Escolar Documentos

Profissional Documentos

Cultura Documentos

WPS GTAW Stainless Steel

Enviado por

Srinivasan MurugananthamDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

WPS GTAW Stainless Steel

Enviado por

Srinivasan MurugananthamDireitos autorais:

Formatos disponíveis

WELDING PROCEDURE SPECIFICATION

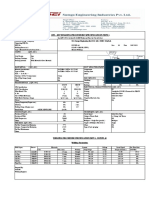

Applicable Codes: ASME SEC IX 2010 Welding Process(es): JOINT DESIGN(QW-402): Single V Groove Single bevel Branch Socket Backing(Yes/No): NO Backing Material: Metal Nonfusing Metal Nonmetallic Other BASE METAL(QW-403): P.No. OR Specification,type, and grade to Specification type, and grade OR Chemical Analysis,and Mechanical properties to Chemical Analysis,and Mechanical properties Thickness Range Qualified: Base Metal: Base Metal Range: Base metal Qualified: Others: Pipe Dia. Range: P.No.: 8 or Equivalent, ASTM A312 Gr.TP316L or Equivalent GrooveAll Fillet All Groove1.5 to 11.08 mm Fillet All : NA : NA : A 312 Gr.TP316L and Equivalent : A 312 Gr.TP316L and Equivalent 8 Group No. 1,2,3,4 To P.No. 8 Group No. Summary: GTAW / 6G / A 312 / 25.4mm OD Type: Manual Automatic, Manual, or Semi Auto) Joint Details 37.50 2.50.

DOC. REF WPS NO: Rev:00 Page No.:

GTAW

1.6mm0.8

2-4 mm

PQR 2" Dia-5.54mm THK

Note: Applicable to all Groove configurations 1, 2, 3,4

FILLER METALS(QW-404): Root + Others Spec. No.(SFA) AWS No.(Class) F.No. A.No. Size of Filler Metals Weld Metal Thickness Groove Range Fillet Electrode Flux (Class) Flux Trade Name Consumable Insert Brand PREPARED BY SIGN. SFA - 5.9 ER 316L 6 8 2 / 2.4 mm dia 5.54 mm + Reinforcement 11.08 mm All NA NA NA ESAB - OK 16.30 REVIEWED BY APPROVED BY

NAME DESN. DATE:

WELDING PROCEDURE SPECIFICATION

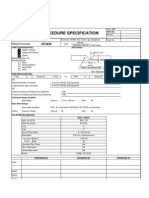

Applicable Codes: ASME SEC IX 2010 POSITIONS(QW-405): Position of Groove 6G & ALL Welding Progression UPHIL Position of Fillet All Others Summary: GTAW / 6G / A 312 / 25.4mm OD

DOC. REF WPS NO: Rev:00 Page No.:

POST WELD HEAT TREATMENT(QW-407): Heating Rate NA Holding Temperature Range NA Holding Time Range NA Cooling Rate NA Others GAS(QW-408): Shielding Trailing Backing Gas : Single Ampere Range: Gas(es) ARGON

NA

PREHEAT(QW-406): Preheat Temperature(Min.) -100 C Min Interpass Temperature(Max.) Preheat Maintenance Yes

Percent composition %Comp. of Flow Rate 99.995 % 8 to 15 LPM

NA NA

1500C Max

ARGON

99.995 %

8 to 15 LPM

ELECTRICAL CHARACTERISTICS(QW-409): Current AC or DC: DC Polarity : Straight for GTAW (NegativeDCEN) 2.4 mm and 2% Thoriated NA NA 75 - 120 Amps Voltage Range: 09 - 15 Volts

Tungeston Electrode Size and Type Mode of Metal transfer for GMAW Electrode/Wire feed speed range -

TECHNIQUE(QW-410): String / Weaving shall not exceed 2.5 times of electrode dia. Stringe or Weave Bead Orifice or Gas Cup Size 5 -8 mm OD Initial and Interpass Cleaning(Brushing,Grinding,etc.) Grinding & Brushing (Use Stainless steel special tools) Method of Back Gouging NA Oscillation NA Contact Tube to Work Distance NA Multiple or Single Pass(per side): Multiple Multiple or Single Electrode Single Travel Speed Range 0.8 - 1.5 mm/sec Peening NA Closed to out chamber : NA Use of thermal Process : NIL Others Filler Metal Current Weld Voltage Travel Speed Weld Layer Diameter Type & Ampere Process Range(V) Range Class mm Polarity Range(A) Root+ Hot Filler/ Capping GTAW GTAW ER 316L ER 316L PREPARED BY SIGN. 2 / 2.4 mm 2 / 2.4 mm DCEN DCEN 75 - 100 95-120 09 - 15 09- 15 0.8 - 1.5 mm/sec 0.8 - 1.5 mm/sec

REMARKS

REVIEWED BY

APPROVED BY

NAME DESN. DATE:

Você também pode gostar

- WPS TITLEDocumento2 páginasWPS TITLERichard Periyanayagam86% (14)

- Wps For SS 304Documento3 páginasWps For SS 304MuraliKrishna87% (23)

- WPS 316 LDocumento4 páginasWPS 316 Llaz_k100% (2)

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocumento4 páginasWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremAinda não há avaliações

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Documento5 páginasWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- GTAW Welding Procedure SpecificationDocumento3 páginasGTAW Welding Procedure SpecificationVimin Prakash100% (1)

- WPS For Structure Mild Steel Fillet WeldDocumento2 páginasWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- WPS MigDocumento3 páginasWPS MigAJOJOY00960% (5)

- Welding Procedure Specification Pipe - 6GDocumento3 páginasWelding Procedure Specification Pipe - 6Gdndudc96% (26)

- WPS For Different Materail by BhelDocumento176 páginasWPS For Different Materail by Bhelsaisssms911691% (46)

- WPSDocumento3 páginasWPSKhurram Burjees100% (1)

- According To ASME IX: Welding Procedure Specification (W.P.S)Documento4 páginasAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehAinda não há avaliações

- WPS PQR A36.20Documento5 páginasWPS PQR A36.20gchaves504100% (2)

- PQR FormatDocumento2 páginasPQR Formatravi0009880% (5)

- WPS GmawDocumento2 páginasWPS Gmawasikur100% (6)

- Procedure Qualification Record (PQR)Documento3 páginasProcedure Qualification Record (PQR)Senthil KumaranAinda não há avaliações

- Loading Unloading Temperature Welding ProgressionDocumento5 páginasLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- Welder Performance Qualification-Interactive Form QW-484ADocumento1 páginaWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- WPS PQR Smaw + Fcaw D1.1Documento8 páginasWPS PQR Smaw + Fcaw D1.1Yhuto W. Putra100% (3)

- Sample WPS SMAW Stainless SteelDocumento7 páginasSample WPS SMAW Stainless Steeldaemsal100% (4)

- Joint Detail (Qw-402)Documento2 páginasJoint Detail (Qw-402)Nitesh Patel100% (3)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Documento48 páginasQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- Welding Procedure Specification for Stainless SteelDocumento5 páginasWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- WPS 6G CS Pipe CorrectDocumento4 páginasWPS 6G CS Pipe CorrectAla ReguiiAinda não há avaliações

- WPS and PQRDocumento4 páginasWPS and PQRdandiar1Ainda não há avaliações

- WPS, PQR, WPQ (Si007)Documento5 páginasWPS, PQR, WPQ (Si007)Suresh RathodAinda não há avaliações

- Wps SawDocumento2 páginasWps Sawdevendrasingh2021100% (6)

- Draft WPS For Carbon Steel PipeDocumento2 páginasDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- A 36 WPSDocumento2 páginasA 36 WPSNaqqash Sajid100% (1)

- WPS For Structure Mild Steel Fillet Weld PDFDocumento2 páginasWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniAinda não há avaliações

- WPS & PQRDocumento46 páginasWPS & PQRJohn Candidate CIns88% (8)

- WPS Sitelca S002Documento2 páginasWPS Sitelca S002Jose Antonio GomezAinda não há avaliações

- Everything You Need to Know About Stainless Steel Welding Procedure SpecificationDocumento6 páginasEverything You Need to Know About Stainless Steel Welding Procedure SpecificationDanem HalasAinda não há avaliações

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Documento20 páginasWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- 6GR WPS PQRDocumento15 páginas6GR WPS PQRKiukStaks100% (6)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Documento2 páginas(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS 2014-002 002 - 1G & 2G S 275 JRDocumento2 páginasWPS 2014-002 002 - 1G & 2G S 275 JRjeswin50% (2)

- PWPS WPS PQR WPQDocumento21 páginasPWPS WPS PQR WPQcsolanki658688% (8)

- Plates ASTM-A240 Gr 304LDocumento6 páginasPlates ASTM-A240 Gr 304Labhishek198327Ainda não há avaliações

- Welding Procedure Specification For 24'' PipeDocumento2 páginasWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocumento5 páginasWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure SpecificationDocumento3 páginasWelding Procedure SpecificationAhmed saber100% (1)

- WPS-46 - Gtaw & Smaw Tig + SmawDocumento8 páginasWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaAinda não há avaliações

- Welding Procedure Specification SampleDocumento2 páginasWelding Procedure Specification Sampleezdi2083% (23)

- Wps Gtaw Monel b127 b164Documento2 páginasWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- WPS GTAW Stainless SteelDocumento4 páginasWPS GTAW Stainless SteelAnand NarayananAinda não há avaliações

- MRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDocumento5 páginasMRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDeepak100% (1)

- Welding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchDocumento4 páginasWelding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchaAinda não há avaliações

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Documento24 páginasPrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarAinda não há avaliações

- Des QC 8505 Ab 08Documento3 páginasDes QC 8505 Ab 08Touseef RafiqueAinda não há avaliações

- Wps p91 - BhelDocumento2 páginasWps p91 - BhelAshish Gupta100% (4)

- WPS Resrvoire Sous Pression Smaw SawDocumento6 páginasWPS Resrvoire Sous Pression Smaw SawDanem HalasAinda não há avaliações

- Gtaw 106Documento2 páginasGtaw 106ganeshkumarg_1Ainda não há avaliações

- SS312 Type310Documento4 páginasSS312 Type310Vimin PrakashAinda não há avaliações

- PWPS For Piping-API 1104Documento6 páginasPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- 1015 To Hastelloy VickoDocumento14 páginas1015 To Hastelloy Vickovgestantyo100% (1)

- WPS FormatDocumento2 páginasWPS FormatAmit SarkarAinda não há avaliações

- WPS (AsmeDocumento8 páginasWPS (AsmeMohammad Elhedaby100% (6)

- Welding Procedure Specification-1Documento8 páginasWelding Procedure Specification-1Suresh Rathod100% (1)

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDocumento6 páginasProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniAinda não há avaliações

- Wps Gtaw Monel b127 b164Documento2 páginasWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- Wps Gtaw Monel b127 b164Documento2 páginasWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- Wps Gtaw Monel b127 b164Documento2 páginasWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- WPS GTAW Stainless SteelDocumento2 páginasWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WPS GTAW Stainless SteelDocumento2 páginasWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Asme V Si UnitsDocumento3 páginasAsme V Si UnitsvidhisukhadiyaAinda não há avaliações

- Weld DesignDocumento51 páginasWeld DesignJoseph Booker100% (1)

- List of EquipmentsDocumento73 páginasList of EquipmentsalibankerAinda não há avaliações

- Sect 11a P Welding DocumDocumento31 páginasSect 11a P Welding DocumRajeev KumarAinda não há avaliações

- Hand BookDocumento300 páginasHand BookGregEverett2Ainda não há avaliações

- Petronas Technical Standards: Specifications and Requirements For Pipeline In-Line InspectionDocumento30 páginasPetronas Technical Standards: Specifications and Requirements For Pipeline In-Line InspectionAsus AsriAinda não há avaliações

- Static and Dynamic Testing of Welded and Woven Mesh For Rock SupportDocumento11 páginasStatic and Dynamic Testing of Welded and Woven Mesh For Rock SupportAyleen LealAinda não há avaliações

- Esab LTN 255 Aristo-Tig 255Documento50 páginasEsab LTN 255 Aristo-Tig 255Branko Ferenčak100% (1)

- Abu Dhabi Crude Oil Pipeline Daily Inspection LogDocumento1 páginaAbu Dhabi Crude Oil Pipeline Daily Inspection LogAhmed AlyAinda não há avaliações

- Method of Statement: Fit Up and ToolsDocumento1 páginaMethod of Statement: Fit Up and ToolsAmul PontingAinda não há avaliações

- 26148-220-V1a-Mfm0-00223 - Hoja de Datos Molino Sag 0320-ML-5001 PDFDocumento10 páginas26148-220-V1a-Mfm0-00223 - Hoja de Datos Molino Sag 0320-ML-5001 PDFLeonel Gamero CardenasAinda não há avaliações

- AKP Storage TanksDocumento51 páginasAKP Storage Tankscris_2010Ainda não há avaliações

- (Corus) Design of SHS Welded JointsDocumento48 páginas(Corus) Design of SHS Welded Joints_at_to_100% (2)

- Cahier de Soudage G 11950 - Ver B - WPS 14Documento1 páginaCahier de Soudage G 11950 - Ver B - WPS 14YassineElabdAinda não há avaliações

- Low - Alloy-Tool - Steel 90sDocumento10 páginasLow - Alloy-Tool - Steel 90smarcos crisostoAinda não há avaliações

- ISLA JHA Temfacil ConstructionDocumento2 páginasISLA JHA Temfacil Constructionaasafety06Ainda não há avaliações

- 6010 5P+ Welding Rod-LincolnDocumento4 páginas6010 5P+ Welding Rod-LincolnjanprakkeAinda não há avaliações

- Harmonised Standards Under Directive 2014 68 EU For Pressure EquipmentDocumento24 páginasHarmonised Standards Under Directive 2014 68 EU For Pressure EquipmentciekawskiAinda não há avaliações

- Painting Procedure Rev.1Documento28 páginasPainting Procedure Rev.1didi sudiAinda não há avaliações

- TWI 581-CTOD Testing Update (1996)Documento25 páginasTWI 581-CTOD Testing Update (1996)Mansour TavakoliAinda não há avaliações

- User manual for Trumpf lasers with Siemens sinumeric 840d controlDocumento13 páginasUser manual for Trumpf lasers with Siemens sinumeric 840d controlAnonymous OTmNmCLAinda não há avaliações

- Welding Engineer: M.E. in Welding TechnologyDocumento4 páginasWelding Engineer: M.E. in Welding TechnologySenthil KumaranAinda não há avaliações

- NPTEL Marine Construction and Welding Course OutlineDocumento3 páginasNPTEL Marine Construction and Welding Course OutlinealiAinda não há avaliações

- Specifications ThermitDocumento34 páginasSpecifications Thermit100offeerAinda não há avaliações

- Steel Connection WeldingDocumento56 páginasSteel Connection WeldingKentDemeterio100% (2)

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Documento1 páginaQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13Ainda não há avaliações

- CSA W47.1 and CSA W59 Exam questions study guideDocumento5 páginasCSA W47.1 and CSA W59 Exam questions study guideAlex Alex100% (1)

- Gas Metal Arc Welding (GMAW)Documento16 páginasGas Metal Arc Welding (GMAW)Akmal Bin Saipul AnuarAinda não há avaliações

- DRP001-OUF-SPE-W-000-008-B4 (Painting of New Equipment & Piping)Documento37 páginasDRP001-OUF-SPE-W-000-008-B4 (Painting of New Equipment & Piping)Kannan MurugesanAinda não há avaliações

- 60TPH Tomato Paste Processing 2Documento19 páginas60TPH Tomato Paste Processing 2Nick Kim67% (3)

- Weldablity of MetalsDocumento15 páginasWeldablity of MetalspchakrAinda não há avaliações