Escolar Documentos

Profissional Documentos

Cultura Documentos

BTS Commissioning For Ericsson

Enviado por

Mavura Michael Mgaya0%(1)0% acharam este documento útil (1 voto)

5K visualizações7 páginasBTS COMMISIONING FOR ERICSSON Firstly open OMT software : Click on CONFIGURATION a. Open IDB b. Create IDB (we can create new IDB) then click on CREATE IDB I. Cabinet SETUP ii. Antenna SECTOR iii. Configuration TYPE. After doing all given above then Connect OMT: Right click on RBS 2000 block in the given Block Diagram Change LOCAL / REMOTE status

Descrição original:

Título original

BTS Commissioning for Ericsson

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoBTS COMMISIONING FOR ERICSSON Firstly open OMT software : Click on CONFIGURATION a. Open IDB b. Create IDB (we can create new IDB) then click on CREATE IDB I. Cabinet SETUP ii. Antenna SECTOR iii. Configuration TYPE. After doing all given above then Connect OMT: Right click on RBS 2000 block in the given Block Diagram Change LOCAL / REMOTE status

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0%(1)0% acharam este documento útil (1 voto)

5K visualizações7 páginasBTS Commissioning For Ericsson

Enviado por

Mavura Michael MgayaBTS COMMISIONING FOR ERICSSON Firstly open OMT software : Click on CONFIGURATION a. Open IDB b. Create IDB (we can create new IDB) then click on CREATE IDB I. Cabinet SETUP ii. Antenna SECTOR iii. Configuration TYPE. After doing all given above then Connect OMT: Right click on RBS 2000 block in the given Block Diagram Change LOCAL / REMOTE status

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 7

BTS COMMISIONING FOR ERICSSON

Firstly open OMT software :

Click on CONFIGURATION

a. Open IDB (we can open any saved IDB)

b. Create IDB (we can create new IDB)

c. Save IDB (we can save IDB of any site)

Then click on CREATE IDB

i. Cabinet Setup

ii. Antenna Sector

iii. Configuration type

Then click on CABINET SETUP

1. cabinet type (2204, 2106i etc.)

2. power system ( BTS i/p voltage)

3. climate (this option is internally selected)

Then click on ANTENNA SECTOR

i. CDU type (G,J)

ii. Frequency band (1800, 900)

iii. TMA (yes/no)

iv. Rx Diversity (TRU in uncombiner, DTRU hybrid combiner)

{ Note: We have to configure 3 antenna sector separately}

Then click on CONFIGURATION TYPE

3+3+4, 1+1+1, 3x4 (max. selection for each sector)

After doing all given above then Connect OMT:

Right click on RBS 2000 block in the given Block Diagram

Change LOCAL/REMOTE status (for installing IDB we will put the DXU in

LOCAL

state)

Then click on INSTALL IDB (by doing this the IDB will get installed)

After all this again right click on RBS 2000 block

Change LOCAL/REMOTE status (again we will put the DXU in REMOTE state)

AFTER THIS ALL THE IDB WILL BE INSTALLED

Note: Remember to save the I DB

After creating IDB we will define alarm by right clicking on ALARM INLETS

Then click on DEFINE ALARMS

After defining alarms click on PCM for cascading site

Define the TIE value (62 for main site, 61 for 1

st

cascading, 60 for 2nd cascading)

ALWAYS REMEMBER:

1. LED always glow in Tx

2. Tx is always connected with Rx

Technician

Classroom & Lab

Training Content

Outline

Basic of Communications a)Roles and Verticals in Telecommunications

b)Evolution of communication & GSM Bands

c)GSM Network Architecture

d)WCDMA Network Architecture

General

a)Identification of site with indoor and outdoor snaps

b)Identification of Tools for installation

c)Material receiving at site

d)EMR survey

e)RFI survey

f)Feasibility Survey

Occupational Health & Safety

a)Proper Uses of PPE (Safety belt, safety shoes, gloves, lanyard, helmet, adequate safety dress)

b)Working on height and towers

C)Electrical safety

d)Safety Signs and Symbols

e)Electrostatic discharge and its preventions

f)Lightening Energy safety

g)Working with batteries

h)Laser light safety

i)Fire Safety and classes of fire

j)RF Safety and its preventions

k)Lifting of equipments

l)Importance of grounding systems for individual and equipments

Safety procedure at work location(BTS, BSC, MSC)

a)Safety for working at heights

b)Safety during Installation, Power taping, commissioning and Integration of BTS at sites

c)Safety during MW link installation, alignment, traffic shifting, changeovers, Night activities

d)Safety during working with Batteries, copper strips, ventilation plugs, torque value, terminals,

shifting and Upgradation of battery bank

e)Safety Working at SMPS, DCDB +ve bar, -ve bar, grounding, critical load, Non critical load,

External alarms SMPS to BTS, MCB rating, recommended MCB for BTS & TRSM

Installation

a) BTS & Node B

a)Opening of cabinet from box/identification of BTS cards/ Cross check with Material Requisition

Note checklist

b)Installation of cabinet

c)Grounding of cabinet

d)Installation of cards and distribution of power

e)Power taping of BTS from SMPS with specified torque values

f)Internal cabling between Duplexer and TRX cards of BTS

g) Installation and routing of feeder jumpers with proper labelling from BTS to feeder cable

h) Installation of signal cables

i) BTS configurations(RBS 2204, 2206, 2202, 2111, 2954, 2964, 6601, 6201, 6202 etc

Installation of cabinet base frame

Installation of cabinet on base frame and fix it with specified torque values

Grounding and power taping of BTS

Installation of jumpers, E1 cables, External alarms cables, ESB cables, power cables, according

to plans

j)Information of IDB and commissioning procedure of above different BTS

Laptop requirements of Installing IDB in different RBS, Software version, login cable pin

configuration, serial port configuration, flash card updating files, create IDB, upload IDB, change

IDB, physical check of IDB

Define External alarms in IDB and cross check to NOC

Define TEI values in RBS

Define cell IDs, change local/remote state of RBS, define identification of RBS, Define GPS

Parameters, cross check IDB, Define Transmission parameters, cascading Standalone, Defined

ESB delay values, define present RUs, Define TF handover modes, define external alarms

Soft and hard Loop break check of E1 at RBS end. TRSM end. Near end Far End upto BSC

b) GSM Antenna and Feeder Cable

a)Opening of GSM antenna box and Install antenna according to Plan ( High Gain and Low Gain

values)

b)Assembling of GSM antenna mounting kit

c) Installation of GSM antenna up the tower and fix on Mount pole at proper height as per TND

Plan

d)Set the (angle) orientation, Electrical and mechanical tilt according to the plan

e)Routing and connecting of feeder jumper at antenna port on tower with proper torque value

f)Weather proofing at all outdoor connections at antenna port, jumper, Earthings

g)Assembling and installation of feeder clamps with exact preferred distance

H)Unwind the feeder cable from Drum to role, cut the length as per requirement and make the

feeder connectors

i)Installation of feeder cable up the tower and connect with jumper to GSM antenna port

j)Proper Routing, bending radius and pulling inside the shelter and feeder earthing of feeder cable

k)Installation of roxtec boots and glands with specified holes for feeder, IF, earthing cables

l)Weather proofing and labelling of GSM and MW antennas.

c) Transmission

a)Unpacking of MW antenna

b)Assembling of MW antenna, As per TND plan, Polarization, height, Degree, accessible

c)Installation of MW antenna up to the tower, fix on tower and set the orientation

d)Assembling and installation of IF Clamps

e)Fix the IF cable, cut the IF cable as per, requirement and make the IF connector

f)Pulling of IF cable and connect at IDU & ODU with IF connectors and jumpers

g)Routing, bending, pulling inside the shelter and IF earthing of IF cable

h)Assembling, installation and power to IDU from SMPS

i)Alignment of MW antenna

j)Weather proofing and labelling of MW antenna

k)Installation and configuration of different TX nodes i.e. MLTN, ML-E etc

Installation of ML-E AMM 1U, 2U, 4U, MLTN 1P, 2P, 6P, 20P

Inserting the card in different TX nodes according to TND plan and perform soft and hard

connection to add drop and forward E1 signals

configuration of MLE & MLTN TX nodes with different nodes as per plan and install MW links ,

Commission and Integrate the RBS with TX nodes

l)Software and Version Upgradation of MLTN, MLE etc

Identification of TX Nodes present software version and procedure to upgrade it

Identification of different MMU and RADIO like N, X, P, RAU1, RAU2 series and its comp ability

and capacity with the existing TX nodes

m)Identification of PDH & SDH transmission equipments and its installation, commissioning,

Integration, Testing and Troubleshooting

n)E1 patching at DDF and perform loop break check at NOC and rectification of faults ASAP

o) Understanding the Internal and External alarms of equipments and reasons of faults.

d) Connectorization

a)RF Feeder cable connectors ( DIN, N Type)

b)TNC IF connector ( RG 213, 214, RG 223)

c)RJ 45 connector as per Pin configuration ( Straight, cross, Login cables etc)

c)BNC connector

d)SMZ connector

e)25 pin connector (D type)

f)9 pin connector (D type)

g)TQ Connectors

h)BQ connectors

i)Power connectors for transmission equipments

j)Cable lugs and thimble for proper termination of power and grounding cables

k)Soldering and Desoldering of the connectors

e) Earthing System at Telecom sites

a)Feeder earthing

b)IF earthing

c)Equipments earthing

d)Measuring Earthing Values

Measurement of earthing values with earthing testing kit

e)Types of earthing systems at telecom sites

Pit earthing system and its procedure

Plate earthing system and its procedure

Bore earthing system and its procedure

Earthing system and its importance at telecom sites

f)Connectivity of all metallic parts and equipments with earthing pits according to grounding

standards

g)Role of Lightening Arrester and surge arrester at Mobile telecom sites

Operations, Maintenance & Troubleshooting Practices

a)Basics of Operation and Maintenance for 2G, 2.5G and 3G Sites BTS, Node B, Mini Link-E,

Mini Link Traffic Node

Night activity, CR Plan, outage activity, changeover, handover procedures, different type of nodes

and its software match and mismatch

b) Replacing IDU/ODU, Software Upgrade etc.

c)Alarm classification, Concepts of Internal and External Alarms

Mains fail, rectifier fail, low battery, DG fails to start, DG fails to stop, LLOP, LFL, aircon failure,

site down due to high room temperature, equipment operational temperature ranges, equipment

sensitivity

d)Infrastructure requirements, power system upgrade, capacity, per site power consumption,

MCB rating, space for equipments etc.

e)Maintenance of Active Infra (DG, PIU, SMPS, BB etc.)

Installation , configuration, automation, rating per site, power consumption and maintenance of

DG

Installation , configuration, Line Conditioner Units, Surge arrestor, Upgradation, automation,

rating per site, power consumption and maintenance of PIU

Installation , configuration, a capacity of rectifier modules, automation, rating per site, power

consumption and maintenance of SMPS

Installation , configuration, rating per site, power consumption and maintenance of Battery bank

f)Maintenance of Passive Infra (Earthing Checks, Cable Routing, Weather Proofing, Tower,

Mount Poles, Shelter, Racks etc.)

Visual checks

Dimension and specification of shelter in equipments need to install and maintain

g)Material Handling and Spares (ODU/IDU/GSM Antenna Cards etc.)

Night activity, CR Plan, outage activity, changeover, handover procedures, different type of nodes

and its software match and mismatch

Identification of different MMU and RADIO like N, X, P, RAU1, RAU2 series and its comp ability

and capacity with the existing TX nodes

h)Outage Related activities and team handling/ WFM

Preplanning and team management procedures

Troubleshooting and outage activities

i)NOC Reporting and Escalation Procedure for Indus and Non-Indus Faults.

Procedure for down call of cell site, responsibility area during outage, Infra related, Power related,

Media related, Transmission related, RF related etc

j)Protection check for Mini Link 1+1, 1+1 configuration, IF Loops, RF Loops, ET reset, KLM, E1

cascading, E1 forwarding, E1 Dumping etc

Hands on experience above technical expertise

Software and hardware activities

Testing Equipments

a)Site Master

b)Power meter

c)BER Meter

d)Megger

e)Clamp Meter

f)GPS

h)Multimeter

Quality

a)Defining Quality Standards

b)Quality for Installation, Connectorization, cabling, labelling

c)Quality for Cable Routing, Grouting, fixing of cabinets, canopy Racks, BTS continuity concepts

d) Quality for Earthing Cables, Ext Alarms cables its colour code, assembling lugs & thimble

termination and connectivity of earthing systems

e)Quality during Installation of BTS, GSM & MW Antenna Labelling, weatherproofing, clamping,

hanging, uses of rope/pulley etc

f)Quality of following plans for Commissioning, Integration and Testing

g)Understanding Acceptance Test procedure and punch point removal as per customer

requirements

h)Demo sites for Indoor/Outdoor 2G & 3 G BTS for reference and best quality work for Telecom

circle

i)Demo sites for MLE, MLTN other transmission equipments and its connectivity with network

j)Identification and rectification of faults at equipment end , BSC end Media end.

k)Labelling & Identification of Site with different IDs, ISP ID, BCF ID , SAM ID, SAP ID, IP ID,

INDUS ID, cell ID etc

l)Rectification of Punch points according to its severity level (critical, major, minor)

Power Systems

a)DG

Rating, cabling, battery charger, capacity, no of sites, load on DG, Specifications

DG automation, changeovers, delay values, self starting, manual starting

DG fuel filling, power outcomes, installation, maintenance, testing

b)PIU

Static Line conditioner unit

Battery management system

Auto Mains Failure

Delays

AC distribution systems and controls

LED status and troubleshooting

c)Battery Bank

Concept of series and parallel battery bank

Rating and capacity of cells in battery bank and its connection in power plant

Installation and maintenance procedure in battery bank system

d)SMPS

Rectifiers and its functions

LVD and its roles

Critical and Non Critical loads

Rating of cables and MCBs

e)DCDB and ACDB

f)EB Meter and AMF Panel and its automation

g) Importance of earthing systems in power systems

i)Power requirement of single BTS site, MCB rating , Needs of power system Upgradation,

capacity of DG, PIU, BB

j)Size of power cable between DG-PIU-SPMS-ACDB-DCDB-AC-LA-BTS-TRSM with specified

rating of MCB

k)Understanding the circuits of AC and DC current, cabling and terminals.

Guidelines and Precautions

a- General Precautions

a)Do not Switch Off any MCB without tracing while removing any equipment.

b)Do not remove MW Antenna without tracing and without informing O&M Engineer.

c)Do not Stand on feeder or IF cable while working

d)Do not enter site without permission from technician /Supervisor.

e)Do not work without safety Eqpt. (PPE) above 3 mtr Height.

f) Do not swap feeder cable Jumpers during connection.

g)Do not leave modules loose while inserting cards in BTS and Node B

i)Do not leave any tool at site.

j)Do not make site dirty.

k)Do not connect Power connections without proper approval from Electrical Supervisor or

Technician

l)Do not step on any eqpt.

m)Do not disturb other operator BTS, DDF, GSM, MW, Antenna lines, all cables and connection

without permission

b-General Guidelines

a)Cable must routed straight as per guidelines provided by customer

b)Proper IF cable routing of MW HOP

c)DDF cable Routing Property for E1 Termination and External alarms

d)Earthing cables routing properly

e) Rear view of MW Hop, Labelling and marking properly

f)RF & IF Jumper labelling

g)RF & IF cable earthing, cable routing procedure

h)BTS & Node-B Earth cable routing and its Torque value

i)Installation of Antennas, Antenna line, waveguides, couplers, TMA, according to specification at

site

j)Shelter Clean and SRN reports

k)Weatherproofing (Tape putty) standards and its implementations

l)Cable Lugs and Thimble assemble and its proper termination

m)Installation of Cable Ties for different type of IF, PCM, E1, alarm, tributary cables

n)Installation of Surge Arresters (EMP) and its specifications

c- Specific Precautions and Guidelines

a)Precautions and Procedures for Planned Activities

Team plan of action must well defined for activities and team should carry all hardware and

software, tools, cables that wil used in activities

Before starting the planned activity one should take permission and conformation on it before

work with live BTS, MW, RF part of the sites

Perform the activity in a time window that is provided by OEM if activity not completed revert on

previous settings

b)Precautions for BTS and Link Installation

Install BTS & MW at specified space provided by infra provider

Do not disturb existing BTS and MW equipments

After cross check of proper power, proper alignment, stability of MW Shift traffic and unlock the

TRX from BSC end

c)Precautions for PIU,SMPS,BB,DG maintenance

Details provided above in power system

d)Precautions for Night Activity and outage activities

Details provided above

Você também pode gostar

- Mobile Terminal Receiver Design: LTE and LTE-AdvancedNo EverandMobile Terminal Receiver Design: LTE and LTE-AdvancedAinda não há avaliações

- Abis Over TDM To Abis IP Over E1Documento14 páginasAbis Over TDM To Abis IP Over E1Sibusiso V Mkhize100% (6)

- Ericsson RBS Commissioning GuideDocumento16 páginasEricsson RBS Commissioning Guidesergiu_bazarciuc100% (5)

- Ericsson Alarm AnaysisDocumento16 páginasEricsson Alarm AnaysisAjay WaliaAinda não há avaliações

- Ericsson Bts Installation and Commissioning PDFDocumento2 páginasEricsson Bts Installation and Commissioning PDFMandi80% (5)

- LTE eNodeB V2 1 CommissioningDocumento26 páginasLTE eNodeB V2 1 CommissioningFerry KurniawanAinda não há avaliações

- Ericsson Bts 2964 PDFDocumento2 páginasEricsson Bts 2964 PDFRay75% (4)

- 2 INTRO 2G RBS6201 Maintenance ResizedDocumento56 páginas2 INTRO 2G RBS6201 Maintenance ResizedBryce100% (1)

- Ericsson - WCDMADocumento9 páginasEricsson - WCDMABassem AbouamerAinda não há avaliações

- Ericsson RAN OAMDocumento210 páginasEricsson RAN OAMMilanjyoti Phatowali100% (2)

- Ericsson RBS 6000 Sync AlarmDocumento4 páginasEricsson RBS 6000 Sync AlarmMinto Issac100% (1)

- BTS Interview Question & ANSwerDocumento11 páginasBTS Interview Question & ANSwerrohitsingh100% (1)

- Ericsson 2G Cell HandlingDocumento34 páginasEricsson 2G Cell Handlingseba100% (1)

- IPasolink OM Training (Ethernet Functions)Documento84 páginasIPasolink OM Training (Ethernet Functions)2012nearAinda não há avaliações

- DUW CommissioningDocumento31 páginasDUW CommissioningOva Døse100% (1)

- Baseband VS DUSDocumento58 páginasBaseband VS DUSawaisahmAinda não há avaliações

- Ericsson RBS 6202 900 - 1800MHZDocumento2 páginasEricsson RBS 6202 900 - 1800MHZAbdelkader Bendjedid100% (1)

- RBS 6000 Spec SheetDocumento6 páginasRBS 6000 Spec SheetRick Brown0% (1)

- Ericsson W-Cdma Bbu/rru SystemDocumento2 páginasEricsson W-Cdma Bbu/rru SystemAbdeladhim Stich67% (3)

- RX Diversity Lost PDFDocumento2 páginasRX Diversity Lost PDFza1osx100% (1)

- OSS LTE CommandsDocumento90 páginasOSS LTE CommandsDmitriy IgnatovAinda não há avaliações

- RNC 3820 Alarm DescriptionDocumento37 páginasRNC 3820 Alarm DescriptionNandha Gopal0% (1)

- LTE Site Troubleshooting GuideDocumento43 páginasLTE Site Troubleshooting GuideAbdou Dabado Obado93% (15)

- Ericsson Node B Integration PDFDocumento2 páginasEricsson Node B Integration PDFChristopher100% (1)

- 3G Node B Alarm Troubleshooting NSN PDFDocumento6 páginas3G Node B Alarm Troubleshooting NSN PDFyunandaAinda não há avaliações

- Huawei DBS3900 Commissioning MOP - V1 - 2 20090515Documento30 páginasHuawei DBS3900 Commissioning MOP - V1 - 2 20090515yetunde77100% (5)

- Ericsson CommandsDocumento2 páginasEricsson Commandssunny kumarAinda não há avaliações

- BSC EvoC 8230Documento7 páginasBSC EvoC 8230nhan sieuAinda não há avaliações

- How To Install Moshell: 2.3 Installation For Unix (Solaris/Linux)Documento4 páginasHow To Install Moshell: 2.3 Installation For Unix (Solaris/Linux)Pratheesh PrasannanAinda não há avaliações

- Introduction To Gen2 (BB5216)Documento34 páginasIntroduction To Gen2 (BB5216)anon_29276483880% (5)

- Ericsson RBS SeriesDocumento2 páginasEricsson RBS SeriesJonattan Da SilvaAinda não há avaliações

- MOSHELL Commands v14Documento91 páginasMOSHELL Commands v14AshishChadha100% (1)

- Ericsson CommandsDocumento8 páginasEricsson CommandsmahadoAinda não há avaliações

- RET Troubleshooting Guide 2Documento82 páginasRET Troubleshooting Guide 2Sieh WeezeAinda não há avaliações

- Introduction To Moshell Useful Commands and TasksDocumento11 páginasIntroduction To Moshell Useful Commands and TasksPrabhat Kumar Singh100% (9)

- HW&Frequent Alarm: Ericsson EquipmentDocumento51 páginasHW&Frequent Alarm: Ericsson EquipmentAlf Nanfade NanfadeAinda não há avaliações

- Ericsson OSS CommandsDocumento7 páginasEricsson OSS CommandsMouslem Bouchamekh100% (4)

- Backhauling / Fronthauling for Future Wireless SystemsNo EverandBackhauling / Fronthauling for Future Wireless SystemsKazi Mohammed Saidul HuqAinda não há avaliações

- LTE Signaling: Troubleshooting and OptimizationNo EverandLTE Signaling: Troubleshooting and OptimizationNota: 3.5 de 5 estrelas3.5/5 (2)

- Cross-Layer Resource Allocation in Wireless Communications: Techniques and Models from PHY and MAC Layer InteractionNo EverandCross-Layer Resource Allocation in Wireless Communications: Techniques and Models from PHY and MAC Layer InteractionAinda não há avaliações

- VoLTE and ViLTE: Voice and Conversational Video Services over the 4G Mobile NetworkNo EverandVoLTE and ViLTE: Voice and Conversational Video Services over the 4G Mobile NetworkAinda não há avaliações

- BTS Commissioning For EricssonDocumento2 páginasBTS Commissioning For EricssonSachin Saxena83% (6)

- Idirect - 7000 QuickstartDocumento2 páginasIdirect - 7000 QuickstartHerig GutierrezAinda não há avaliações

- BTS Commissioning For EricssonDocumento1 páginaBTS Commissioning For EricssonMantoo KumarAinda não há avaliações

- Microwave Installation and CommisioningDocumento54 páginasMicrowave Installation and CommisioningAli SharafAinda não há avaliações

- Site Standardization - Region Name - Site CodeDocumento53 páginasSite Standardization - Region Name - Site CodeRokan ZamanAinda não há avaliações

- Quick Start Guide: RS-485 Analog I/O Remote ModuleDocumento2 páginasQuick Start Guide: RS-485 Analog I/O Remote ModuleWall_uaAinda não há avaliações

- SDR Commissioning ZteDocumento44 páginasSDR Commissioning ZteOmer Jarral75% (4)

- Quality ChecklistDocumento9 páginasQuality ChecklistShah FahadAinda não há avaliações

- Modified ReportDocumento95 páginasModified ReportPriyankaAinda não há avaliações

- cMT-G03 Datasheet ENG PDFDocumento2 páginascMT-G03 Datasheet ENG PDFAshutosh Vivek ParabAinda não há avaliações

- Huawei RNC Site Maintenance Guide...Documento13 páginasHuawei RNC Site Maintenance Guide...Zaheer Ahmed TanoliAinda não há avaliações

- So What's An Intranet: Introduction To IntranetsDocumento5 páginasSo What's An Intranet: Introduction To IntranetsMavura Michael MgayaAinda não há avaliações

- ComputerArchitecture Chapter1 Introduction ColorDocumento94 páginasComputerArchitecture Chapter1 Introduction ColorProsenjit ChatterjeeAinda não há avaliações

- Intranet PDFDocumento17 páginasIntranet PDFMavura Michael MgayaAinda não há avaliações

- RBS 6601Documento15 páginasRBS 6601Mavura Michael MgayaAinda não há avaliações

- BTS Commissioning For EricssonDocumento7 páginasBTS Commissioning For EricssonMavura Michael Mgaya0% (1)

- NEC Corporation: Easily Installed and Configured ! Integrated Network Management SystemDocumento16 páginasNEC Corporation: Easily Installed and Configured ! Integrated Network Management SystemMavura Michael MgayaAinda não há avaliações

- Andrew CatalogDocumento145 páginasAndrew Catalogdutta.somnathAinda não há avaliações

- It's True That It's Got Some Advantages. It's Selfcontained, To Start With, and There's Quite A Bit ofDocumento2 páginasIt's True That It's Got Some Advantages. It's Selfcontained, To Start With, and There's Quite A Bit ofMavura Michael MgayaAinda não há avaliações

- Operation & MaintenanceDocumento1 páginaOperation & MaintenanceMavura Michael MgayaAinda não há avaliações

- Green Line TransformerDocumento4 páginasGreen Line TransformerwakasAinda não há avaliações

- Reading Material CH 14 Other Artificial Lift MethodsDocumento18 páginasReading Material CH 14 Other Artificial Lift MethodsSagar DadhichAinda não há avaliações

- Fm-II Quiz 1 19-20 - Section1 - Set1Documento2 páginasFm-II Quiz 1 19-20 - Section1 - Set1nivedithashetty0123Ainda não há avaliações

- Connection DiagramsDocumento3 páginasConnection Diagramsfahad pirzadaAinda não há avaliações

- Seminar Report ON "Linux"Documento17 páginasSeminar Report ON "Linux"Ayush BhatAinda não há avaliações

- Quarter-Wave Impedance TransformerDocumento4 páginasQuarter-Wave Impedance TransformerEric SkinnerAinda não há avaliações

- Economics BasisDocumento14 páginasEconomics BasiskumarAinda não há avaliações

- Simple and Compound Gear TrainDocumento2 páginasSimple and Compound Gear TrainHendri Yoga SaputraAinda não há avaliações

- E Insurance ProjectDocumento10 páginasE Insurance ProjectChukwuebuka Oluwajuwon GodswillAinda não há avaliações

- Error Number Mentor GraphicsDocumento30 páginasError Number Mentor GraphicsMendesAinda não há avaliações

- As4e-Ide-2 7 0 851-ReadmeDocumento10 páginasAs4e-Ide-2 7 0 851-ReadmeManoj SharmaAinda não há avaliações

- Alloc 150 DMDocumento301 páginasAlloc 150 DMSheik Mohamed ImranAinda não há avaliações

- Lifting Plan For CranesDocumento9 páginasLifting Plan For CranesBibin JohnAinda não há avaliações

- CPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFDocumento51 páginasCPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFMar SolAinda não há avaliações

- VarPlus Can - BLRCH104A125B48Documento2 páginasVarPlus Can - BLRCH104A125B48Achira DasanayakeAinda não há avaliações

- MMD 74 XX DR PS 0020 - C03Documento1 páginaMMD 74 XX DR PS 0020 - C03bramexAinda não há avaliações

- Jun SMSDocumento43 páginasJun SMSgallardo0121Ainda não há avaliações

- Notes Mechanism of Methanol Synthesis From Carbon Monoxide and Hydrogen On Copper CatalystsDocumento4 páginasNotes Mechanism of Methanol Synthesis From Carbon Monoxide and Hydrogen On Copper CatalystsArif HidayatAinda não há avaliações

- CS 303e, Assignment #10: Practice Reading and Fixing Code Due: Sunday, April 14, 2019 Points: 20Documento2 páginasCS 303e, Assignment #10: Practice Reading and Fixing Code Due: Sunday, April 14, 2019 Points: 20Anonymous pZ2FXUycAinda não há avaliações

- An Analysis of The Ejector-Ram-Rocket EngineDocumento9 páginasAn Analysis of The Ejector-Ram-Rocket Enginefundamental_aeroAinda não há avaliações

- Inspection and Quality Control in Production ManagementDocumento4 páginasInspection and Quality Control in Production ManagementSameer KhanAinda não há avaliações

- Limak 2017 Annual ReportDocumento122 páginasLimak 2017 Annual Reportorcun_ertAinda não há avaliações

- Centrala Termica Pe Lemn Si Carbune Rima SF Manual Tehnic LB EnglezaDocumento26 páginasCentrala Termica Pe Lemn Si Carbune Rima SF Manual Tehnic LB EnglezaDobrin PaulAinda não há avaliações

- Black Invention MythsDocumento16 páginasBlack Invention MythsjoetylorAinda não há avaliações

- Jrules Installation onWEBSPHEREDocumento196 páginasJrules Installation onWEBSPHEREjagr123Ainda não há avaliações

- Steering Gear TestingDocumento9 páginasSteering Gear TestingArun GK100% (1)

- Operate A Personal Computer PDFDocumento56 páginasOperate A Personal Computer PDFBirhanu Girmay100% (8)

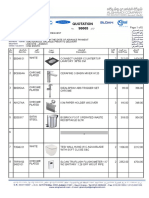

- Quotation 98665Documento5 páginasQuotation 98665Reda IsmailAinda não há avaliações

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDocumento4 páginasMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoAinda não há avaliações

- Activation and Deactivation of CatalystsDocumento16 páginasActivation and Deactivation of Catalystsshan0214Ainda não há avaliações