Escolar Documentos

Profissional Documentos

Cultura Documentos

Renault Semiauto Gearbox

Enviado por

Steve GaddisDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Renault Semiauto Gearbox

Enviado por

Steve GaddisDireitos autorais:

Formatos disponíveis

Transmission

21B

SEMIAUTOMATIC GEARBOX

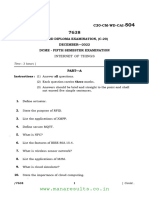

Semiautomatic Gearbox Vdiag no.: 04 Fault finding - Introduction Fault finding - System operation Fault finding - Allocation of computer tracks Fault finding - Replacing components Fault finding - Configurations and Programming Fault finding - Summary table of faults Fault finding - Interpretation of faults Fault finding - Conformity check Fault finding - Status summary table Fault finding - Summary table of parameters Fault finding - Interpretation of statuses Fault finding - Dealing with command modes Fault finding - Customer complaints Fault finding - Fault finding Chart

21B - 2 21B - 7 21B - 14 21B - 16 21B - 21 21B - 22 21B - 23 21B - 62 21B - 64 21B - 65 21B - 66 21B - 72 21B - 74 21B - 76

V3

"The repair procedures given by the manufacturer in this document are based on the technical specifications current when it was prepared. The procedures may be modified as a result of changes introduced by the manufacturer in the production of the various component units and accessories from which his vehicles are constructed." All rights reserved by Renault s.a.s.

Edition Anglaise

Copying or translating, in part or in full, of this document or use of the service part reference numbering system is forbidden without the prior written authority of Renault s.a.s.

Renault s.a.s.

MR-379-X70-21B000$000_engTOC.mif V3

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX 121B Fault finding - Introduction

21B

1. SCOPE OF THIS DOCUMENT This document presents the fault finding procedure applicable to all computers with the following specifications: Vehicles: MASTER for engines Function concerned: Semiautomatic gearbox Computer name: Program no.: Vdiag No.: 04

2. PREREQUISITES FOR FAULT FINDING Documentation type: Fault finding procedures (this manual): Assisted fault finding (integrated into the diagnostic tool), Dialogys. Wiring Diagrams: Visu-Schma (CD-ROM), paper. Diagnostic tools type: CLIP Type of special tooling required:

Special tooling required Multimeter El. 1589 El. 1681 Semiautomatic gearbox bornier Test probe kit

BVRPA6_V04_PRELI

MR-379-X70-21B000$065_eng.mif V3

BVR X7083 04 3.0

21B - 2

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - Introduction

21B

3. RECAP Procedure To run fault finding on the vehicle computers, switch on the ignition.

Fault Faults are declared as either present or stored (depending on whether they appeared in a certain context and have disappeared since, or whether they remain present but have not been diagnosed within the current context). The present or stored status of the fault should be taken into consideration when the diagnostic tool is used after the + after ignition feed has been connected (without any of the system components being activated). For a present fault, apply the procedure described in the Interpretation of faults section. For a stored fault , note the faults displayed and apply the Notes section. If the fault is confirmed when the instructions in the Notes section are applied, the fault is present. Deal with the fault If the fault is not confirmed, check: the electrical lines which correspond to the fault, the connectors for these lines (for oxidation, bent pins, etc.), the resistance of the component detected as faulty, the condition of the wires (melted or cut insulation, wear). Or use the fault finding procedure to check the circuit of the component concerned.

Check conformity The aim of the conformity check is to check data that does not produce a fault on the diagnostic tool because the data is inconsistent. Therefore, this phase allows: run fault finding on faults that do not have a fault display, and which may correspond to a customer complaint, a check to be carried out to check that the system is operating correctly and that there is no risk of a fault recurring after repairs. This section gives the fault finding procedures for statuses and parameters and the conditions for checking them. If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the corresponding fault finding page.

Customer complaints - Fault finding chart If the diagnostic tool check is in order, but the customer complaint is still present, the fault should be dealt with by customer complaints . A summary of the overall procedure to follow is provided on the following page in the form of a flow chart.

BVR X7083 04 3.0

MR-379-X70-21B000$065_eng.mif V3

21B - 3

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - Introduction

21B

4. FAULT FINDING PROCEDURE Check the battery charge and the condition of the fuses

Print the system fault finding log (available on CLIP or in the MR or TN)

Connect CLIP

Dialogue with the computer?

no See Fault Finding Chart no. 1

yes Read the faults

no Faults present Conformity check

yes Deal with faults found The cause is still present no Fault solved

Deal with stored faults Use the fault finding charts The cause is still present no Fault solved The cause is still present yes

no

Fault solved

Contact Techline with the completed fault finding log

BVR X7083 04 3.0

MR-379-X70-21B000$065_eng.mif V3

21B - 4

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - Introduction

21B

4. FAULT FINDING PROCEDURE (continued) Wiring check Fault finding problems Disconnecting the connectors and/or manipulating the wiring harness may temporarily remove the cause of a fault. Electrical voltage, resistance and insulation measurements are generally correct, especially if the fault is not present when the analysis is made (stored fault). Visual inspection Look for damage under the bonnet and in the passenger compartment. Carefully check the protective parts, insulators and wiring harness routing. Look for signs of oxidation. Tactile inspection While manipulating the wiring harness, use the diagnostic tool to note any change in fault status from stored to present. Make sure that the connectors are properly locked. Apply light pressure to the connectors. Twist the wiring harness. If there is a change in status, try to locate the source of the fault. Inspection of each component Disconnect the connectors and check the appearance of the clips and tabs, as well as their crimping (no crimping on the insulating section). Make sure that the clips and tabs are properly locked in the sockets. Check that no clips or tabs have been dislodged during connection. Check the clip contact pressure using an appropriate model of tab. Resistance check Check the continuity of entire lines, then section by section. Look for a short circuit to earth, the + 12 V feed or with another wire. If a fault is detected, repair or replace the wiring harness.

BVR X7083 04 3.0

MR-379-X70-21B000$065_eng.mif V3

21B - 5

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - Introduction

21B

5. FAULT FINDING LOG IMPORTANT Any fault on a complex system requires a full fault finding procedure with the appropriate tools. The FAULT FINDING LOG, which should be completed during the procedure, enables you to keep track of the procedure which is carried out. It is an essential document when consulting the manufacturer.

WARNING

IT IS MANDATORY TO FILL OUT A FAULT FINDING LOG FOR EACH FAULT FINDING PROCEDURE. You are always asked for this log: when requesting technical assistance from the Techline, for approval requests when replacing parts for which approval is obligatory, to be enclosed when returning monitored parts on request. The log is needed for warranty compensation, and enables better analysis of the parts removed.

6. SAFETY ADVICE Safety rules must be observed during any work on a component to prevent any damage or injury: make sure the battery is properly charged to avoid damaging the computers with a low load, use the appropriate tools.

BVR X7083 04 3.0

MR-379-X70-21B000$065_eng.mif V3

21B - 6

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - System operation

21B

Having already converted the "JH" gearbox to semiautomatic for the Twingo and Clio, Renault has now converted the "PK6" for the Trafic and Master. The converted PK6 is known as the PA6 The electrohydraulic system attached to the gearbox comprises two actuators, one for gear selection and changing, the other for operating the clutch, and a hydraulic power unit which supplies power to the actuators. The assembly is linked to the semiautomatic gearbox computer, which itself is linked to the engine computer by a CAN connection. The gear lever is used to select gears: in automatic mode, gear changes are controlled by the computer which uses auto-adaptive shift patterns; in manual mode, the driver moves a lever, which via the computer, changes the gears. When the gear is changed, the semiautomatic gearbox computer controls the engine management computer and the torque in such a way as to reduce jolts, leaving the driver free to leave his foot on the accelerator. The automatic mode used by the semiautomatic gearbox is based on the design of the DP0 automatic gearbox which uses shift patterns which adapt automatically to the driving style and road conditions. The gear change is determined by a set of gear change graphs as a function of the accelerator pedal position and the vehicle speed. The semiautomatic gearbox is a manual gearbox with a hydraulic control.

Description of user operation: The interface between the driver and the semiautomatic gearbox system inside the passenger compartment comprises: a gear lever (mechanical section and internal electronic section), a display, a TRACTION CONTROL (snow mode) button, a LOAD mode button, a buzzer. Using this interface, the driver can: request gear changes (up or down), request a specific gear change (into neutral or reverse), change between manual and automatic mode, activate and deactivate the traction control mode, activate and deactivate the load mode.

Description of passenger compartment control: Description of gear lever positions: S: Standby this is the only stable gear lever position. After each time the driver shifts the gear lever up or down, it returns to the S position. R: Reverse: moving the lever to this position enables the driver to select reverse. Given the lever position of the reverse function, it is possible, if the movement is too slow, for the semiautomatic gearbox computer to read N and hence select neutral before reverse.

BVR X7083 04 3.0

MR-379-X70-21B000$130_eng.mif V3

21B - 7

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - System operation

21B

Description of gear lever positions (continued): N: Neutral : moving the lever to this position enables the driver to select neutral. A/M: AUTO/MANUAL: moving the lever to this position enables the driver to select either manual mode (or semiautomatic) or automatic mode. If AUTO mode is selected, moving the lever will enable the driver to select manual mode, if manual mode is selected; moving the lever will enable the driver to select automatic mode. +: moving the gear lever towards this position enables the driver to shift up. If AUTO mode is selected, this action will also enable the driver to exit automatic mode. -: moving the gear lever towards this position will enable the driver to shift down. If AUTO mode is selected, this action will also enable the driver to exit automatic mode.

Description of the TRACTION CONTROL button: This is a one touch button. Pressing this button once allows the driver to select or deselect the TRACTION CONTROL mode.

Description of the LOAD button: This is a one touch button. Pressing this button once allows the driver to select or deselect the LOAD mode.

Description of the display: This display is designed for the PA6 gearbox. It features 6 displays to aid the driver: indicates the selected gear: 1, 2, 3, 4, 5, 6, N or R, the symbol displaying AUTO (A) mode: this symbol lights up when auto mode is selected. the TRACTION CONTROL indicator light: this lights up when the TRACTION CONTROL mode is selected. the LOAD mode indicator light: this lights up when the LOAD mode is selected. the depress brake pedal symbol: this symbol lights up when a driver action requires the brake pedal to be depressed when the driver is not depressing the brake. This symbol only lights up when there is an error (driver actions without depressing the brake pedal = symbol lighting up). the semiautomatic gearbox fault warning light: this lights up when the semiautomatic gearbox computer detects a fault on the semiautomatic gearbox system.

BVR X7083 04 3.0

MR-379-X70-21B000$130_eng.mif V3

21B - 8

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - System operation

21B

General information about the function: Reminder: creeping is only possible in first or reverse gears; it makes parking manoeuvres easier: if the brake pedal or the handbrake is released, the vehicle moves forward by itself, without the driver having to accelerate. Creeping is not possible in second gear. Operation in MANUAL mode: Manual mode allows the driver to select gears by moving the gear lever. However, in manual mode, the driver is not completely free to do what he/she likes. This is why this mode is also called semiautomatic mode because the driver is assisted by the semiautomatic gearbox computer in the following instances: when driving, shifting the lever towards the + position may result in underspeed. As a result, the semiautomatic gearbox computer forbids the driver's request, when driving, shifting the lever towards the - position may result in overspeed. As a result, the semiautomatic gearbox computer forbids the driver's request, when driving, as the overspeed threshold is approached, the computer automatically selects a higher gear, when driving, as the underspeed threshold is approached, the computer automatically selects a lower gear, when driving, if the vehicle speed decreases too quickly (brakes applied), the semiautomatic gearbox computer can order a downshift. when driving, the selection of N is only accepted by the semiautomatic gearbox computer if the driver's foot is on the brake pedal, when driving, selection of reverse is prohibited, when the vehicle is slowing and approaching 0 mph, the semiautomatic gearbox computer engages 1st gear automatically. In manual mode, the driver decides when to change gears by: moving the gear lever towards +, which enables a higher gear to be selected, moving the gear lever towards -, which enables a lower gear to be selected, moving the gear lever to N, which enables neutral to be selected, moving the gear lever to R, which enables reverse to be selected.

Operation in AUTOMATIC mode: Automatic mode frees the driver from having to worry about changing gear: instead, the semiautomatic gearbox computer determines when best to change gear in relation to the different vehicle parameters (speed, acceleration, position of accelerator pedal etc.). The main characteristics of automatic mode are as follows: AUTO mode is only operational and accessible when the engine is running. AUTO mode is preselected when the engine is started.

BVR X7083 04 3.0

MR-379-X70-21B000$130_eng.mif V3

21B - 9

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - System operation

21B

Operation in AUTOMATIC mode (continued): The AUTO mode entry conditions are as follows: Moving the gear lever to the left (towards A/M) when manual mode is selected, when a forward gear is engaged and AUTO mode was selected. TRACTION CONTROL mode deselected by pressing the TRACTION CONTROL button. Engine started up. To exit the AUTO mode when driving and in rated operation (no faults), the following conditions must apply: Movement of the gear lever to the left (deselecting automatic mode using the lever). Movement of gear lever towards "+" (except when engaging R towards 1 or N towards "X "). Movement of the gear lever towards "-" (except when changing from N to X or when reverse gear is engaged). Engine switched off. Ignition switched off or + Accessories active. TRACTION CONTROL mode selected by pressing the TRACTION CONTROL button.

Operation of the TRACTION CONTROL mode: The TRACTION CONTROL button imposes a special TRACTION CONTROL strategy which affects the middle levels (starting programming, gear change management) and the high levels ( LAA). The TRACTION CONTROL mode does not impose starting in 2 nd gear; starting is in 1st gear with special clutch management. The main characteristics of the TRACTION CONTROL mode are as follows: The TRACTION CONTROL mode imposes AUTO mode: if the driver presses the TRACTION CONTROL when manual mode is selected, the semiautomatic gearbox switches to AUTO mode and TRACTION CONTROL mode. There is no TRACTION CONTROL mode in manual mode; TRACTION CONTROL mode is only active in AUTO mode. When the TRACTION CONTROL button is pressed while TRACTION CONTROL mode is active, TRACTION CONTROL mode is deselected, but AUTO mode remains active. TRACTION CONTROL is only operational and accessible after the engine is started. The mode is not stored in the memory when the ignition is switched off; the driver must reselect snow mode each time the engine is started. The conditions for exiting TRACTION CONTROL mode are as follows: TRACTION CONTROL button pressed. Engine switched off. Ignition switched off and + Accessories reactivated. Select manual mode (move lever towards A/M). Movement of the gear lever towards "+" (except when engaging R towards 1 or N towards "X"). Movement of the gear lever towards "-" (except when engaging R towards 1 or N towards "X "). When driving, if the lever is moved towards "+" or "-", TRACTION CONTROL mode is deselected (return to MANUAL mode) and the request is accepted.

BVR X7083 04 3.0

MR-379-X70-21B000$130_eng.mif V3

21B - 10

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - System operation

21B

Operation of the LOAD MODE: The LOAD MODE is activated when the driver presses the LOAD button. LOAD MODE is only accessible after the engine is started. The mode is not stored in the memory when the ignition is switched off; the driver must reselect LOAD MODE each time the engine is started. If LOAD MODE is selected, the load indicator light comes on. However, if the computer detects a load even though the button has not been pressed, the load indicator light will not come on. LOAD MODE is independent of the other driving modes: LOAD MODE is active in manual mode, AUTO mode and TRACTION CONTROL mode. LOAD MODE is independent of all other driver actions (+, -, N, R, A/M). Conditions for exiting LOAD MODE are as follows: Switch off engine. Ignition switched off or + Accessories active. Load button pressed. Buzzer function: The buzzer operates in the following cases: Safety risk: the buzzer sounds when one of the front doors is opened, if the following conditions are met: the engine is running, a gear is engaged, the driver is not applying the brakes. The buzzer cuts out if one of the following conditions is confirmed: the engine is stopped, the driver applies the brakes, the driver closes the door(s). Driver warning when push-starting vehicle: The buzzer will sound to inform the driver that moving the lever to select a gear will enable the engine to start. The buzzer will sound when the vehicle has reached the speed that will allow the engine to start. When the computer detects that the clutch is overheating.

BVR X7083 04 3.0

MR-379-X70-21B000$130_eng.mif V3

21B - 11

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - System operation

21B

Lever operation: When the vehicle is stationary, the engine switched off and the key at + after ignition feed position, gear changes are possible. Each time the lever is moved, it returns to the S position automatically. When the vehicle is stationary, the engine switched off and the key at + after ignition feed, position, lever movements will only be considered if the driver depresses the brake pedal. In this case, all gears are available. The number of gear changes possible is unlimited. When the vehicle is stationary and the engine is running, lever movements will only be considered if the driver depresses the brake pedal. In this case, only N, 1, 2, R gears are available. Position N only allows neutral to be engaged if the driver depresses the brake pedal. Position R enables reverse to be engaged. Reverse will only be engaged if the vehicle has stopped or has nearly stopped and if the driver depresses the brake pedal. Engaging reverse when driving is prevented by the semiautomatic gearbox computer.

Operation of the display:

AUTO repeater: AUTO ("A") symbol lit: it lights up when AUTO mode is selected. Instrument panel display: the display shows "A" and the gear engaged. Symbol goes out: it goes out when AUTO mode is deselected.

TRACTION CONTROL MODE repeater: TRACTION CONTROL MODE symbol lit ("*"): it is lit when the TRACTION CONTROL MODE is selected and accepted by the computer (pressing the TRACTION CONTROL MODE requires the switch to AUTO mode, hence the display "A" + "*"). Instrument panel display: the display shows "*" + "A" + the gear engaged. the display is controlled in the same way as in AUTO mode. TRACTION CONTROL MODE goes out: the symbol goes out when TRACTION CONTROL mode is deselected.

LOAD MODE repeater: The LOAD MODE symbol lit: it is lit when LOAD MODE is selected and accepted by the computer. Instrument panel display: the display shows "C" + the gear engaged + "A" if AUTO mode is active or "A" + "*" if TRACTION CONTROL MODE is active. LOAD MODE goes out: The symbol goes out when LOAD MODE is deselected.

BVR X7083 04 3.0

MR-379-X70-21B000$130_eng.mif V3

21B - 12

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - System operation

21B

Display programming when gears cannot be engaged: When a request leads to overspeed or underspeed: the requested gear flashes then initial gear reappears. Flashing ends after a delay. When there is a mechanical fault (gearbox blockage etc.): application of the retry (1) program by the computer. During retry: the requested gear flashes; then, the engaged gear is displayed on the instrument panel at the end of the retry period. This program cannot be applied to neutral because the N position cannot flash on the instrument panel. (1) RETRY: If there is a mechanical problem engaging a gear (lower or higher), the computer will detect this and will attempt to re-enage twice more; if this does not work, the requested gear will flash on the instrument panel display and the gearbox will return to the gear used prior to this request.

Depress brake pedal repeater: This indicator is used when, during normal operation, it is necessary to depress the brake pedal and the driver has not done so. The indicator asks the driver to depress the brake pedal in order for his request to be accepted. Consequently: the symbol only lights up if there is a fault (driver action without brake pedal depressed = symbol lights up) and only if depressing the brake pedal allows the driver's request to be accepted. Depress brake pedal symbol lit: request to change gear when stopped without the brake pedal depressed, request to start engine with gear engaged without brake pedal depressed, request to select N when driving without brake pedal depressed, request to select AUTO, with the vehicle stationary, the engine running and 2nd gear engaged, request to select TRACTION CONTROL MODE, with the vehicle stationary, the engine running and 2 nd gear engaged. Foot on brake symbol goes out: The symbol goes out if the driver depresses the brake pedal or after an adjustable delay. Note: If, while the symbol is lit, the driver depresses the brake pedal, the symbol will go out and the display will return to its previous status (the lever request is not acted upon). In the event that the driver makes a request causing the gear requested to flash and the symbol to be displayed at the same time, they will be synchronised and last for the same period of time. Fault warning light: This warning light comes on when a fault is detected by the semiautomatic gearbox computer.

BVR X7083 04 3.0

MR-379-X70-21B000$130_eng.mif V3

21B - 13

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX

Fault finding - Allocation of computer tracks

21B

52-TRACK CONNECTOR Computer track 1 2 3 4 to 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 Power earth 1 Power earth 2 Selection solenoid valve 2 control Not used + lever switch feed + battery + after ignition feed Selection solenoid valve 1 control Not used Pump assembly relay Engagement solenoid valve 1 control CAN L Not used Not used Vehicle speed Not used Gearbox input speed sensor signal Engagement position sensor signal Oil pressure sensor signal Reversing lights relay Not used Clutch solenoid valve control Engagement solenoid valve 2 control CAN H Not used Not used Engine speed Diagnostic line K Speed sensor earth Selection position sensor signal Clutch position sensor signal

Allocation

BVR X7083 04 3.0

MR-379-X70-21B000$195_eng.mif V3

21B - 14

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX

Fault finding - Allocation of computer tracks

21B

28-TRACK CONNECTOR Computer track 53 to 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

Allocation Not used Lever contact earth Sensor earth (except clutch position sensor) Stb (stand-by) lever contact - lever switch feed Brake contact closed Load contact Traction control mode contact Not used 5 V supply from sensors N (neutral) lever contact Not used Starter motor key switch + signal Not used Front door switches Not used Not used

BVR X7083 04 3.0

MR-379-X70-21B000$195_eng.mif V3

21B - 15

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - Replacing components

21B

COMPUTER (RE)PROGRAMMING OPERATIONS The system can be programmed and reprogrammed via the diagnostic socket using the RENAULT CLIP fault finding tool (Consult Technical Note 3585A and follow the instructions provided by the diagnostic tool). IMPORTANT Switch on the diagnostic tool (mains or cigarette lighter supply). Connect a battery charger. Cut off all the electrical consumers (lights, interior lighting, air conditioning, radio CD, etc.). Put the gearbox in neutral. Before any computer (re)programming In the old computer, note the clutch replacement date ("Read new clutch fitting date") in the "Computer identification" screen. After any computer (re)programming A) B) C) Switch on the ignition. The engine coolant temperature must be below 50 C for the following stages to proceed correctly. Enter the VIN using command VP001 Enter VIN. Check the entry in the "Computer identification" screen. Repeat procedure C if unsuccessful. Clear all programming using the commands: RZ001 Stored fault(s), RZ002 Programming, RZ008 Initial closed position of clutch. Carry out automatic programming of the clutch end of travel using command VP017 "Program clutch closed position". In the "Function test" carry out the programming check: ET064 Clutch position programming = DONE. Repeat procedure E if unsuccessful. Use command AC007 Hydraulic unit pump rehabilitation. Program the gears using command VP008 Programming the selection/engagement ranges. Wait for the procedure to end. Exit fault finding mode and switch off the ignition. Wait 1 minute and then re-establish dialogue with the computer. In the "Function test" carry out the programming check: ET061 Gear programming = "CORRECT" Repeat procedure G if unsuccessful.

D)

E)

F) G)

BVR X7083 04 3.0

MR-379-X70-21B000$260_eng.mif V3

21B - 16

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - Replacing components

21B

COMPUTER (RE)PROGRAMMING OPERATIONS (continued) H) I) Brake and engage all gears, checking that they are recognised on the display. Put the gearbox in neutral. Start the engine. Wait 10 seconds without changing gear (for programming the clutch biting point). In the "Function test" carry out the programming check: ET062 Programme biting point = DONE, ET063 Solenoid valve zero point programming = DONE. Repeat procedure I if unsuccessful. Check that the coolant temperature is above 80C and that the PR095 "Clutch temperature" is below 180C. Repeat starting at half-load 5 or 6 times to program the clutch progressivity. Exit fault finding mode and switch off the ignition. Wait 1 minute and then re-establish dialogue with the computer. In the "Function test" carry out the programming check: ET065 "Progressivity proramming" = "COMPLETE". Repeat procedure J if unsuccessful. Enter the clutch replacement date using command VP013 Enter new clutch fitting date. Check the entry using Read new clutch fitting date in the Computer identification screen. Repeat procedure K if unsuccessful. Enter the last After-Sales operation date using command VP009 "Enter last After-Sales operation date". Check the entry using "Read last After-Sales operation date" in the "Computer identification" screen Repeat procedure L if unsuccessful. Exit fault finding mode and switch off the ignition. Wait 1 minute and then re-establish dialogue with the computer. Check the faults and clear the computer fault memory (some faults are stored when the command modes are used) or deal with the present faults. Carry out a road test followed by another check with the diagnostic tool.

J)

K)

L)

M) N) O)

BVR X7083 04 3.0

MR-379-X70-21B000$260_eng.mif V3

21B - 17

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - Replacing components

21B

ANY PART REPLACEMENT REQUIRES THE COMPULSORY REMOVAL OF THE WHOLE SEMIAUTOMATIC SYSTEM AND THE IMPLEMENTATION OF THE FOLLOWING PROGRAMMING AND CONFIGURATION PROCEDURES: A) B) C) Switch on the ignition and check that the engine coolant temperature is below 50C in order for the following stages to proceed correctly. Clear the computer fault memory using command: RZ001 Stored fault(s), Bleed the clutch circuit in accordance with the following procedure. Special tooling required: A 60 cc medical-type syringe, or one from hardener kit part no. 77 01 421 080 . Procedure condition: Engine switched off, handbrake engaged or brake pedal depressed, gearbox in neutral and no faults present on the solenoid valves or position sensor. Procedure:

Note: When bleeding, use a 19 mm ring spanner to immobilise the rotating union while tightening and loosening the bleed screw so as not to damage the slave cylinder and the pipe. Fill up the reservoir with the approved liquid for the clutch circuit. Remove the bleed screw cover. Connect a transparent pipe to the bleed screw connected to an empty syringe with a volume of 60 cc. Loosen the bleed screw. Suck up the liquid using the syringe, without emptying the reservoir. Wait until the sucked-up air is above the liquid level in the syringe. Discharge all of the fluid contained in the syringe without releasing the air contained in the top part of the syringe. The majority of the air bubbles go back up into the reservoir. Repeat this suction and discharge procedure a number of times, until all of the air bubbles have disappeared. Tighten the bleed screw and refit the cap. D) Bleed the clutch slave cylinder using command AC025 Bleed clutch slave cylinder hydraulic circuit. Wait for the procedure to end. Repeat procedure D if unsuccessful. Bleed the hydraulic pressure unit using command AC011 "Bleed hydraulic pressure unit". Wait for the procedure to end. Bleed the clutch hydraulic circuit using command AC009 "Clutch circuit phase 2 bleed". Wait for the procedure to end (this should take 8 minutes).

E) F)

BVR X7083 04 3.0

MR-379-X70-21B000$260_eng.mif V3

21B - 18

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - Replacing components

21B

G)

Before clearing all the programming using the following commands, the enigne coolant temperature must be below 50C for the following stages to proceed correctly: RZ002 Programming, RZ003 Clutch biting point programming, RZ008 Initial closed position of clutch. Exit fault finding mode and switch off the ignition. Wait 1 minute and then re-establish dialogue with the computer. Carry out automatic programming of the clutch end of travel using command VP017 "Program clutch closed position". In the "Function test" carry out the programming check: ET064 Clutch position programming = DONE. Repeat procedure H if unsuccessful. Program the gears using command VP008 Programming the selection/engagement ranges. Wait for the procedure to end Exit fault finding mode and switch off the ignition. Wait 1 minute and then re-establish dialogue with the computer. In the "Function test" carry out the programming check: ET061 Gear programming = "CORRECT" Repeat procedure I if unsuccessful. Brake and engage all gears, checking that they are recognised on the display. Put the gearbox in neutral. Start the engine. Wait 10 seconds without changing gear (for programming the clutch biting point). In the "Function test" carry out the programming check: ET062 Programme biting point = DONE, ET063 Solenoid valve zero point programming = DONE. Repeat procedure K if unsuccessful. Check that the coolant temperature is above 80C and that the PR095 "Clutch temperature" is below 180C. Repeat starting at half-load 5 or 6 times to program the clutch progressivity. Exit fault finding mode and switch off the ignition. Wait 1 minute and then re-establish dialogue with the computer. In the "Function test" carry out the programming check: ET065 "Progressivity proramming" = "COMPLETE". Repeat procedure L if unsuccessful. Exit fault finding mode and switch off the ignition.

H)

I)

J) K)

L)

M)

BVR X7083 04 3.0

MR-379-X70-21B000$260_eng.mif V3

21B - 19

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX Fault finding - Replacing components

21B

N)

Only use this configuration if the clutch has been replaced, otherwise go straight to stage O. Enter the clutch replacement date using command VP013 Enter new clutch fitting date. Check the entry using Read new clutch fitting date in the Computer identification screen. Repeat procedure N if unsuccessful. Enter the last After-Sales operation date using command VP009 "Enter last After-Sales operation date". Check the entry using "Read last After-Sales operation date" in the "Computer identification" screen Repeat procedure O if unsuccessful. Exit fault finding mode and switch off the ignition. Wait 1 minute and then re-establish dialogue with the computer. Check the faults and clear the computer fault memory (some faults are stored when the command modes are used) or deal with the present faults. Carry out a road test followed by another check with the diagnostic tool.

O)

P) Q) R)

BVR X7083 04 3.0

MR-379-X70-21B000$260_eng.mif V3

21B - 20

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX

Fault finding - Configurations and Programming

21B

CONFIGURATION VP001: Write VIN. This command permits manual entry of the vehicle's VIN into the computer. Use this command each time the computer is replaced or (re)programmed. Programming selection/engagement zones. This command enables the gears to be programmed.

VP008:

Use this command each time parts are replaced; see "Replacing components". Note: When replacing or (re)programming a computer, use command AC007 Hydraulic unit pump rehabilitation before running parameter VP008 . VP009: Write date of the last After Sales service. Use this command for each workshop operation on the semiautomatic gearbox.

Select command VP009 on the diagnostic tool. Enter the service date using the tool's keypad. VP013: Enter date of fitting new clutch. This command should be used when the clutch is replaced.

Select command VP013 on the diagnostic tool. Enter the service date using the tool's keypad. VP014: Enter initial closed position of clutch. This command enables the value of the initial closed position of the clutch to be re-entered into a new or reprogrammed computer in order to keep a consistent record of the clutch wear.

Use this command each time the computer is replaced or reprogrammed. VP017: Clutch closed position programming. This command is used to automatically program the clutch end of travel.

Use this command each time parts are replaced; see "Replacing components".

BVR X7083 04 3.0

MR-379-X70-21B000$325_eng.mif V3

21B - 21

Semiautomatic Gearbox Vdiag no.: 04

SEMIAUTOMATIC GEARBOX

Fault finding - Summary table of faults

21B

Tool fault DF002 DF005 DF039 DF046 DF048 DF057 DF062 DF065 DF066 DF067 DF068 DF069 DF070 DF071 DF072 DF073 DF074 DF075 DF076 DF077 DF078 DF080 DF082 DF107 DF108 DF144 DF145 DF146 DF148 DF152 DF153 DF183 DF184 DF186 DF188 DF189 DF190

Diagnostic tool title Computer Oil pressure sensor circuit Engine speed signal Idling setpoint multiplex signal Vehicle speed signal Gearbox input speed sensor circuit CAN fault Pump relay circuit Starter motor relay circuit Lever position switch circuit Clutch position sensor circuit Selection position sensor circuit Engagement position sensor circuit Clutch solenoid valve circuit Engagement solenoid valve 1 circuit Engagement solenoid valve 2 circuit Selection solenoid valve 1 circuit Selection solenoid valve 2 circuit Clutch control Gearbox control Hydraulic control Battery voltage Stop lights switch circuit Engine speed multiplex signal Multiplex effective average torque signal Coolant temperature multiplex signal Multiplex pedal position signal Off-gear reduction torque multiplex signal P/N contact secondary brake multiplex contact P/N contact total distance covered multiplex signal reversing lights control No UCH multiplex signal No instrument panel multiplex signal No injection multiplex signal System operation Gears programming Clutch position programming

BVR X7083 04 3.0

MR-379-X70-21B000$390_eng.mif V3

21B - 22

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

COMPUTER

21B

DF002 PRESENT

1.DEF: internal electronic fault 2.DEF: main relay fault (integral to computer)

NOTES

None

Check the condition and position of the sequential gearbox fuses in the engine compartment and in the passenger compartment. Check the condition and the connection of the computer's 52-track connector. Repair if necessary. Check for + before ignition feed on track 27 and of + after ignition feed on track 28 on the computer's 52-track connector. Repair if necessary. Check the insulation, continuity and absence of interference resistance on the following connections: Chassis earth Tracks 1 and 2 of the 52-track computer connector Repair if necessary.

Clear the computer fault memory and exit fault finding. Switch off the ignition. Switch on the ignition again and carry out a new check using the diagnostic tool. If the fault is still present, contact the Techline.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF002P

MR-379-X70-21B000$455_eng.mif V3

21B - 23

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

OIL PRESSURE SENSOR CIRCUIT

21B

DF005 PRESENT

CO.0 : open circuit or short circuit to earth CC.1 : short circuit to + 12 V 1.DEF: consistent

NOTES

None

CO.0 CC.1

NOTES

None

Check the condition and positioning of the 30A pump fuse in the engine compartment. Repair if necessary. Check the connections of the sensor connector and computer connectors. Check the continuity and insulation of the connections between: Sensor connector track A Track 66 computer connector Sensor connector track B Track 73 computer connector Sensor connector track C Track 40 computer connector If the connection is faulty: Disconnect the intermediate black 24-track connector positioned on the hydraulic unit; check the condition of its connections. Check the continuity and insulation of the connections between: Sensor connector track A Track C1 intermediate connector Sensor connector track B Track C8 intermediate connector Sensor connector track C Track C5 intermediate connector Also check the insulation between these connections. Check the continuity and insulation of the connections between: Computer connector track 66 Track C1 intermediate connector Computer connector track 73 Track C8 intermediate connector Computer connector track 40 Track C5 intermediate connector Also check the insulation between these connections. If the fault is still present, replace the oil pressure sensor on the sequential gearbox.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check using the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF005P

MR-379-X70-21B000$455_eng.mif V3

21B - 24

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

21B

DF005 CONTINUED

1.DEF

NOTES

None

Check the level of oil with the accumulator discharged, see the interpretation of command AC081 Discharge pressure accumulator . Check the condition and positioning of the 30A pump fuse in the engine compartment. Repair if necessary. Use command AC012 Hydraulic pump relay with the diagnostic tool and check that the pump assembly is working. If the pump is not working, perform the necessary repairs. If the fault is still present, replace the oil pressure sensor. Switch off the ignition. Switch on the ignition again and carry out a new check using the diagnostic tool. Replace the pump unit if the fault reappears.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check using the diagnostic tool.

BVR X7083 04 3.0

MR-379-X70-21B000$455_eng.mif V3

21B - 25

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

ENGINE SPEED SIGNAL (wire connection)

21B

DF039 STORED

1.DEF: consistent 2.DEF: no signal

NOTES

Conditions for applying the fault finding procedure to stored faults: The fault is declared present after the engine starts.

Check the injection system and deal with any faults. Check the connection and condition of the 52-track sequential gearbox computer connectors and the injection computer black 32-track connector A. Repair if necessary. Check the insulation, continuity and absence of interference resistance on the following connection: Sequential gearbox computer track 48 Track B2 injection computer black connector A Repair if necessary.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF039M

MR-379-X70-21B000$455_eng.mif V3

21B - 26

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

IDLING SETPOINT MULTIPLEX SIGNAL

21B

DF046 STORED

1.DEF: incorrect parameter

NOTES

Conditions for applying the fault finding procedure to stored faults: The fault appears after: The computer fault memory has been cleared. The ignition has been switched off and on again. Starting the engine.

Carry out the multiplex network test. Check the injection system.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check using the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF046M

MR-379-X70-21B000$455_eng.mif V3

21B - 27

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

VEHICLE SPEED SIGNAL

21B

DF048 STORED

1.DEF: consistent 2.DEF: no signal

NOTES

Special notes: The fault can only be cleared from the memory using the diagnostic tool after a road test where the vehicle speed signal is detected by the computer. Conditions for applying the fault finding procedure to stored faults: The fault is declared present after a road test.

Check that the gearbox input speed sensor and the engine speed sensor are operating correctly. Check the mechanical condition of the clutch. Check that the speedometer is working correctly when driving. Check the connection and condition of the sequential gearbox and ABS computer connectors. Repair if necessary. Check the insulation, continuity and the absence of interference resistance on the following connection: Sequential gearbox computer track 36 Track 14 instrument panel black connector Repair if necessary. Apply the After repair procedure to clear this fault.

AFTER REPAIR

A road test must be performed along with another check using the diagnostic tool to clear the vehicle speed signal fault.

BVR X7083 04 3.0

BVRPA6_V04_DF048M

MR-379-X70-21B000$455_eng.mif V3

21B - 28

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

GEARBOX INPUT SPEED SENSOR CIRCUIT

21B

DF057 STORED

1.DEF: consistent 2.DEF: no signal

NOTES

Special notes: The fault can only be cleared from the memory using the diagnostic tool after a road test where the vehicle speed signal is detected by the computer. Conditions for applying the fault finding procedure to stored faults: The fault is declared present following a road test at a speed above 6 mph (10 km/h)).

1.DEF

NOTES

None

Check that the engine speed sensor is operating correctly and check by performing a road test that the speedometer is operating. Check the mechanical condition of the clutch.

AFTER REPAIR

A road test must be performed along with another check using the diagnostic tool to clear the gearbox input speed sensor fault.

BVR X7083 04 3.0

BVRPA6_V04_DF057M

MR-379-X70-21B000$455_eng.mif V3

21B - 29

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

21B

DF057 CONTINUED

2.DEF

NOTES

None

Check the condition and connection of the gearbox input speed sensor connector. Repair if necessary. Check that the sensor is correctly fitted on the gearbox. Check the speedometer is operating correctly. Check the connection and condition of the 52-track sequential gearbox computer connector. Repair if necessary. Check the continuity and insulation of the connections between: Sensor connector track 1 Track 38 computer connector Sensor connector track 2 Track 50 computer connector If the connection is faulty: Disconnect the 24-track black intermediate connector positioned on the hydraulic unit; check the condition of its connections. Check the continuity and insulation of the connections between: Computer connector track 38 Track C7 intermediate connector Computer connector track 50 Track C6 intermediate connector Also check the insulation between these connections. Check the continuity and insulation of the connections between: Sensor connector track 1 Track C7 intermediate connector Sensor connector track 2 Track C6 intermediate connector Also check the insulation between these connections. If the fault is still present, replace the engine speed sensor on the sequential gearbox.

AFTER REPAIR

A road test must be performed along with another check using the diagnostic tool to clear the gearbox input speed sensor fault.

BVR X7083 04 3.0

MR-379-X70-21B000$455_eng.mif V3

21B - 30

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

MULTIPLEX LINE FAULT

21B

DF062 PRESENT

1.DEF: CAN connection fault

NOTES

Conditions for applying the fault finding procedure to stored faults: The fault appears after: the computer fault memory is cleared, the ignition is switched off and on again and the engine is started.

Carry out the multiplex network test.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF062P

MR-379-X70-21B000$455_eng.mif V3

21B - 31

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

PUMP RELAY CIRCUIT

21B

DF065 PRESENT

CC.0 : short circuit to earth CO.1 : open circuit or short circuit to + 12 volts 1.DEF: pump motor permanent control or open circuit

NOTES

Priorities when dealing with a number of faults: First, deal with fault DF005 Oil pressure sensor circuit.

CC.0 CO.1

NOTES

None

Check for the presence and conformity of the relay in the engine fuse box. Check the connections and condition of the computer and pump relay connectors. Check for + before ignition feed between tracks 2 and 3 of the relay. Repair if necessary. Check for continuity and insulation on the connections between: Relay connector track 1 Track 31 computer connector If the fault is still present, replace the pump relay.

1.DEF

NOTES

None

Check that PR018 Hydraulic pressure when the ignition is switched on is between 40 bar and 50 bar, if not, apply fault finding procedure DF005. If the checks described in DF005 are correct and PR018 shows a pressure value lower than the one given previously following the pump motor starting up, replace the pressure sensor. Ensure that the pump motor is not seized. Disconnect the relay and check there is no continuity between tracks 3 and 5 of the relay. Replace the relay if necessary (relay is jammed). Check that there is insulation to + 12 V between track 5 of the relay and track B of the pump motor. Repair if necessary. Check for the absence of + 12 V on track 1 of the relay. Check for insulation to + 12 V between track 31 of the computer connector and track 1 of the relay mounting. Repair if necessary. If the checks are in order, the computer is continuously supplying the pump motor. Replace the sequential gearbox computer.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF065P

MR-379-X70-21B000$455_eng.mif V3

21B - 32

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

STARTER RELAY CIRCUIT

21B

DF066 PRESENT

CC.1 : short circuit to + 12 V CO : open circuit

NOTES

None

CO.0 CC.1

NOTES

None

Check the presence and conformity of the relay in the engine fuse box. Check the connection and condition of the computer and starter relay connections. Repair if necessary. Check for + after ignition feed on track 1 on the relay connector and the vehicle earth. Repair if necessary. Check for continuity and insulation on the connections between: Relay connector track 2 Track 42 computer connector Relay connector track 3 Track 76 computer connector If the checks are correct, check the earth connection via the computer on the relay connector between tracks 1 (+ 12 V) and 2 (earth) with command AC013 Starter relay using the diagnostic tool. If the voltage is correct, replace the starter relay. If the voltage is incorrect, contact Techline.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check using the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF066P

MR-379-X70-21B000$455_eng.mif V3

21B - 33

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

LEVER POSITION SWITCH CIRCUIT

21B

DF067 PRESENT

CC.0 : short circuit to earth CO.1 : open circuit or short circuit to + 12 volts

NOTES

None

CC.0 CO.1

NOTES

None

Check the connection and condition of the lever switch and computer connectors. Check the continuity and insulation of the connections between: Switch connector track A1 Track 74 Computer connector Switch connector track A2 Track 65 Computer connector Switch connector track A3 Track 26 Computer connector Switch connector track B2 Track 67 Computer connector Switch connector track B3 Track 68 Computer connector Also check the insulation between these 5 connections. Repair if necessary. Apply the fault finding procedure associated with statuses: ET043, ET044, ET045 and ET046 in the interpretation of statuses fault finding procedure.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF067P

MR-379-X70-21B000$455_eng.mif V3

21B - 34

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

CLUTCH POSITION SENSOR CIRCUIT

21B

DF068 PRESENT

CC.0 : short circuit to earth CO.1 : open circuit or short circuit to + 12 volts 1.DEF: consistent

NOTES

None

CC.0 CO.1

NOTES

None

Check the connection and condition of the computer and sensor connections. Check the continuity and insulation of the connections between: Sensor connector track A Track 73 computer connector Sensor connector track B Track 66 computer connector Sensor connector track C Track 52 computer connector If the connection is faulty: Disconnect the 24-track intermediate connector positioned on the hydraulic unit; check the condition of its connections. Check the continuity and insulation of the connections between: Computer connector track 73 Track C8 intermediate connector Computer connector track 66 Track C1 intermediate connector Computer connector track 52 Track C4 intermediate connector Also check the insulation between these connections. Repair if necessary. Check the continuity and insulation of the connections between: Sensor connector track A Track C8 intermediate connector Sensor connector track B Track C1 intermediate connector Sensor connector track C Track C4 intermediate connector Also check the insulation between these connections. Repair if necessary.

Check the condition of the hydraulic control (leak, etc.). Repair if necessary. If the fault is still present, replace the clutch position sensor.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF068P

MR-379-X70-21B000$455_eng.mif V3

21B - 35

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

21B

DF068 CONTINUED

1.DEF

NOTES

None

Check the condition and fitting of the clutch position sensor (potentiometer mounting and mechanism, etc.). Check the connection and condition of the computer and sensor connections. Check the continuity and insulation of the connections between: Sensor connector track A Track 73 Computer connector Sensor connector track B Track 66 Computer connector Sensor connector track C Track 52 Computer connector Also check the insulation between these 3 connections. Repair if necessary. With the engine running, check using the diagnostic tool that PR006 = PR014. Repair if necessary. If the checks show no faults, replace the clutch position sensor. If the fault is still present, check that the clutch is not overheating.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

MR-379-X70-21B000$455_eng.mif V3

21B - 36

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

SELECTION POSITION SENSOR CIRCUIT

21B

DF069 PRESENT

CC.0 : short circuit to earth CO.1 : open circuit or short circuit to + 12 volts

NOTES

None

Check the connection and condition of the computer and sensor connections. Check the continuity and insulation of the connections between: Sensor connector track A Track 73 computer connector Sensor connector track B Track 66 computer connector Sensor connector track C Track 51 computer connector If the connection is faulty: Disconnect the 24-track intermediate connector positioned on the hydraulic unit; check the condition of its connections. Check the continuity and insulation of the connections between: Computer connector track 73 Track C8 intermediate connector Computer connector track 66 Track C1 intermediate connector Computer connector track 51 Track C3 intermediate connector Also check the insulation between these 3 connections. Repair if necessary. Check the continuity and insulation of the connections between: Sensor connector track A Track C8 intermediate connector Sensor connector track B Track C1 intermediate connector Sensor connector track C Track C3 intermediate connector Also check the insulation between these 3 connections. Repair if necessary. Remove the selection position sensor and check the wear of the potentiometer-cylinder mechanical connection. Repair if necessary. If the checks show no faults, replace the selection position sensor.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF069P

MR-379-X70-21B000$455_eng.mif V3

21B - 37

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

ENGAGEMENT POSITION SENSOR CIRCUIT

21B

DF070 PRESENT

CC.0 : Short circuit to earth CO.1 : Open circuit or short circuit to + 12 V

NOTES

None

Check the connection and condition of the computer and sensor connections. Check the continuity and insulation of the connections between: Sensor connector track A Track 73 computer connector Sensor connector track B Track 66 computer connector Sensor connector track C Track 39 computer connector If the connection is faulty: Disconnect the 24-track intermediate connector positioned on the hydraulic unit; check the condition of its connections. Check the continuity and insulation of the connections between: Computer connector track 73 Track C8 intermediate connector Computer connector track 66 Track C1 intermediate connector Computer connector track 39 Track C2 intermediate connector Also check the insulation between these 3 connections. Repair if necessary. Check the continuity and insulation of the connections between: Sensor connector track A Track C8 intermediate connector Sensor connector track B Track C1 intermediate connector Sensor connector track C Track C2 intermediate connector Also check the insulation between these 3 connections. Repair if necessary. Remove the engagement position sensor and check the wear of the mechanical cylinder-potentiometer connection. Repair if necessary. If the checks show no faults, replace the engagement position sensor.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check using the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF070P

MR-379-X70-21B000$455_eng.mif V3

21B - 38

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

CLUTCH SOLENOID VALVE CIRCUIT

CC.0 : short circuit to earth CC.1 : short circuit to + 12 V CO : open circuit

21B

DF071 PRESENT OR STORED

NOTES

Conditions for applying the fault finding procedure to stored faults: A fault is declared present after engaging all gears, with the brake pedal depressed and the engine stopped.

Check the connections and condition of the computer and solenoid valve connections. Check the continuity and insulation of the connections between: Sensor connector track 1 Track 43 computer connector Sensor connector track 2 Earth terminal on hydraulic block If the connection is faulty: Disconnect the 24-track intermediate connector positioned on the hydraulic unit; check the condition of its connections. Check and ensure the continuity and insulation of the connection between: Computer connector track 43 Track B2 intermediate connector Repair if necessary. Check and ensure the continuity and insulation of the connection between: Solenoid valve connector track 1 Track B2 intermediate connector Repair if necessary. If the checks reveal no faults, replace the clutch solenoid valve.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check using the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF071

MR-379-X70-21B000$455_eng.mif V3

21B - 39

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

ENGAGEMENT SOLENOID VALVE 1 CIRCUIT

CC.0 : short circuit to earth CC.1 : short circuit to + 12 V CO : open circuit

21B

DF072 PRESENT OR STORED

NOTES

Conditions for applying the fault finding procedure to stored faults: A fault is declared present after engaging all gears, with the brake pedal depressed and the engine stopped.

Check the connections and condition of the computer and solenoid valve connections. Check the continuity and insulation of the connections between: Solenoid valve connector track 1 Track 32 computer connector Solenoid valve connector track 2 Earth terminal on hydraulic block If the connection is faulty: Disconnect the 24-track intermediate connector positioned on the hydraulic unit and check the condition of its connection. Check and ensure the continuity and insulation of the connection between: Computer connector track 32 Track B5 intermediate connector Repair if necessary. Check and ensure the continuity and insulation of the connection between: Solenoid valve connector track 1 Track B5 intermediate connector Repair if necessary. If the checks are correct, replace engagement solenoid valve 1.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF072

MR-379-X70-21B000$455_eng.mif V3

21B - 40

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

ENGAGEMENT SOLENOID VALVE 2 CIRCUIT

CC.1 : short circuit to + 12 V CC.0 : short circuit to earth CO : open circuit

21B

DF073 PRESENT OR STORED

NOTES

Conditions for applying the fault finding procedure to stored faults: A fault is declared present after engaging all gears, with the brake pedal depressed and the engine stopped.

Check the connections and condition of the computer and solenoid valve connections. Check the continuity and insulation of the connections between: Solenoid valve connector track 1 Track 44 computer connector Solenoid valve connector track 2 Earth terminal on hydraulic block If the connection is faulty: Disconnect the 24-track intermediate connector positioned on the hydraulic unit; check the condition of its connections. Check and ensure the continuity and insulation of the connection between: Computer connector track 44 Track B3 intermediate connector Repair if necessary. Check and ensure the continuity and insulation of the connection between: Solenoid valve connector track 1 Track B3 intermediate connector Repair if necessary. If the checks are correct, replace engagement solenoid valve 2.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check using the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF073

MR-379-X70-21B000$455_eng.mif V3

21B - 41

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

SELECTION SOLENOID VALVE 1 CIRCUIT

21B

DF074 STORED

CC.1 : short circuit to + 12 V CO.0 : open circuit or short circuit to earth

NOTES

Conditions for applying the fault finding procedure to stored faults: If DF077 is present with DF074 stored, first apply the fault processing procedure below. If only DF074 is stored, apply the fault finding procedure below, if the fault is present following engagement of all the gears, with the brake pedal depressed and the engine stopped.

Check the connections and condition of the computer and solenoid valve connections. Check the continuity and insulation of the connections between: Solenoid valve connector track 1 Track 29 computer connector Solenoid valve connector track 2 Earth terminal on hydraulic block If the connection is faulty: Disconnect the 24-track intermediate connector positioned on the hydraulic unit; check the condition of its connections. Check and ensure the continuity and insulation of the connection between: Computer connector track 29 Track B4 intermediate connector Repair if necessary. Check and ensure the continuity and insulation of the connection between: Solenoid valve connector track 1 Track B4 intermediate connector Repair if necessary. If the checks are correct, replace selection solenoid valve 1.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF074M

MR-379-X70-21B000$455_eng.mif V3

21B - 42

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

SELECTION SOLENOID VALVE 2 CIRCUIT

21B

DF075 STORED

CC.1 : short circuit to + 12 V CO.0 : open circuit or short circuit to earth

NOTES

Conditions for applying the fault finding procedure to stored faults: If DF077 is present with DF075 stored, first apply the fault processing procedure below. If only DF075 is stored, apply the fault finding procedure below, if the fault is present following engagement of all the gears, with the brake pedal depressed and the engine stopped.

Check the connections and condition of the computer and solenoid valve connections. Check the continuity and insulation of the connections between: Solenoid valve connector track 1 Track 3 computer connector Solenoid valve connector track 2 Earth terminal on hydraulic block If the connection is faulty: Disconnect the 24-track intermediate connector positioned on the hydraulic unit; check the condition of its connections. Check and ensure the continuity and insulation of the connection between: Computer connector track 3 Track B6 intermediate connector Repair if necessary. Check and ensure the continuity and insulation of the connection between: Solenoid valve connector track 1 Track B6 intermediate connector Repair if necessary. If the checks are correct, replace selection solenoid valve 2.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check using the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF075M

MR-379-X70-21B000$455_eng.mif V3

21B - 43

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

CLUTCH CONTROL

21B

DF076 STORED

1.DEF: clutch overheating 2.DEF: position inconsistency between master cylinder and slave cylinder 3.DEF: clutch inconsistency when changing gear

Priorities when dealing with a number of faults: If faults DF076, DF039 and DF107 are all present, deal with faults DF039 and DF107 first. NOTES Conditions for applying the fault finding procedure to stored faults: Apply the fault finding procedure below if the fault is present or stored. Special notes: This fault appears following excessive use of the clutch (prolonged holding on slopes, PR095 > 248 C). When PR095 > 248 C, the buzzer sounds.

1.DEF

NOTES

None

Check that the clutch is not slipping by performing a road test, driving with a low load and then up or down an incline. If the clutch is slipping: pull away several times with a low load and check the development of the PR096 Clutch progressivity. If the fault is still present, replace the clutch.

2.DEF

NOTES

None

Check the fluid level and the clutch control circuit sealing. Repair if necessary (see MR 377, section 2 or 3 or Technical Note 3803A for the vehicle concerned).

3.DEF

NOTES

None

Check the hydraulic and mechanical condition (leaks, discharge, sticking) of the clutch control circuit. Check the condition of the clutch solenoid valve. Repair if necessary (see MR 377, section 2 or 3 or Technical Note 3803A for the vehicle concerned).

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF076M

MR-379-X70-21B000$455_eng.mif V3

21B - 44

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

GEARBOX SERVO CONTROL

21B

DF077 PRESENT OR STORED

1.DEF: 2.DEF: 3.DEF: 4.DEF: 5.DEF:

automatic mode fault mechanical fault gear selection impossible loss of engaged gear automatic transmission malfunction when changing gear.

Priorities when dealing with a number of faults: If faults DF077 and DF076 (2.DEF, 3.DEF) are stored, deal with fault DF076 first. Conditions for applying the fault finding procedure to stored faults: Apply the fault finding procedure below if the fault is present or stored. Special notes: This fault appears following excessive use of the clutch (prolonged holding on slopes, PR095 > 248 C). When PR095 > 248 C, the buzzer sounds.

NOTES

1.DEF

NOTES

None

If there is a fault linked to the injection, deal with the engine injection fault finding part. If there are no faults in the engine, this fault is only due to forward movement with significant skidding on a slippery road followed by a return to tyre adhesion. Clear the fault and carry out a road test.

2.DEF 3.DEF 4.DEF

NOTES

Special notes: Improper use of lever when the vehicle is stationary may lead to this fault.

Check that there are no faults on a selection or engagement sensor and repair if necessary. Via the inspection flap, check that the hydraulic unit is correctly clipped to the gearbox control. Carry out the necessary repairs. Check there is no water in the gearbox oil. Repair if necessary. If it is difficult to select gears, especially reverse gear, apply the procedure for PR018 Hydraulic pressure described in the conformity check. Clear the computer fault memory. Follow the programming procedure described in Replacement of components. If the fault is still present, there is an internal mechanical fault in the gearbox, replace the gearbox (see MR377 Mechanical systems, 21 B, Sequential gearbox: Removal - Refitting).

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF077

MR-379-X70-21B000$455_eng.mif V3

21B - 45

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

21B

DF077 CONTINUED 1

5.DEF

NOTES

None

Step 1 Switch on the ignition, connect the diagnostic tool, engage 1st gear and display the value of parameter PR017 Engagement position . Engage neutral, wait 15 seconds and check the value of parameter PR017 Engagement position. 1) If the value changes: go to step 3. 2) If the value does not change, check that the connectors on the engagement position sensor, computer and intermediate connector are correctly connected and check the value of parameter PR017 Engagement position. If the value changes after an operation on the engagement position sensor and computer connectors, repair the connector, otherwise change the wiring (see Technical Note 6015A, Repairing electrical wiring, wiring: Precautions for repair ). Repeat the procedure and if the value still does not change: go to step 2.

Step 2 Check the continuity and insulation of the connections between: 57AF between components 1055 and 119 , 57AD between components 1055 and 119, 51FA between components 1055 and 119 . If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it. Remove the engagement position sensor and check the wear on the mechanical connection of the cylinderpotentiometer (excessive play, mechanical connection broken or jammed). If the checks are correct, replace the engagement position sensor (see MR377 Mechanical systems, 21 B, Sequential gearbox, engagement sensor: Removal - Refitting). Step 3 Carry out step 1 for each gear change (1st, 2nd, 3rd, 4 th, 5th and 6 th). 1) If the engagement position sensor values differ from the neutral value, go to step 4. 2) If there is an inconsistency in the engagement position sensor during these checks, check the wear on the cylinder-potentiometer mechanical connection (excessive play, mechanical connection broken or jammed). If the checks are correct, replace the engagement position sensor (see MR377 Mechanical systems, 21 B, Sequential gearbox, Engagement sensor: Removal - Refitting).

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

MR-379-X70-21B000$455_eng.mif V3

21B - 46

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

21B

DF077 CONTINUED 2

Step 4 With a warm engine, carry out step 1 for each gear change (1 st, 2nd, 3 rd, 4 th, 5 th and 6th). 1) If there is an inconsistency in the engagement position sensor during these checks, check the wear on the cylinder-potentiometer mechanical connection (excessive play, mechanical connection broken or jammed). If the checks are correct, replace the engagement position sensor (see MR377 Mechanical systems, 21 B, Sequential gearbox, engagement sensor: Removal - Refitting). 2) If the engagement position sensor values differ from the neutral value, go to step 5.

Step 5 Start the engine, engage 1st gear and wait 15 seconds. Engage neutral and display the value of parameter PR017 Engagement position , wait 15 seconds and check that the value does not change. 1) Switch off the engine and wait 15 seconds, if it is impossible to push the vehicle, either the engagement solenoid valve or the engagement position sensor is the cause (see MR377 Mechanical systems, 21 B, Sequential gearbox, engagement sensor: Removal - Refitting) and (see MR408 Mechanical systems, 21B, Solenoid valves: Removal - Refitting). 2) If it is possible to push the vehicle: go to step 6 Step 6 Start the engine, engage 2 nd gear and wait 15 seconds. Engage neutral and display the value of parameter PR017 Engagement position , wait 15 seconds and check that the value does not change. Switch off the engine and wait 15 seconds, if it is impossible to push the vehicle, either the engagement solenoid valve or the engagement position sensor is the cause (see MR377 Mechanical systems, 21 B, Sequential gearbox, engagement sensor: Removal - Refitting) (see MR 408 Mechanical systems, 21B Solenoid valves: Removal - Refitting). If the fault is still present, contact the Techline.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

MR-379-X70-21B000$455_eng.mif V3

21B - 47

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

HYDRAULIC SERVO CONTROL

21B

DF078 PRESENT OR STORED

1.DEF: 2.DEF: 3.DEF: 4.DEF: 5.DEF:

pressure too low pump fault slow pressure loss pressure accumulator fault rapid pressure loss

Priorities when dealing with a number of faults: Apply the interpretation of the other faults first. NOTES Conditions for applying the fault finding procedure to stored faults: The fault is declared present during a road test.

1.DEF

NOTES

Special notes: Improper use of lever when the vehicle is stationary may lead to this fault.

Check PR018 Hydraulic pressure, using the diagnostic tool, to make sure that the pump starts at 40 bar and stops at 50 bar. Pressure level below a pressure threshold. Fault linked to a lack of oil (internal or external leak) or to a pump failure. Repair or replace if necessary.

2.DEF

NOTES

None

Case of excessive pump operation: Internal or external leak in the circuit. For an external leak, locate the leak and repair if necessary. For an internal leak, replace the hydraulic unit. Accumulator diaphragm porous or punctured: replace the accumulator.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

BVRPA6_V04_DF078

MR-379-X70-21B000$455_eng.mif V3

21B - 48

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

21B

DF078 CONTINUED

3.DEF 5.DEF

NOTES

None

Slight internal leak: replace the clutch solenoid valve. If the fault is still present, replace the hydraulic unit. Slight external leak: repair or replace the faulty component.

4.DEF

NOTES

None

Accumulator diaphragm porous or punctured: replace the accumulator.

AFTER REPAIR

Clear the computer fault memory. Carry out a road test followed by another check with the diagnostic tool.

BVR X7083 04 3.0

MR-379-X70-21B000$455_eng.mif V3

21B - 49

BVR Vdiag No.: 04

SEQUENTIAL GEARBOX Fault finding - Interpretation of faults

BATTERY VOLTAGE

21B

DF080 PRESENT

1.DEF: feed voltage too low 2.DEF: loss of computer supply voltage

NOTES

None