Escolar Documentos

Profissional Documentos

Cultura Documentos

Kiln Inlet Lamella Seal FLS

Enviado por

amir100%(3)100% acharam este documento útil (3 votos)

2K visualizações2 páginasThe Inlet Lamella Seal consists of two sets of spring steel lamellae. A layer of heatresistant fabric is positioned between the two sets. To prevent overheating, a separate fan delivers cooling air to the space between the kiln shell and the cooling mantle.

Descrição original:

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThe Inlet Lamella Seal consists of two sets of spring steel lamellae. A layer of heatresistant fabric is positioned between the two sets. To prevent overheating, a separate fan delivers cooling air to the space between the kiln shell and the cooling mantle.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(3)100% acharam este documento útil (3 votos)

2K visualizações2 páginasKiln Inlet Lamella Seal FLS

Enviado por

amirThe Inlet Lamella Seal consists of two sets of spring steel lamellae. A layer of heatresistant fabric is positioned between the two sets. To prevent overheating, a separate fan delivers cooling air to the space between the kiln shell and the cooling mantle.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

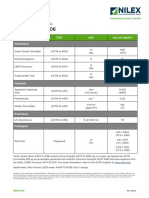

Kiln Inlet

Lamella Seal

Some of the advantages of

FLS Kiln Inlet Lamella Seals

• Extremely flexible Sealing between

kiln and prehealer

• Independent of kiln rotation

• Insulation incorporated to protect the

lamella spring effect

• Scoop arrangement included

• Rapid and easy maintenance

• High-rated, secure sealing effect

• Straightforward Installation even on

non-FLS equipment

• 10,000 - 20,000 service hours for wear parts

(dependent on the process conditions)

Parts & Services

Division

Kiln Inlet

Lamella Seal

The FLS Kiln Inlet Lamella Seal is

superior to the traditional

pneumatic seal because of its

modern, rugged design and

construction.

The inlet lamella seal consists

of two sets of spring steel

lamellae with a layer of heat-

resistant fabric positioned

between the two sets of

lamellae. Between the inner and

outer lamellae, a layer of heat-

resistant fabric is positioned to

protect the outer set of lamellae and

enable them to maintain their

resilience. This spring effect forces the

inner set of lamellae against the cooling

mantle and provides a seal.

To prevent overheating of the kiln shell and sealing

parts, a separate fan delivers cooling air to the

space between the kiln shell and the cooling

mantle. It also supplies air to the cooling air

chamber, which cools down the shell surface of the

kiln riser transition piece.

If back spillage occurs, the scooping system (a

system of open scoops made of heat-resistant steel)

collects the spillage in the bottom of the scooping

chamber and, as the kiln rotates, lifts it and returns

it to the kiln. In the smoke chamber, the exit gases

will suspend the spillage and carry it up into the

kiln riser pipe.

Inlet Lamella Seal

Inlet Lamella Seal

F.L.Smidth & Co. A/S Vigerslev Allé 77 - DK - 2500 Valby Denmark

l

Phone: +45 36 18 10 00 Fax: +45 36 44 11 19 e-mail: psd@flsmidth.com website: http://www.flsmidth.com

l l l

Você também pode gostar

- Cooler ETA Vs Grate JG (Documento39 páginasCooler ETA Vs Grate JG (NaelAinda não há avaliações

- Kiln Mechanics - (4.1) - ''Action Plan''Documento5 páginasKiln Mechanics - (4.1) - ''Action Plan''Diego AlejandroAinda não há avaliações

- What To Do When A Kiln Tire Stops MigratingDocumento16 páginasWhat To Do When A Kiln Tire Stops MigratingVisnu Sankar100% (3)

- KILN TechnicalDocumento37 páginasKILN TechnicalVisnu SankarAinda não há avaliações

- Co Processing Cement KilnsDocumento10 páginasCo Processing Cement Kilnshanhccid0% (1)

- Hydraulic Thrust DeviceDocumento2 páginasHydraulic Thrust DeviceAlbar Budiman100% (6)

- Rotary Inclinometer Product DescriptionDocumento8 páginasRotary Inclinometer Product DescriptionfetniAinda não há avaliações

- ILC SLC-D Kiln SystemDocumento45 páginasILC SLC-D Kiln SystemAndris Risyat100% (1)

- Clinker Coolers Part 1 & 2 96dpiDocumento246 páginasClinker Coolers Part 1 & 2 96dpigustavo50% (2)

- Kiln Control UnicemfinalDocumento26 páginasKiln Control UnicemfinalOUSSAMA LAKHILI100% (1)

- MHR21924 CMC Chapter CCDocumento48 páginasMHR21924 CMC Chapter CCDede KaladriAinda não há avaliações

- Clinker Coolers PDFDocumento22 páginasClinker Coolers PDFAhmed AwadAinda não há avaliações

- 10 Golden Rules For Clinker Burning - INFINITY FOR CEMENT EQUIPMENT PDFDocumento15 páginas10 Golden Rules For Clinker Burning - INFINITY FOR CEMENT EQUIPMENT PDFNahro AdnanAinda não há avaliações

- Repair and Maintenance: CoolerDocumento61 páginasRepair and Maintenance: CoolerYhaneAinda não há avaliações

- Kiln Mechanics - (1.4) - ''Quizz Practices''Documento7 páginasKiln Mechanics - (1.4) - ''Quizz Practices''Diego AlejandroAinda não há avaliações

- Kilns Khaled PDFDocumento16 páginasKilns Khaled PDFbulentbulut100% (1)

- 7holcim PDFDocumento41 páginas7holcim PDFbulentbulut100% (2)

- Kiln Doctor FAQDocumento3 páginasKiln Doctor FAQgvrr1954Ainda não há avaliações

- Cement Kiln DustDocumento36 páginasCement Kiln DustjagrutAinda não há avaliações

- Clinker CoolersDocumento74 páginasClinker CoolersMuhammed EmamiAinda não há avaliações

- Kiln LiningDocumento39 páginasKiln LiningMUNNALURU UMAKANTHA RAO100% (1)

- 1 Exemplary Technical Report 2012Documento99 páginas1 Exemplary Technical Report 2012MKPashaPashaAinda não há avaliações

- Snowman FormationDocumento1 páginaSnowman FormationKEERTHI INDUSTRIES100% (1)

- Kiln Migration and Its Effect On Brick LiningDocumento3 páginasKiln Migration and Its Effect On Brick LiningJunaid Mazhar100% (2)

- D3 2 100701 Kiln Mec Behav Patroller PDFDocumento30 páginasD3 2 100701 Kiln Mec Behav Patroller PDFbulentbulut100% (3)

- Rueddenklau Snowman PreventionDocumento102 páginasRueddenklau Snowman PreventionIonela Dorobantu100% (2)

- Operation of The Kiln Line: TrainingDocumento32 páginasOperation of The Kiln Line: TraininglafecapoAinda não há avaliações

- Rotary Kiln Reconditioning Tyre and Roller GrindingDocumento8 páginasRotary Kiln Reconditioning Tyre and Roller GrindingTiago CamposAinda não há avaliações

- ETA Inspection and Maintanance - ETA 10+15 - Rev - 09 - 09Documento66 páginasETA Inspection and Maintanance - ETA 10+15 - Rev - 09 - 09serkalemtAinda não há avaliações

- 3 Calciner Technology 105 MinutesDocumento29 páginas3 Calciner Technology 105 MinutesIrshad HussainAinda não há avaliações

- Cement Kiln Dust CKD Methods For ReductioDocumento21 páginasCement Kiln Dust CKD Methods For ReductiofaheemqcAinda não há avaliações

- Combined PDF Courses Outlines A&E 2011Documento47 páginasCombined PDF Courses Outlines A&E 2011emad sabriAinda não há avaliações

- Kiln Trouble ShootingDocumento3 páginasKiln Trouble Shootingemad sabriAinda não há avaliações

- Kiln Preheater Fan CoatingDocumento6 páginasKiln Preheater Fan CoatingVijay Bhan100% (1)

- Pyro ProcessingDocumento29 páginasPyro ProcessingMKPashaPasha100% (2)

- Rotary Kilns For Cement PlantsDocumento6 páginasRotary Kilns For Cement PlantsAngshuman Dutta100% (3)

- Kiln Mechanics 222222Documento59 páginasKiln Mechanics 222222Said EL FakkoussiAinda não há avaliações

- Calciner Technology in AF Firing PDFDocumento22 páginasCalciner Technology in AF Firing PDFJohn GiannakopoulosAinda não há avaliações

- FK PumpDocumento29 páginasFK PumpPP2 Common ID/OperationAinda não há avaliações

- Phillips Kiln Kiln Alignment Gebhart 2006Documento36 páginasPhillips Kiln Kiln Alignment Gebhart 2006mustaf100% (2)

- Rotary Kiln ZonesDocumento1 páginaRotary Kiln ZonesVijay BhanAinda não há avaliações

- V6 EngineeringDocumento252 páginasV6 EngineeringRRHH100% (1)

- V2 Materials Technology 2Documento523 páginasV2 Materials Technology 2RRHH100% (1)

- Anh hưởng độ mịn xmDocumento112 páginasAnh hưởng độ mịn xmBùi Hắc Hải100% (1)

- V6 EngineeringDocumento330 páginasV6 EngineeringRRHHAinda não há avaliações

- Precalciners: Cement Manufacturing Course 2003Documento29 páginasPrecalciners: Cement Manufacturing Course 2003Salud Y Sucesos100% (1)

- Energy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case StudyDocumento12 páginasEnergy Auditing and Recovery For Dry Type Cement Rotary Kiln Systems A Case Study1977julAinda não há avaliações

- 8-Lecture 8Documento45 páginas8-Lecture 8mustafAinda não há avaliações

- Rotary Kilns: Transport Phenomena and Transport ProcessesNo EverandRotary Kilns: Transport Phenomena and Transport ProcessesNota: 4.5 de 5 estrelas4.5/5 (4)

- Kiln Out LetDocumento2 páginasKiln Out LetSamehibrahemAinda não há avaliações

- The Heart of Operations - World Cement - 02-2015Documento4 páginasThe Heart of Operations - World Cement - 02-2015fetniAinda não há avaliações

- Insulation Systems For Refrigerant Piping: Insulation Properties at Below-Ambient TemperaturesDocumento11 páginasInsulation Systems For Refrigerant Piping: Insulation Properties at Below-Ambient TemperaturesFlorin OnucAinda não há avaliações

- Vitosol - FM - Flyer 2Documento4 páginasVitosol - FM - Flyer 2Todd CrossleyAinda não há avaliações

- Flat Plate Collectors Vitosol 200-FmDocumento4 páginasFlat Plate Collectors Vitosol 200-FmSenn OdrapmasdAinda não há avaliações

- SARAPE 150lb. & 1 TON: Gas Cylinder Heating BlanketsDocumento5 páginasSARAPE 150lb. & 1 TON: Gas Cylinder Heating BlanketsDanielAinda não há avaliações

- Cool-N-Comfort-Data-Sheet-V2 PrintDocumento4 páginasCool-N-Comfort-Data-Sheet-V2 Printafiz safariAinda não há avaliações

- Facts at Your Fingertips: Insulating Heat-Transfer-Fluid PipingDocumento1 páginaFacts at Your Fingertips: Insulating Heat-Transfer-Fluid PipingEhrlish UrribarriAinda não há avaliações

- Advanced Glazing SystemsDocumento45 páginasAdvanced Glazing SystemsSwati Singh100% (1)

- Designing and Analysis of Cryogenic Storage VesselDocumento6 páginasDesigning and Analysis of Cryogenic Storage VesselmuratAinda não há avaliações

- IRM200 Insulation Selection-Cold PDFDocumento6 páginasIRM200 Insulation Selection-Cold PDFmika cabelloAinda não há avaliações

- A Better Kiln CoatingDocumento2 páginasA Better Kiln Coatingamir100% (4)

- Cement Kiln ReportDocumento22 páginasCement Kiln Reportamir100% (1)

- Kiln Ring GapDocumento3 páginasKiln Ring Gapamir100% (2)

- Compact System For Secondary FuelsDocumento8 páginasCompact System For Secondary FuelsamirAinda não há avaliações

- Cement KilnDocumento2 páginasCement Kilnamir100% (2)

- Dry Process KilnDocumento20 páginasDry Process KilnISLAM I. Fekry100% (8)

- PID-Fuzzy Controller For Grate Cooler in Cement PlantDocumento5 páginasPID-Fuzzy Controller For Grate Cooler in Cement PlantamirAinda não há avaliações

- IKN Pendulum CoolerDocumento11 páginasIKN Pendulum Cooleramir100% (3)

- SF Cross-Bar Cooler FLSDocumento8 páginasSF Cross-Bar Cooler FLSamir100% (4)

- Coolax Grate Cooler FLSDocumento4 páginasCoolax Grate Cooler FLSamirAinda não há avaliações

- Presentation For JBF-TP MGMT Meeting-Rev1 020216Documento17 páginasPresentation For JBF-TP MGMT Meeting-Rev1 020216SajeshKumarAinda não há avaliações

- Laundry GroupDocumento65 páginasLaundry Groupotim timothy williamsAinda não há avaliações

- TigerTurf Sports Product Brochure 2011Documento24 páginasTigerTurf Sports Product Brochure 2011safinditAinda não há avaliações

- Bolt Torque & Bolt Tap TestDocumento20 páginasBolt Torque & Bolt Tap Testbudymood100% (3)

- B24-Fabircaition and Erection of PipingDocumento12 páginasB24-Fabircaition and Erection of PipingRajAinda não há avaliações

- Glass Transition Temperature-Agglomeration, Sticky PointDocumento9 páginasGlass Transition Temperature-Agglomeration, Sticky Pointgalu348Ainda não há avaliações

- Mahligai Phase 3 I Valuation Purpose 14072023Documento13 páginasMahligai Phase 3 I Valuation Purpose 14072023Chan SCAinda não há avaliações

- Places of Assembly: Indoor Air ConditionsDocumento8 páginasPlaces of Assembly: Indoor Air ConditionsPraveenRavinAinda não há avaliações

- Literature Case Study On Design CollegeDocumento21 páginasLiterature Case Study On Design CollegeSophia Chin100% (1)

- 2011 Trs SowDocumento56 páginas2011 Trs SowmaniAinda não há avaliações

- 0010 en 15122016Documento5 páginas0010 en 15122016Bojan IlicAinda não há avaliações

- Steady Flows in Pressurised NetworksDocumento63 páginasSteady Flows in Pressurised NetworksAyele ErmiyasAinda não há avaliações

- Specs Woven 2006 - Updated 102018Documento1 páginaSpecs Woven 2006 - Updated 102018tranoAinda não há avaliações

- Fire Door Assembly Classifications: DecodedDocumento3 páginasFire Door Assembly Classifications: DecodedTty SmithAinda não há avaliações

- HVAC Value EngineeringDocumento2 páginasHVAC Value EngineeringamarandmoazAinda não há avaliações

- Experimental Investigation of Optimum Feed Hole Position For Plain Journal Bearing With Central CircumferentialDocumento17 páginasExperimental Investigation of Optimum Feed Hole Position For Plain Journal Bearing With Central CircumferentialSuren SirohiAinda não há avaliações

- Pages From Sor PWD WBDocumento12 páginasPages From Sor PWD WBUTTAL RAYAinda não há avaliações

- 332CDocumento2 páginas332CLo Siento de VerdadAinda não há avaliações

- Dmi 2016 Final Lowres SingleDocumento60 páginasDmi 2016 Final Lowres SingleJaimasaAinda não há avaliações

- Calculating Conduit Capacity PDFDocumento1 páginaCalculating Conduit Capacity PDFTTaanAinda não há avaliações

- Green Roof Handbook: Systems and Components For Optimal-Performance Green RoofsDocumento52 páginasGreen Roof Handbook: Systems and Components For Optimal-Performance Green RoofsFarah AlSheyabAinda não há avaliações

- Piping Identification and Valve Tagging StandardDocumento6 páginasPiping Identification and Valve Tagging Standardmanox007Ainda não há avaliações

- Thermochemistry Final PDFDocumento47 páginasThermochemistry Final PDFAyush SinghAinda não há avaliações

- UV Coating Flooring - Radtech 2003 - D. Bontinck M. IdacageDocumento6 páginasUV Coating Flooring - Radtech 2003 - D. Bontinck M. IdacageJuan Antonio Tito Esp CalAinda não há avaliações

- Polycab LedDocumento35 páginasPolycab LedSunny K IAinda não há avaliações

- 1 - C.J. Carter, C.J. Duncan - Recent Changes in U.S. Connection Design PracticeDocumento8 páginas1 - C.J. Carter, C.J. Duncan - Recent Changes in U.S. Connection Design Practiceb52raleighAinda não há avaliações

- Design: of Shell & Tube Heat ExchangerDocumento27 páginasDesign: of Shell & Tube Heat ExchangerBalamurugan SakthivelAinda não há avaliações

- Water Phase DiagramDocumento9 páginasWater Phase DiagramboddarambabuAinda não há avaliações

- History of PiezopolymersDocumento14 páginasHistory of PiezopolymersrachmajuwitaAinda não há avaliações

- Transportation Hub - Sample WorkDocumento17 páginasTransportation Hub - Sample WorkMohamed LabibAinda não há avaliações