Escolar Documentos

Profissional Documentos

Cultura Documentos

Water and drainage system diagrams

Enviado por

ntt_121987Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Water and drainage system diagrams

Enviado por

ntt_121987Direitos autorais:

Formatos disponíveis

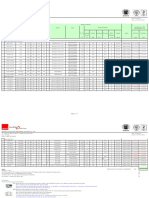

0-G-001

A1=NONE, A3=NONE

1

TNG TH

DRAWING LIST

DANH SCH BN V

GENERAL

DISCRIPTION SYMBOL

COOLING WATER SUPPLY

REFRIGERANT LIQUID

REMARK

A

REFRIGERANT GAS

CWS

CWR

R L

R G

STEEL

STEEL

STEEL

STS

STS

COPPER

COPPER

V

F.D

V.T.W

V.T.R

VENT PIPE

FLOOR DRAIN

FLOOR CLEAN OUT

VENT THROUGH WALL

VENT THROUGH ROOF

PVC

UPVC

UPVC

-

-

-

UPVC

UPVC

A.A.V

G

M

GLOVE VALVE

CHECK VALVE

AUTOMATIC AIR VALVE

WATER HAMMER ARRESTER

GAS METER

GENERAL

GH CH

0-G-002

A1=NONE, A3=NONE

COMPRESSEDAIR PIPE

NG KH NN

NG CP NUC G NHET

COOLING WATER RETURN

NG NUC TUN HON G NHET

CHS

CHR

CHILLEDWATER SUPPLY

NG CP NUC MY LM LANH

CHILLEDWATER RETURN

NG NUC TUN HON MY LM LANH

NG DN GAS LM LANH

NG DN M CHT LM LANH

NG THNG HO

D

DRAIN PIPE

NG THOT NUC DO

S

SOIL PIPE

NG THOT PHN

PHU THU SN

C.O

CLEAN OUT

THNG TC

F.C.O

THNG TC TRN SN

THNG HO XUYN TUNG

THNG HO XUYN M

DISCRIPTION SYMBOL REMARK

VAN MOT CHU

VAN CNG

M N MM

VAN TAY GAT

VAN dU KHN 2 CHU

VAN KHA

VAN BUM

VAN AN TON

VAN GM P

VAN dU CHNH P LUC

VAN SOLENOID

VAN X KH TU dONG

BA NUC

NG H GAS

NG H LUU LUONG

NHET K

P K

GATE VALVE

FLEXIBLE J OINT

2-WAY CONTROL VALVE

BUTTERFLY VALVE

COCK VALVE

SAFETY VALVE

PRESSURE REDUCING VALVE

DIFFERENTIAL PRESSURE VALVE

SOLENOIDVALVE

PRESSURE GAUGE

THERMOMETER GAUGE

FLOWMETER

LEGEND

TNG TH

1

PW

STS

WW

RD

UPVC

WASTE FLOOR DRAIN

POTABLE WATER SUPPLY

NG CP NUC SNH HOAT

STEEL ROOF DRAIN

VG1

VG1

VG1

VG1

VG1

VG1

KS D3509

KS D3576(80A over)

KS D3507

KS D3562

KS D3507

KS D3562

KS D5301

KS D3576

KS D3507

KS D5301

KS D3576

KS D3507

KS D3507

KSB-2301

KSB-2301

KSB-2350

KSB-2301

(65 over)

(15-50mm)

KSB-2301

THP

NG

INOX

THP

NG

INOX

INOX

THP

THP

NG THOT NUC M

NG THOT NUC RA SN

LET K THT B|

G-M-003

A1=NONE, A3=NONE

OUTDOOR UNT / DN NGO TR

MM

CONN. PIPE

LOCATION SYMBOL TYPE

W

EA

Q'TY

W MM PHVHZ

FAN

MM

TYPE

KW

POWER

CMM

AIR VOLUME

W

SYMBOL

EA

Q'TY FAN

W

CMM TYPE

COMPRESSOR

KW PHVHZ

REMARKS

CONN. PIPE

MM MM

GAS LIQUID DRAIN LIQUID GAS

NDOOR UNT / DN TRONG NH

System Air Conditioner / HKK

1

PAC

COOLING

CAPACITY

HEATING

CAPACITY SOURCE

ELEC. POWER

SOURCE

COOLING

CAPACITY

HEATING

CAPACITY

POWER

ERANT

FAN / QUAT

SERVICE LOCATION TYPE SYMBOL

Q'TY

EA

PHVHZ

AIR VOL. MODEL

# &

CMM

POWER

MMAQ KW REMARKS DRIVE

F

1

EL. POWER SOURCE

REST ROOM-2

1 338060 350 28 15 0.75

6

ROOM WALL

122060 250 MAX.12 - 0.044

DIRECT

DIRECT

3

2

F

3

EA

A B

PHVHZ % %

1

P

1set

303 x 3 27 - 2.2 x 3 - 338060 100 100

2

P

1set

65 x 2 27 - 0.75 x 3 - 338060 50 50

SYMBOL TYPE

CMM

Pa

UNT VENTLATOR / THT B| THNG G

AIR VOL.

1,000 160 250

UV

1

POWER

KW PH x V x HZ

122060 0.385

SIZE

W D H

1,140 1,062 365

EA

1

2

PAC

Stand

Stand

- 4 13,000 9.52 19.05 19 - 32/30/25 R22 3.90 122060

- 6 14,500 9.52 19.05 19 - 32/30/25 R22 4.70 338060

1

PAC

4 13,000 - 106 SCROLL 9.52 19.05 - -

-

1F TEST ROOM

(MAIN SHOP-2,

DINING ROOM

(CANTEEN-2) 2

PAC

6 14,500 - 106 SCROLL 9.52 19.05 -

EQUIPMENT SCHEDULE

F

4

3

F

2 ROOM

122060 200 MAX.8 - 0.037

DIRECT

TRAINNING RM

3

OFFICE-5

2

OFFICE-1,3

2

OFFICE-2,4

2

122060 300 MAX.17 - 0.044

DIRECT ROOM WALL

1

SP

2 x 4

Mechanical Seal, sequential control

50 5 - 0.75 - - 50 338060

INCLUDE ALL ACCESSORIES

INCLUDE ALL ACCESSORIES

INCLUDE ALL ACCESSORIES

INCLUDE ALL ACCESSORIES

INCLUDE ALL ACCESSORIES

INCLUDE ALL ACCESSORIES

AR COMPRESSOR(Part of the contractor) / KH NN (PHN NH THU)

1

Air Compressor

1

SUPPLIEDBY KYUNGBANG

2

Air Receiver Tank

1

3

After Cooler

1

4

REF. Air Dryer

2

Air Cooled, Refrigerated Type, 4 (at Press.), 47.0 Nm3/min, 220V3Ph60Hz, nclude Auto Drain

5

Pre Filter

1

5 , 73.0 Nm3/min, Housing Mat'l : C.S, nclude Auto Drain

6

Line Filter

1

1 , 72.0 Nm3/min, Housing Mat'l : C.S, nclude Auto Drain

7

Coale. Filter

1

0.01 , 42.0 Nm3/min, Housing Mat'l : C.S, nclude Auto Drain

8

Cooling Tower

1

Counter Flow Type, 80RT, F.R.P, Fan Motor : 2.2kW, 220V3Ph60Hz 1set stand-by

9

Cooling Water Pump

2

SNGLE-SATGE VOLUTE PUMP, Q=30 Ton/hr, H : 35m Motor : 7.5kW, 220V3Ph60Hz 1set stand-by

10

Air Compressor

1

2 : Piston Type, Air Cooled, 8.5 barg, (1.89) Sm3/min, Main Motor : 20HP, 380Vx3Phx60Hz, With Starter SUPPLIEDBY KYUNGBANG

TNG TH CHUNG

T

1

1

1

F

5 MEETING ROOM

122060 200 12 17 0.1

DIRECT INCLUDE ALL ACCESSORIES

LET K THT B|

EQUIPMENT SCHEDULE

GENERAL

V TNH

M/ PHT

INCLUDE ALL ACCESSORIES

Auditorium

NO. SERVICE Q'TY SPECIFICATION REMARKS

CITY WATER

STORAGE TANK

STORAGE TANK

TO FACTORY PROCESS

PUMP ROOM

#1 FACTORY

M

M

#2 DORMITORY

POTABLE WATER

TO FACTORY OFFICE

FOR PLUMBING PIPING

TO HVAC EQUIPMENT

#2 DORMITORY

FOR PLUMBING PIPING

WASTE WATER

STORAGE TANK

WASTE WATER TANK

M

WASTE WATER

FLOWMETER

TO SEWER

P

W

PW

PW

PW

PW

CITY WATER

GENERAL

0-G-004

A1=NONE, A3=NONE

GLOBE VALVE(TYP.)

SOLENOIL VALVE

PW

SO NUC CP TNG TH TY LE : NONE

GENERAL WATER SUPPLY

FLOWDIAGRAM

SEPTICK TANK

SEPTICK TANK

SEPTICK TANK

SEPTICK TANK

1

P.WBOOSTER PUMP

M

P.WBOOSTER PUMP

PW

P

W

POTABLE WATER

FLOWMETER

POTABLE WATER

FLOWMETER

(SEPTICK TANK)

SO NGUYN L

HE THNG CP NUC

TNG TH

GENERAL WATER SUPPLY FLOW DIAGRAM SCALE : NONE

1

FACTORY

DORMITORY

TOILET

TOILET

TOILET

SEPTIC TANK

50,100

80,100,100

TOILET TOILET

P

WDSV

100

PHNG BOM

XEM BN V 5-M-001

PUMP ROOM

REFER TO DWG NO:5-M-001

B TU HOAI

125

65,100,100,50

SO NUC TH TNG TH TY LE : NONE

PRE-SPINNING AHU-1 SPINNING AHU-3, 4 PRE-SPINNING AHU-2 TOILET TOILET SPINNING AHU-1, 2

SEPTIC TANK

B TU HOAI

SEPTIC TANK

B TU HOAI

SEPTIC TANK

B TU HOAI

SEPTIC TANK

B TU HOAI

100

WINDER AHU-1 WINDER AHU-2

50 V.T.W (TYP.)

GENERAL

0-G-005

A1=NONE, A3=NONE

GENERAL WATER DRAINAGE

FLOWDIAGRAM

15 A.A.V (TYP.)

80

1

SP

1

SP

1

SP

1

SP

TNG TH

SO NGUYN L

HE THNG THOT NUC

GENERAL WATER DRAINAGE FLOW DIAGRAM SCALE : NONE

1

MAT BNG NG BN NGO TY LE 1/600 OUTDOOR PIPING PLAN

0-G-006

GENERAL

A1=1/600, A3=1/1200

SEPTICK TANK

SEPTICK TANK SEPTICK TANK

SEPTICK TANK

100(CW) DN

+1.30

+1.30

+1.30 +1.30 +1.30 +1.30

+1.30

+1.30

+1.30

+1.30

+1.30 +1.30

+1.30 +1.30 +1.30 +1.30 +0.00

+1.30

+1.30

+1.30 +1.30 +1.30 +1.30

+1.30

+1.30 +1.30

+1.30

+1.30

+0.00

+1.30

+0.00

-0.5

-0.5

W D

UP

DN UP

UP

UP UP DN

UP

UP

UP

DN UP UP DN

UP

UP

UP UP UP

DN UP

UP

UP DN

UP

DN UP UP DN

UP

UP

UP

UPUP

UPUP

REST ZONE Main Shop 1

Guard House

Staff Dormitory

Dormitory 1

Canteen

Waste Zone

Sub Station

Green

Canteen Expansion

Dormitory 2

Sub Station Expansion

Pump Room

Main Shop 2

Expansion Of

SLOPE SLOPE

Main Shop 1

Expansion Of

Main Shop 1

B TU HOA

B TU HOA

B TU HOA

B TU HOA

MAT BNG NG BN NGO

TNG TH

OUTDOOR PIPING PLAN SCALE: 1/600

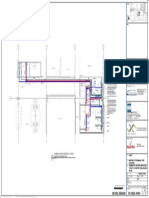

SCALE :1/30

KEY PLAN

'A' SECTION

SCALE :1/30

'C' SECTION

SCALE :1/30

'D' SECTION

SCALE :1/30

'E' SECTION

1900

200 1500 200

2

2

0

0

2

0

0

1

8

0

0

2

0

0

1

1

1

2800

200 2400 200

2

2

0

0

2

0

0

1

8

0

0

2

0

0

200 2500 200

2900

2

0

0

1

5

0

0

2

0

0

2

2

0

0

1

1

1 1

1 1

3

0

0

UP

UP

REST ZONE Main Shop 1

Guard House

Staff Dormitory

Dormitory 1

Canteen

Waste Zone

Sub Station

Green

Canteen Expansion

Dormitory 2

Sub Station Expansion

Pump Room

Main Shop 2

Expansion Of Main Shop 1

Expansion Of Main Shop 1

SCALE :1/30

'B' SECTION

SCALE :1/30

'F' SECTION

1

0-G-007

A1=1/30, A3=1/60

1 2

3 3

2

3

4

2

3 4

1 2

3

200 3000 200

3400

2

0

0

2

2

0

0

2

0

0

2

6

0

0

MV

MV

MV(FUTURE)

LV

TELECOM

1 2 3 4

5 6 7

1 2

3 3

200 2500 200

2900

2

0

0

1

9

0

0

2

0

0

2

6

0

0

3

0

0

MV

MV

MV(FUTURE)

LV

TELECOM

3

3

5

3

3

5

4

3

5

3

3

5

3

3

5

6

5

1

0

0

6

5

6

5

6

5

6

5

3

3

5

3

3

5

4

3

5

3

3

5

3

3

5

6

5

1

0

0

6

5

6

5

6

5

6

5

3

3

5

3

3

5

3

8

5

3

8

5

6

5

6

5

6

5

6

5

1

0

0

3

3

5

3

3

5

3

8

5

3

8

5

6

5

6

5

6

5

6

5

1

0

0

3

3

5

3

3

5

3

8

5

3

8

5

6

5

6

5

6

5

6

5

1

0

0

CHANNEL 100x50x5tx7.5t(TYP.)

INSERT PLATE 200x200x9t(TYP.)

ANGLE : 75 x 75 x 6t(TYP.)

200 3000 200

3400

2

0

0

2

2

0

0

2

0

0

2

6

0

0

MV

MV

MV(FUTURE)

LV

TELECOM

3

3

5

3

3

5

4

3

5

3

3

5

3

3

5

6

5

1

0

0

6

5

6

5

6

5

6

5

SECTION &DETAIL

GENERAL

OUTDOOR PIPING PLAN

TNG TH

BNG NG BN NGO

CH TT V MAT CT MAT

S M T K NG

1

2

3

4

25

COMPRESSOR AIR (A)

150

HYDRANT WATER SUPPLY (H)

100

HYDRANT WATER SUPPLY (H)

100

5

COMPRESSOR AIR (A)

125

COMPRESSOR AIR (A)

6

POTABLE WATER SUPPLY(PW)

125

7

HYDRANT WATER SUPPLY (SP)

125

1

2

3

4

100

HYDRANT WATER SUPPLY (H)

100

POTABLE WATER SUPPLY(PW)

125

HYDRANT WATER SUPPLY (SP)

125

HYDRANT WATER SUPPLY (H)

1

2

3

4

NG HEN HU

-

NG CP NUC SNH HOAT (PW)

80

NG NUC CHA CHY (H)

100

NG NUC CHA CHY (H)

100

1

2

3

4

100

NG NUC CHA CHY (H)

100

NG CP NUC SNH HOAT (PW)

80

NG NUC CHA CHY SPRNKLER (SP) 125

NG NUC CHA CHY (H)

1

2

3

4

NG HEN HU

-

NG NUC CHA CHY (H)

100

NG NUC CHA CHY (H)

100

NG CP NUC SNH HOAT (PW)

80

1

2

3

NG NUC CHA CHY (H)

100

NG NUC CHA CHY (H)

100

NG CP NUC SNH HOAT (PW)

80

No. DESCRIPTION PIPE DIA.

S M T K NG

No. DESCRIPTION PIPE DIA.

S M T K NG

No. DESCRIPTION PIPE DIA.

S M T K NG

No. DESCRIPTION PIPE DIA.

S M T K NG

No. DESCRIPTION PIPE DIA.

S M T K NG

No. DESCRIPTION PIPE DIA.

NG KH NN (A)

NG NUC CHA CHY (H)

NG NUC CHA CHY (H)

NG KH NN (A)

NG KH NN (A)

NG CP NUC SNH HOAT (PW)

NG NUC CHA CHY SPRNKLER (SP)

NG NUC CHA CHY (H)

NG CP NUC SNH HOAT (PW)

NG NUC CHA CHY SPRNKLER (SP)

NG NUC CHA CHY (H)

EXISTING PIPE

POTABLE WATER SUPPLY(PW)

HYDRANT WATER SUPPLY (H)

HYDRANT WATER SUPPLY (H)

HYDRANT WATER SUPPLY (H)

POTABLE WATER SUPPLY(PW)

HYDRANT WATER SUPPLY (SP)

HYDRANT WATER SUPPLY (H)

EXISTING PIPE

HYDRANT WATER SUPPLY (H)

HYDRANT WATER SUPPLY (H)

POTABLE WATER SUPPLY(PW)

HYDRANT WATER SUPPLY (H)

HYDRANT WATER SUPPLY (H)

POTABLE WATER SUPPLY(PW)

MAT CT 'A' MAT CT 'B'

MAT CT 'C' MAT CT 'D' MAT CT 'E' MAT CT 'F'

THP HOP 100x50x5tx7.5t(TYP.)

CHN 200x200x9t(TYP.)

THP GC : 75 x 75 x 6t(TYP.)

CHANNEL 100x50x5tx7.5t(TYP.)

INSERT PLATE 200x200x9t(TYP.)

ANGLE : 75 x 75 x 6t(TYP.)

THP HOP 100x50x5tx7.5t(TYP.)

CHN 200x200x9t(TYP.)

THP GC : 75 x 75 x 6t(TYP.)

CHANNEL 100x50x5tx7.5t(TYP.)

INSERT PLATE 200x200x9t(TYP.)

ANGLE : 75 x 75 x 6t(TYP.)

THP HOP 100x50x5tx7.5t(TYP.)

CHN 200x200x9t(TYP.)

THP GC : 75 x 75 x 6t(TYP.)

CHANNEL 100x50x5tx7.5t(TYP.)

INSERT PLATE 200x200x9t(TYP.)

ANGLE : 75 x 75 x 6t(TYP.)

THP HOP 100x50x5tx7.5t(TYP.)

CHN 200x200x9t(TYP.)

THP GC : 75 x 75 x 6t(TYP.)

CHANNEL 100x50x5tx7.5t(TYP.)

INSERT PLATE 200x200x9t(TYP.)

ANGLE : 75 x 75 x 6t(TYP.)

THP HOP 100x50x5tx7.5t(TYP.)

CHN 200x200x9t(TYP.)

THP GC : 75 x 75 x 6t(TYP.)

CHANNEL 100x50x5tx7.5t(TYP.)

INSERT PLATE 200x200x9t(TYP.)

ANGLE : 75 x 75 x 6t(TYP.)

THP HOP 100x50x5tx7.5t(TYP.)

CHN 200x200x9t(TYP.)

THP GC : 75 x 75 x 6t(TYP.)

CHANNEL 100x50x5tx7.5t(TYP.)

INSERT PLATE 200x200x9t(TYP.)

ANGLE : 75 x 75 x 6t(TYP.)

0-G-008

A1=NONE, A3=NONE

1

WELL

1" PT

600

480

3" ANDSMALLER LINE SIZE

4" PIPE

CAPILLARY TUBE

LENGTH 3M

TYPE - A/LOA A TYPE - B/LOA B

LINE SIZE

100 MMANDLARGER

LINE SIZE

80 MMANDSMALLER

LINE SIZE

80 MMANDSMALLER

TYPE - A/LOA A TYPE - B/LOA B

LINE SIZE

100 MMANDLARGER

LINE SIZE

80 MMANDSMALLER

HORZONTAL / UNG NG NM NGANG

VERTCAL / UNG NG NG

100 MMPIPE

100 MMPIPE

100 MMPIPE

LP AT VAN V BO U CHNH NHET O

CHILLED WATER PIPE INSULATION

NG 3" V NH HON

PRESSURE REDUCING VALVE 3 - WAY MOTORIZED VALVE

PRESSURE GAUGE

SAFETY VALVE

GATE VALVE

STRAINER

PRESSURE REDUCING VALVE

GLOBE VALVE

D

C

d

S

L

FOR ANCHOR

FOR GUIDE

PIPE SIZE DIMENSIONS/

K.LUONG

D d C L S

M10 21.7

M10

35 45 40 0.13

27.2

M10

40 50 40 0.16

34.0

M10

45 55 45 0.16

48.6

M10

60 60 45 0.18

60.5 75 65 45 0.20

M12 89.1 105 85 55 0.38

M16 114.3 135 100 60 0.44

M16 165.2

M20

185 130 70 1.04

267.4

240 165 80 2.05

290 195 90 2.40

216.3

M20

NOTE

1. MATERIAL : GALVANIZEDCARBON STEEL

2. MAX. TEMP. : 350C

U - BOLT

(KG)

15

20

25

40

50

80

100

150

200

250

C

O

N

C

E

A

L

E

D

P

IP

IN

G

GLASS WOOL PIPE COVER

NG NUC LANH

ITEM

INSULATION THICKNESS

50 32 40 25 20 15 NPS

40

(24KG/M)

VAPOR BARRIER

250 80 100 65 200 125 150

40 50

E

X

P

O

S

E

D

P

IP

IN

G

TM THP TRNG KM (CH NG TRN G )

GALVANIZEDSTEEL PLATE (ONLY PIPE RACK)

COPPER,STAINLESS OR GALVANIZEDSTEEL PIPE

VINYL

STAINLESS STEEL BAND(0.4MM- 0.6MM) THK

VINYL

SUPER #303

NG THP

BNG VNYL

GLASS WOOL PPE COVER (24KG/M)

V BAO NG BNG BNG THY TNH (24KG/M)

A THP KHNG G DY (0.4MM - 0.6MM)

LP CHN M

BNG VNYL

SUPER #303

3 - WAY MOTORIZED VALVE

UNION

UNION

UNION

UNION

RIGIDINSULATION

(L=100MMMIN.)

INSULATION

RIGIDINSULATION

INSULATION

(L=100MMMIN.)

FIELDTO PROVIDE HOLES TO

FIT BOILTS (TYP.)

NPS

ITEM 15

25

20 25 32 40 50 65 80 100 125 150

25 40 40

200

O DY CCH NHET

ARTLON NSULATON (24KG/M)

VAPOR BARRIER

ST'L WIRE

STAINLESS STEEL PIPE

ALUMINUMSHEET (0.4MM- 0.6MM) THK

STAINLESS STEEL BAND(0.4MM- 0.6MM) THK

E

X

P

O

S

E

D

P

IP

IN

G

C

O

N

C

E

A

L

E

D

P

IP

IN

G

ARTLON NSULATON (24KG/M)

40 40

DEMI WATER(OUT DOOR)

WATER PIPE INSULATION

REMARKS

THERMOMETER INSTALLATION LOOP - BOLT (CHILLED WATER)

C NG

KCH THUC WEIGHT

GH CH

VAT LEU : THP TRNG KM

NHET O CUC A. : 350C

CCH NHET

C |NH CCH NHET

CCH NHET

C |NH CCH NHET

V| TR UC L LP BU LNG

KCH THUC UNG NG

100 MM V LN HON

KCH THUC UNG NG

80 MM V NH HON

KCH THUC UNG NG

80 MM V NH HON

BO LOC

VAN CU

VAN CNG

P K

VAN AN TON

VAN GM P SUT

VAN CU

VAN EN 3 NG

KHP N

NG MAO DN D 3M

INSULATION THICKNESS

O DY CCH NHET

A THP KHNG G DY (0.4MM - 0.6MM)

TM NHM DY (0.4MM - 0.6MM)

N

G

K

H

U

N

G

T

H

Y

d

U

O

C

DY THP

LP CHN M

N

G

K

H

U

N

G

T

H

Y

d

U

O

C

V BAO NG BNG BNG THY TNH (24KG/M)

NG THP TRNG KM, KHNG G, NG NG

CCH NHET NG NUC LANH

VAN GM P VAN EN 3 NG

CM - BULONG

CCH NHET NG NUC

LP AT NG H NHET LP AT NG NUC LANH

CHILLEDWATER

LP CHN M

BNG VNYL

A THP KHNG G DY (0.4MM - 0.6MM)

BNG VNYL

STEEL PIPE

VINYL

STAINLESS STEEL BAND(0.4MM- 0.6MM) THK

VAPOR BARRIER

VINYL

TM THP TRNG KM (CH NG TRN G )

GALVANIZEDSTEEL PLATE (ONLY PIPE RACK)

CCH NHET ARTLON (24KG/M)

NG NOX

CCH NHET ARTLON (24KG/M)

NG NUC BN NGO

KHP N

KHP N

KHP N

NG 4"

NG 100mm

NG 100mm

NG 100mm

KCH THUC UNG NG

100 MM V LN HON

KCH THUC UNG NG

80 MM V NH HON

0-G-009

A1=NONE, A3=NONE

1

HUYEN BN CT-TNH BNH DUONG

L 3A-CN, KCN BU BNG

CH U TU - NVESTOR :

KYUNGBANG VN PROJ ECT

EXTENSION WORK

HUYEN BN CT - TNH BNH DUONG

L 3A-CN, KCN BU BNG

CNG TY TNHH HUY TN

A

W

F

T

18B ung s 2,Khu cu x

L Gia,P.15,Q.11, Tp. HCM,

Vit Nam

(84-8) 3866-9361

(84-8) 3866-5230

http://www.huytan.com.vn

HUYTAN ENGINEER CO., LTD

HUYNH NGOC THNH

CAO THANH SON

HUYNH NGOC THNH

1

0

UP TO 600

OVER 600

KHP N MM

KHUCH TN TRN

EXTENSION COUPLING

KHP N D

MIN. 150

COTTER PIN

MAX. 45

AIR CUSHION

DAMPER STOP

ENDOF DUCT

CEILING

X L GC (NG G CNG)

NG G

GN

COMBINATION DAMPER

DUCT RING

ANDDEFLECTOR

AIR

300

HA LP

FLEXIBLE SHAFT

DY L XO

ST TRNG KM 0.8t+

150

+

TRT KN BN TRONG

N P LUC

X

X

X

X

X

X

X

X

X

X

X

+

FLANGE SECTION

CONER PLATE FASTENEDTO

DUCT SIZE " Wx D"

5 5

OVER 2,460

780 ~1,070

480 ~ 760

1,090 ~1,500

2,180 ~2,400

1,550 ~2,100

VAN XOAY

XEM CH TT "A"

A

114 83

54

A

57

25 50

24

26

R2 R1

W

175

115

B

B

R

1

90

R

2

G NG G

A

TM D|CH CHUYN

VAN

25 X 16 GA.

40 X 16 GA.

25 X 18 GA.

25 X 18 GA.

25 X 22 GA.

25 X 16 GA.

16

9

9

9

9

9

25 X 25 X 3

25 X 25 X 3

25 X 25 X 3

25 X 25 X 3

25 X 25 X 3

25 X 25 X 3

3,000

3,000

3,000

3,000

3,000

3,000

KEP NG G

150 300

CHT

LU UC L

TM THC

CH TT "A"

TM ST TRNG KM BNG THY TNH

KEO

TRANSFORMELBOWOR SQUARE

1. REFER DUCT SIZE TO RELATEDFLOOR PLAN

THANH GNG

2. HEIGHT OF DUCT UNTIL 600mmGET 1 HINGE,

CHU CAO NG T 600mm C 1 BN L, T 1500mm C

LP AT NG NHNH V CHA G

HANGER RODS

NG NHNH - 1

150

Q1

R

=

L1

L

1

3/4

THP GC 25 X 25 X 3

DETAIL "A"

Chi tit "A"

B MAT

EM CAO SU

L BULONG 9 BUC 100mm

GA CUNG GC

MOT LP

NH TN 4.5

SO THY TNH

DY L XO

9 BOLT HOLE 100 PTCH

NH TN 4.5

1

0

NG G

Luu luong gi Q1, Q2 :

L4

L3

=

Q2

Q1

CC THANH U CHNH

5

BULONG HOAC KEP

TRN

"A"

KEP

UP TO 460

NH VT

25 MIN

1,500 MAX

MP

Chi tit "B"

NG NHNH - 2

NG G

M

NH TN

* NOTE / GH CH

L3 L4

3/4

R

=L2

L

2Q2

NG CHNH

NH TN

NH TN

PACKING

HUNG G

"B"

"A"

BULONG

CO CHUYN HAY CO VUNG

CMH 3

BN L

L THM

THP TRN

STRAP HANGER

HANGAR SIZE (SQUARE DUCT)

25 x 22 GA. - 25 X 25 X 3

VOLT DECISION

THANH GNG

3,000

THP GC

A C

W3 X D3 X W1

W2xD2+W3xD3+W4xD4

W4 X D4 X W1

W2xD2+W3+D3+W4+D4

CMH 2

A1=

A2=

B1 =0.75 A1

B2 =0.75 A2

>MIN.100

>MIN.100

A

2 + 3/4 W

4

W2XD2

W

3

X

D

3

DON'T PASS OVER VARATON ANGLE 20

GC THAY KHNG UOC VUOT QU 20

W

4

X

D

4

A2 A1

3/4 W

3 B

2

B

1

CMH 1

W1XD1

CN U KHN(XEM GH CH 2)

SET SCREW

CONTROL ROD(NOTE 2. REFERENCE)

BO CHA G

CMH3

A1=

CMH1

CMH1

CMH4

A2=

W1

W1

CMH 4

S TM THP CA MNG CHN

UP TO 450

475 TO 900

B RONG NG G (W)

16

4.373

7.5

2.5

KEP L XO THANH NG V VNG B

TM CHN

THP GC 25x25x3

CU CH C 72

MN CHN LA (LOA L ON)

S - SLIP

TUNG CHN LA

CA THM

CU CH (72C)

-50x50x5t

NG LT THP #14

ST TRNG KM #16

MN CHN LA (LOA NHU L

OVER 900

12

7

ACT ON IN WEIGHT

BNG THY TNH

ELBOWIS WITH TURNING VANE

ST TRNG KM 0.8t+

NU KHNG GH R LUU LUONG G

FLEXIBLE J OINT

CEILING DIFFUSER CONNER TREATMENT (MECHANICAL DUCT)

INSTALL GRILLE AND REGISTER(CEILING)

TURNING VANE

DUCT HANGAR

INSTALL BRANCH DUCT AND SPLIT DAMPER BRANCH DUCT - 1 BRANCH DUCT - 2 FIRE DAMPER (SINGLE LEAF TYPE)

FIRE DAMPER (MULTI-BLADE)

Air Volume

FLANGE

DUCT

CEILING

RIVET

MAIN DUCT

RIVET

RIVET

PACKING

AIR FLOW

BOLT &NUT

Detail "A" Detail "B"

HINGE

ACCESS HOLE

SET SCREW

SPLIT DUCT

V VAN CHUYN

1. REFER DUCT SIZE TO RELATEDFLOOR PLAN

ABOVE 600mmGET 2 HINGE, ABOVE 1500mmGET 3 HINGE.

2 BN L, TRN 1500mm C 3 BN L

SPRING CLIP BRASS RODANDBEARINGS

EARTH PLATE

ANGLE 25x25x3

FUSE SET AT 72

IRON PLATE NUMBER FOR DAMPER WIDTH OF DUCT(W) WEIGHT LBS/SQFT

PIANO WIRE

0.8t+GALVANIZEDIRON

ANGLE REINFORCEMENT

4.5 RVET

GLASS FIBER

PIANO WIRE

4.5 RVET

GLASS FIBER

0.8t+GALVANIZEDIRON

IN CASE OF DOUBLE

IN CASE OF SINGLE

DUCT

NON ASBESTOS PACKING

ANGLE 25 X 25 X 3

SURFACE

RUBBER GASKET

DUCT

GRILLE OR REGISTER

CONTROL EACH BAR

BOLT OR CLAMP

CEILING

CLAMP

HANGAR STRAP

SCREWS

ROUNDBAR

ANGLE

NUT

STRAP OR

ANGLE

TY THUOC VO

TRONG LUONG

TY TREO THANH GNG

KCH THUC G (NG G VUNG)

FIREWALL

ACCESS DOOR

FUSE(72C)

AIR FLOW

#14 IRON SLEEVE

#16 GALVANIZEDIRON

KHA TRUC

MAX. 45

EM KH

V| TR DNG DAMPER

KT THC NG G

TRN

CHUP NG G

AIR

TRUC MM

BEAD

SEAL TO INSIDE

PRESS J OINT

TM GN CHAT VO MAT BCH

RUNNER

VANE

WIDTH OF DUCT(W)

DUCT CLIP

PIN

TIN PLATE

GLASS WOOL 50 mm

GALVANIZEDPLATE GLASS FIBER

GLUE

DETAIL "A"

SEE TO DETAIL "A"

PERFORATEDGRILLE

0-G-010

A1=NONE, A3=NONE

1

VENT THROUGH ROOF(OR WALL)

PVC 90 ELBOW

PVC PIPE

SEALANT

PIPE SLEEVE

WATER PROOFING

TM THP TRN C |NH

ROUNDST'L PLATE FOR SUPPORT

CONCRETE

ESCUTCHEON

PVC 90 ELBOW

5

0

0

2

2

550

CAULKING COMPOUND

A

SPLIT STEEL PLATE

120 100 80 65

L-75x75x9t L-65x65x6t

M20 M16 M16 M12

REMARKS 200 150 125 100

M12 M10

L-50x50x6t

50 50 50 40 40

L - 40 x 40 x 5t

M10

A

ANGLE

U - BOLTS

ITEM

N.P.S 80 65 50 40 32 25 20 15

STEEL ANGLE

STEEL PIPE

PIPE ANCHOR

CLEAN OUT

LOCKING SET SCREWS

PVC PIPE

FINISH FLOOR

CHT THNG TC

45 ELBOW

45 ELBOW

PVC PIPE

FLOOR CLEAN - OUT

FLOOR DRAIN

HOR. LINE FIN. FLOOR

CLEAN - OUT

PVC PIPE

P - TRAP

PVC PIPE

CONNECTOR

C CHNH

CAULKING COMPOUND

ADJ USTABLE STRAINER

WITH OR WITHOUT

H

A

H

50

15

50

H

A

CAULKING COMPOUND(SILICON)

ST'L PLATE

PIPE SLEEVE

ESCUTCHEON

MORTAR

WALL

STEEL PIPE

CAULKING COMPOUND(SILICON)

WATER PROOFING FINISH

ESCUTCHEON

YARN

SLEEVE SCHEDULE

CAULKING METHOD & PIPE SLEEVE

ITEM

NPS 20

50

25

50

32

65

40

80

50

50

100

60

65

100

80

150

100

150

125

200

150

250

200

300

60

REMARKS

LU #10

WIRE MESH #10

PIPE HANGER

PIPE HANGER SCHEDULE

4.5x55 4.5x55 378 267.4 235.7 10 12 1300

3.0x50 3.0x50 325 216.5 210.3 10 12 900

3.0x50 3.0x50 274 165.2 184.6 10 12 450

2.3x40 2.3x40 204 114.3 142.2 6 10 450

2.3x40 2.3x40 179 89.1 129.6 6 10 450

2.0x32 2.0x32 130 60.5 95.3 6 10 280

1.6x25 1.6x25 113 48.6 85.3 6 10 280

1.6x25 1.6x25 100 34.0 79 6 10 280

1.6x25 1.6x25 93 27.2 75.6 6 10 280

1.6x25 1.6x25 87 21.7 73 6 10 280

H G

STEEL SIZE F D C B A

(KG)

KT NG

C

H

D

B

G

A

F

15

20

25

40

50

80

100

150

200

250

5

0

ALL HARDWARES SHALL BE GALVANIZEDSTEEL

NOTE :

(SILICON)

PHU THU SN NG CH V PHUONG PHP TRM NG

NT KM TRA

NG PVC

NG PVC

N NG

HN HOP VAT LEU TRT ( SLCON)

SN HON THEN

LU LOC U CHNH UOC

NP KHA

TUNG

VA

NG CH

HN HOP VAT LEU TRT ( SLCON)

SO

NP KHA

NG THP

HN HOP VAT LEU TRT ( SLCON)

LP NGN NUC

VA / MORTAR

NEO NG

THP GC

NG THP

BN NEO THP

NG THNG HO XUYN M ( HOAC TUNG) THNG TC M SN G TREO NG

1.TT C LM BNG THP TRNG KM

GH CH :

NG PVC

THNG TC

SN HON THEN

CO 45

CO 45

NG PVC

VT KHA

CO PVC 90

CO PVC 90

NG PVC

KEO TRT KN

NG CH

LP NGN NUC

HN HOP VAT LEU TRT

NP KHA

BTNG

LET K G NG

NG THP

THREADEDCLEAN OUT PLUG

CON TH

MAT NGANG

LEVELOC SCREWS

INVERTIBLE FLASHING COLLAR

TM THP

LET K NG CH

2

1

- -

1

2500

200

2900

FFL

100 200 1410

100

1410

100

2820

200

100

100 100

1500

200

365

335

100

100

1000

600

50

600

50

500

500

150

150

500

585

2065

3400

150

100

1500

100

2900

6640

550

200

200

200

200

200

200

200

550

550

200

200

200

200

200

200

200

550

200 1410 100 1410 100 2820 200

6240

550

200 200 200 200 200 200 200

550

550

200 200 200 200 200 200 200

550

3300

100 200 2500 200 100

2500

100

2900

200

400

Concrete slab thk 50, G25,pierce D20,a200

Tm b tng dy 50mm M.250;duc l D20,a200

SECTION 1-1

MAT CT 1-1

SECTION 2-2

MAT CT 2-2

SEPTIC TANK PLAN TYPE 1

MAT BNG B TU HOA LOA 1

Agg 4x6 thk 200

4x6 dy 200mm

Charcoal, cinder thk 200

Lp than xi dy 200mm

Agg 1x2 thk 200

1x2 dy 200mm

Agg 4x6 thk 300

4x6 dy 300mm

uPVC D150

Sewer pipe connection to public sewerage

2500

600

200

1265

937

50

DETAIL OF COVER 600x600

CH TT NP 600x600

L 50x50x4

12

2500

2770 1310 1360

2500

2500

4000

150

200 200 250

D12a150 D12a150 D12a150 D12a150

250

500 250 250 500 250 500

7340

200

200

200

200

200

200

200

200

D10a150 D10a150

100

D12a150

D12a150

D8a150

D12a150

D12a150

TY LE (SCALE): 1/150

SECTION 1-1

MAT CAT 1-1

TY LE (SCALE): 1/150

SECTION 2-2

MAT CAT 2-2

200

1500

700

100

600

200

1600

100

500

600

600

150

500

250 150

4540

150 500 250

250

80

D12a150

D12a150

550 200 200 200 200 200 200 200 550

550 200 200 200 200 200 200 200 550

100

700

200

1500

D10a150

D12a150

D12a150

D12

500

D12 D12 D12

250

2500

650

3400

100

0-G-011

A1=NONE, A3=NONE

1

1

TY LE : 1/400 MAT BNG NG KH NN TON BO PT NH XUNG

MAIN SHOP

1-M-001

A1=1/400, A3=1/800

1

7000

35000

7000 7000 7000 7000

X0 X1 X2 X3 X4

217000

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 9000 5000 7000 7000

X5 X6 X7 X8 X9 X10 X11 X12 X13 X14 X15 X16 X17 X18 X19 X20 X21 X22 X23 X24 X25 X26 X27 X28 X29 X30

1

2

0

0

0

0

1

0

0

0

0

Y0

2

0

0

0

0

3

0

0

0

0

3

0

0

0

0

2

0

0

0

0

1

0

0

0

0

7000

X31

Y1

Y2

Y3

Y4

Y5

Y6

2

3

0

0

2

3

0

0

7000

156000 26000

DN

UP

DN

UP

UP

DN

UP

DN

UP

DN

UP

DN

UP

DN

UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP

UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP

DN

DN

DN

DN

DN

UP

UP

DN DN DN DN DN

DN DN DN DN DN

UP

DN

DN

UP

E.A E.A E.A E.A

E.A E.A E.A E.A

25,150,125

32

32

32

32

32

32

150,125

125

125

40

40

40

40

40

40

32 32 125 40 40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

40

100 80 80 65

100 80 80 65

UP

40

AIR

65

65

65

65

65

UP

15

AIR

CONN TO. OUTDOOR PIPING PLAN

REFER TO DWG NO:0-G-006

415 UP (TYP.)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

425 UP (TYP)

425 UP (TYP)

425 UP (TYP)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 UP (TYP.)

425 UP (TYP)

415 UP (TYP.)

425 UP (TYP)

425 UP (TYP)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

AUTO AIR DRAIN TRAP

PRESSURE RE DUCING VALVE

AUTO AIR DRAIN TRAP

PRESSURE RE DUCING VALVE

AUTO AIR DRAIN TRAP

PRESSURE RE DUCING VALVE

AUTO AIR DRAIN TRAP

PRESSURE RE DUCING VALVE

415 BALL VALVE

FOR CLEAN

SCALE : 1/400 MAIN SHOP PIT OVERALL COMPRESSED AIR PIPING PLAN

NH XUNG

KT N V NG BN NGO

XEM BN V NO:0-G-006

TCH NUC TU ONG

VAN GM P

TCH NUC TU ONG

VAN GM P

UP

DN UP

UP

UP UP DN

UP

UP

DN UP UP DN

UP

UP

UP

DN UP

UP

UP DN

UP

DN UP UP DN

UP

UP

DN

DN

UP

UP

UP

UP

UP

UP

STORAGE

Kho

BLOW&CARD

ROOM

PRE SPINNNIG

AHU

ELECTRICAL

ROOM

COMBER

WASTE ROOM

LOADING DOCK

/ OPENING

STORAGE

KHO

PACKING RM

Khu vuc dong goi

( )

STORAGE

KHO STORAGE

KHO

RAWMATERIAL

Nguyn liu th

PRE SPINNNIG

AHU

BLOW&CARD

ROOM

COMBER

WASTE ROOM

SPINNNIG-1

AHU

SPINNNIG-2

AHU

WINDER

AHU

CHILLER

ROOM

ELECTRICAL

ROOM

ELECTRICAL

ROOM

BALE PRESS

ROOM

STORAGE

KHO

CHILLER ROOM

SPINNNIG-1

AHU

SPINNNIG-2

AHU

WINDER

AHU

ELECTRICAL

ROOM LOADING DOCK

Khu bc hng

LOADING DOCK

Khu bc hng

VS-3 /RESTROOM-3

RESTROOM-2

( )

TEST ROOM

OPERATING

ROOM

VS-5 /RESTROOM-5

ROLLER

my cn

RESTROOM-4

1

2

0

0

0

0

1

0

0

0

0

Y0

2

0

0

0

0

3

0

0

0

0

3

0

0

0

0

2

0

0

0

0

1

0

0

0

0

Y1

Y2

Y3

Y4

Y5

Y6

7000

35000

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 9000 5000 7000 7000 7000 7000

26000 156000

X31 X30 X29 X28 X27 X26 X25 X24 X23 X22 X21 X20 X19 X18 X17 X16 X15 X14 X13 X12 X11 X10 X9 X8 X7 X6 X5 X4 X3 X2 X1 X0

1

25

TY LE : 1/400 MAT BNG NG KH NN TON BO TNG TRET NH XUNG

MAIN SHOP

1-M-002

A1=1/400, A3=1/800

1

1 1

DN

40

AIR

415 BALL VALVE

FROMCEILING

415 DN (TYP.)

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

425 DN (TYP)

425 DN (TYP)

425 DN (TYP)

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 DN (TYP.)

415 BALL VALVE FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FOR CLEAN

415 (TYP.) 415 (TYP.)

415 (TYP.)

415 DN (TYP.)

415 DN (TYP.)

425 DN (TYP)

415 DN (TYP.)

425 DN (TYP)

425 DN (TYP)

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

DN

15

AIR

415 (TYP.)

415 (TYP.)

415 (TYP.)

40

40

40

40

40

40

415 BALL VALVE

FOR CLEAN

SCALE : 1/400 MAIN SHOP GROUND FLOOR OVERALL COMPRESSED AIR PIPING PLAN

NH XUNG

P. ph phm

thi v chi soi

Phng HN

truc khi dt

P. ph phm

chi soi

Khu bc hng

/ m

Phng HN

my dt 1

Phng HN

my dt 2

Phng HN

my cun soi

P. in

VE SNH-2

Phng Lm Lanh

Phong p kin

Phng HN

truc khi dt

PRE-SPINNING

MAINTENANCE ROOM-1

P. bo dung

my soi 1

P. thi v chi soi

Tram din 1 P. ph phm

chi soi

P. kim tra P. vn hnh P. Lm Lanh

P. HN

my dt 1

P. HN

my dt 2

P. din

VS-4

P.HN

my cun soi

1

1-M-003

A1=1/250, A3=1/500

7000 7000 7000 7000 7000

X0 X1 X2 X3 X4

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000

X5 X6 X7 X8 X9 X10 X11 X12 X13 X14 X15 X16

3

0

0

0

0

2

0

0

0

0

1

0

0

0

0

Y3

Y4

Y5

Y6

2

3

0

0

7000

TY LE : 1/250 MAT BNG NG KH NN TON BO PT NH XUNG - 1

MAIN SHOP

X0 X5 X10 X15 X20 X25 X30

Y0

Y2

Y3

Y4

Y6

E.A E.A E.A E.A

KEYPLAN

DN

UP

DN

UP UP UP UP UP UP

DN

DN

DN

UP

DN

UP

E.A

40

40

40

40

40

40

40

40

40

40

40

40

80 65

UP

40

AIR

65

65

65

415 UP (TYP.)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

AUTO AIR DRAIN TRAP

PRESSURE RE DUCING VALVE

SCALE : 1/250 MAIN SHOP PIT OVERALL COMPRESSED AIR PIPING PLAN-1

NH XUNG

TCH NUC TU ONG

VAN GM P

1 1

1-M-004

A1=1/250, A3=1/500

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 9000 5000 7000 7000

X15 X16 X17 X18 X19 X20 X21 X22 X23 X24 X25 X26 X27 X28 X29 X30

3

0

0

0

0

2

0

0

0

0

1

0

0

0

0

7000

X31

Y3

Y4

Y5

Y6

2

3

0

0

TY LE : 1/250 MAT BNG NG KH NN TON BO PT NH XUNG - 2

MAIN SHOP

X0 X5 X10 X15 X20 X25 X30

Y0

Y2

Y3

Y4

Y6

E.A E.A E.A E.A

KEYPLAN

UP

DN

UP

UP UP UP UP UP UP UP UP UP UP UP UP

DN DN DN DN

DN

UP

E.A E.A E.A

32

32

32

32

125

125

100 80

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

425 UP (TYP)

425 UP (TYP)

425 UP (TYP)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

AUTO AIR DRAIN TRAP

PRESSURE RE DUCING VALVE

SCALE : 1/250 MAIN SHOP PIT OVERALL COMPRESSED AIR PIPING PLAN-2

NH XUNG

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

VAN B 415VE SNH

1 1

1-M-005

A1=1/250, A3=1/500

7000 7000 7000 7000 7000

X0 X1 X2 X3 X4

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000

X5 X6 X7 X8 X9 X10 X11 X12 X13 X14 X15 X16

1

0

0

0

0

Y0

2

0

0

0

0

3

0

0

0

0

Y1

Y2

Y3

2

3

0

0

7000

TY LE : 1/250 MAT BNG NG KH NN TON BO PT NH XUNG - 3

MAIN SHOP

X0 X5 X10 X15 X20 X25 X30

Y0

Y2

Y3

Y4

Y6

E.A E.A E.A E.A

KEYPLAN

DN

UP

DN

UP

DN

UP UP UP UP UP UP UP

DN

DN

DN

E.A

40

40 40

40

40

40

40

40

40

40

40

80 65

65

65

415 UP (TYP.)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

AUTO AIR DRAIN TRAP

PRESSURE RE DUCING VALVE

40

SCALE : 1/250 MAIN SHOP PIT OVERALL COMPRESSED AIR PIPING PLAN-3

NH XUNG

VAN GM P

TCH NUC TU ONG

1 1

TY LE : 1/250 MAT BNG NG KH NN TON BO PT NH XUNG - 4

MAIN SHOP

1-M-006

A1=1/250, A3=1/500

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 9000 5000 7000 7000

X16 X17 X18 X19 X20 X21 X22 X23 X24 X25 X26 X27 X28 X29 X30

1

0

0

0

0

Y0

2

0

0

0

0

3

0

0

0

0

7000

X31

Y1

Y2

Y3

2

3

0

0

7000

X15

X0 X5 X10 X15 X20 X25 X30

Y0

Y2

Y3

Y4

Y6

E.A E.A E.A E.A

KEYPLAN

UP

DN

UP

UP UP UP UP UP UP UP UP UP UP UP UP

UP

DN DN DN DN

DN

E.A E.A E.A

25,150,125

32

32

32 32 125

100 80

UP

15

AIR

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 UP (TYP.)

425 UP (TYP)

415 UP (TYP.)

425 UP (TYP)

425 UP (TYP)

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 UP (TYP.)

415 BALL VALVE

FOR CLEAN

AUTO AIR DRAIN TRAP

PRESSURE RE DUCING VALVE

415 BALL VALVE

FOR CLEAN

CONN TO. OUTDOOR PIPING PLAN

REFER TO DWG NO:0-G-006

150,125

SCALE : 1/250 MAIN SHOP PIT OVERALL COMPRESSED AIR PIPING PLAN-4

NH XUNG

KT N V NG BN NGO

XEM BN V NO:0-G-006

1

STORAGE

Kho

BLOW&CARD

ROOM

PRE SPINNNIG

AHU

ELECTRICAL

ROOM

COMBER

WASTE ROOM

LOADING DOCK

/ OPENING

RAWMATERIAL

Nguyn liu th

LOADING DOCK

Khu bc hng

415 BALL VALVE

FROMCEILING

415 DN (TYP.)

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 DN (TYP.)

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

TY LE : 1/250 MAT BNG NG KH NN TON BO TNG TRET NH XUNG - 1

MAIN SHOP

1-M-007

A1=1/250, A3=1/500

1

( )

3

0

0

0

0

2

0

0

0

0

1

0

0

0

0

Y3

Y4

Y5

Y6

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000

X15 X14 X13 X12 X11 X10 X9 X8 X7 X6 X5 X4 X3 X2 X1 X0

DN

40

AIR

415 BALL VALVE

FOR CLEAN

40

40

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X0

KEYPLAN

415 BALL VALVE

FOR CLEAN

DN UP

UP

UP

DN

UP

UP

UP

40' TRAILER

O.A E.A

5

0

MNG SNG 425

VAN BI

"A"

CH TT A

SCALE : 1/250 MAIN SHOP GROUND FLOOR OVERALL COMPRESSED AIR PIPING PLAN-1

NH XUNG

P. ph phm

thi v chi soi

Phng HN

truc khi dt

P. ph phm

chi soi

Khu bc hng

/ m

Phng din

A DETAIL

BALL VALVE

STORAGE

Kho

CHILLER ROOM

SPINNNIG-1

AHU

SPINNNIG-2

AHU

WINDER

AHU

ELECTRICAL

ROOM

LOADING DOCK

Khu bc hng

VS-3 /RESTROOM-3

ROLLER

My cn

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

425 DN (TYP)

425 DN (TYP)

425 DN (TYP)

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

1

MAIN SHOP

1-M-008

A1=1/250, A3=1/500

1

VS-2 /RESTROOM-2

3

0

0

0

0

2

0

0

0

0

1

0

0

0

0

Y3

Y4

Y5

Y6

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 9000 5000 7000 7000 7000

X31 X30 X29 X28 X27 X26 X25 X24 X23 X22 X21 X20 X19 X18 X17 X16

TY LE : 1/250 MAT BNG NG KH NN TON BO TNG TRET NH XUNG - 2

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X0

KEYPLAN

UP

DN

UP UP

DN

DN

UP

UP

E.A E.A E.A O.A O.A O.A

THP G NHET

CHILLER COOLING TOWER

"A" "B"

5

0

MNG SNG 425

VAN BI

CH TT B

5

0

MNG SNG 425

VAN BI

CH TT A

HOSE JONT 419

SCALE : 1/250 MAIN SHOP GROUND FLOOR OVERALL COMPRESSED AIR PIPING PLAN-2

NH XUNG

Phng Lm Lanh

Phng HN

my dt 1

Phng HN

my dt 2

P. din

P. HN

my cun soi

BALL VALVE

BALL VALVE

SLEEVE 425

A DETAIL

SLEEVE 425

B DETAIL

N NG MM 419

1

MAIN SHOP

1-M-009

A1=1/250, A3=1/500

1

PRE SPINNNIG

AHU

BLOW&CARD

ROOM

COMBER

WASTE ROOM

ELECTRICAL

ROOM

BALE PRESS

ROOM

TEST ROOM

VS-5 /RESTROOM-5

25

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 DN (TYP.)

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

415 BALL VALVE

FROMCEILING

1

0

0

0

0

Y0

2

0

0

0

0

3

0

0

0

0

Y1

Y2

Y3

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000

X15 X14 X13 X12 X11 X10 X9 X8 X7 X6 X5 X4 X3 X2 X1 X0

415 (TYP.) 415 (TYP.)

415 (TYP.)

TY LE : 1/250 MAT BNG NG KH NN TON BO TNG TRET NH XUNG - 3

40

40

40

40

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X0

KEYPLAN

DN UP

UP

UP UP

DN

UP

UP

UP

UP

UP

O.A E.A

"A"

5

0

MNG SNG 425

VAN BI

CH TT A

SCALE : 1/250 MAIN SHOP GROUND FLOOR OVERALL COMPRESSED AIR PIPING PLAN-3

NH XUNG

Phong p kin

Phng HN

truc khi dt

PRE-SPINNING

MAINTENANCE ROOM-1

P. bo dung

my soi 1

P. thi v chi soi

P. din 1

P. ph phm

chi soi

P. kim tra

BALL VALVE

SLEEVE 425

A DETAIL

1

MAIN SHOP

1-M-010

A1=1/250, A3=1/500

1

PACKING RM

( )

STORAGE

KHO STORAGE

KHO

SPINNNIG-1

AHU

SPINNNIG-2

AHU

WINDER

AHU

CHILLER

ROOM

ELECTRICAL

ROOM

STORAGE

( )

OPERATING

ROOM

VS-4 /RESTROOM-4

415 DN (TYP.)

415 DN (TYP.)

415 (TYP.)

415 (TYP.)

425 DN (TYP)

415 DN (TYP.)

425 DN (TYP)

425 DN (TYP)

415 DN (TYP.)

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 BALL VALVE

FOR CLEAN

415 DN (TYP.)

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 9000 5000 7000 7000 7000

X31 X30 X29 X28 X27 X26 X25 X24 X23 X22 X21 X20 X19 X18 X17 X16

1

0

0

0

0

Y0

2

0

0

0

0

3

0

0

0

0

Y1

Y2

Y3

415 BALL VALVE

FOR CLEAN

415 (TYP.)

TY LE : 1/250 MAT BNG NG KH NN TON BO TNG TRET NH XUNG -4

DN

15

AIR

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X0

KEYPLAN

UP

DN

UP UP

DN

UP

UP

UP

DN

E.A E.A E.A O.A O.A O.A

THP G NHET

CHILLER COOLING TOWER

5

0

MNG SNG 425

VAN BI

CH TT B

5

0

MNG SNG 425

VAN BI

CH TT A

"B"

"A"

N NG MM 419

SCALE : 1/250 MAIN SHOP GROUND FLOOR OVERALL COMPRESSED AIR PIPING PLAN-4

NH XUNG

P. dong goi

P.HN

my cun soi

P. HN

my dt 1

P. HN

my dt 2

P. vn hnh P. Lm Lanh

BALL VALVE

HOSE JONT 419

BALL VALVE

SLEEVE 425 SLEEVE 425

B DETAIL A DETAIL

UP

DN

RESTROOM-4 RESTROOM-3

TEST ROOM

OPERATING

ROOM

RESTROOM-1

ROLLER

ROOM

RESTROOM-2

PRE-SPINNING

PRE-SPINNING

F

4

F

3

F

4

F

3

F

1

F

3

F

4

1

PAC

1

PAC

7000 7000 7000

X16 X15 X14 X17

1

0

0

0

0

Y5

Y6

1

0

0

0

0

Y5

Y6

5700

X26

1

0

0

0

0

Y0

Y1

1

0

0

0

0

Y0

Y1

1

0

0

0

0

Y0

Y1

7000 7000 7000

X16 X15 X14 X17

7000

X7 X6

5000

X28 X27

1-M-101

A1=1/100, A3=1/200

1

Electric Fan (TYP.)

Electric Fan (TYP.)

DSCHARGE N OUTDOOR/ X RA NGO

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X5 X0

KEYPLAN

3

3

1

PAC

1

PAC

A B

C D E

1

PAC

1

PAC

1

PAC

1

PAC

3

3

1H PBL-1601H2

3H PBL-3501H2

7H PBL-7001H2

8H PBL-8701H2

PPE DSPLAY/K HEU NG

BRANCHNG/BO CHA PPE LENGTH LMT/G HAN CHU D NG

RG.RL: NG GAS (TRN TRN) / D NG NUC NGUNG (TRN TRN)

9

RL:19.05

RG:41.3

8

RL:19.05

RG:34.9 RG:28.58

RL:15.88 RL:9.52

RG:19.05 RG:12.7

RL:6.35

1

SIZE

NO. 2

RL:9.52

RG:15.88

4 3

RL:9.52

RG:22.2

6 5

RL:12.7

RG:28.58

7

RL:15.88

RG:34.9

RG.RL: REFRIGERANT PIPING (CEILING PIPE) / DDRAIN PIPE (CEILING PIPE)

X BN NGO

DISCHARGE IN OUTDOOR

V LU CHN CN TRNG

SIZE:450x400

WITH BIRDSCREEN E.A DUCT OPENING

E A 8 1680 210

AIR MM,

TYPE

EALH EA

SIZE TN PHNG Q`ty AIR FLOW(CMH)

REMARKS

TOTAL (mm)

NECK DIA.

420 200

RESTROOM-2

G LOA GH CH

NG N

1-M-102

A1=1/100, A3=1/200

1

DN

UP

DN

UP

1

0

0

0

0

Y5

Y6

7000 7000 7000 7000

OFFICE-3 OFFICE-4

OFFICE-5

OFFICE-1 OFFICE-2

TRAINNING

ROOM

CORRIDOR-2

CORRIDOR-1

F

3

F

3

F

4

F

4

F

4

2 x

F

4

2 x

X17 X16 X15 X14 X13

7000 7000 7000 7000

X17 X16 X15 X14 X13

1

0

0

0

0

Y0

Y1

DN

MAINTENANCE

ROOM

1

0

0

0

0

Y0

Y1

7000 7000

X7 X6 X5

Electric Fan (TYP.) Electric Fan (TYP.)

1

KEYPLAN

X30 X25 X20 X15 X10 X5 X5 X0

Y0

Y6

Y4

Y2

A

B C

1

2

0

0

0

0

1

0

0

0

0

Y0

2

0

0

0

0

3

0

0

0

0

3

0

0

0

0

2

0

0

0

0

1

0

0

0

0

Y1

Y2

Y3

Y4

Y5

Y6

2

2

0

0

2

2

0

0

1

0

0

0

0

1

0

0

0

0

9

6

2

5

3

7

5

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

9

6

2

5

3

7

5

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

7000

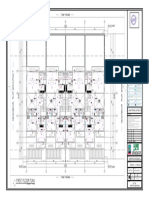

35000

7000 7000 7000 7000

X0 X1 X2 X3 X4

217000

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 9000 5000 7000 7000

X5 X6 X7 X8 X9 X10 X11 X12 X13 X14 X15 X16 X17 X18 X19 X20 X21 X22 X23 X24 X25 X26 X27X28 X29 X30

7000

X31

7000

26000 156000

1300

4500

3200

PRE-SPINNING

PRE-SPINNING

FILTER ROOM-3

FILTER ROOM-4

PT UNG NG

PT THNG GO

PT THNG GO

PIPING PIT

SPINNING

FILTER ROOM-3

SPINNING

FILTER ROOM-4

CONSTRUCTION

MATERIAL-2

WINDER

FILTER ROOM-2

PT UNG NG

1

1 1 1 1 1 1 1

UP

PW

20

50(PD)

MAIN SHOP

1-M-201

A1=1/400, A3=1/800 MAT BNG NG TNG HM NH XUNG TY LE : 1/400

1

DN

UP

DN

UP

UP

DN

UP

DN

UP

DN

UP

DN

UP

DN

UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP

UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP UP

DN

DN

DN

DN

DN

UP

UP

DN DN DN DN DN

DN DN DN DN DN

UP

DN

DN

UP

E.A E.A E.A E.A

E.A E.A E.A E.A

MAIN SHOP BASEMENT FLOOR PLUMBING PIPING PLAN SCALE : 1/400

VENTILATION PIT

VENTILATION PIT

P. loc xe chi

truc khi dt 3

P. loc xe chi

truc khi dt 4

PT UNG NG

P. loc xe chi -4

P. loc xe chi-3

Vt liu thi cng 2 Phong loc qun-2

PIPING PIT

PIPING PIT

NH XUNG

1

2

0

0

0

0

1

0

0

0

0

Y0

2

0

0

0

0

3

0

0

0

0

3

0

0

0

0

2

0

0

0

0

1

0

0

0

0

Y1

Y2

Y3

Y4

Y5

Y6

2

2

0

0

2

2

0

0

9

8

2

5

1

0

0

0

0

1

7

5

9

6

2

5

3

7

5

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

9

8

2

5

1

0

0

0

0

1

7

5

9

6

2

5

3

7

5

1

0

0

0

0

1

0

0

0

0

1

0

0

0

0

7000

35000

7000 7000 7000 7000

X0 X1 X2 X3 X4

217000

7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 7000 9000 5000 7000 7000

X5 X6 X7 X8 X9 X10 X11 X12 X13 X14 X15 X16 X17 X18 X19 X20 X21 X22 X23 X24 X25 X26 X27X28 X29 X30

7000

X31

7000

26000 156000

6625 375 6625375 3754625 375 6625

STORAGE-6

SPARE PARTS

BLOW&CARD

ROOM-2

PRE-SPINNING

AHU-2

ELECTRICAL

ROOM-3

COMBER

WASTE ROOM-2

LOADING DOCK

/ OPENING

STORAGE-1

RAWMATERIAL

PRE-SPINNING AHU-1

P. HN truc khi dt 1

BLOW&CARD

ROOM-1

COMBER

WASTE ROOM-1

WINDER

AHU-1

CHILLER

ROOM-1

BALE PRESS

ROOM

LOADING DOCK

RAWCOTTON

TEST ROOM OPERATING

ROOM

ROLLER

ROOM

CHILLER

ROOM-2

Hall - 4

DUST

COLLECTOR

MAIN SHOP

Hall - 1

PRE-SPINNING

LOADING DOCK

WASTE DISCHARGE

Hall - 2

1 1

50 BALL TAP VALVE & 65 VALL VALVE

DN

PW

20

MAIN SHOP

1-M-202

A1=1/400, A3=1/800 MAT BNG NG TNG TRET NH XUNG TY LE : 1/400

1

UP

DN UP

UP

UP UP DN

UP

UP

DN UP UP DN

UP

UP

UP

DN UP

UP

UP DN

UP

DN UP UP DN

UP

UP

DN

DN

UP

UP

UP

UP

UP

UP

40' TRAILER

O.A E.A E.A E.A E.A O.A O.A O.A

O.A E.A E.A E.A E.A O.A O.A O.A

THP G NHET

CHILLER COOLING TOWER

MAIN SHOP GROUND FLOOR PLUMBING PIPING PLAN SCALE : 1/400

P. thit bj loc bui

Khu bc hng

nguyn liu bng

Kho - 6

phu tng

Kho -1

Nguyn liu th

Khu bc hng

Phong p kin

Snh - 1

Phong Bo dung

my soi 1

P. ph phm thi

v chi soi 1

P. ph phm chi soi 1 Snh - 2

P. thi v

chi soi 2

P. din-3

P. ph phm

chi soi 2

Snh - 4

Khu bc hng/ m

Phong Bo dung

my soi 2

P. my cn

P. Lm Lanh-2

P.Lm Lanh 1

1

0

0

0

0

9

6

2

5

3

7

5

7000 3700 3900

X9 X10

Y6

Y5

1

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X5 X0

KEYPLAN

50 BALL TAP VALVE & 65 VALL VALVE

VAN PHAO 50 V VAN B 65

75 F.D x 4EA 100 C.O

100 C.O

100 C.O

100 C.O

KT N V MAT BNG NG

TNG HM NH XUNG

KT N V MAT BNG NG

TNG TRET NH XUNG

THAM KHO BN V S:1-M-201

THAM KHO BN V S :1-M-202

MAIN SHOP

1-M-203

A1=1/50, A3=1/100

MB NG TRCH OAN PHNG HN MY TRUC KH DET - 2 NH XUNGTY LE : 1/50

1

UP

DN

MAIN SHOP PRE-SPINNING AHU-2 ENLARGED PLUMBING PLAN SCALE : 1/50

CONN. TO MAIN SHOP GROUNDFLOOR

PLUMBING PIPING PLAN

REFER TO DWG NO:1-M-202

CONN. TO MAIN SHOP BASEMENT FLOOR

PLUMBING PIPING PLAN

REFER TO DWG NO:1-M-201

NH XUNG

1 1

7000 7000 7000 7000

1

0

0

0

0

9

6

2

5

3

7

5

Y6

Y5

X19 X20 X21 X22 X23

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X5 X0

KEYPLAN

50 BALL TAP VALVE & 65 VALL VALVE

VAN PHAO 50 V VAN B 65

50 BALL TAP VALVE & 65 VALL VALVE

VAN PHAO 50 V VAN B 65

75 F.D x 4EA 75 F.D x 4EA

WW

W

W

WW

WW

W

W

WW

WW

100 C.O

100 C.O

100 C.O

100 C.O

100 C.O

100 C.O

100 C.O

MAIN SHOP

1-M-204

A1=1/50, A3=1/100

MAT BNG NG TRCH OAN PHNG HN MY DET - 3, 4 NH XUNG TY LE : 1/50

1

UP

DN

UP

MAIN SHOP SPINNING AHU-3, 4 ENLARGED PLUMBING PLAN SCALE : 1/50

THOT SN 75 x 4EA

THNG TC 100 THNG TC 100

THNG TC 100

THOT SN 75 x 4EA

THNG TC 100

THNG TC 100

NH XUNG

1 1

X26

7000

X25

3300

1

0

0

0

0

1

7

5

9

6

2

5

3

7

5

Y5

Y6

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X5 X0

KEYPLAN

50 BALL TAP VALVE & 65 VALL VALVE

VAN PHAO 50 V VAN B 65

100 C.O

75 F.D x 3EA

MAT BNG NG TRCH OAN PHNG HN MY CUN SO - 2 NH XUNG TY LE : 1/50

1

100 C.O

100 C.O

MAIN SHOP

1-M-205

A1=1/50, A3=1/100

MAIN SHOP WINDER AHU-2 ENLARGED PLUMBING PLAN SCALE : 1/50

THNG TC 100

THOT SN 75 x 3EA

THNG TC 100

NH XUNG

1

7000 3700 3900

1

0

0

0

0

9

6

2

5

3

7

5

Y0

Y1

X9 X10

50 BALL TAP VALVE & 65 VALL VALVE

VAN PHAO 50 V VAN B 65

75 F.D x 4EA 100 C.O

1

MAT BNG NG TRCH OAN PHNG HN TRUC KH DET - 1 NH XUNGTY LE : 1/50

1

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X5 X0

KEYPLAN

100 C.O

100 C.O

MAIN SHOP

1-M-206

A1=1/50, A3=1/100

MAIN SHOP PRE-SPINNING AHU-1 ENLARGED PLUMBING PLAN SCALE : 1/50

THNG TC 100

THNG TC 100

THNG TC 100

NH XUNG

1

7000 7000 7000 7000

1

0

0

0

0

9

6

2

5

3

7

5

Y0

Y1

X19 X20 X21 X22 X23

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X5 X0

KEYPLAN

50 BALL TAP VALVE & 65 VALL VALVE

VAN PHAO 50 V VAN B 65

50 BALL TAP VALVE & 65 VALL VALVE

VAN PHAO 50 V VAN B 65

75 F.D x 4EA 75 F.D x 4EA

WW

W

W

WW

WW

W

W

WW

WW

100 C.O

100 C.O

100 C.O

100 C.O

100 C.O

100 C.O

100 C.O

MAT BNG NG TRCH OAN PHNG HN XE CH 1,2 NH XUNG TY LE: 1/50

1

1

MAIN SHOP

1-M-207

A1=1/50, A3=1/100

MAIN SHOP SPINNING AHU-1, 2 ENLARGED PLUMBING PLAN SCALE : 1/50

THNG TC 100

THNG TC 100

THOT SN 75 x 4EA

THNG TC 100 THNG TC 100

THNG TC 100

THOT SN 75 x 4EA

THNG TC 100

NH XUNG

1 1

7000 3300

X25 X26

1

0

0

0

0

9

6

2

5

3

7

5

Y0

Y1

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X5 X0

KEYPLAN

VAN PHAO 50 V VAN B 65

& 65 VALL VALVE 50 BALL TAP VALVE

100 C.O

75 F.D x 3EA

MAT BNG NG TRCH OAN PHNG HN MY CUN SO - 1 NH XUNG TY LE : 1/50

1

100 C.O

NH XUNG

1-M-208

A1=1/50, A3=1/100

MAIN SHOP WINDER AHU-1 ENLARGED PLUMBING PLAN SCALE : 1/50

THNG TC 100

THOT SN 75 x 3EA

THNG TC 100

MAIN SHOP

1 1

1

0

0

0

0

1

7

5

9

6

2

5

3

7

5

3000 2800

X16

Y5

Y6

5700

X26

1

0

0

0

0

1

7

5

9

6

2

5

3

7

5

Y5

Y6

1

0

0

0

0

9

6

2

5

3

7

5

Y0

Y1

5700

X14

1

0

0

0

0

9

6

2

5

3

7

5

Y0

Y1

5000

X27 X28

P

W

MAT BNG TRCH OAN 1 VE SNH TY LE : 1/50

MAT BNG TRCH OAN 2 VE SNH TY LE : 1/50

MAT BNG TRCH OAN 3 VE SNH TY LE : 1/50 MAT BNG NG TRCH OAN VE SNH - 4 T l: 1/50

Y0

Y6

Y4

Y2

X30 X25 X20 X15 X10 X5 X5 X0

KEYPLAN

1 2

3 4

MB NG TRCH OAN VE SNH NH XUNG TY LE : 1/50

1