Escolar Documentos

Profissional Documentos

Cultura Documentos

(RT) Exposure Time-Charts

Enviado por

Vivek BhangaleDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

(RT) Exposure Time-Charts

Enviado por

Vivek BhangaleDireitos autorais:

Formatos disponíveis

EXPOSURE TIME / CHARTS:

EXPOSURE TIME CALCULATIONS

( R. Holten )

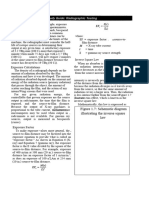

The quality of radiographs and consequently the detection of flaws in materials depends to a considerable extent, on the density of image. Thus, the selection of exposure required to produce the radiography density for best revilement of detects is necessary. The radiographic exposure time for a particular set up can either be calculated directly or read off from exposure charts. Commercial X-ray machine are generally supplied with exposure charts. For gamma source, exposure charts can be prepared by the user or exposure can be calculated by using below equation.

n = job thickness expressed in number of HVLs. FF = Film Factor SFD = Source Film Distance [ cm ] SS = Source Strength [ Ci ] RHM = Roentgen Hour per Meter

The exposure charts are prepared by exposing a step wedge having different thickness, as shown in figure below, to different exposure doses. Five or six different densities corresponding to each thickness are obtained. The exposure for obtaining a given density (for e.g. 2.0), for each thickness are then found out. A graph is then plotted between thickness and exposure in Roentgens (in logarithm scale) for gamma rays or mA-mins for Xrays. This graph is called exposure chart.

Step Wedge

Sometimes, the exposure chart for gamma rays is plotted between curie hrs (Exposure factor) Vs, thickness. In this chart, following factors are kept constant. 1. Radiation source 3. Density of radiograph 5. Processing conditions Then for the given object thickness, the exposure factor can be read off from the chart and exposure time calculated by the formula: 2. Film screen combination 4. Source to film distance ( SFD)

EF = Exposure factor (in Curies Hrs .) for SFD =D 1 D2 = actual source to film distance C = source strength in curie

After knowing the exposure time for one metal, say steel, the exposure time under the same conditions for another metal of equal thickness can be calculated using the radiography equivalence factors. Exposure charts for steel with lr-192 and Co-60 are shown in figure below. Gamma-Ray Exposure Charts Manual Processing Automatic Processing Manual Processing Automatic Processing

Iridium 192 Lead screen density 2,5 SFD=1m

Cobalt 60 Lead screen density 2,5 SFD=1m

Iridium 192 Lead screen density 2.5 , SFD = 1 m

Cobalt 60 Lead screen density 2.5 , SFD = 1 m

X-Ray Exposure Charts

Você também pode gostar

- Industrial radiography A Complete Guide - 2019 EditionNo EverandIndustrial radiography A Complete Guide - 2019 EditionAinda não há avaliações

- RT Formulas For CalculationsDocumento15 páginasRT Formulas For CalculationsAwais Jamil70% (10)

- 8.4.4 - Radiographic Training ProgramDocumento31 páginas8.4.4 - Radiographic Training ProgramMaduabuchi Serge Enemuo100% (1)

- Useful Radiography Formulas GuideDocumento1 páginaUseful Radiography Formulas GuideTonyo Ayshiyu100% (9)

- Level Ii QuestionsDocumento19 páginasLevel Ii QuestionsAmit Sindhya0% (1)

- B Scan - C Scan - D ScanDocumento52 páginasB Scan - C Scan - D ScanHee Wee JianAinda não há avaliações

- Level III UT Study NoteDocumento3 páginasLevel III UT Study NoteAllen Situ83% (6)

- UT Level III exam Paper 2012 questions and answersDocumento2 páginasUT Level III exam Paper 2012 questions and answersSani Tipare100% (1)

- Iso 5580-1985 Illuminators RT PDFDocumento9 páginasIso 5580-1985 Illuminators RT PDFMario Gaytan100% (1)

- Practical RadiographicDocumento176 páginasPractical RadiographicDung Nguyen100% (1)

- UT For Duplex Stainless Steel WeldsDocumento5 páginasUT For Duplex Stainless Steel WeldsvsnaiduqcAinda não há avaliações

- UT L3 Problems & SolutionsDocumento28 páginasUT L3 Problems & SolutionsJiten Karmakar50% (4)

- Visual Testing Level I and II Course OutlineDocumento1 páginaVisual Testing Level I and II Course OutlineMohammed Al-OdatAinda não há avaliações

- Radiography Test Course MaterailDocumento16 páginasRadiography Test Course MaterailYuvaraj Sathish100% (5)

- R1 Part 1Documento56 páginasR1 Part 1OLiver Robert100% (1)

- RT LEVEL LL EXAM 08 - 30 - 06Documento14 páginasRT LEVEL LL EXAM 08 - 30 - 06reiazh100% (5)

- PA-UT Presentation by All NationsDocumento57 páginasPA-UT Presentation by All NationsRamesh mudunuri100% (9)

- R1 Part 1 TWIDocumento56 páginasR1 Part 1 TWIYasir NassrullahAinda não há avaliações

- ASNT RECER RT QB (Aligned) MAIN FOILDERDocumento26 páginasASNT RECER RT QB (Aligned) MAIN FOILDERkingston100% (1)

- BarcDocumento15 páginasBarcsojeck0% (1)

- RT Level IIDocumento24 páginasRT Level IIEtnad Ortsac0% (1)

- NDT Training - Mo. 8866050850 - Gulfnde - Com - Asnt Level 2Documento12 páginasNDT Training - Mo. 8866050850 - Gulfnde - Com - Asnt Level 2Gulfnde Industrial ServicesAinda não há avaliações

- How to Prepare for the ASNT NDT Level-III Visual and Optical Testing ExaminationDocumento23 páginasHow to Prepare for the ASNT NDT Level-III Visual and Optical Testing ExaminationIke Duaka100% (2)

- Asnt Level 3 UT ExamDocumento1 páginaAsnt Level 3 UT Examprem nautiyal100% (2)

- Radiographic InterpretationDocumento34 páginasRadiographic InterpretationAzim SukimanAinda não há avaliações

- Ga Irrsp Study GuideDocumento7 páginasGa Irrsp Study Guidechesspupil100% (2)

- 4 Ok RTDocumento31 páginas4 Ok RTAnky Fadharani100% (1)

- TOFD Technique for Weld InspectionDocumento31 páginasTOFD Technique for Weld Inspectionvenkat100% (1)

- Level I Radiography TestDocumento33 páginasLevel I Radiography Testndi101100% (1)

- NDT LEVEL-III EXAM: RT TESTINGDocumento6 páginasNDT LEVEL-III EXAM: RT TESTINGRahul Musale100% (1)

- VT Level III Study NoteDocumento5 páginasVT Level III Study NoteAllen Situ100% (3)

- RT Specific ExamDocumento3 páginasRT Specific ExamGoutam Kumar Deb100% (1)

- Visual Testing - L-3 - QBDocumento16 páginasVisual Testing - L-3 - QBManoj SivalingamAinda não há avaliações

- EDDY CURRENT LEVEL III EXAM REVIEWDocumento5 páginasEDDY CURRENT LEVEL III EXAM REVIEWGaurav Chopra100% (2)

- RTFI Assessment Presentation 5-23-05Documento185 páginasRTFI Assessment Presentation 5-23-05shaban100% (5)

- Radiographic Interpretation Answers WIS10 CSWIP 3.2Documento3 páginasRadiographic Interpretation Answers WIS10 CSWIP 3.2andrewAinda não há avaliações

- The AnswerDocumento24 páginasThe AnswerrezokaAinda não há avaliações

- PT Quiz & Ans 2Documento6 páginasPT Quiz & Ans 2Goutam Kumar Deb100% (1)

- Dac CurveDocumento24 páginasDac Curvesantu_23Ainda não há avaliações

- API 1104 - UT Acceptance StandardsDocumento5 páginasAPI 1104 - UT Acceptance StandardsABDIELAinda não há avaliações

- UT LVL III ExamDocumento1 páginaUT LVL III ExamRicardo Andres Santamaria TorresAinda não há avaliações

- NDT RT NDS1Documento46 páginasNDT RT NDS1naganathanAinda não há avaliações

- Ultrasonic Testing On Duplex SsDocumento9 páginasUltrasonic Testing On Duplex Sskukuriku13Ainda não há avaliações

- VT For NDT - 2017Documento29 páginasVT For NDT - 2017Selvakpm06Ainda não há avaliações

- Rad Interpretation NotesDocumento85 páginasRad Interpretation NotesJames Keller100% (12)

- ASNT Basic Exam Study PlanDocumento1 páginaASNT Basic Exam Study Planalouis50% (2)

- Twi Ut2Documento48 páginasTwi Ut2Bhavani Prasad33% (3)

- Film Characteristic Curves RTDocumento3 páginasFilm Characteristic Curves RTMomo ItachiAinda não há avaliações

- Asnt 3Documento6 páginasAsnt 3amin.adineh97Ainda não há avaliações

- Gamma camera performance effects of scattered radiationDocumento12 páginasGamma camera performance effects of scattered radiationMohamed GhoneimAinda não há avaliações

- Film Characteristic CurvesDocumento7 páginasFilm Characteristic CurvesvinaAinda não há avaliações

- Exposure Calculations For IRDocumento10 páginasExposure Calculations For IRAlzaki AbdullahAinda não há avaliações

- Thickness of Spin-Cast Polymer Thin Films Determined by Angle-Resolved XPS and AFM Tip-Scratch MethodsDocumento4 páginasThickness of Spin-Cast Polymer Thin Films Determined by Angle-Resolved XPS and AFM Tip-Scratch MethodsEm là của anhAinda não há avaliações

- Dose CalculationDocumento5 páginasDose CalculationAbdul Al-FattahAinda não há avaliações

- Feb PeroDocumento6 páginasFeb PeroSadaf KhanAinda não há avaliações

- Radiographic Exposure FactorsDocumento6 páginasRadiographic Exposure FactorsJahan ZebAinda não há avaliações

- Shielding and Buildup TutorialDocumento7 páginasShielding and Buildup TutorialjjirwinAinda não há avaliações

- Fabrey Perot Lab ReportDocumento6 páginasFabrey Perot Lab ReportShyam KumarAinda não há avaliações

- 08 Image QualityDocumento9 páginas08 Image QualityNiranjan khatuaAinda não há avaliações

- MaterialsDocumento1 páginaMaterialsVivek Bhangale0% (1)

- Heat ExchangersDocumento49 páginasHeat Exchangersbluelion_19100% (1)

- CHEVRON Inspection and Testing Heat ExchangerDocumento21 páginasCHEVRON Inspection and Testing Heat ExchangerVivek Bhangale100% (3)

- Intro To Basic UTDocumento41 páginasIntro To Basic UTgirish310100% (1)

- Tube To Tube SheetDocumento9 páginasTube To Tube Sheetcmpatel_00100% (2)

- Welding Tips and TricksDocumento24 páginasWelding Tips and TricksgullipalliAinda não há avaliações

- Ultrasonic Testing of Materials at Level 2Documento278 páginasUltrasonic Testing of Materials at Level 2albertzaldivia87% (15)

- Fabrication NotesDocumento76 páginasFabrication NotesnicekhanAinda não há avaliações

- Heat Exchanger InspectionDocumento11 páginasHeat Exchanger InspectionVivek Bhangale100% (1)

- MetallurgyDocumento13 páginasMetallurgyVivek BhangaleAinda não há avaliações

- Heat Exchanger TheoryDocumento9 páginasHeat Exchanger TheoryVivek BhangaleAinda não há avaliações

- Section Viii Div 1 Div 2 Div ComparisonDocumento2 páginasSection Viii Div 1 Div 2 Div Comparisonapparaokr100% (5)

- Periodic TableDocumento1 páginaPeriodic TableChemist MookaAinda não há avaliações

- BA (Hons) Philosophy CurriculumDocumento123 páginasBA (Hons) Philosophy CurriculumDARSHAN RAAJANAinda não há avaliações

- CS5371 Theory of Computation: Lecture 1: Mathematics Review I (Basic Terminology)Documento23 páginasCS5371 Theory of Computation: Lecture 1: Mathematics Review I (Basic Terminology)Kamal WaliaAinda não há avaliações

- 1) Computer Concepts NotesDocumento6 páginas1) Computer Concepts NotesVenus Leilani Villanueva-Granado100% (2)

- Weld-Ing On in Inservice Pipelines - tcm153574190Documento7 páginasWeld-Ing On in Inservice Pipelines - tcm153574190Freddy Rondonil SAinda não há avaliações

- Notes Knouckout and BanyanDocumento13 páginasNotes Knouckout and BanyanmpacAinda não há avaliações

- Hibbeler D14 e CH 12 P 23Documento2 páginasHibbeler D14 e CH 12 P 23Mona fabrigarAinda não há avaliações

- Valuation and Risk ModelsDocumento226 páginasValuation and Risk Models1690295017qq.comAinda não há avaliações

- Record results of toy soldier experiment times with different massesDocumento42 páginasRecord results of toy soldier experiment times with different massesTeoh Han Jie100% (1)

- TVS Apache RTR 180 Service ManualDocumento25 páginasTVS Apache RTR 180 Service ManualSandino JoseAinda não há avaliações

- Rex - O. Ed. Wagner - W-Waves - BiocommDocumento13 páginasRex - O. Ed. Wagner - W-Waves - BiocommLeon BlažinovićAinda não há avaliações

- 1 Gauss SeidelDocumento20 páginas1 Gauss SeidelYanes Kristianus HediAinda não há avaliações

- Week 11 - Fundamentals of Distribution SystemsDocumento39 páginasWeek 11 - Fundamentals of Distribution SystemsEstika Vriscilla GintingAinda não há avaliações

- Testing The AdapterDocumento8 páginasTesting The AdapterrejnanAinda não há avaliações

- DeZURIK VPB VPort Ball 031317Documento19 páginasDeZURIK VPB VPort Ball 031317Joel VeraAinda não há avaliações

- RPGS Complete Lecture Note1 Inpdf Compressed1Documento203 páginasRPGS Complete Lecture Note1 Inpdf Compressed1Purusottam PandeyAinda não há avaliações

- 2.design and Analysis of Escalator FrameDocumento7 páginas2.design and Analysis of Escalator FrameSyamil Dzulfida100% (1)

- ScanKromsator ManualDocumento9 páginasScanKromsator ManualcensoredchapterAinda não há avaliações

- Alexander DisciplineDocumento7 páginasAlexander DisciplinePatricia TagartaAinda não há avaliações

- Na2xckbr2y Rev 08Documento1 páginaNa2xckbr2y Rev 08dardakAinda não há avaliações

- Danfoss PVE - Series - 7 - Technical - Information PDFDocumento56 páginasDanfoss PVE - Series - 7 - Technical - Information PDFJuan Felipe Garza GAinda não há avaliações

- Control Yokogawa PDFDocumento59 páginasControl Yokogawa PDFmiraAinda não há avaliações

- LCD Interfacing PDFDocumento37 páginasLCD Interfacing PDFPeeyush Kp100% (1)

- Adverb Clause of Time (Adverbial Cause of Time)Documento9 páginasAdverb Clause of Time (Adverbial Cause of Time)Toh Choon HongAinda não há avaliações

- D.Abbas M AlkebsiDocumento40 páginasD.Abbas M AlkebsiruchikaAinda não há avaliações

- Explanation Text About RainbowDocumento11 páginasExplanation Text About RainbowBagas FatihAinda não há avaliações

- Sisweb Sisweb Techdoc Techdoc Print Pag - pdf1Documento91 páginasSisweb Sisweb Techdoc Techdoc Print Pag - pdf1MatiussChesteerAinda não há avaliações

- Journal of King Saud University - Computer and Information SciencesDocumento10 páginasJournal of King Saud University - Computer and Information SciencesArunima MaitraAinda não há avaliações

- CO2 Dosing and Generation SystemDocumento344 páginasCO2 Dosing and Generation SystemABAID ULLAHAinda não há avaliações

- LIFTING PERFORMANCE OF THE SY215C EXCAVATORDocumento4 páginasLIFTING PERFORMANCE OF THE SY215C EXCAVATORAkhmad SebehAinda não há avaliações