Escolar Documentos

Profissional Documentos

Cultura Documentos

Gmaw Complete Aws d1.6

Enviado por

Hamza NoumanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Gmaw Complete Aws d1.6

Enviado por

Hamza NoumanDireitos autorais:

Formatos disponíveis

Prepared by: WPSAmerica.

com

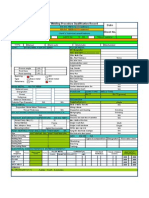

WELDING PROCEDURE SPECIFICATION (WPS)

Identification #

Ref. Code

PQR No.

DEMO-GMAW

AWS D1.6

PREQUALIFIED

Company Name: www.WPSAmerica.com Address: info@WPSAmerica.com, Toll Free: 1 (877) WPS-WELD

Process Base Metals Filler Metals

Shielding Gas Flux (SAW)

GMAW

Process Type

Semi-Automatic

Position

Flat

Austenitic Stainless Steel Alloy Grades 304, 304L, 316 or 316L of Group A or B of Table 3.2-AWS D1.6

AWS A5.9: ER308L; ER308LSi; ER308; ER308Si; ER316L; ER316LSi; ER316; ER316Si

Ar+ 2% CO2 (Or) Ar+ 2% O2

Complete Joint Penetration Groove Weld

5/8 to 3/4

Flow Rate Nozzle Dia.

Preheat / Interpass Temp., Min

30-45 CFH

5/8 in

Weld Type Electrical Stick Out

ESO (in)

Current/ Polarity DCEP

To free surfaces from moisture, Max Interpass 175 C (350 F)

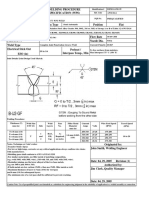

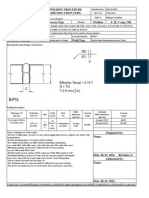

Joint Details/ Joint Design Used/ Sketch:

Welding Procedure:

Thickness (T) mm (in)

T<=6 mm (1/4) T>=6 mm (1/4) T>=6 mm (1/4) T>=10 mm (3/8)

Weld Size ETT (E)

Side

Weld Layers

Pass No.

Filler Metal Diameter mm (in)

Current Amps

260-310 310-330 330-360 360-390

Volts

25-28 26-29 27-31 28-32

Wire Feed Speed (IPM)

175-200 200-250 250-275 275-300

Travel Speed (IPM)

1 and 2

Root, Fill, Cap

As 1.6 mm (0.062, Required, 1/16) see notes

10 to 20

Notes, Technique or Codes rules: -Transfer Mode: Spray -For low or high temp., corrosive or any critical applications always confirm wire choice with manufacturer. -Shielding gases shall conform to AWS A5.32/A5.32M -For similar metal joints, use filler metal of matching composition, (e.g.: weld 304L with 308L wire), (316 with 316, and 316L with 316L wire). -Dissimilar joining, use the lower alloyed of the two base metals, (e.g. use 308 to join 304 to 316). -If both metals are low carbon (3XXL), then use 3XXL filler metal as well. -Maximum thickness of layer is 5 mm (3/16) for root pass and 6 mm (1/4) for subsequent layers. -The minimum size of a root pass shall be sufficient to prevent cracking.

Originated by: John Smith, Welding Engineer

Date: 04, 29, 2005 Revision (1) Authorized by: Jim Clark, Quality Manager

Date: 04, 29, 2005

Caution Note: Use of prequalified joint is not intended as a substitute for engineering judgment in the suitability of application to a welded assembly or connection.

Você também pode gostar

- Multi Process Welding Procedures QW200.4 (ASME IX)Documento1 páginaMulti Process Welding Procedures QW200.4 (ASME IX)HoangAinda não há avaliações

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocumento1 página193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraAinda não há avaliações

- 004 Gtaw P5aDocumento16 páginas004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Wps AluminiumDocumento2 páginasWps Aluminiumsatrahe100% (1)

- Aluminium WPSDocumento2 páginasAluminium WPSAnonymous yCpjZF1rF100% (1)

- LBW WOPQ REV. 2010a Interactive FormDocumento1 páginaLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- Weldspec ASME PQRDocumento2 páginasWeldspec ASME PQRSunil KumarAinda não há avaliações

- WPS RegisterDocumento2 páginasWPS RegisterdaveswinburneAinda não há avaliações

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Documento2 páginasWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusAinda não há avaliações

- Brazing BPS 107-1 PDocumento5 páginasBrazing BPS 107-1 Pmbe josephAinda não há avaliações

- Weld AbilityDocumento34 páginasWeld AbilityGauthamSarangAinda não há avaliações

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 páginasIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Astm A1078Documento5 páginasAstm A1078mmendez11333% (3)

- Qw-482 Welding Procedure Specification (WPS)Documento4 páginasQw-482 Welding Procedure Specification (WPS)Aldeline SungahidAinda não há avaliações

- Guidance To Prepare Wps PQR For WeldingDocumento1 páginaGuidance To Prepare Wps PQR For WeldingHamid MansouriAinda não há avaliações

- Ami-001 WPSDocumento2 páginasAmi-001 WPSPramod Athiyarathu100% (1)

- Wps Magi Tig Exemple PDFDocumento6 páginasWps Magi Tig Exemple PDFJaime PatrónAinda não há avaliações

- Submerged Arc WeldingDocumento5 páginasSubmerged Arc Weldingmanikandan.vAinda não há avaliações

- WPS-PQR (Er309l Mo)Documento4 páginasWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- Welding Domex SteelsDocumento16 páginasWelding Domex Steelspozolab100% (1)

- Gta+sma PQRDocumento3 páginasGta+sma PQRRahul MoottolikandyAinda não há avaliações

- PQR 01 PDFDocumento2 páginasPQR 01 PDFVijay BhaleraoAinda não há avaliações

- Alu WpsDocumento4 páginasAlu WpsdselvakuuAinda não há avaliações

- Format WPQDocumento2 páginasFormat WPQAkash Singh TomarAinda não há avaliações

- WPS, PQR 041Documento21 páginasWPS, PQR 041swamykommula100% (1)

- Fcaw 16 THKDocumento5 páginasFcaw 16 THKparesh2387Ainda não há avaliações

- Ami-003 WPSDocumento2 páginasAmi-003 WPSBenjamin BrownAinda não há avaliações

- SAE MS1003 Dated 12-2002 Compressor OilsDocumento16 páginasSAE MS1003 Dated 12-2002 Compressor Oilsanon_94010986Ainda não há avaliações

- WPQR SMAW EN-2 - 30mm (Under Modification)Documento2 páginasWPQR SMAW EN-2 - 30mm (Under Modification)Mohamed Reda HusseinAinda não há avaliações

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocumento1 páginaWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Blotting TechniqueDocumento34 páginasBlotting TechniqueUmair100% (1)

- AWS D1.1 GuidesDocumento7 páginasAWS D1.1 GuidesMuhammad FakhriAinda não há avaliações

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Documento2 páginasWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialAinda não há avaliações

- Aws d1.5 PQRDocumento2 páginasAws d1.5 PQRjacquesmayolAinda não há avaliações

- Guideline For Technical Regulation Vol.2 - Design of Thermal Power Facilities Book 4.12 Coal Fuel Handling FacilityDocumento114 páginasGuideline For Technical Regulation Vol.2 - Design of Thermal Power Facilities Book 4.12 Coal Fuel Handling FacilityQuang Minh Trần100% (1)

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS)Documento2 páginasQw-482 Suggested Format For Welding Procedure Specifications (WPS)Ravelo Jeisson100% (2)

- Filler Materials TestingDocumento34 páginasFiller Materials TestingSunilAinda não há avaliações

- Industrial radiography A Complete Guide - 2019 EditionNo EverandIndustrial radiography A Complete Guide - 2019 EditionAinda não há avaliações

- P1 To P8Documento9 páginasP1 To P8Pat AuffretAinda não há avaliações

- Fillet Weid Break and Macroetch Test PlateDocumento1 páginaFillet Weid Break and Macroetch Test PlatewijiestAinda não há avaliações

- WPS - Welding Instruction - FUCHSDocumento23 páginasWPS - Welding Instruction - FUCHSShanoor AS100% (1)

- APSM WPS 008R Rev. 0Documento3 páginasAPSM WPS 008R Rev. 0Amir NorAinda não há avaliações

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocumento4 páginas163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraAinda não há avaliações

- 25 Tack Welder - ABSDocumento7 páginas25 Tack Welder - ABSvudinhnambrAinda não há avaliações

- ASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricDocumento14 páginasASTM-F1941-F1941M Standard Specification For Electrodeposited Coatings On Mechanical Fasteners, Inch and MetricSinan Chen100% (1)

- SS WPSDocumento1 páginaSS WPSMOHAMEDABBASAinda não há avaliações

- CSM-QR-02-2, Medical Gas BPS TablesDocumento8 páginasCSM-QR-02-2, Medical Gas BPS TablesaadmaadmAinda não há avaliações

- KGP-Flamme Cutting Proce For BEI PDFDocumento4 páginasKGP-Flamme Cutting Proce For BEI PDFoomoomAinda não há avaliações

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Documento1 páginaWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- WPQR2Documento3 páginasWPQR2Thanasis KyrgiazoglouAinda não há avaliações

- Wps For Aluminium WeldingDocumento8 páginasWps For Aluminium WeldingMohammed MusaAinda não há avaliações

- Surface Tension Transfer (STT) Pipe WeldingDocumento3 páginasSurface Tension Transfer (STT) Pipe WeldingahmedAinda não há avaliações

- WPQ CS SmawDocumento1 páginaWPQ CS Smawniket0Ainda não há avaliações

- BPV IX-16-3 QW-283 - ButteringDocumento1 páginaBPV IX-16-3 QW-283 - ButteringyutweldingAinda não há avaliações

- Welding Procedure Qualification Record: Shipyard LogoDocumento4 páginasWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- ASME 9 - CalculatorDocumento2 páginasASME 9 - CalculatorEmel Besir100% (1)

- Gmaw Complete Aws d1.6Documento1 páginaGmaw Complete Aws d1.6Solda DorAinda não há avaliações

- Gmaw Complete Aws d1.6Documento1 páginaGmaw Complete Aws d1.6Silvia CardenasAinda não há avaliações

- Atlas Stainless Steel Data SheetsDocumento57 páginasAtlas Stainless Steel Data Sheetszoksi67% (3)

- Wpsnereza5 140610002538 Phpapp02 PDFDocumento12 páginasWpsnereza5 140610002538 Phpapp02 PDFHendrias Ari SujarwoAinda não há avaliações

- Members Data 8Documento2 páginasMembers Data 8jaime huertasAinda não há avaliações

- Stainless Steel Brochure LRDocumento8 páginasStainless Steel Brochure LRHuỳnh TrươngAinda não há avaliações

- Data EC309 LDocumento1 páginaData EC309 LbabakjooonAinda não há avaliações

- Ficha Tecnica - Os&y Flanged FivalcoDocumento1 páginaFicha Tecnica - Os&y Flanged FivalcoDiana C. Parrado MartínezAinda não há avaliações

- Materials Stud Bolts: ASTM A197 B7Documento5 páginasMaterials Stud Bolts: ASTM A197 B7scribddisantoAinda não há avaliações

- CV Hamza wORKSHOP eNGINEERDocumento3 páginasCV Hamza wORKSHOP eNGINEERHamza NoumanAinda não há avaliações

- Direction On How To Replace A Fuel Filter.Documento5 páginasDirection On How To Replace A Fuel Filter.Hamza NoumanAinda não há avaliações

- Replacing An Engine Drive BeltDocumento5 páginasReplacing An Engine Drive BeltHamza NoumanAinda não há avaliações

- List of Documetns, Rev-2, 29-09-2012Documento4 páginasList of Documetns, Rev-2, 29-09-2012Hamza NoumanAinda não há avaliações

- List of Workshop Machines, 2011 RevisedDocumento3 páginasList of Workshop Machines, 2011 RevisedHamza Nouman100% (1)

- Quality Plan For WorkshopDocumento1 páginaQuality Plan For WorkshopHamza NoumanAinda não há avaliações

- Direction On How To Replace A Fuel Filter.Documento5 páginasDirection On How To Replace A Fuel Filter.Hamza NoumanAinda não há avaliações

- Quality Plan For WorkshopDocumento1 páginaQuality Plan For WorkshopHamza NoumanAinda não há avaliações

- Outsource Job Quality CertificateDocumento1 páginaOutsource Job Quality CertificateHamza NoumanAinda não há avaliações

- Index of Units ManualDocumento7 páginasIndex of Units ManualHamza NoumanAinda não há avaliações

- List of Workshop Machines, 2011 RevisedDocumento3 páginasList of Workshop Machines, 2011 RevisedHamza Nouman100% (1)

- List of Documetns, Rev-2, 29-09-2012Documento4 páginasList of Documetns, Rev-2, 29-09-2012Hamza NoumanAinda não há avaliações

- System Support Request Form: Pakarab Fertilizers Ltd. MultanDocumento1 páginaSystem Support Request Form: Pakarab Fertilizers Ltd. MultanHamza NoumanAinda não há avaliações

- Soc Waiver Form: Safety Critical Systems / InspectionDocumento1 páginaSoc Waiver Form: Safety Critical Systems / InspectionHamza NoumanAinda não há avaliações

- Cranes Load Test Status Cum ScheduleDocumento5 páginasCranes Load Test Status Cum ScheduleHamza NoumanAinda não há avaliações

- Standardansi Scaffold A10 8 2001Documento1 páginaStandardansi Scaffold A10 8 2001Julian David TellezAinda não há avaliações

- Vendor Evaluation FormDocumento1 páginaVendor Evaluation FormHamza NoumanAinda não há avaliações

- V & B Feedback FormatDocumento1 páginaV & B Feedback FormatHamza NoumanAinda não há avaliações

- Vendor Evaluation FormDocumento1 páginaVendor Evaluation FormHamza NoumanAinda não há avaliações

- Load Test Stauts (Fork Lifters)Documento1 páginaLoad Test Stauts (Fork Lifters)Hamza NoumanAinda não há avaliações

- Guidelines For Access ScaffoldingDocumento28 páginasGuidelines For Access ScaffoldingHamza Nouman100% (1)

- Scaffolding: "It's Big, It's Ugly, It's There,"Documento2 páginasScaffolding: "It's Big, It's Ugly, It's There,"Hamza NoumanAinda não há avaliações

- Scaffold 2Documento2 páginasScaffold 2Hamza NoumanAinda não há avaliações

- Aerial Lifts Safety Tips: Safe Work PracticesDocumento1 páginaAerial Lifts Safety Tips: Safe Work PracticesHamza NoumanAinda não há avaliações

- Bridge Cranes, Overhead Electric, Top RunningDocumento28 páginasBridge Cranes, Overhead Electric, Top RunningHamza NoumanAinda não há avaliações

- Department of Labor: Supported Scaffold Tips2Documento2 páginasDepartment of Labor: Supported Scaffold Tips2USA_DepartmentOfLaborAinda não há avaliações

- G L o S S A R y of ScaffoldingDocumento2 páginasG L o S S A R y of ScaffoldingHamza NoumanAinda não há avaliações

- 02-All Incidents (Year-2017)Documento14 páginas02-All Incidents (Year-2017)Hamza NoumanAinda não há avaliações

- Tips Critical Crane Lift PDFDocumento7 páginasTips Critical Crane Lift PDFb_wooAinda não há avaliações

- Lifting Personnel PDFDocumento18 páginasLifting Personnel PDFfaithablazebAinda não há avaliações

- Practical General and Inorganic Chemistry Manual (Unlocked)Documento194 páginasPractical General and Inorganic Chemistry Manual (Unlocked)fosfos1510Ainda não há avaliações

- M.M.A. Welding ElectrodeDocumento1 páginaM.M.A. Welding ElectrodecwiksjAinda não há avaliações

- Synergistic Effect of NaCl and SO2 On The Initial Atmospheric Corrosion of Zinc Under Wet-Dry Cyclic ConditionsDocumento17 páginasSynergistic Effect of NaCl and SO2 On The Initial Atmospheric Corrosion of Zinc Under Wet-Dry Cyclic ConditionsNaci BolcaAinda não há avaliações

- E387-04 (2014) Standard Test Method For Estimating Stray Radiant Power Ratio of Dispersive Spectrophotometers by The Opaque Filter MethodDocumento11 páginasE387-04 (2014) Standard Test Method For Estimating Stray Radiant Power Ratio of Dispersive Spectrophotometers by The Opaque Filter Methodislamaktham100% (2)

- Food Chemistry: Research ArticleDocumento10 páginasFood Chemistry: Research ArticleJohana Marcela AcostaAinda não há avaliações

- Dental AmalgamDocumento73 páginasDental AmalgamProstho JCSeminarAinda não há avaliações

- MS 2021-2022Documento106 páginasMS 2021-2022Ege Arda AkyürekAinda não há avaliações

- API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)Documento5 páginasAPI Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)Luis Ernesto Marin JaimesAinda não há avaliações

- Pure LabDocumento42 páginasPure LabJohann RyobiAinda não há avaliações

- Heavy Metal Removal From Water Using Moringa Oleifera Seed Coagulant and Double FiltrationDocumento4 páginasHeavy Metal Removal From Water Using Moringa Oleifera Seed Coagulant and Double FiltrationAena RabonzaAinda não há avaliações

- Cutting Processes - Plasma Arc Cutting - Process and Equipment ConsiderationsDocumento5 páginasCutting Processes - Plasma Arc Cutting - Process and Equipment ConsiderationsSairul SahariAinda não há avaliações

- Interlac 665 PDFDocumento4 páginasInterlac 665 PDFEngTamerAinda não há avaliações

- Advanced Material Modeling in AbaqusDocumento13 páginasAdvanced Material Modeling in AbaqusUdhamAinda não há avaliações

- Chemistry MCQ2Documento28 páginasChemistry MCQ2SABARI SRINIVAS AAinda não há avaliações

- Register of Pesticides March 26 2020 Active IngredientDocumento26 páginasRegister of Pesticides March 26 2020 Active Ingredient20 Võ Xuân KỳAinda não há avaliações

- Jahangirabad Instiute of Technology Barabanki Department of Mechanical EngineeringDocumento23 páginasJahangirabad Instiute of Technology Barabanki Department of Mechanical EngineeringMuhammad ImranAinda não há avaliações

- Unit-I Chemical Bonding and Molecular Structure: (18 Contact Hours)Documento3 páginasUnit-I Chemical Bonding and Molecular Structure: (18 Contact Hours)Imran Afzal BhatAinda não há avaliações

- Two Solid Cylindrical Rods AB and 2. Select The Appropriate Pair of ElementsDocumento4 páginasTwo Solid Cylindrical Rods AB and 2. Select The Appropriate Pair of ElementsAhmed Dhempsey Hali AbdulbasikAinda não há avaliações

- First Quarter Examination in Science ViDocumento2 páginasFirst Quarter Examination in Science ViRODELITO ARAMAYAinda não há avaliações

- Ncert Notes Class 9 Science Chapter1Documento8 páginasNcert Notes Class 9 Science Chapter1ng_nirmalAinda não há avaliações

- Smart Choices Grades 7-8Documento15 páginasSmart Choices Grades 7-8Tan TaylorAinda não há avaliações

- GOR Vs GVFDocumento8 páginasGOR Vs GVFlutfi awnAinda não há avaliações

- Basic Principles of Tube Line FabricationDocumento69 páginasBasic Principles of Tube Line Fabricationshan4600Ainda não há avaliações

- DGA and Its Interpretation Techniques For Power Transformers No CoverDocumento51 páginasDGA and Its Interpretation Techniques For Power Transformers No CovermriveroAinda não há avaliações

- 10000-PVC Fabric BpsDocumento4 páginas10000-PVC Fabric BpsHussain ElboshyAinda não há avaliações