Escolar Documentos

Profissional Documentos

Cultura Documentos

Prestressed Concrete Poles

Enviado por

Ion Riswan SinagaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Prestressed Concrete Poles

Enviado por

Ion Riswan SinagaDireitos autorais:

Formatos disponíveis

Prestressed concrete poles

In a classic demonstration, French Engineer Freyssinet took a normally reinforced concrete pole and a pre stressed concrete pole both designed to the same ultimate load and subjected both poles to alternating loads: over and over again he loaded each pole first with a load equal to the designed ultimate load, then with a load equal to half the designed ultimate load. The normally reinforced concrete pole failed at a few thousand repetitions, but the prestressed pole was still going strong after 500,000. operation, the concrete is denser and stronger. Other shapes that can also be spin-cast are hexagonal, octagonal, square with chamfered corners, and triangular with chamfered edges. Cylindrical poles can be made, but most spun-cast poles have a uniform taper from top to bottom. The taper usually ranges from 0.15 to 0.18 inch per foot. Vierendeel poles (named for Belgian engineer, M. Vierendeel) are sometimes used when poles over 30 feet high will encounter high transverse loads. The thin elements and larger exposed areas of Vierendeel poles, though, are more susceptible to failure of the concrete and to corrosion. Also, if the horizontal webs are not far enough apart, they will be misused for climbing.

irst designed and constructed by Freyssinet in the middle 1930s, prestressed concrete poles are used today worldwide for flag poles, sign poles, telephone poles, telegraph poles, and poles that support street lights, electric power lines, antenna masts, and overhead power lines for electric trains. In part because they can be factory produced, prestressed concrete poles are now used widely throughout Europe, Japan and the Soviet Union, and their use in the United States and Canada is growing. Compared with normally reinforced concrete poles, prestressed concrete poles offer several advantages: Prestressed poles are lighter and stronger, and they require less reinforcing steel. The concrete is generally in compression, so cracking is unlikely except from rough handling, and the concrete that is used is usually of higher strength so it can withstand the prestressing operation. Due to the special manufacturing process, in which the poles are spun at high speeds, they have a smoother surface that is denser and less permeable. This lower permeability in combination with the absence of cracks p re vents corrosion of reinforcement or pre s t re s s i n g wire. With the use of 10,000- and 12,000-psi concrete that is now available, prestressed poles can be made even stronger and more slender. Admixtures that make concrete an electrical insulator may also, in the future, allow integrated design. Operational life of a transmission line with prestressed concrete poles is about 60 years. The first cost of prestressed concrete poles is usually less than steel, but greater than timber.

Design considerations

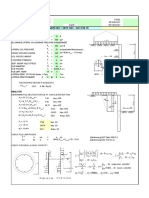

A pole generally acts as a cantilevered structure, and should be designed and analyzed as a tapered member with combined axial and bending loads. Because shear forces are small compared to bending moments, prestressed concrete poles are very resilient. Axial loads are small, too, and are generally ignored except when the structure is guyed. Stresses induced by handling, transportation and erection should always be considered in design. Common lifting points are the third points or in some cases the center of gravity. Weight of crossarms and other attachments should not be overlooked in calculating the center of gravity. Unlike other prestressed concrete structures, a prestressed concrete pole has to withstand equal bending moments in opposite directions. Because this requires uniform prestressing, the magnitude of the prestress can only be about half that normally used to provide for bending in one direction. In the United States, prestressed concrete poles should be designed for ultimate strength according to the basic assumptions sand requirements of Building Code Requirements for Reinforced Concrete, ACI 31883, modified to include the effects of prestressing. Poles should be designed to withstand the maximum loading condition, including design overload factors, without exceeding the ultimate strength of the pole, and under normal working conditions without exceeding the cracking moment of the pole. Loads that must be considered are wind, ice, wire, weight of fixtures, construction loads, maintenance loads and transportation loads.

The prestressed look

Prestressed poles can be made in many shapes. Poles up to 40 feet long with square or rectangular solid crosssections are easy to manufacture, occupy less space during transportation, and facilitate positioning of steel at corners for maximum resisting moment at a given depth. Circular hollow cross-sections are better for longer poles. Because theyre hollow, they weigh less. Because theyre circular, strength is equal in all directions. And because they are spun at high speeds in the casting

Manufacturing

Prestressed concrete poles can be manufactured in specialized factories by spin-casting and heated curing, or, as in India, they can be precast in remote areas on

site, using portable pretensioning beds, local untrained labor, air curing and specially designed bullock carts to transport and erect the poles. Long poles may be cast in sections and assembled on site by post-tensioning or splicing. In the United States, prestressed poles are made by spin-casting or by the long line method, both of which are briefly described here. In general, prestressed concrete poles are made of a dense concrete with a 28-day compressive strength of 3000 to 8500 psi; but some poles have been made with 10,000- and 12,000-psi concrete. Centrifugal castingIn most of Europe and Japan, centrifugal casting or spin-casting is used to make hollow, tapered concrete poles. A steel form is placed on a spinning machine, partially filled with a precalculated amount of concrete, then spun for several minutes (see photo). The tremendous centrifugal force created by the spinning consolidates the concrete by forcing it against the form. Excess water that is squeezed out of the concrete is poured from the hollow cavity created in the center of the pole. After spinning, the form is steam-cured until the strength of the concrete is 3500 psi. The p re s t ressing wire is then released, and the pole is a i r- c u red for 28 days. The result: a hollow pole made of dense concrete. Mensels MethodIn this East German method of casting concrete poles, poles are manufactured on a production line. Lightweight horizontal molds are carried from work station to work station on mobile frames. Vibration is used to consolidate the concrete, and a blockout is used to form the hollow cavity of the pole. After the concrete has begun to harden, the blockout is rotated slowly and finally removed when the concrete has fully hardened. Curing is done in a 24-hour cycle. The temperature of the poles is raised to 163 degrees F, held constant, then lowered back to room temperature. Long line methodThis is the most common method for casting solid sections, either square, rectangular, channeled, I- or Y-shaped. Forms are placed end to end on a casting bed up to 400 feet long. Prestressing wires are threaded through holes in the bulkheads of the forms and pretensioned against abutments at each end of the line of forms. Se ve ral poles are thus pretensioned in one operation. Concrete is compacted with external vibrators. The long line method can be used in any precast yard or on site.

Segmental prestressed concrete poles

Precasting round hollow poles: Prestressing strand and spiral reinforcing steel are placed inside the bottom half of two-part steel pole form; top half of the form is attached to the bottom half; and the prestressing strand is stressed against the form end plate (foreground, top photo). Concrete is then pumped into form through opening in center of form end plate, and form is spun on spinning machine (bottom photo). Centrifugal force created by the spinning forces the concrete against the inside of the form and squeezes out excess mix water. To avoid problems with transporting long poles, precast pole segments can be assembled on site. Prestressed or non-stressed pole segments can be post-tensioned, or prestressed pole segments can be spliced together. Four ways to splice pole segments are shown in the drawings.

Handling, transportation and erection

Although prestressed concrete poles are generally resilient and resistant to cracking, they do require care in handling, transporting and erecting. Here are a few tips:

Lap spliceA tapered, galvanized steel sleeve with a plate welded to the inside is inserted in the large end of the tapered pole form. Prestressing strand is pulled through holes in the plate and prestressed, then the form is filled with concrete, using the plate as a bulkhead. To splice two pole segments together, the steel sleeve now anchored to the bottom of the pole segment is slipped over the small end of

the pole segment below. A key way is used to orient the segments correctly. Flange plate spliceA steel plate is stressed onto the splice end of each pole segment, and the steel plates are bolted together like a pipe joint. Bolted spliceBolts are embedded into the top end of the bottom pole segment, and a special galvanized steel section that accepts these bolts is cast into the bottom of the top segment. To connect segments two nuts are tightened on each bolt. Welded spliceA thick steel plate is stressed onto the splice end of each pole segment; the steel plates are then welded together.

Handle prestressed poles with the major axis in the h o ri zontal direction, using a two-point balanced pickup. Handle poles gently while unloading them from trucks, railroad cars or barges. Never throw them in a pile. Stack poles level and support them so their own dead weight will not cause them to sag. While transporting a pole by pole trailer, keep the pole from oscillating. Use a strongback, if necessary, to keep the pole rigid, so that excessive deflection doesnt cause cracking.

of this 53-page report are available to PCI members for $5.00 (nonmember cost is $10.00) from the Prestressed Concrete Institute, Wells Tower Building, Suite 1410, 201 N. Wells St., Chicago, IL 60606 (312-346-4071). Guide for Design of Prestressed Concrete Poles, a 67-page booklet which illustrates one approach to the design of spun-cast prestressed poles, is available from PCI for $12.00. Topics include cracking and deflection limitations, longitudinal and spiral reinforcement, splicing, shrinkage, shear and bond. A computer program used to design poles is also explained. Guide Specification for Prestressed Concrete Poles is available from PCI for $5.00. This 13-page booklet can be used to develop an office master specification or specifications for a particular project.

References This article is abstracted from Prestressed Concrete Poles: A State-of-the-Art Report, by Thomas E. Rodgers, Jr., published by the Prestressed Concrete Institute (PCI) in the September/October 1984 issue of the PCI Journal. Copies

PUBLICATION #C850245

Copyright 1985, The Aberdeen Group All rights reserved

Você também pode gostar

- Comparison of Piled Raft DeisgnDocumento21 páginasComparison of Piled Raft Deisgnpile raftAinda não há avaliações

- Prestressed Concrete PolesDocumento3 páginasPrestressed Concrete PolesvenkateshAinda não há avaliações

- Fib Various Types of Structures For Namma MetroDocumento34 páginasFib Various Types of Structures For Namma MetroRohitAinda não há avaliações

- Artificial Ground Freezing Techniques GuideDocumento28 páginasArtificial Ground Freezing Techniques Guidekavya.dasthariAinda não há avaliações

- Disclosure To Promote The Right To InformationDocumento25 páginasDisclosure To Promote The Right To InformationSharan Pratap SinghAinda não há avaliações

- Experimental Investigation On Concrete Filled Unplasticized Poly Vinyl Chloride (Upvc) TubesDocumento37 páginasExperimental Investigation On Concrete Filled Unplasticized Poly Vinyl Chloride (Upvc) TubesSaranyaleoAinda não há avaliações

- Suspension Bridge: Abstract: Bridge Is A Structure Built To Span Across A Valley, RoadDocumento6 páginasSuspension Bridge: Abstract: Bridge Is A Structure Built To Span Across A Valley, RoadSheffy AbrahamAinda não há avaliações

- Assignment 1 - 2020 - Bridge Design ProjectDocumento4 páginasAssignment 1 - 2020 - Bridge Design ProjectMCAinda não há avaliações

- Implementation Technology of Bubble Deck SlabDocumento3 páginasImplementation Technology of Bubble Deck SlabMohamad Fadhilatul AzrynAinda não há avaliações

- Aftab Ahmed C.V For RE To Khalid YousafDocumento11 páginasAftab Ahmed C.V For RE To Khalid YousafKhalid YousafAinda não há avaliações

- Research into Coffee Husk Ash as an Affordable PozzolanDocumento16 páginasResearch into Coffee Husk Ash as an Affordable PozzolanMaina EriccAinda não há avaliações

- "Flexible Pavement: Presentation On Seminar EntitledDocumento15 páginas"Flexible Pavement: Presentation On Seminar EntitledKamlesh chaudhariAinda não há avaliações

- Mukul's Final ReportDocumento75 páginasMukul's Final Reportkuldeep_chand10Ainda não há avaliações

- Iare RrsDocumento180 páginasIare RrsDhuha AAinda não há avaliações

- Types of Structural SteelDocumento4 páginasTypes of Structural SteelPti RaheelAinda não há avaliações

- VSL CCT Pot BearingsDocumento8 páginasVSL CCT Pot BearingsalsvsuryaAinda não há avaliações

- Pre Bored Steel H Piling System Engineering EssayDocumento6 páginasPre Bored Steel H Piling System Engineering EssayfieeeeyAinda não há avaliações

- Code ListDocumento26 páginasCode ListChandra Prakash JyotiAinda não há avaliações

- Seismic & Wind Analysis OF Braced Steel: FramesDocumento71 páginasSeismic & Wind Analysis OF Braced Steel: FramesTHEJASHWINI MRAinda não há avaliações

- Stone Column 123Documento34 páginasStone Column 123NileshAinda não há avaliações

- MTRD Attachment Report on Civil Engineering TrainingDocumento9 páginasMTRD Attachment Report on Civil Engineering TrainingJohn KosgeiAinda não há avaliações

- Strength of Concrete Structure Partial Replacement of Sand by Copper SlagDocumento6 páginasStrength of Concrete Structure Partial Replacement of Sand by Copper SlagEditor IJTSRDAinda não há avaliações

- 2015 Kajal Mtech (R) 613CE3002Documento98 páginas2015 Kajal Mtech (R) 613CE3002haryantoaditAinda não há avaliações

- Types of Rigid Pavements: Jointed Plain Concrete Pavement (JPCP), Jointed Reinforced Concrete Pavement (JRCP), Continuously Reinforced Concrete Pavement (CRCPDocumento48 páginasTypes of Rigid Pavements: Jointed Plain Concrete Pavement (JPCP), Jointed Reinforced Concrete Pavement (JRCP), Continuously Reinforced Concrete Pavement (CRCPashoknrAinda não há avaliações

- Optimum Design of Suspension BridgeDocumento92 páginasOptimum Design of Suspension BridgeshubhadipAinda não há avaliações

- 35th Monitroing ReportDocumento81 páginas35th Monitroing ReportamitAinda não há avaliações

- Experimental Study On Redmud Based Geopolymer Concrete With Fly Ash & Ggbs in Ambient Temperature CuringDocumento4 páginasExperimental Study On Redmud Based Geopolymer Concrete With Fly Ash & Ggbs in Ambient Temperature CuringIsrael VenkatAinda não há avaliações

- Overhead Water Tank Planning and DesignDocumento72 páginasOverhead Water Tank Planning and Designaathif kabeer100% (1)

- Lead Removal from Soil Using Phytoremediation in Constructed WetlandDocumento32 páginasLead Removal from Soil Using Phytoremediation in Constructed WetlandAmeya Gawande100% (1)

- Simple Bridges NicholsonDocumento94 páginasSimple Bridges Nicholsonfarhaad shaikAinda não há avaliações

- (LECT - 19,20) Prestressed Concrete Poles, Piles, SleepersDocumento28 páginas(LECT - 19,20) Prestressed Concrete Poles, Piles, SleepersSushil Mundel100% (1)

- Internship Report On Commercial Building: Project Guide Ms. Mahalakshmi M Assistant ProfessorDocumento17 páginasInternship Report On Commercial Building: Project Guide Ms. Mahalakshmi M Assistant ProfessorvenkateshsrinivasanAinda não há avaliações

- Statement of Release of The 2019 Primary Leaving Examination ResultsDocumento7 páginasStatement of Release of The 2019 Primary Leaving Examination ResultsGCICAinda não há avaliações

- Rigid Pavement Design PDFDocumento14 páginasRigid Pavement Design PDFvikashAinda não há avaliações

- Partial Replacement of Cement With Glass Powder and Egg Shell (Powder) Ash in ConcreteDocumento51 páginasPartial Replacement of Cement With Glass Powder and Egg Shell (Powder) Ash in Concreteshivanand hippargaAinda não há avaliações

- Evaluation of Concrete Strength Using Marble Powder and Crushed Tile AggregatesDocumento43 páginasEvaluation of Concrete Strength Using Marble Powder and Crushed Tile AggregatesAndrea DeleonAinda não há avaliações

- Dynamic Load Testing of Bridges PDFDocumento6 páginasDynamic Load Testing of Bridges PDFankurshah1986Ainda não há avaliações

- Book NameDocumento2 páginasBook NameLogeswaran RajiAinda não há avaliações

- 4 Design of Slab Bridges PDFDocumento6 páginas4 Design of Slab Bridges PDFsohanpmeharwadeAinda não há avaliações

- Indian Mega ProjectDocumento56 páginasIndian Mega ProjectMohammad Munazir AliAinda não há avaliações

- PSCC PolesDocumento13 páginasPSCC PolesChaitanya Bhargav KotikeAinda não há avaliações

- ScienceDirect - Quay WallsDocumento15 páginasScienceDirect - Quay WallsYayoi IshikawaAinda não há avaliações

- FinalDocumento85 páginasFinalRavi Dutta100% (1)

- Federal Republic of Nigeria Work ReportDocumento12 páginasFederal Republic of Nigeria Work ReportDike Peter100% (1)

- MTRD Report on Foot Bridge TestingDocumento32 páginasMTRD Report on Foot Bridge TestingSimon Gikonyo100% (1)

- 48a - 40 Years of Experience Final 2011-05-26Documento14 páginas48a - 40 Years of Experience Final 2011-05-26scribd_geotecAinda não há avaliações

- MEL203 2019 Lab ManualDocumento72 páginasMEL203 2019 Lab ManualDharm-astra :The Weapon of Righteousness100% (1)

- Technical Seminar Report On Extradosed BridgeDocumento13 páginasTechnical Seminar Report On Extradosed BridgeAdithya H.BAinda não há avaliações

- Fluid Mechanics Multiple Choice QuestionsDocumento51 páginasFluid Mechanics Multiple Choice QuestionsSajil KrishnaAinda não há avaliações

- Notes On Updated Seismic Codes in Ethiopia Samuel Kinde Kassegne Et Al March2012Documento36 páginasNotes On Updated Seismic Codes in Ethiopia Samuel Kinde Kassegne Et Al March2012Sudhakar Krishnamurthy100% (1)

- Analyzing cable-stayed bridges using STAAD Pro softwareDocumento5 páginasAnalyzing cable-stayed bridges using STAAD Pro softwareMananAinda não há avaliações

- 08 Chapter 9 - Sheet Pile WallsDocumento65 páginas08 Chapter 9 - Sheet Pile WallsHazem AlmasryAinda não há avaliações

- Ws 34 CTC Chemicall HouseDocumento3 páginasWs 34 CTC Chemicall HouseCONFIANCE INFRATECH MANAGEMENTAinda não há avaliações

- Civil Design Handbook - RC StructuresDocumento166 páginasCivil Design Handbook - RC StructuresKen Liew0% (1)

- ACC Cement Users GuideDocumento51 páginasACC Cement Users GuideArijit dasguptaAinda não há avaliações

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionAinda não há avaliações

- Prestressed Concrete 2Documento30 páginasPrestressed Concrete 2Mehdi AliAinda não há avaliações

- (LECT 17,18) Prestressed Concrete Pipes and TanksDocumento40 páginas(LECT 17,18) Prestressed Concrete Pipes and TanksSushil Mundel50% (4)

- ToS Case StudiesDocumento44 páginasToS Case Studieskshipra gandhi100% (1)

- Sheet Pile Wall Design Based On 2018 IBC / 2019 CBC / ACI 318-19Documento3 páginasSheet Pile Wall Design Based On 2018 IBC / 2019 CBC / ACI 318-19afvilavilanoriegaAinda não há avaliações

- Evonik-Ancamine K54 EUDocumento2 páginasEvonik-Ancamine K54 EUOswaldo Manuel Ramirez MarinAinda não há avaliações

- Fit-Up Inspection ReportDocumento2 páginasFit-Up Inspection ReportChe Wan Aswadi100% (1)

- Example 3.1 Selection of Minimum Strength Class and Nominal Concrete Cover To Reinforcement (BS 8110)Documento53 páginasExample 3.1 Selection of Minimum Strength Class and Nominal Concrete Cover To Reinforcement (BS 8110)Mohamed AbdAinda não há avaliações

- Module 3 Quarter 3Documento3 páginasModule 3 Quarter 3Jenevie Tagalicud100% (2)

- Pressure Vessel Lifting LugsDocumento8 páginasPressure Vessel Lifting LugsArindam GhosalAinda não há avaliações

- Rema Tip Top Product Portfolio - Material Processing 2019Documento268 páginasRema Tip Top Product Portfolio - Material Processing 2019Alexandre RogerAinda não há avaliações

- Conductivity Papermachine TAPPIDocumento14 páginasConductivity Papermachine TAPPITaniaAinda não há avaliações

- Wastewater Engineering Advanced Wastewater Treatment SystemsDocumento244 páginasWastewater Engineering Advanced Wastewater Treatment Systemshos.a.faryadAinda não há avaliações

- Demonstrating Welded TPC Repair: TFP Stepped Repair PatchDocumento52 páginasDemonstrating Welded TPC Repair: TFP Stepped Repair Patchwpp8284Ainda não há avaliações

- Asme Ii.c 2017Documento1 páginaAsme Ii.c 2017Anonymous SLI4aGAinda não há avaliações

- Assessing Pollution in Jaipur's LakesDocumento4 páginasAssessing Pollution in Jaipur's LakesSuchitra SharmaAinda não há avaliações

- VLSI DesignDocumento11 páginasVLSI DesignRishi JhaAinda não há avaliações

- FDS Bayblend T 65 XFDocumento9 páginasFDS Bayblend T 65 XFDjaafar DerguiniAinda não há avaliações

- Mss-Method StatementsDocumento864 páginasMss-Method Statementsmitendra singhAinda não há avaliações

- Guiding Formulation for Aluminium Pigment Powder CoatDocumento2 páginasGuiding Formulation for Aluminium Pigment Powder Coatpodolsky-1Ainda não há avaliações

- Helical Buckling in Tubing: Supplied ForceDocumento13 páginasHelical Buckling in Tubing: Supplied ForceUthman MohammedAinda não há avaliações

- Geo-textiles Erosion StrengthDocumento1 páginaGeo-textiles Erosion StrengthAfif AzharAinda não há avaliações

- Recent Progress On The Nanoparticles-Assisted Greenhouse Carbon Dioxide Conversion ProcessesDocumento26 páginasRecent Progress On The Nanoparticles-Assisted Greenhouse Carbon Dioxide Conversion ProcessesNguyễn TuânAinda não há avaliações

- Heathcote (1995) - Durabilityof Earthwall BuildingsDocumento5 páginasHeathcote (1995) - Durabilityof Earthwall BuildingsDiana ZavaletaAinda não há avaliações

- A Hsitory of PlatinumDocumento461 páginasA Hsitory of PlatinumCiprian DimofteAinda não há avaliações

- Atkins - Almas-TowerDocumento12 páginasAtkins - Almas-TowerAshish BorkarAinda não há avaliações

- Master Thesis InterfaceDocumento71 páginasMaster Thesis InterfaceHaroon ImtiazAinda não há avaliações

- Material Safety Data Sheet: WWW - Smartlab.co - IdDocumento8 páginasMaterial Safety Data Sheet: WWW - Smartlab.co - IdHilman SyehbastianAinda não há avaliações

- Safety Data Sheet: Identification of The Substance/Preparation and of The Company/UndertakingDocumento3 páginasSafety Data Sheet: Identification of The Substance/Preparation and of The Company/UndertakingSeptian AdityaAinda não há avaliações

- Pelletization Process: Key Steps, Properties & StandardsDocumento60 páginasPelletization Process: Key Steps, Properties & StandardsMohammadNouman KabutarwalaAinda não há avaliações

- MDDI Using Chemical Characterization May 2007Documento5 páginasMDDI Using Chemical Characterization May 2007basakerpolatAinda não há avaliações

- TDS 20920 Penguard HSP ZP Euk GBDocumento5 páginasTDS 20920 Penguard HSP ZP Euk GBpavan kumarAinda não há avaliações

- About Deem Roll Tech Limited - Annexure - 4Documento1 páginaAbout Deem Roll Tech Limited - Annexure - 4Dhritisundar DeAinda não há avaliações

- Contact Details for Finance Professionals in Various Indian CompaniesDocumento28 páginasContact Details for Finance Professionals in Various Indian CompaniesData Centrum0% (1)