Escolar Documentos

Profissional Documentos

Cultura Documentos

Preview 92103

Enviado por

aloisio80Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Preview 92103

Enviado por

aloisio80Direitos autorais:

Formatos disponíveis

ABS Piranha submersible grinder pump 08-125

Type tested

and monitored

ABS submersible pumps for problem-free pumping of sewage

containing faecal matter in pipe lines from 1 (DN 32) in

accordance with EN 12050-1.

Applications

Piranha submersible pumps have been designed for effective and

economic dewatering using discharge lines of small diameter, in

private, municipal and industrial areas.

* Sewage removal from living units and houses in remote settle-

ments where the laying of a conventional sewer would be too

expensive, where large ground undulations are present or where

it is only possible to lay pipe lines of small diameter.

* Sewage removal from motorway resting sites, communal build-

ings and for renovation of buildings or areas of a city.

* For use in slaughter houses, food processing plants, paper

factories, agriculture and similar areas.

* Piranha 08 and 09 are specially designed for private and domes-

tic applications.

* Maximum allowable temperature of the medium for continuous

operation is 40 C, or if unit is submerged, short term to 60 C

(max. 5 minutes).

Construction

The water pressure-tight, encapsulated fully ood-proof motor

and the pump section form a compact ,robust, unit construction.

Motor

Three-phase 460 V or single-phase 230 V, 60 Hz, 2-pole (3400

r/min) or 4-pole (1750 r/min). Insulation class F; protection type

IP 68. Cooled by amply dimensioned cooling areas. Piranha S10-

M125 available in explosive-proof version to EEXd IIB T4 and FM

standards.

Bearings

The stainless steel motor shaft is supported in lubricated-for-life

ball bearings.

Shaft sealing

Between motor and hydraulic section by means of a high quality

sealing unit using a silicon carbide mechanical seal, independent

of direction of rotation and resistant to temperature shock. Seal at

motor side is by oil lubricated lip seal.

Discharge

Piranha 08 and 09: G 1 internal thread

Piranha S10 to M50: DN 32 ange (G 1 threaded adaptor avail-

able as accessory)

Piranha M70 to M125: DN 50 with DIN-ange

Shredding system

Spiral bottom plate and stationary cutter ring combined with

a shredding rotor located before the impeller, for optimum

blockage-free running.

Temperature monitoring

TCS (Thermo-Control-System) with thermal sensors in the stator

to switch off the pump in the case of overheating and switch on

automatically after cooling down.

Seal monitoring

DI system consisting of a sensor in the motor and oil chambers

which signals an inspection alert if there is leakage at the shaft

seals. Not available for Piranha 08 and 09.

Features

* Unique ABS Piranha shredding system capable of shredding

items such as cloths and plastic bags.

* For the pumping of wastewater containing sewage, offal, organic

and industrial efuent.

* Piranha 08 and 09 tted with MF modular motor; Piranha S10

- M125 with AS or AFP.

* Small discharge lines from 1 (DN 32).

* Installations are possible where large ground undulations are

present.

* Standard and Ex-versions available (Piranha S10 - M125)

* Piranha 08 and 09 have capacitor in upper lid and do not require

a control box.

* Low installation costs due to small diameter discharge pipe-

work.

Materials

Description Material

Upper Lid * Stainless steel 1.4301 (AISI 304)

Motor Housing Cast iron EN-GJL-250

Rotor Shaft Stainless steel 1.4021 (AISI 420)

Volute Cast iron EN-GJL-250

Impeller ** Cast iron EN-GJL-250

Fasteners Stainless steel 1.4401 (AISI 316)

* Piranha 08 and 09

** Polyamide for Piranha 08

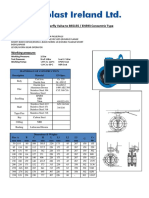

Technical Data

Piranha

Discharge

Flange Internal

DN thread *

Motor power **

(kW)

P

1

P

2

Rated

current

(A)

Rated

voltage

(V)

Speed

(r/min)

Cable size ***

Std & Ex

Weight ****

(kg)

08/2W - G 1 2.15 1.50 9.39 230 1~ 3400 SJTOW-A 16/3 18

08/2D - G 1 1.85 1.50 2.87 460 3~ 3400 STOW-A 16/4 18

09/2W - G 1 2.83 2.25 13.50 230 1~ 3400 SJTOW-A 16/3 23

09/2D - G 1 2.53 2.00 3.98 460 3~ 3400 STOW-A 16/4 23

S10/4W

(1

32 G 1 1.48 1.00 6.50 230 1~ 1750 SOW-A 14/7 32

S10/4D 32 G 1 1.33 1.00 2.60 460 3~ 1750 SOW-A 14/7 32

S20/2W

(1

32 G 1 2.45 1.80 11.50 230 1~ 3400 SOW-A 14/7 32

S20/2D 32 G 1 2.42 1.80 3.61 460 3~ 3400 SOW-A 14/7 32

S26/2W

(1

32 G 1 3.13 2.60 13.70 230 1~ 3400 SOW-A 14/7 40

S30/2D 32 G 1 3.87 3.00 5.50 460 3~ 3400 SOW-A 14/7 53

M25/2W 32 G 1 3.74 2.50 16.60 230 1~ 3400 7G2.5 40

M25/2D 32 G 1 3.04 2.50 4.66 460 3~ 3400 7G1.5 40

M35/2W 32 G 1 5.19 3.50 24.00 230 1~ 3400 7G2.5 53

M35/2D 32 G 1 4.26 3.50 6.08 460 3~ 3400 7G1.5 53

M46/2D 32 G 1 5.60 4.60 7.69 460 3~ 3400 7G1.5 53

M50/2W 32 G 1 6.68 5.00 29.30 230 1~ 3400 7G2.5 40

M70/2D 50 DIN - 8.16 7.00 11.60 460 3~ 3400 7G2.5 76

M80/2D 50 DIN - 9.39 8.00 13.10 460 3~ 3400 7G2.5 77

M100/2D 50 DIN - 11.80 10.00 17.00 460 3~ 3400 10G2.5 78

M125/2D 50 DIN - 14.50 12.50 21.30 460 3~ 3400 10G2.5 80

* Piranha S10-M50 with threaded ange adaptor as accessory ** P

1

= Power at mains; P

2

= Power at motor shaft

*** Ex cable variations: M70 & 80/2 = 10G2.5 **** Weight with 10 m cable

(1

Start and Run capacitor to the following specication required for use without control panel.

Start: 161-193F for S10/4W & S20/2W, 200F for S26/2W

Run: 30F for S10/4W, 20F for S20/2W, 50F for S26/2W

The recommended start time for the motors is two seconds.

Performance Curves

Q

[m

3

/h]

[l/s]

H [m]

0

0

0

4

8

1 2

20

2.5

24

12

3

28

32

16

4

36

40

5 7.5 10 12.5 15 17.5

44

48

x

S

3

0

/2

D

S

2

0

/2

D

&

W

0

8

D

0

9

D

&

W

0

8

W

S

10/4D

&

W

S

2

6

/2

W

x

Q

[m

3

/h]

[l/s]

H [m]

0

0

0

8

2 4

40

5

48

6

56

64

16

8

72

80

10 15 20 25 30 35

88

96

24

32

M

125/2D

M

80/2D

M

70/2D

M

35/2D &

W

M25/2D & W

M

50/2W

M

46/2D

M

100/2D

= max. ow

09 W

H = Total Head; Q = Discharge Volume. Curves to ISO 9906 N.B. please use the ABSEL program to validate pump selection.

Dimensions (mm)

40

1

1

0

9

1

1

1

5

1

4

0

2

1

1

8

0

1

3

8

G

1

1

8

0

1

3

8

G

1

5

5

2

3

85

85

90

90

512

392

18

18

65

172

130

180

218

170

1

1

14

D

B

A

2

7

9

52

455

125

4

0

15

1

0

5

1

0

6

2

0

0

3

3

5

1

8

0

1

8

1

1

0

D

N

5

0

85

2

200

160

20

B

C

A

B

*

*

*

**

*

9

5

5

5

2

3

14

40

65

1

8

0

1

3

8

G

1

85

90

18

65

1

40

1

1

0

1

1

5

1

6

0

5

5

8

5

2

3

14

B

D

Piranha 08 & 09 Piranha S10 - S30

Piranha M25 - M70 Piranha M80 - M125

Piranha A B C D

08

09

S10 & S20

S26 & S30

M25 - M46

M50 & M70

M80 & M100

M125

420

445

347

360

-

-

-

-

445

470

414

427

556

614

628

672

117

108

-

-

-

-

-

-

-

-

368

374

400

420

-

-

Piranha 08 - M125: Minimum sump opening 625 mm

Pedestal base secured using M10 masonry anchor bolts, drill hole size 14 mm

* Lowest switch-off point for automatic operation

Piranha M80 - M125: Discharge line connection with threaded ange DN 50/2 PN16

Discharge elbow supplied by customer

** Hexagon head wood screw 10 x 70 DIN 571 and dowel size 12

Accessories

Description Size Part no. Piranha

Fixed installation

with pedestal

Pedestal (EN-GJL-250)

90 cast bend

G 1

G 1

G 1

62325007

62320674

62320676

08 & 09

S10-S30,

M25-M50

90 cast bend with built-in

non-return valve

G 1

G 1

62320536

62320538

S10-S30

M25-M50

without bend DN 50/G2 62320660 M70-M125

Threaded Adaptor

hexagon double nipple

G 1 13770011 08 & 09

Guide Rail (galvanized steel) 1 x 1 m

1 x 2 m

1 x 3 m

1 x 4 m

1 x 5 m

31380007

31380008

31380009

31380010

31380011

08-M125

Chain Kit (galvanized steel)

including shackle

3 m

4 m

6 m

7 m

61265065

61265093

61265069

61265096

08-M125

Chain Kit (stainless steel)

including shackle

3 m

4 m

6 m

7 m

61265081

61265099

61265085

61265102

08-M125

Transportable

applications

Threaded Flange Kit (EN-GJL-250)

including discharge piece, gasket and bolts

G 1 61180512 S10-M50

Ground Support Stand (St. 37)

with xing bolts

61900013

61900007

S10-S30

M25-M125

Fixed Coupling (brass) GEKA

with external thread

G 1 15020003 S10-M50

Hose Coupling

with nozzle, outer dia. 34 mm

G 1 15020018 S10-M50

Horizontal

(tank connection)

Pump

with built-in ange on suction side

DN 150/PN 16

to DIN 2633

On request S10-M125

Head Support (EN-GJL-250)

with vibration damping

62665103

41425005

S10-S30

M25-125

General Non-return Valve (EN-GJL-250)

ball valve with internal thread

G1

G1

G2

61400525

61400526

61400527

08-M125

Shut-off Valve (brass)

with internal thread

G1

G1

G2

14040005

14040006

14040007

08-M125

A

B

S

P

i

r

a

n

h

a

s

u

b

m

e

r

s

i

b

l

e

g

r

i

n

d

e

r

p

u

m

p

0

8

-

1

2

5

,

6

0

H

z

G

B

2

0

0

9

-

0

8

-

1

0

|

W

e

r

e

s

e

r

v

e

t

h

e

r

i

g

h

t

s

t

o

a

l

t

e

r

s

p

e

c

i

c

a

t

i

o

n

s

d

u

e

t

o

t

e

c

h

n

i

c

a

l

d

e

v

e

l

o

p

m

e

n

t

s

.

Você também pode gostar

- Piranha 08 110 TDSDocumento4 páginasPiranha 08 110 TDSchu42Ainda não há avaliações

- Piranha - 08 - 110 - TDS EngleskiDocumento4 páginasPiranha - 08 - 110 - TDS EngleskiZoran CirjakovicAinda não há avaliações

- AMRI ISORIA 16 Type Series Booklet DataDocumento20 páginasAMRI ISORIA 16 Type Series Booklet Datarudiskw456Ainda não há avaliações

- Applications: Type TestedDocumento4 páginasApplications: Type TestedFV AllanAinda não há avaliações

- 100 SeriesDocumento5 páginas100 Seriesfathur2107Ainda não há avaliações

- Pulleys TechDocumento8 páginasPulleys TechashkansoheylAinda não há avaliações

- Secondary CrusherDocumento1 páginaSecondary CrusherVivek SakthiAinda não há avaliações

- Reliable wastewater pumps for buildingsDocumento4 páginasReliable wastewater pumps for buildingsArmando BarrancoAinda não há avaliações

- 01 MF New Pages PDFDocumento22 páginas01 MF New Pages PDFSlobodan AnticAinda não há avaliações

- Serie HP eDocumento10 páginasSerie HP eMarceloPolicastroAinda não há avaliações

- Sez 6 ENGDocumento20 páginasSez 6 ENGGumersindo MelambesAinda não há avaliações

- 06 SCT Extended PDFDocumento40 páginas06 SCT Extended PDFSlobodan Antic100% (2)

- MPVN BrochureDocumento32 páginasMPVN Brochurefernando_naciamentAinda não há avaliações

- DAB. Prays Zapchasti 01.11.2021Documento616 páginasDAB. Prays Zapchasti 01.11.2021Belgacem ArramiAinda não há avaliações

- Information - Regarding - Import - Substitution and de Proprietarisation NewDocumento5 páginasInformation - Regarding - Import - Substitution and de Proprietarisation Newsameguy sameguyAinda não há avaliações

- P-EG Stainless Steel Filter Housing DatasheetDocumento5 páginasP-EG Stainless Steel Filter Housing DatasheetalineAinda não há avaliações

- Butterfly Valve Technical Data SheetDocumento6 páginasButterfly Valve Technical Data SheetMr. AAinda não há avaliações

- MK18-20 SparelistDocumento26 páginasMK18-20 SparelistaritmeticsAinda não há avaliações

- Hja-Hjn Leaflet-RbcDocumento3 páginasHja-Hjn Leaflet-Rbcapi-97482572Ainda não há avaliações

- FRD Product LineDocumento8 páginasFRD Product Linegiapy0000Ainda não há avaliações

- Reject RBC UpgradationDocumento9 páginasReject RBC Upgradationirfan.ali0463Ainda não há avaliações

- CAT 003 1 - 06 U TronicDocumento20 páginasCAT 003 1 - 06 U Tronic4nagAinda não há avaliações

- Butterfly Valves EgeplastDocumento4 páginasButterfly Valves EgeplastdsyashankaAinda não há avaliações

- LTG - VSR Ru MS e - 450 60Documento18 páginasLTG - VSR Ru MS e - 450 60Ahsan JavedAinda não há avaliações

- Threading Tools (SST Series)Documento8 páginasThreading Tools (SST Series)Gilberto ManhattanAinda não há avaliações

- TTM Post TensioningDocumento103 páginasTTM Post Tensioninghorea67100% (2)

- Pump STDRDocumento7 páginasPump STDRsopian320Ainda não há avaliações

- 1020 PDFDocumento180 páginas1020 PDFСергій XрестикAinda não há avaliações

- KWP Non-Clogging Centrifugal Pump: Automation Products AvailableDocumento16 páginasKWP Non-Clogging Centrifugal Pump: Automation Products Availablefedeparamos5030100% (1)

- Catalogue Solenoid ValveDocumento6 páginasCatalogue Solenoid ValveshrikantbelekarAinda não há avaliações

- Bernard Q - Gun Parts Break DownDocumento13 páginasBernard Q - Gun Parts Break DownullwnAinda não há avaliações

- Bar bending schedule for OHT constructionDocumento5 páginasBar bending schedule for OHT constructionengineerkranthi4055Ainda não há avaliações

- As TDS 60Hz MetricDocumento4 páginasAs TDS 60Hz MetricMarko Antonio AguilarAinda não há avaliações

- Fisa Tehnica Pompe MultifreeDocumento10 páginasFisa Tehnica Pompe MultifreeOčtáv VátčoAinda não há avaliações

- Wear-resistant agitator pumps for heavy slurriesDocumento4 páginasWear-resistant agitator pumps for heavy slurriesDaniel MocanuAinda não há avaliações

- Cat01 BaDocumento11 páginasCat01 BaTemporiusAinda não há avaliações

- Added Steel (SPS) Total 30KM (18-8-2019)Documento35 páginasAdded Steel (SPS) Total 30KM (18-8-2019)arun kumar vermaAinda não há avaliações

- 2 Port Poppet ValveDocumento4 páginas2 Port Poppet ValveganeshpapannaAinda não há avaliações

- SOCOLMATICDocumento15 páginasSOCOLMATICtavi230Ainda não há avaliações

- Kubota PumpsDocumento19 páginasKubota PumpsВенцислав Венев50% (2)

- Service and Parts Manual Rexel Shredder P170 & 190s Range 230V Issue 18Documento34 páginasService and Parts Manual Rexel Shredder P170 & 190s Range 230V Issue 18Raltec Ltd100% (1)

- Rotorseal Tech Specs PDFDocumento19 páginasRotorseal Tech Specs PDFMykola TitovAinda não há avaliações

- 830 CB 120 M07 - Rev0Documento1 página830 CB 120 M07 - Rev0EDUARDOAinda não há avaliações

- 1091 Bombas CentrifugasDocumento17 páginas1091 Bombas CentrifugasEugenio GomezAinda não há avaliações

- B3887BHF1Documento4 páginasB3887BHF1xianmingAinda não há avaliações

- Min1244a12 - Tag 130-Pu-029Documento7 páginasMin1244a12 - Tag 130-Pu-029Monty MathewsAinda não há avaliações

- Ebara Price ListDocumento61 páginasEbara Price ListDileep C Dileep50% (6)

- Bringing valuable water solutions to various applicationsDocumento32 páginasBringing valuable water solutions to various applicationsAhmadMoaazAinda não há avaliações

- 8" Submersible Motors Standard: ApplicationsDocumento7 páginas8" Submersible Motors Standard: Applicationswpt_meAinda não há avaliações

- KSB WKLNDocumento2 páginasKSB WKLNgangruka0% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAinda não há avaliações

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PNo EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PAinda não há avaliações

- Weld Like a Pro: Beginning to Advanced TechniquesNo EverandWeld Like a Pro: Beginning to Advanced TechniquesNota: 4.5 de 5 estrelas4.5/5 (6)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryAinda não há avaliações

- Ocean Engineering: Ali Mahrooghi, Esmail LakzianDocumento17 páginasOcean Engineering: Ali Mahrooghi, Esmail LakzianAlmir RodriguesAinda não há avaliações

- Renewable Energy: A. Mahboubidoust, A. RamiarDocumento18 páginasRenewable Energy: A. Mahboubidoust, A. RamiarAlmir RodriguesAinda não há avaliações

- Energy Conversion and ManagementDocumento12 páginasEnergy Conversion and ManagementAlmir RodriguesAinda não há avaliações

- Ocean Engineering: Abdullah Muratoglu, Ramazan Tekin, Omer Faruk Ertu GrulDocumento14 páginasOcean Engineering: Abdullah Muratoglu, Ramazan Tekin, Omer Faruk Ertu GrulAlmir RodriguesAinda não há avaliações

- Ocean Engineering: ReviewDocumento23 páginasOcean Engineering: ReviewAlmir RodriguesAinda não há avaliações

- Optimizing Wells Turbine Rotor Geometry Reduces LCOE by 20Documento12 páginasOptimizing Wells Turbine Rotor Geometry Reduces LCOE by 20Almir RodriguesAinda não há avaliações

- Sustainable Energy Technologies and Assessments: Abolfazl Pourrajabian, Maziar Dehghan, Saeed RahgozarDocumento10 páginasSustainable Energy Technologies and Assessments: Abolfazl Pourrajabian, Maziar Dehghan, Saeed RahgozarAlmir RodriguesAinda não há avaliações

- Renewable Energy: Paresh Halder, Abdus Samad, Dominique TH EveninDocumento13 páginasRenewable Energy: Paresh Halder, Abdus Samad, Dominique TH EveninAlmir RodriguesAinda não há avaliações

- The Controlled Random Search Algorithm in Optimizing Regression ModelsDocumento6 páginasThe Controlled Random Search Algorithm in Optimizing Regression ModelsAlmir RodriguesAinda não há avaliações

- Sedimentation Calculations 8.jan.2014Documento1 páginaSedimentation Calculations 8.jan.2014Almir RodriguesAinda não há avaliações

- Mollier 2Documento1 páginaMollier 2Almir RodriguesAinda não há avaliações

- Mollier Chart WaterDocumento1 páginaMollier Chart Waterchouchou575% (8)

- Acuity Assessment in Obstetrical TriageDocumento9 páginasAcuity Assessment in Obstetrical TriageFikriAinda não há avaliações

- Indian Patents. 232467 - THE SYNERGISTIC MINERAL MIXTURE FOR INCREASING MILK YIELD IN CATTLEDocumento9 páginasIndian Patents. 232467 - THE SYNERGISTIC MINERAL MIXTURE FOR INCREASING MILK YIELD IN CATTLEHemlata LodhaAinda não há avaliações

- The CongoDocumento3 páginasThe CongoJoseph SuperableAinda não há avaliações

- Motor GraderDocumento24 páginasMotor GraderRafael OtuboguatiaAinda não há avaliações

- VivsayamDocumento87 páginasVivsayamvalarumsakthi100% (2)

- The Apu Trilogy - Robin Wood PDFDocumento48 páginasThe Apu Trilogy - Robin Wood PDFSamkush100% (1)

- Concept Page - Using Vagrant On Your Personal Computer - Holberton Intranet PDFDocumento7 páginasConcept Page - Using Vagrant On Your Personal Computer - Holberton Intranet PDFJeffery James DoeAinda não há avaliações

- CAE The Most Comprehensive and Easy-To-Use Ultrasound SimulatorDocumento2 páginasCAE The Most Comprehensive and Easy-To-Use Ultrasound Simulatorjfrías_2Ainda não há avaliações

- Chapter 16 - Energy Transfers: I) Answer The FollowingDocumento3 páginasChapter 16 - Energy Transfers: I) Answer The FollowingPauline Kezia P Gr 6 B1Ainda não há avaliações

- Reflective Essay 4Documento1 páginaReflective Essay 4Thirdy AngelesAinda não há avaliações

- Organizing Small Items with Glass Bottle OrganizersDocumento70 páginasOrganizing Small Items with Glass Bottle OrganizersDy SaiAinda não há avaliações

- Revolutionizing Energy Harvesting Harnessing Ambient Solar Energy For Enhanced Electric Power GenerationDocumento14 páginasRevolutionizing Energy Harvesting Harnessing Ambient Solar Energy For Enhanced Electric Power GenerationKIU PUBLICATION AND EXTENSIONAinda não há avaliações

- Air Arms S400 EXPDocumento3 páginasAir Arms S400 EXPapi-3695814Ainda não há avaliações

- Handouts For TLG 3 1Documento5 páginasHandouts For TLG 3 1Daniela CapisnonAinda não há avaliações

- Abdomen - FRCEM SuccessDocumento275 páginasAbdomen - FRCEM SuccessAbin ThomasAinda não há avaliações

- Oral Nutrition Support NotesDocumento28 páginasOral Nutrition Support Notesleemon.mary.alipao8695Ainda não há avaliações

- JK Paper Q4FY11 Earnings Call TranscriptDocumento10 páginasJK Paper Q4FY11 Earnings Call TranscriptkallllllooooAinda não há avaliações

- Antennas Since Hertz and MarconiDocumento7 páginasAntennas Since Hertz and MarconiTaiwo Ayodeji100% (1)

- Chap 2 Debussy - LifejacketsDocumento7 páginasChap 2 Debussy - LifejacketsMc LiviuAinda não há avaliações

- Problem SolutionsDocumento5 páginasProblem SolutionskkappaAinda não há avaliações

- Air Wellness QRSDocumento2 páginasAir Wellness QRSapi-3743459Ainda não há avaliações

- Survey Report on Status of Chemical and Microbiological Laboratories in NepalDocumento38 páginasSurvey Report on Status of Chemical and Microbiological Laboratories in NepalGautam0% (1)

- Internship ReportDocumento18 páginasInternship ReportRathan Kumar SMAinda não há avaliações

- Chain Surveying InstrumentsDocumento5 páginasChain Surveying InstrumentsSachin RanaAinda não há avaliações

- B. Pharmacy 2nd Year Subjects Syllabus PDF B Pharm Second Year 3 4 Semester PDF DOWNLOADDocumento25 páginasB. Pharmacy 2nd Year Subjects Syllabus PDF B Pharm Second Year 3 4 Semester PDF DOWNLOADarshad alamAinda não há avaliações

- Draft Initial Study - San Joaquin Apartments and Precinct Improvements ProjectDocumento190 páginasDraft Initial Study - San Joaquin Apartments and Precinct Improvements Projectapi-249457935Ainda não há avaliações

- Troubleshooting Hydraulic Circuits: Fluid PowerDocumento32 páginasTroubleshooting Hydraulic Circuits: Fluid PowerMi LuanaAinda não há avaliações

- Placenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MDocumento40 páginasPlacenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MMikes CastroAinda não há avaliações

- The Templist Scroll by :dr. Lawiy-Zodok (C) (R) TMDocumento144 páginasThe Templist Scroll by :dr. Lawiy-Zodok (C) (R) TM:Lawiy-Zodok:Shamu:-El100% (5)

- SB Z Audio2Documento2 páginasSB Z Audio2api-151773256Ainda não há avaliações