páginasElectrical Boq for Sulphuric Handling at EnclosureKrishAinda não há avaliações

- Annex 1 - Technical SpecificationsDocumento197 páginasAnnex 1 - Technical SpecificationsmanojAinda não há avaliações

- Precommissioning Procedures of Testing & CommissioningDocumento96 páginasPrecommissioning Procedures of Testing & CommissioningTasawar Hussain85% (34)

- Inspection of TransformersDocumento17 páginasInspection of Transformerssbpathi50% (2)

- Transformer Specification - GTP (25MVA)Documento1 páginaTransformer Specification - GTP (25MVA)SathishAinda não há avaliações

- Moulded Case Circuit Breakers Product HighlightsDocumento56 páginasMoulded Case Circuit Breakers Product HighlightsAmit NagAinda não há avaliações

- Data Sheet - Rev.0Documento4 páginasData Sheet - Rev.0mahesh reddy mAinda não há avaliações

- Lightning Arresters Sl. No. Description Lightning Arresters: Peak Peak PeakDocumento3 páginasLightning Arresters Sl. No. Description Lightning Arresters: Peak Peak PeakAnil MarturiAinda não há avaliações

- Cable Installation Notes - GeneralDocumento6 páginasCable Installation Notes - GeneralraghvendraAinda não há avaliações

- Battery Sizing CalculationDocumento3 páginasBattery Sizing CalculationBelos SahajiAinda não há avaliações

- 33KV Switchboard Panel DetailsDocumento3 páginas33KV Switchboard Panel DetailsArunava Basak100% (1)

- PLCC Tech SpecsDocumento42 páginasPLCC Tech Specsevonik123456Ainda não há avaliações

- BUS BAR Sizing CalculationDocumento2 páginasBUS BAR Sizing Calculationmohan babuAinda não há avaliações

- Baranagar-TSS Relay Test ReportDocumento75 páginasBaranagar-TSS Relay Test ReportHari haranAinda não há avaliações

- GTP Inverter Transformer Rev 02Documento5 páginasGTP Inverter Transformer Rev 02Jaks JaksAinda não há avaliações

- Is:1239 Part 1 - Mild Steel Tube PipeDocumento17 páginasIs:1239 Part 1 - Mild Steel Tube PipeRathnakar Naik86% (36)

- Relay Setting Calculation-NPC-Yas152Documento15 páginasRelay Setting Calculation-NPC-Yas152মোঃ মহসিনAinda não há avaliações

- IMPORTANT QUESTION IN ELECTRICAL ENGG FOR ASSISTANT ENGINEER EXAMS OF UPRVUNL, UPPCL, MPPKVVNL, HPPSC, IES, GATE and Other State Psus.Documento223 páginasIMPORTANT QUESTION IN ELECTRICAL ENGG FOR ASSISTANT ENGINEER EXAMS OF UPRVUNL, UPPCL, MPPKVVNL, HPPSC, IES, GATE and Other State Psus.Rishi Kant Sharma100% (1)

- Record PlusDocumento250 páginasRecord PlusDixie VictoriaAinda não há avaliações

- Annexure 2Documento2 páginasAnnexure 2Anoop DamodaranAinda não há avaliações

- BS en 1092Documento21 páginasBS en 1092Pranay Kharbe100% (5)

- BS en 1092Documento21 páginasBS en 1092Pranay Kharbe100% (5)

- REC Construction Standards: Name of The SpecificationDocumento9 páginasREC Construction Standards: Name of The SpecificationJasmin ShethAinda não há avaliações

- 9.6MVA - Technical Specifications For Inverter Duty TransformerDocumento7 páginas9.6MVA - Technical Specifications For Inverter Duty Transformerarunghandwal100% (2)

- Calculatin For Voltage Drop ¤t MV CircuitDocumento9 páginasCalculatin For Voltage Drop ¤t MV CircuitSatyaAinda não há avaliações

- 11KV VCBDocumento3 páginas11KV VCBeagles1109Ainda não há avaliações

- Transformer stability test for differential and REF protectionDocumento2 páginasTransformer stability test for differential and REF protectionykh92167Ainda não há avaliações

- GTP - 33KV (E) 3C AL XLPE Armd CableDocumento1 páginaGTP - 33KV (E) 3C AL XLPE Armd Cableshivam dwivediAinda não há avaliações

- GTP For TransformerDocumento5 páginasGTP For TransformerSatheesh Kumar NatarajanAinda não há avaliações

- VR La Batterie Edited 15Documento8 páginasVR La Batterie Edited 15SOMU_61Ainda não há avaliações

- 220-132kV Power and Control Cable Schedule - Dhalkebar With CommentDocumento53 páginas220-132kV Power and Control Cable Schedule - Dhalkebar With CommentmanishAinda não há avaliações

- Perkins Fans&BlowersDocumento12 páginasPerkins Fans&BlowersPranay KharbeAinda não há avaliações

- 2240 162 Pve U 004 SHT 3 3 01Documento13 páginas2240 162 Pve U 004 SHT 3 3 01Anagha DebAinda não há avaliações

- Pilot Cable Specs FewaDocumento13 páginasPilot Cable Specs Fewabharat_22nandulaAinda não há avaliações

- GTP 63 Mva - R0 FinalDocumento10 páginasGTP 63 Mva - R0 FinalmidhunvarAinda não há avaliações

- CBIP SPEC For 420 KV Class TransformerDocumento11 páginasCBIP SPEC For 420 KV Class TransformerRejith MuraleeAinda não há avaliações

- Commissioning of DAVRDocumento70 páginasCommissioning of DAVRPMG Bhuswal Project100% (1)

- Tech. Specifications On Power TransformerDocumento2 páginasTech. Specifications On Power Transformershine1975Ainda não há avaliações

- Busbar Sizing of MCCDocumento1 páginaBusbar Sizing of MCCrukmagoudAinda não há avaliações

- BHEL 11kV VCB specificationDocumento6 páginasBHEL 11kV VCB specificationSHAJAHANAinda não há avaliações

- A. Wound Type:: 1. What Are The Types of CT? Example?Documento8 páginasA. Wound Type:: 1. What Are The Types of CT? Example?deltavijayakumarAinda não há avaliações

- 850 KVAR 400v.doc - 400V Capacitor Bank - SpecDocumento10 páginas850 KVAR 400v.doc - 400V Capacitor Bank - Specdeepthik27Ainda não há avaliações

- Bistable Relays RXMVB 2 and RXMVB 4Documento5 páginasBistable Relays RXMVB 2 and RXMVB 4Angie LeónAinda não há avaliações

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsAinda não há avaliações

- Auxiliary Transformer DatasheetDocumento3 páginasAuxiliary Transformer DatasheetRigoberto UrrutiaAinda não há avaliações

- 8.I-11 KV Xlpe CablesDocumento5 páginas8.I-11 KV Xlpe CablesAnkur SinhaAinda não há avaliações

- GTP BatteryDocumento17 páginasGTP Batteryraj_stuff006Ainda não há avaliações

- 33 KV Outdoor VCB Pv1750bDocumento4 páginas33 KV Outdoor VCB Pv1750bAnoop Kumar PandayAinda não há avaliações

- CT TestingDocumento8 páginasCT TestingsankalptiwariAinda não há avaliações

- 6 +acsr+zebra+conductorDocumento17 páginas6 +acsr+zebra+conductorBagusIrawanSaputraAinda não há avaliações

- Transformer DSDocumento4 páginasTransformer DSjuliyet vAinda não há avaliações

- 03HYUNDAI Intelligent Preventative Diagnostic System (HiPDS)Documento12 páginas03HYUNDAI Intelligent Preventative Diagnostic System (HiPDS)juliancansenAinda não há avaliações

- Over Current & Earth Fault Relay-Type Vn100R: FeaturesDocumento4 páginasOver Current & Earth Fault Relay-Type Vn100R: Featuressujan723Ainda não há avaliações

- Hence To Keep The CT Burden Lower, CT With 1A Secondary Is PreferableDocumento1 páginaHence To Keep The CT Burden Lower, CT With 1A Secondary Is PreferableAjay PatilAinda não há avaliações

- Substation 220 KVDocumento1 páginaSubstation 220 KVrahulkudlu0% (1)

- Technical Data Sheet - 250kva TransformersDocumento2 páginasTechnical Data Sheet - 250kva TransformerspavanAinda não há avaliações

- JD-132-QA-E41-01 - TUBE SIZING 50 DGRDocumento14 páginasJD-132-QA-E41-01 - TUBE SIZING 50 DGRRami The OneAinda não há avaliações

- 220KV Line - 2 P444Documento5 páginas220KV Line - 2 P444JayamkondanAinda não há avaliações

- 6 6 KV APFC Panel SpecificationDocumento8 páginas6 6 KV APFC Panel Specificationjoydeep_d3232Ainda não há avaliações

- 33kv Capacitor With Allied EquipmentDocumento9 páginas33kv Capacitor With Allied EquipmentsbpathiAinda não há avaliações

- 32/7 kV yard componentsDocumento31 páginas32/7 kV yard componentsHarsh TanwarAinda não há avaliações

- TS PHIIR Part2Documento186 páginasTS PHIIR Part2Soumya SahooAinda não há avaliações

- Technical Submittal 1000kVA PAECDocumento9 páginasTechnical Submittal 1000kVA PAECGhilman HabibAinda não há avaliações

- Distribution Transformer Training: Specs, Design, Testing & MaintenanceDocumento51 páginasDistribution Transformer Training: Specs, Design, Testing & MaintenanceAnonymous hWRGcOe4X100% (2)

- Sabah ScheduleDocumento12 páginasSabah ScheduleLee RoAinda não há avaliações

- MCT 3Documento1 páginaMCT 3Pranay KharbeAinda não há avaliações

- Car Ent CatalogueDocumento21 páginasCar Ent CataloguePranay KharbeAinda não há avaliações

- Locations ServicesDocumento3 páginasLocations ServicesszabeeAinda não há avaliações

- Mathematics Notes PDFDocumento89 páginasMathematics Notes PDFbalarajeAinda não há avaliações

- Name Plate Title Block PDFDocumento1 páginaName Plate Title Block PDFPranay KharbeAinda não há avaliações

- Project ManagementDocumento2 páginasProject ManagementAmmiraju ChoudharyAinda não há avaliações

- Free and Public DNS Server List (Updated June 2015)Documento6 páginasFree and Public DNS Server List (Updated June 2015)Pranay KharbeAinda não há avaliações

- PCMC B - ZoneDocumento1 páginaPCMC B - ZonePranay KharbeAinda não há avaliações

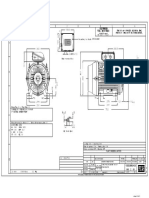

- Name Plate WEG-w22 PDFDocumento1 páginaName Plate WEG-w22 PDFPranay KharbeAinda não há avaliações

- Sec 144 8-05screen PDFDocumento9 páginasSec 144 8-05screen PDFPranay KharbeAinda não há avaliações

- Trolley SpecificationsDocumento1 páginaTrolley SpecificationsPranay KharbeAinda não há avaliações

- Scan 0023Documento16 páginasScan 0023Pranay KharbeAinda não há avaliações

- Name Plate Title BlockDocumento1 páginaName Plate Title BlockPranay KharbeAinda não há avaliações

- Thermal Performance and Nameplate Details of WEG Electric MotorsDocumento1 páginaThermal Performance and Nameplate Details of WEG Electric MotorsPranay KharbeAinda não há avaliações

- DetailsDocumento1 páginaDetailsPranay KharbeAinda não há avaliações

- GHGDocumento88 páginasGHGPranay KharbeAinda não há avaliações

- BITS Pilani WILP List of Textbooks 1-2014Documento8 páginasBITS Pilani WILP List of Textbooks 1-2014Vipul GoyalAinda não há avaliações

- 70 1012 CDocumento1 página70 1012 CPranay KharbeAinda não há avaliações

- ACB MVS CatalougeDocumento59 páginasACB MVS CatalougePranay KharbeAinda não há avaliações

- 1250GAS GA Cogen-ModelDocumento1 página1250GAS GA Cogen-ModelPranay KharbeAinda não há avaliações

- Movie ListDocumento1 páginaMovie ListPranay KharbeAinda não há avaliações

- Higher Algebra - Hall & KnightDocumento593 páginasHigher Algebra - Hall & KnightRam Gollamudi100% (2)