Escolar Documentos

Profissional Documentos

Cultura Documentos

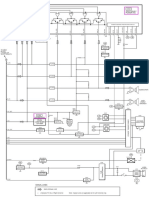

Vpa & Slurry Tank

Enviado por

Magesh MDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Vpa & Slurry Tank

Enviado por

Magesh MDireitos autorais:

Formatos disponíveis

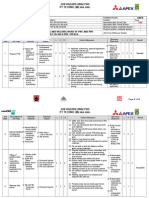

PLANT BENEFICATION

DEPARTMENT MECHANICAL

NUMBER OF

ITEMS 2

INCHARGE AR KRISHNA

a. EQUIPMENT DETAILS

b.

NAME OF

MANUFACTURER (MAKE)

c. PART NO

d. DRAWING NO

e Type

a. Designation

b. Size(idxodxwidth)

c. Wire dia

d. Clamp Type

e. PCD

f. NO OF GROOVE

g. ANGLE

h. RADIUS

i. CAPACITY

a.

MATERIAL OF

CONSTRUCTION (MOC)

b. GRADE

c. SCHEDULE NO

3. M A T E R I A L D E S I G N

MECHANICAL

4. M A T E R I A L S P E C I F I C A T I O N

MECHANICAL

2. S P E C I F I C A T I O N D E S I G N

METSO

SA951671-1

REMARKS FOR

INCHARGE

1. D E S C R I P T I O N

VPA HANGING ASSEMBLY

UOM

FORMAT FOR MATERIAL CODIFICATION

d.

MANUFACTURING

PROCESS

e. WORKING PRESSURE

f. WORKING TEMPERATURE

g. OPERATING PRESSURE

h.

OPERATING

TEMPERATURE

i. THREAD TYPE

j. END CONNECTION

k. COATING

l. BODY

m.

CHEMICAL

COMPOSITION

a. APPLICATION

b. MODEL

d. OPERATING METHOD

e. FRAME

f. MOUNTING

g. AS PER STANDARD

NS PAILVAN

BENEFICIATION

1339

9945289392

5. A D D I T I O N A L I N F O R M A T I O N

REQUESTNER NAME

CONTACT DETAIL

LAND LINE NO.

MOBILE NO.

APPROVED by INCHARGE YES

KW

HP

RPM

DUTY CYCLE

VOLTAGE

FREQUENCY

FULL LOAD CURRENT

NO OF POLE

NO OF CORE

MATERIAL OF CONSTRUCTION (MOC)

INSULATION

BREAKING CAPACITY

3. M A T E R I A L D E S I G N

ELECTRICAL

4. M A T E R I A L S P E C I F I C A T I O N

ELECTRICAL

2. S P E C I F I C A T I O N D E S I G N

METSO

SA951671-1

1. D E S C R I P T I O N

SET

FOR MATERIAL CODIFICATION

MATERIAL CONDUCTOR

WORKING PRESSURE

WORKING TEMPERATURE

OPERATING PRESSURE

OPERATING TEMPERATURE

MATERIAL INNER SHEATH

MATERIAL OUTER SHEATH

COATING

BODY

5. A D D I T I O N A L I N F O R M A T I O N

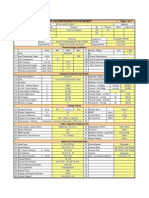

PLANT BENEFICATION

DEPARTMENT MECHANICAL

NUMBER OF

ITEMS 2

INCHARGE AR KRISHNA

a. EQUIPMENT DETAILS

b.

NAME OF

MANUFACTURER (MAKE)

c. TYPE

d. SR NO

e

a. N1 1500 RPM

b. N2 30 RPM

c. POWER 73 KW

d. T2 23.3 Knm

e. PCD

f. NO OF GROOVE

g. ANGLE

h. RADIUS

i. CAPACITY

a.

MATERIAL OF

CONSTRUCTION (MOC)

b. GRADE

c. SCHEDULE NO

REMARKS FOR

INCHARGE

1. D E S C R I P T I O N

GEAR BOX

UOM

2. S P E C I F I C A T I O N D E S I G N

SLURRY TANK AGITATOR

ELECON

PLC-25-U3-3-V-11-50-Z5

711097 HDLS-2727/1

3. M A T E R I A L D E S I G N

MECHANICAL

4. M A T E R I A L S P E C I F I C A T I O N

MECHANICAL

FORMAT FOR MATERIAL CODIFICATION

d.

MANUFACTURING

PROCESS

e. WORKING PRESSURE

f. WORKING TEMPERATURE

g. OPERATING PRESSURE

h.

OPERATING

TEMPERATURE

i. THREAD TYPE

j. END CONNECTION

k. COATING

l. BODY

m.

CHEMICAL

COMPOSITION

a. APPLICATION

b. MODEL

d. OPERATING METHOD

e. FRAME

f. MOUNTING

g. AS PER STANDARD

NS PAILVAN

BENEFICIATION

1339

9945289392

5. A D D I T I O N A L I N F O R M A T I O N

REQUESTNER NAME

CONTACT DETAIL

LAND LINE NO.

MOBILE NO.

APPROVED by INCHARGE YES

KW

HP

RPM

DUTY CYCLE

VOLTAGE

FREQUENCY

FULL LOAD CURRENT

NO OF POLE

NO OF CORE

MATERIAL OF CONSTRUCTION (MOC)

INSULATION

BREAKING CAPACITY

1. D E S C R I P T I O N

NOS

ELECTRICAL

2. S P E C I F I C A T I O N D E S I G N

SLURRY TANK AGITATOR

ELECON

PLC-25-U3-3-V-11-50-Z5

711097 HDLS-2727/1

3. M A T E R I A L D E S I G N

ELECTRICAL

4. M A T E R I A L S P E C I F I C A T I O N

FOR MATERIAL CODIFICATION

MATERIAL CONDUCTOR

WORKING PRESSURE

WORKING TEMPERATURE

OPERATING PRESSURE

OPERATING TEMPERATURE

MATERIAL INNER SHEATH

MATERIAL OUTER SHEATH

COATING

BODY

5. A D D I T I O N A L I N F O R M A T I O N

Você também pode gostar

- GCI Storage Tank Data SheetDocumento4 páginasGCI Storage Tank Data SheetAlvin Smith60% (5)

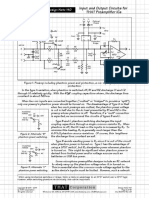

- Measuring High Voltages and Currents (40Documento21 páginasMeasuring High Voltages and Currents (40Syed Z50% (8)

- Esquema Fusiveis ml320Documento5 páginasEsquema Fusiveis ml3202008profAinda não há avaliações

- JSA Fitting and Welding Work For Pipe Trench InstalationDocumento6 páginasJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Insulation Daily Report FormDocumento56 páginasInsulation Daily Report Formjayson_581669935Ainda não há avaliações

- Method of Statement ElectricalDocumento30 páginasMethod of Statement ElectricalNaveed70% (10)

- MTC of Pipe - SSP MakeDocumento4 páginasMTC of Pipe - SSP Makemubeennavaz100% (1)

- 6GR WPS PQRDocumento15 páginas6GR WPS PQRKiukStaks100% (6)

- Datasheet Pompa Submersible Rev.0Documento5 páginasDatasheet Pompa Submersible Rev.0NasrulSyahruddinAinda não há avaliações

- Daily Ispection ReportDocumento4 páginasDaily Ispection Reportrizki4kbarAinda não há avaliações

- Material Inspection Report: Project Name Date InspDocumento22 páginasMaterial Inspection Report: Project Name Date InspRafiqKuAinda não há avaliações

- 8.8-Data Sheet EP-1103 (Ambient Air Vaporizers)Documento1 página8.8-Data Sheet EP-1103 (Ambient Air Vaporizers)Fer VF100% (1)

- WPS INSPECTION FORMATDocumento6 páginasWPS INSPECTION FORMATAkhilesh KumarAinda não há avaliações

- Analysis Report Mahakeret PDFDocumento105 páginasAnalysis Report Mahakeret PDFrocketAinda não há avaliações

- Fuel Oil System Equipment Data Sheet (Filter & Accummulator)Documento6 páginasFuel Oil System Equipment Data Sheet (Filter & Accummulator)epbamdadAinda não há avaliações

- Studies of Plasma Properties in Rocket PlumesDocumento63 páginasStudies of Plasma Properties in Rocket Plumesfkaya13Ainda não há avaliações

- Data Sheet For Dry Chemical Portable Pportable Extinguisher: ProjectDocumento3 páginasData Sheet For Dry Chemical Portable Pportable Extinguisher: ProjectmAinda não há avaliações

- A 139728Documento338 páginasA 139728Wes RamirezAinda não há avaliações

- GeneratorDocumento55 páginasGeneratorVlad Iulian100% (3)

- Client: Medco E & P Lematang Project Title: Singa Gas Development Project Location: Lematang Block, South SumateraDocumento7 páginasClient: Medco E & P Lematang Project Title: Singa Gas Development Project Location: Lematang Block, South SumateraRohmat Benny IsmantoAinda não há avaliações

- Perhitungan Struktur Pondasi Tower PLN Dengan Software AFESDocumento28 páginasPerhitungan Struktur Pondasi Tower PLN Dengan Software AFESardhieAinda não há avaliações

- PQRDocumento2 páginasPQRnaseema1100% (1)

- Project Report: Design of Mould & Press ToolDocumento67 páginasProject Report: Design of Mould & Press ToolBharat SinghAinda não há avaliações

- Iso ManualDocumento3 páginasIso ManualSanjay MalhotraAinda não há avaliações

- FO14-104 Vacuum Deaerator Datasheet - Rev ADocumento3 páginasFO14-104 Vacuum Deaerator Datasheet - Rev AHuzefa Calcuttawala100% (2)

- Design and Analysis of Riser For Sand CastingDocumento16 páginasDesign and Analysis of Riser For Sand Castingrpadhra8803Ainda não há avaliações

- GE-103002, Waste Oil Transfer Pumps, P-102A&BDocumento4 páginasGE-103002, Waste Oil Transfer Pumps, P-102A&BMohammed AnwerAinda não há avaliações

- Injection Molding SimulationDocumento25 páginasInjection Molding SimulationRajesh KumarAinda não há avaliações

- Bhije:. T: Phase - I) Chandwa, JharkhandDocumento4 páginasBhije:. T: Phase - I) Chandwa, Jharkhandsuleman247Ainda não há avaliações

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocumento23 páginas008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanAinda não há avaliações

- Status of Inspection Report &documentation: Job No: Fab. Location: Raslaffan W/S ClientDocumento5 páginasStatus of Inspection Report &documentation: Job No: Fab. Location: Raslaffan W/S ClientSahad VarambankallanAinda não há avaliações

- 8829 SubstationDocumento87 páginas8829 SubstationUttam Kumar Ghosh100% (3)

- GE-103009, Diesel Unloading Pumps, P-201 A, BDocumento4 páginasGE-103009, Diesel Unloading Pumps, P-201 A, BMohammed AnwerAinda não há avaliações

- Bkmishra PDFDocumento33 páginasBkmishra PDFSharad JhaAinda não há avaliações

- WPS - Smaw - 2Documento6 páginasWPS - Smaw - 2Harkesh RajputAinda não há avaliações

- Phase - 2: Engineering Change RequestDocumento6 páginasPhase - 2: Engineering Change RequestwildanputratamaAinda não há avaliações

- Conduit and Instrumentation Fittings LayoutDocumento221 páginasConduit and Instrumentation Fittings LayoutMr.thawatchai100% (1)

- Chimney Pile DesignDocumento140 páginasChimney Pile DesignUttam Kumar GhoshAinda não há avaliações

- Kvaerner Process Api Member Check at Face TG For: 19, Primrose Road, Bangalore - 560 025Documento4 páginasKvaerner Process Api Member Check at Face TG For: 19, Primrose Road, Bangalore - 560 025abdul kareeAinda não há avaliações

- Tank Data Sheet with 52 Design ParametersDocumento1 páginaTank Data Sheet with 52 Design ParametersakhildhameliyaAinda não há avaliações

- Interconnection Pipe Rack Line ListDocumento16 páginasInterconnection Pipe Rack Line ListPhucChuVanAinda não há avaliações

- DC S3-1301 REV.0 OriginalDocumento93 páginasDC S3-1301 REV.0 OriginalPeja JusohAinda não há avaliações

- WPS PQR-02Documento8 páginasWPS PQR-02Ranjan Kumar100% (1)

- Cooling Tower Data Sheet and Drawing ScheduleDocumento8 páginasCooling Tower Data Sheet and Drawing ScheduleakshayAinda não há avaliações

- Type I: - Printed Copies Are UncontrolledDocumento14 páginasType I: - Printed Copies Are UncontrolledALIAinda não há avaliações

- Weld-Free ROV D-Handle: Features FeaturesDocumento2 páginasWeld-Free ROV D-Handle: Features FeaturesCCTV1Ainda não há avaliações

- Cp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Documento1 páginaCp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Triana Rosma Fikriyati DinaAinda não há avaliações

- t64401 Northmainsubspt For PricingDocumento1 páginat64401 Northmainsubspt For Pricingapi-305988893Ainda não há avaliações

- Exploding FireworksDocumento384 páginasExploding FireworksPijush SarkarAinda não há avaliações

- CAS & CRT FoundationsDocumento10 páginasCAS & CRT Foundationsmasarriam1986Ainda não há avaliações

- Sae Ams 2417e PDFDocumento8 páginasSae Ams 2417e PDFunknown17110% (1)

- Line ListDocumento1 páginaLine ListChirag ShahAinda não há avaliações

- API STD 676-2009 - Hoja de RequisiciónDocumento28 páginasAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroAinda não há avaliações

- TCE Consulting Engineers Process Data Sheet for Ammonia Storage and Compression VesselsDocumento59 páginasTCE Consulting Engineers Process Data Sheet for Ammonia Storage and Compression Vesselsrotatic_engineerAinda não há avaliações

- Training Format - Diploma in MiningDocumento15 páginasTraining Format - Diploma in MiningTEN TV100% (1)

- DRILL JIG (Final One)Documento21 páginasDRILL JIG (Final One)Varshasonawane962Ainda não há avaliações

- Cse I Year Lab ManualDocumento80 páginasCse I Year Lab ManualNIRMAL KAinda não há avaliações

- Kertas Kerja: Program'S Code & NameDocumento5 páginasKertas Kerja: Program'S Code & NameHadi azfar channelAinda não há avaliações

- TestReport en FormDocumento7 páginasTestReport en FormKyeong Cheol LeeAinda não há avaliações

- Environmental Testing Techniques for Electronics and Materials: International Series of Monographs on Electronics and InstrumentationNo EverandEnvironmental Testing Techniques for Electronics and Materials: International Series of Monographs on Electronics and InstrumentationAinda não há avaliações

- Electronic Connection Techniques and Equipment 1968-69: Pergamon Electronics Data SeriesNo EverandElectronic Connection Techniques and Equipment 1968-69: Pergamon Electronics Data SeriesAinda não há avaliações

- Bac HD 230 Holiday Detector: FeaturesDocumento1 páginaBac HD 230 Holiday Detector: FeaturesAhmed MagdiAinda não há avaliações

- Question Bank Ac MachinesDocumento4 páginasQuestion Bank Ac Machinesashwin paulAinda não há avaliações

- TPS548A29 2.7-V To 16-V Input, 15-A Synchronous Buck Converter With Remote Sense, 4.5-V Internal LDO and Hiccup Current LimitDocumento50 páginasTPS548A29 2.7-V To 16-V Input, 15-A Synchronous Buck Converter With Remote Sense, 4.5-V Internal LDO and Hiccup Current LimitAlbert NguyenAinda não há avaliações

- L297/L298 Chopper Drive Printed Circuit Board: Robotic and Microcontrollers ProductsDocumento6 páginasL297/L298 Chopper Drive Printed Circuit Board: Robotic and Microcontrollers ProductsmarylizethAinda não há avaliações

- RSN311W64B PDocumento1 páginaRSN311W64B Pmiguel angel jaramilloAinda não há avaliações

- 5B3 Fact Sheet (New) PDFDocumento4 páginas5B3 Fact Sheet (New) PDFDave ChaudhuryAinda não há avaliações

- Multi Pulse ConverterDocumento5 páginasMulti Pulse ConverterVishal ParekhAinda não há avaliações

- RFIA Push Button CatalogueDocumento89 páginasRFIA Push Button CatalogueBio Eng Eslam TahaAinda não há avaliações

- Saudi Electricity Company: Eastern Operating Area Dammam, Saudi ArabiaDocumento26 páginasSaudi Electricity Company: Eastern Operating Area Dammam, Saudi Arabiasrigirisetty208Ainda não há avaliações

- Transformer Design FormulasDocumento8 páginasTransformer Design FormulasJavierAinda não há avaliações

- TractorDocumento4 páginasTractorVanita BariayaAinda não há avaliações

- Características Cable DCDocumento2 páginasCaracterísticas Cable DCpablo luis andreattaAinda não há avaliações

- PLA M Series RelaysDocumento2 páginasPLA M Series RelaysYogesh DetheAinda não há avaliações

- Group 4 Connectors: 1. Connector DestinationDocumento23 páginasGroup 4 Connectors: 1. Connector DestinationDavid SolisAinda não há avaliações

- Recent Trends in Ultra Large-Capacity Three-Phase Transformer TechnologyDocumento15 páginasRecent Trends in Ultra Large-Capacity Three-Phase Transformer Technologyvenky123456789Ainda não há avaliações

- FormulaDocumento4 páginasFormulamargaret_navaeiAinda não há avaliações

- SIRCOVERDocumento12 páginasSIRCOVERsaumya DuttaAinda não há avaliações

- High-Power IGBT Modules For Industrial UseDocumento5 páginasHigh-Power IGBT Modules For Industrial UseOmar AlhakimiAinda não há avaliações

- Physics Project On "Transformers"Documento17 páginasPhysics Project On "Transformers"Jaÿ Üx100% (1)

- Talyvel SchematicDocumento1 páginaTalyvel SchematicChuck NorrisAinda não há avaliações

- ABB Surge Arrester POLIM-D PI Outdoor - Data Sheet 1HC0093993 E01 AADocumento4 páginasABB Surge Arrester POLIM-D PI Outdoor - Data Sheet 1HC0093993 E01 AAHan HuangAinda não há avaliações

- That - DN140 (Verschoben) 2Documento1 páginaThat - DN140 (Verschoben) 2sdtrnkAinda não há avaliações

- OLTC DM Box wiring schematicsDocumento9 páginasOLTC DM Box wiring schematicsADE MRTAinda não há avaliações

- Potential transformers and other switchboard devices protectionDocumento4 páginasPotential transformers and other switchboard devices protectionJoel JusayAinda não há avaliações

- Oraye - ELX201 - Lab 1 Diode IV Curve PDFDocumento4 páginasOraye - ELX201 - Lab 1 Diode IV Curve PDFXheluj Sheluj ZhelujAinda não há avaliações

- 3-Phase IMDocumento16 páginas3-Phase IMk rajendraAinda não há avaliações