Escolar Documentos

Profissional Documentos

Cultura Documentos

2800 Electronic, Mech Jan07

Enviado por

ijosephsuresh95%(20)95% acharam este documento útil (20 votos)

3K visualizações150 páginasELECTRONIC ENGINE

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PPT, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoELECTRONIC ENGINE

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

95%(20)95% acharam este documento útil (20 votos)

3K visualizações150 páginas2800 Electronic, Mech Jan07

Enviado por

ijosephsureshELECTRONIC ENGINE

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PPT, PDF, TXT ou leia online no Scribd

Você está na página 1de 150

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Perkins 23/25/2800 Series

Diesel Engine Training

Perkins Product Training

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Domestics

Fire Exits

Breaks

Lunch

Toilets

Smoking

Mobile Phones

Health & Safety

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Please Note

The product training information is distributed for

informational purposes only. It is not to be construed as

creating or becoming part of Perkins Engines contractual

or warranty obligations

The appropriate service literature, including Service

Bulletins now available on the www.perkins.com

Secured Website, should always be the final authority

and source of information

Wiring Diagrams/Electrical Drawings, wire numbers and

connection points may change.

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Course Objectives

At the end of the course the delegates will be able to

Show technicians strip down techniques and the use of

special tools

EST(Electronic Service Tool) and fault diagnosis

procedures specific to 23/25/2800

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Worldwide Off Road Legislation Today

Environmental Protection Agency / European Union

Regional Legislation

No Legislation Requirements

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Off Road Emissions Legislation

Tier 0

"A" rated engines can be used in regions

without Emissions Legislation.

Tier 1

"B" rated engines are suitable for regions

with Tier 1/Stage I Emissions Legislation

Tier 2

"C" rated engines are suitable for regions

with Tier 2/Stage II Emissions Legislation.

Tier 3

"D" rated engines are suitable for regions

with Tier 3/Stage III Emissions Legislation.

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Off Road Industrial - Ever Cleaner Engines

0

0 1

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

2 3 4 5 6

Tier 3: 56kW<75

Tier 3: 75kW<130

Tier 3: 130kW<560

Tier 4A: 56kW<130

Tier 4A: 130kW<560

Tier 4B: 56kW<560

NO

x

; NO

x

+ HC (g/kWh)

PM

(g/kWh)

1980s

Particulate Matter

(PM) 0.6g/kWh

Oxides of

Nitrogen

(NOx) 10.00g/kWh

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Electronic Engine Benefits

Electronic Engine Management system gives:

Improved Specific Fuel Consumption (SFC) through precise control

of Injection Timing and Duration.

Machine protection under extreme operating conditions.

Easy servicing and fault diagnostics, Electronic Service Tool, (EST)

Exceeds emissions legislation and has a lower noise level.

Better engine responsiveness.

Improved reliability,engine monitoring and protection.

Further cost savings through integration into Genset' design (CAN)

Improved torque, different torque curves available, torque shaping

Rating changes available, Base Load, Prime, Standby, 1500/1800

Configuration files, gives the customer flexibility, droop, etc

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

FGA 06 - 1234 - U - 5678 - K

F Engine Family, 14.6 litre

H Engine Family, 15.8 litre

J Engine Family, 18 litre

A = TAG 1 (Turbo-Air to air charge cooled-Genset)

B = TAG 2 (Turbo-Air to air charge cooled-Genset)

D = TAG 3 (Turbo-Air to air charge cooled-Genset)

Generator Set

Engine

Number of Cylinders

Engine Serial Number

Country of Manufacture

Year of Manufacture 03

Build List

2306 and 2806 Engine Numbering

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Engine Ratings - Definitions

Base Load or Continuous

Unlimited hours usage, load factor 100%

of published base load/continuous power

10% overload available 1 hour in 12

Power available for continuous full load

Prime Power

Unlimited hours usage, load factor 80%

of published prime power over 24 hours

10% overload available 1 hour in 12

Standby (maximum)

Power available at variable load in the event of a mains power network

failure, up to a maximum of 500 hours/year of which 300 hours may be

continuous

No overload is permitted and the load factor is 100%

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2300/2800 Series Engines

Electronic Control System, Identical

Economic Power

Mechanically actuated Electronically controlled Unit Injection.(MEUI)

Optimum turbo-charging, excellent fuel atomisation (30,000 PSI) and

combustion, very low emissions.

Reliable Power

Low oil usage and wear rates, high

compression ratios ensure clean rapid

starting. World Wide Support from

4000 Distributors.

Compact, Efficient Power

Exceptional power to weight ratio,

compact size, excellent service access for

ease of maintenance

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2300/2800 - Engine Component Changes

Noticeable Physical Differences - Air Filter Size

Performance Related

Pistons

Connecting Rods

Liner

Ring Pack

Crankshaft

Turbo

Air Cleaner

Package Size Related

Radiator

Charge Cooler

Fan and Cowling

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Combined primary and

secondary Eco

Fuel filters

Integral inlet manifold

(18 litre horizontal)

Fuel transfer

pump

Timing

Calibration

Probe access

hole

ADEM 3 ECM

With Perkins

software

Unique wiring

harness

Radial seal

air filter

element

2306/2806 Product Features

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Composite oil pan

Composite

top cover

Oil cooler

Ecoplus full

flow

oil filtration

Single stage

high boost

turbocharger

Torsional

vibration

damper

Air to air

charge

cooler

16 litre

2306/2806 Product Features

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2806 -18 litre Product Features

Twin exhaust

manifolds

External oil feed

to the cylinder

head

Twin

turbochargers

Large output

coolant pump

New oil filler

tube

Aluminium sump

30% larger

capacity oil

cooler

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Rocker Assemblies

Roller Type Rockers

Second oil pressure feed to

cylinder head 18 Litre (external)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Forged

steel

overhead

camshaft

Four

valves

per

cylinder

Cylinder Head

Four Valve Mono-Block Cylinder Head

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

One of three oil

feed drillings

Valve Assemblies

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

TDC locator

Turning

tool

Valve/Injector Clearance

Establishing Number 1 TDC

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Valve

screw and locknut

adjuster

Injector adjuster

Injector

trim code

Button and O ring

Valve/Injector Clearance

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Tool CH11149

Machine shoulder

Checking correct

adjustment

Valve/Injector Clearance

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Valve/Injector Clearance

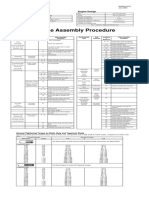

With Number 1 Cylinder at TDC compression stroke adjust

Inlet valves 1,2,4

Exh valves 1,3,5 Injectors 3,5,6

With Number 6 Cylinder at TDC compression stroke adjust

Inlet valves 3,5,6

Exh valves 2,4,6 Injectors 1,2,4

Clearances

Inlet valves 0.38mm (0.015in)

Exh Valves 0.76mm (0.030in)

Injectors 78.0mm (3.07in) Tool N CH11149

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Injector Sleeve

A stainless steel sleeve is used in the injector

bore to seal the coolant

The sleeve is sealed using three O rings.

However, combustion gases are sealed by the

injector seating on the metal in the cylinder

head bore.

The O ring seal fitted on the injector nozzle

provides a combustion gas seal until a carbon

dam is formed.

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

A failed seal

results in

blow by and a

hot injector

Injector Sleeve

A line

contact seal

is attained

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Injector Sleeve

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Valve lobes Injector lobe

Drive gear

dowel location

Camshaft

Long Overlap Camshaft

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Camshaft

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Camshaft

Thrust Plate and Seal

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Cylinder head gasket

Spacer plate

Shim gasket

Oil feed O ring

Coolant bobbin

Oil seal

Head Gasket/Spacer Plate

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Thermal sleeve

Air gap

Exhaust Manifold

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Cylinder Block

Open Summit Cylinder Block

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Oil soaked filler band

Rubber O rings

(2806)

2306 three lower liner O ring seals are all identical in size

Cylinder Liners

Induction Hardened Liners

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Cylinder Liners

Protrusion

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Oil cooling gallery

Oil cooling spray cutaways

Pistons

2306 Gallery Cooled Articulated Piston

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Cooling oil reservoir

Pistons

2806-16 Articulated Piston

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Tightening con-rod bolts

Piston/Con-Rod Assembly

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Pistons

2806-18 Piston

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Big end cap secured by

four bolts

Oil supply to small end

bearing

Pistons/Con-Rod Assembly

2806-18 Piston

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Piston cooling jet

alignment tool

Part Number GE50004

Piston Cooling Jets

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Piston cooling jet

pipe assembly

Entry to cooling

gallery

Connecting rod

Piston

Piston Cooling Jets

2806-18

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Thrust washer position

Crankshaft

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Crankshaft

2806-18

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Grooved main bearing

fitted to block

180 thrust washers

fitted to block

Crankshaft

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Block Stiffener Plates

2300 Series

2800 Series 16 litre

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2

Torsional Damper

Hasse and Wrede Damper

1. Housing

2. Casing

3. Inertia Ring (mass)

4. Bearings

5. Silicone Fluid

Block Stiffener Plate

2800 18 litre

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Pendulum

camshaft gear

Adjustable

idler gear

Idler gear

Fuel transfer

pump

Crankshaft gear

Oil pump gear

position

Compound

gear

assembly

Coolant pump

drive gear

position

Timing Gears

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Locating

dowel

Rotating

balance

weights

Timing Gears

Pendulum Camshaft Gear

Timing case

Alignment

marks

Timing gear

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Timing Gears

Checking Gear Backlash

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Crankshaft Seals

Seal Removal/Fitting

Gear case-split protection ring

Wear sleeve crimp tool

Must be fitted as assembly

Must not be separated

Must be fitted dry

Crankshaft Seals

Oil Seal and Wear Sleeve

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Blue seal (rear) Green seal (front)

Crankshaft Seals

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Induction System

2809-18

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Induction System

Air Filter Type Single medium duty paper element

Max Air Inlet Temp 60C (140F)

Initial Restriction 2.5kPa

(inlet depression new)

Maximum Inlet Depression 6.2Kpa

(with dirty filter)

Max Pressure Drop 14Kpa (2.03 psi)

(across charge cooler)

Maximum Charge Air Temp 260C (500F)

at high (ambient conditions)

Turbo Charger 2306 Allied Signal GT 50

2806 Borge Warner S 500

2806-18 twin Borge Warner S310

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Induction System

Radial Seal Filters

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Single stage high boost turbochargers

No oil priming required

Induction System

Turbochargers

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Exhaust gas outlet

Forward turbocharger

Rear turbocharger

Induction System

2806-18 Turbochargers

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

A

I

R

C

O

O

L

A

N

T

Induction System

Air Charge Cooling/Radiator

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Air charge cooling / radiator

Boost air

Coolant

Turbo boost air

Coolant

Induction System

2806-18

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Induction System

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Trim code,

Below barcode

Fuel System

EUI Location

Put lever here

to remove Injector

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

O ring seals

6 hole

injector nozzle

Sacrificial

compression O ring

Do not re-use seals

Fuel System

Injector Seals

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Transfer pump Primary filter Fuel supply

Fuel return

Venting points

Priming pump

Fuel System

Low Pressure Fuel System

Secondary filter

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Flow =413 litres/h at 1500

Flow =457 litres/h at 1800

Return flow dependant on

engine load Thermostat.

Fuel System

Fuel Cooler/Return

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Fuel System

Ecoplus Fuel Filtration

Fuel System

Fuel Transfer Pump

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Fuel Secondary

Fuel primary

Oil

Fuel System

Ecoplus Fuel Filtration Identification

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

From

Tank

To

transfer

pump

From

transfer

pump

Temp sensor

Return to

cooler

Return from

head

Pressure

Relief

Valve

Air vent

Supply to head

Hand

primer

By-pass

valve

Fuel System

Ecoplus Fuel Filtration

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Fuel System

Non-return/PRV

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Lubrication System

Type Wet sump - full flow

system

Oil pump Gear driven - with PRV

Capacity - total system 68 litres

Sump maximum 60 litres

Sump minimum 45 litres

Lube oil temp - normal (sump) 95C

Lube oil temp - maximum 113C

Lube oil pressure - rated speed 2.7-6 bar (40-88psi)

Lube oil pressure - min rated speed 2 bar (30psi)

Oil pressure relief valve opening pressure 6.1 bar (88psi)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Lubrication System

Composite High Capacity Sump

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Lubrication System

Oil Pump

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Sampling

point

O/P switch

Filter by-pass

valve

Cooler by-pass

valve

Lubrication System

Ecoplus Oil Filtration

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Oil cooler

assembly

Re-positioned

oil filler

tube

Re-designed

Oil filter

head

Lubrication System

2806-18

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Cooling System

Capacity of engine 20.8 Litres

Capacity of complete system 50 Litres

Pressure cap setting 70kPa (0.7 Bar) (10psi)

Thermostat operating range Starts 88C. Fully open 98C

Coolant pump Gear driven, centrifugal type

Radiator Aluminium core, composite tanks

Fan Plastic, 8 blade, pusher type.

Maximum temperature. Top tank - 103C

Recommended Coolant. 50% extended life coolant,

50% de-ionised clean water.

Coolant Life 3,000 hours or six years - max

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Composite top and bottom radiator tanks

ELC coolant to be used at all times

Cooling System

Air Charge Cooling/Radiator

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Thermostat

Thermostat seal

Flow to radiator

By-pass

return to

coolant pump

Cooling System

Thermostat Housing

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Coolant

Temp Sensor

Inlet Manifold

Air Pressure

sensor

Fuel Temp Sensor

Inlet Manifold

Air Temp Sensor

Engine Oil and

Atmospheric

Pressure Sensors

Location of Calibration Probe (Plugged)

23/25/2800 Series

Temperature and Pressure Sensors

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Electronic Control

Module

40 Pin Customer

Connection (J3)

110 Volt MEUI Solenoid Feeds

ECM On Engine Connector (J2)

Cam Speed/

Position Sensor

Crank

Speed/Position

Sensor

9 Pin

Diagnostic

Connector

23/2800 Series

Connections and Speed/Position Sensors

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

23/25/2800 Series Electrical System

36-1 TOOTH

CRANK

GEAR

36+1 TOOTH

CAM GEAR

Internal Injector Harness

Engine Oil Pressure

Inlet Manifold Sensor

Crank Speed/Timing

Cam Speed/Timing

Atmospheric Pressure Sensor

Calibration Probe

Jack 1 (J1)

Jack 2 (J2)

Fuel Temperature Sensor

Coolant Temperature Sensor

Inlet Manifold Sensor

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

23/25/2800 On Engine Wiring Harness

ECM

J2/44 Injector Common Cylinders 1 & 2

Injector

Cyl 1

Injector

Cyl 2

Injector

Cyl 3

Injector

Cyl 4

Injector

Cyl 5

Injector

Cyl 6

J2/45

J2/46

J2/55

J2/54

J2/39

J2/38

J2/37

J2/36

Injector Common Cylinders 3 & 4

Injector Common Cylinders 5 & 6

Injector Cylinder 6

Injector Cylinder 5

Injector Cylinder 4

Injector Cylinder 3

Injector Cylinder 2

Injector Cylinder 1

5

7

6

10

3

11

2

12

1

J300 P300

A

C

+5V

Signal

B Return

A

C

+5V

Signal

B Return

A

C

+5V

Signal

B Return

Atmospheric Pressure Sensor

J2/2

J2/14

J2/3

J2/24

J2/32

J2/33

J2/35

J2/40

Turbo Outlet Pressure Sensor

Oil Pressure Sensor

J2/18

+5VDC Supply

Analogue Return

Fuel Temperature

Inlet Air Temperature

Return

Inlet Air Temperature Sensor

C Signal

B Return

Coolant Temperature Sensor

C Signal

B Return

Fuel Temperature Sensor

C Signal

B Return

Atmospheric Pressure

Turbo Outlet Pressure

Oil Pressure

Coolant Temperature

J2/48

J2/49 Crank Speed Timing -

2 Signal

1 Return

Crankshaft Position Sensor

Crank Speed Timing +

Cam speed timing -

Camshaft Position Sensor

Cam Speed timing + J2/58

J2/59

2 Signal

1 Return

J2/22

J2/23 2

Signal 1

Return

Calibration Probe

Calibration Probe +

Calibration Probe -

P2 J2

P203 J203

P200 J200

P201 J201

J100 P100

J105 P105

J103 P103

J401 P401

J402 P402

J400 P400

All fed from Jack 2 (J2) on the ECM

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Connectors A Reminder:

Always use high quality connectors (Gold/Nickel Plated)

Keep connections to a minimum

Make sure all rubber seals are correctly fitted

Remember

Bad connections cause

resistance!

Resistance causes voltage

drop!

Lack of a rubber seal caused this

To happen to an ECM!

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Effects of Bad (Resistance) Connections

24v dc Lamp

Possible Bad Connections

24v dc Lamp Resistors

Has the same effect as.Resistances in circuit

1 volt 2 volt

0.1 volt 1 volt

24v dc

19.9v dc

J Jack P Plug

Dont forget all connections!

Dont forget all connections!

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

23/25/2800 Series MEUI Injection

Mechanically actuated by the cam shaft

Injection controlled by the 110 Volt Solenoid

The length of time the Solenoid is energized, and the

timing of the energization are both controlled by the

Electronic Control Module (ECM)

Mechanically Actuated

Electronically Controlled

Unit

Injector

110 Volt Solenoid

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

110v dc injector solenoid

Poppet Valve

Shut when energised

23/25/2800 Series MEUI Injector

+

110v

Supply

Off

-

Flow

Poppet Valve Principals

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Poppet Valve

de-energised

O

Rings

Fuel

chamber

MEUI Injector

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

O Rings

Worn MEUI Injector Poppet Valves

Wear on seat, caused by dirty fuel.

Primary Filter 10 microns,

Secondary, 2 microns

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Injector trim code

Injector trim code

Extended life

coolant

Intake

manifold

Fuel chamber

MEUI Injector Location

Torque setting on solenoid

Screws 2.5 Nm (22 lb in)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Electronic Control Module (ECM)

Inside the ECM is the management system that controls

Speed Governing

Air/Fuel Ratio

Start/Stop Sequence

Engine Protection Devices

Diagnostics

110 Volt Injector Pulses

Jack 2 (J2) all on

engine mounted

components

Jack 1 (J1)

Customer interface,

power supply etc

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Basic System A3-ECM Interactions

Inputs Outputs

Cables/

Connectors

Digital speed Adjust

analogue speed

Adjust

PWM speed Adjust

Push

buttons/switches

fault reset,injection

disable,lower/raise

digital speed,

etc,etc

ECM power supply,

24 v

Control

Voltage to operate

diagnostic lamps

and crank terminate

relay

5 volt + 8 volt

Power Supplies

110 Volt DC pulse

for Injectors

Digital output

for speed control

Cables/

Connectors

Cables/

Connectors

Cables/

Connectors

Electronic

Service

Tool

PDL

PROCESSOR

MEMORY

(Engine

Programme)

Power supply

for 5 volt

6.5 volts and

8 volts

CAN

J 1939

Diagnostic

Code Reader

J 1939

Engine Control

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2300/2500/2800 Off Engine Wiring Diagram

J1- 70 Jack - Customer connection.

Also J3 - 40 Jack - Customer connection

Machine Wiring Schematic, All Options

9 Pin Perkins Data

Link Connector

Notes:

Outputs may be used to

drive lamps or relays.

Crank Terminate should be

a relay used to disconnect

the starter motor in OEM

panel start circuit.

Diagnostic lamp lights

when active systemfault

registered

For full details of inputs/

outputs, refer to

Installation Manual

Action Alert

Warning

Diagnostics

Low Oil Pressure

High Coolant Temp

Overspeed

Critical Override

To PWM

Speed Control

ECM

J1/19

J1/20

J1/31

Action Alert Lamp Output

Warning Lamp Output

Diagnostics Lamp Output

J1/28 Oil Pressure Lamp Output

J1/29 Coolant Temperature Lamp Output

J1/30 Overspeed Lamp Output

J1/18

J1/66

J1/5

J1/4

Digital Ground

PWM Input

Ground

+8V

J1/67

D E

Key

Switch

Circuit

Breaker (16A)

Starter

Motor

Start Button

Emergency

Stop Button

5K Analogue

Speed Setting

Potentiometer or

Input fromLoad

Sharer/Synchroniser

A B G F C

Battery

24V DC

+ -

H J

Unswitched Battery Positive

P1 J1

J1/61 Unswitched Battery Negative

J1/63

J1/65

J1/52

J1/53

J1/48

J1/70 Switched Battery Positive

J1/3

J1/17

J1/2

Analogue Ground

Analogue Speed Input

+5V

J1/50

J1/34

J1/42

J1939 Data Link +

J1939 Data Link -

J1939 Screen

J1/8 Perkins Data Link +

J1/9 Perkins Data Link -

J1/55

J1/69

Charging

Alternator

GRD POS

U

P

K

O

N

A

B

B

W

R

B

B

W

R

B

B

B

R

R

R

Y

Y

G

G

N

R

B

680R

680R

This Wiring Supplied By OEM

Shutdown

J1/10 Shutdown lamp Output

G

J1/13 Crank Terminate Output

K

Crank Terminate

(Engine Running

Signal)

Injection Disable

J1/64 Shutdown Emergency Override

K

J1/62 Injection Disable

U

Off - Disabled - Stop

On - Enabled - Run

Off

On

(Disables Oil & Water shutdowns

when on)

Off

On

Unswitched Battery Negative

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Positive

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Negative

Power

Supply to

Service

Tool

Main

Battery

Feed

(Direct

from

starter/

battery)

(ECM latched out)

1500/1800

rpmSelect

Droop/

Isochronous

Fault Reset

J1/56

J1/46

J1/41

1500/1800 rpm Select

Droop/Isochronous

Fault Reset

N

A

Y

1500

1800

Droop

Isoch

O

Raise Speed

J1/7 Raise Speed

O

J1/49 Digital Speed Control Enable

G

J1/59 Lower Speed

P Lower Speed

Enable

Digital

Speed

Control

Disable Digital Speed Control

C

T

PWM

Ground

+8V

J1 Jack

(Different Diagram)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Some Typical Connections - ECM

Inputs

Outputs

ECM Power Supply,

24 v

CONTROL

E C M

Shutdown

Diagnostics

Analogue

Speed Adjust

Crank Terminate

Injection Disabled

Power Supply,

24 v

+

-

+ -

5 volt to

Sensors

+

-

J1939 PDL

+

-

Ignition Key Switch

Communications Adapter

24 v

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

23/2800 Series ECM Jack Connections

J1 (Jack 1)

Customer Side

J2 (Jack 2)

On Engine Mounted Components

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

ECM Grounding

Grounding

Always ensure the ground straps are on the Engine and

the ECM is connected to the engine block, via the tag to

prevent EMI, Electro Magnetic Interference, affecting the

interior electronic circuits of the ECM.

Warning!

When carrying out welding or electrostatic paint spraying,

special precautions should always be followed.

These are listed in the Perkins Mechanical and Electronic

Installation Manual. TSL 4262, & TSL 4247.

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Electronic Control Module

Nominal battery supply voltage 18-32 volts (Max 48 for 2 mins)

Approximately 2 - 6 amps in typical application

10-15 mA in sleep mode (ignition off/ECM power on)

High Reliability.

External connectors most vulnerable: bent jacks, J1, J2 over

tightened ECM plugs etc.

No internal fuses or serviceable parts.

Never replace an ECM without first connecting Electronic Service Tool

(EST) and carrying out basic diagnostics.

The ECM is the last component you should suspect.

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2300/2800 Series ECM Power Supplies

Machine Wiring Schematic, All Options

9 Pin Perkins Data

Link Connector

Notes:

Outputs may be used to

drive lamps or relays.

Crank Terminate should be

a relay used to disconnect

the starter motor in OEM

panel start circuit.

Diagnostic lamp lights

when active system fault

registered

For full details of inputs/

outputs, refer to

Installation Manual

Action Alert

Warning

Diagnostics

Low Oil Pressure

High Coolant Temp

Overspeed

Critical Override

To PWM

Speed Control

ECM

J1/19

J1/20

J1/31

Action Alert Lamp Output

Warning Lamp Output

Diagnostics Lamp Output

J1/28 Oil Pressure Lamp Output

J1/29 Coolant Temperature Lamp Output

J1/30

Overspeed Lamp Output

J1/18

J1/66

J1/5

J1/4

Digital Ground

PWM Input

Ground

+8V

J1/67

D E

Key

Switch

Circuit

Breaker (16A)

Starter

Motor

Start Button

Emergency

Stop Button

5K Analogue

Speed Setting

Potentiometer or

Input from Load

Sharer/Synchroniser

A B G F C

Battery

24V DC

+

-

H J

Unswitched Battery Positive

P1 J1

J1/61 Unswitched Battery Negative

J1/63

J1/65

J1/52

J1/53

J1/48

J1/70

Switched Battery Positive

J1/3

J1/17

J1/2

Analogue Ground

Analogue Speed Input

+5V

J1/50

J1/34

J1/42

J1939 Data Link +

J1939 Data Link -

J1939 Screen

J1/8 Perkins Data Link +

J1/9 Perkins Data Link -

J1/55

J1/69

Charging

Alternator

GRD POS

U

P

K

O

N

A

B

B

W

R

B

B

W

R

B

B

B

R

R

R

Y

Y

G

G

N

R

B

680R

680R

This Wiring Supplied By OEM

Shutdown

J1/10 Shutdown lamp Output

G

J1/13 Crank Terminate Output

K

Crank Terminate

(Engine Running

Signal)

Injection Disable

J1/64 Shutdown Emergency Override

K

J1/62 Injection Disable

U

Off - Disabled - Stop

On - Enabled - Run

Off

On

(Disables Oil & Water shutdowns

when on)

Off

On

Unswitched Battery Negative

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Positive

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Negative

Power

Supply to

Service

Tool

Main

Battery

Feed

(Direct

from

starter/

battery)

(ECM latched out)

1500/1800

rpm Select

Droop/

Isochronous

Fault Reset

J1/56

J1/46

J1/41

1500/1800 rpm Select

Droop/Isochronous

Fault Reset

N

A

Y

1500

1800

Droop

Isoch

O

Raise Speed

J1/7 Raise Speed

O

J1/49 Digital Speed Control Enable

G

J1/59 Lower Speed

P Lower Speed

Enable

Digital

Speed

Control

Disable Digital Speed Control

C

T

PWM

Ground

+8V

+ to Diagnostics Lamps

- to Diagnostics Lamps

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Minimum J1 Connections, to run a

23/2800 Series

ECM Power Supply,

24 v

Control

ECM

Injection Disabled

+ -

Ignition Key Switch

Note

We do suggest that

a connection is made to the

Perkins Electronic Service Tool

(EST) to allow communication

With Perkins Data Link (PDL)

What are the Jack connection

numbers?

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Ignition Circuit

Ignition Key Switch

This switch may be used for a controlled engine stop. The ignition

switch does not switch off power to the ECM. The ECM remains

connected to the battery via a fuse/circuit breaker, even when the

ignition is switched off. Can also be used to reset faults. The

Electronic Service Tool (EST) cannot communicate with the ECM

when the Ignition switch is off.

Injection Disabled

If you want to stop the engine, use the Injection Disabled. This

allows communication with the service tool (EST) to continue.

Emergency Shut-down

This button, interrupts the main battery power supply to the ECM and

stops the engine. Not Recommended, Dont forget the ECM is a

computer, you do not just chop off the power.

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

23/25/2800 Series Engine Mounted Sensors

Engine coolant temperature.

Inlet manifold air temperature.

Fuel temperature.

Inlet manifold air pressure.

Atmospheric/crankcase pressure.

Engine oil pressure.

Camshaft/crankshaft speed/timing.

Calibration probe (only in special circumstances)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

32

33

35

18

ECM

Engine Coolant Temperature Sensor

Fuel Temperature Sensor

Signal Voltage

Signal Voltage

0 Volts

Inlet Air Temperature Sensor

Signal Voltage

2300/2800 Series Temperature Sensors

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

18

ECM

Temperature Sensor

R

5 Volts

0 Volts

Signal

Ground

23/2800 Series Temperature Sensor Operation

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Engine Coolant Temperature Sensor

EST Code 110

Temperature can be viewed

through the ECM in C/F via:

J1939 CAN link

Perkins Data Link (PDL)

The sensor enables the cold

start strategy

Also enables the calculation of

the fuel limit and engine timing

Engine protection, Warning,

Action Alert and Shutdown.

Coolant Temperature

Sensor

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Engine Coolant Temperature Sensor

EST Code 110 (Typical Temperature Sensor graph)

110-4 Signal shorted to a lower voltage (voltage under 0.2)

110-3 Signal shorted to a higher voltage or open circuit (voltage over 4.8)

Temperature

0.2

4.8

Shutdown Temp 361 (3)

Very cold Temp

Action Alert Temp 361 (2)

Warning Temp 361 (1)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Manifold Air Inlet Temperature Sensor

EST Code 174

Temperature can be viewed

through the ECM in C/F via:

J1939 CAN link.

Perkins Data Link (PDL)

The sensor enables the cold

start strategy.

Also enables the calculation of

the fuel limit and engine timing

Engine protection, warning and

Action Alert.

Manifold Air Inlet

Sensor

High inlet air temperatures lead to high

exhaust temperatures, which can cause

damage to exhaust system components

(such as turbochargers and exhaust valves)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Engine Fuel Temperature Sensor

EST Code 174

Higher Temperature lower mass

Lower Temperature greater mass

Temperature can be viewed through

the ECM in C/F via:

J1939 CAN link

Perkins Data Link (PDL)

Also enables the calculation of the

fuel limit and engine timing.

Protection, Warning and Action Alert.

Fuel Temperature

Sensor

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Voltage between 1 and 2

Wiring harness plug connections

(check the harness to ECM)

2 1

Fuel Temperature Sensor

Coolant Temperature Sensor

Intake Manifold Temperature Sensor

Temperature Sensor Feeds, Harness Voltages

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

32

33

2

35

18

3

2

ECM Jack 2

Engine Coolant Temperature Sensor

Fuel Temperature Sensor

Intake Manifold Temperature Sensor

Fault 1.

Fault 2.

Fault 3.

Break

1

2300/2800 Series Sensors

Different Fault Codes and How they could be Created

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2

3

40

24

14

ECM J2

Engine Oil Pressure Sensor

Intake Manifold Air Pressure Sensor

5 Volts

Signal Voltage

0 Volts

Signal Voltage

Atmospheric/Crankcase Pressure Sensor

Signal Voltage

2300/2800 Series Pressure Sensors

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2

3

ECM J2

Pressure Sensor

R

5 Volt

6.5 Volts

0 Volts

Sensor Fly Lead Main Engine Harness

23/25/2800 Series Pressure Sensor Operation

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Inlet Manifold Air Pressure Sensor

EST Code 273 - (Code also known as Turbo Boost!)

Pressure can be viewed in PSI and Kpa

through the ECM via:

J1939 CAN link

Perkins Data Link (PDL)

Used to determine mass air flow

Enables the calculation of the correct

air/fuel ratio

Used for smoke limiting strategy

Range 52 Kpa Abs. 472 Kpa Abs

Protection- Warning and Action Alert.

Inlet Manifold Air

Pressure Sensor

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Inlet Manifold Air

Pressure Sensor

Inlet Manifold Air Pressure Values

2800 Kpa Gauge

1800 rpm

Full load 295

1/2 Load 126

1500 rpm

Full Load 249 263 Half TA Luft

1/2 Load 94 95

2300 Kpa Gauge

1800 rpm

Full load 205

1/2 Load 119

1500 rpm

Full Load 195 234 Half TA Luft

1/2 Load 71 71

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Engine Oil Pressure Sensor

EST Code 100

Pressure can be viewed in PSI and

Kpa through the ECM via:

J1939 CAN link

Perkins Data Link (PDL)

Protection,Warning,Action Alert

Protection mapped

Range 106 Kpa to 1135 Kpa

Engine Oil Pressure

Sensor

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Engine Oil Pressure Sensor

EST Code 100 (Typical Pressure Sensor graph)

100-4 Signal shorted to a lower voltage (less than 0.2 volts)

100-3 Shorted to a higher voltage or open circuit (over 4.8 volts)

Pressure

0.2

4.8

Warning Pressure E360-1

Action Alert Oil Pressure E360-3

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Atmospheric (Crankcase) Pressure Sensor

EST Code 274

Pressure can be viewed in PSI and

Kpa, absolute through the ECM

via:

J1939 CAN link.

Perkins Data Link (PDL)

Used to calibrate the Inlet Air and

Oil Pressure Sensors.

With Critical Override active, if the

sensor fails the engine will Derate

by 10%.

Range 40 Kpa A to 116 Kpa A

Atmospheric

Pressure Sensor

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2800 Series De-rate Information

The 2306 / 2806 series engine electronic control, does not

automatically de-rate at high altitudes or high ambient

temperatures

The de-rate information for this

engine can be obtained from

Perkins Engines

Applications Department

These de-rate limits must

be adhered to or severe

engine damage may result

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Atmospheric/Crankcase Pressure Sensor (DT06-3S)

Oil Pressure Sensor (DT06-3S)

Intake Manifold Air Pressure Sensor (DT06-3S)

C

A

B

Voltage between A and B

Voltage between B and C

Voltage between A and C

Pressure Sensor Feeds, Harness Voltages

Wiring Harness Plug Connections,

(Checks the harness to ECM)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2300/2800 Series Sensors

Different Fault Codes and How they could be Created

2

3

40

24

14

3

2

ECM J2

Engine Oil Pressure Sensor

Intake Manifold Air Pressure Sensor

5 Volts

Signal Voltage

0 Volts

Signal Voltage

Atmospheric/Crankcase Pressure Sensor

Signal Voltage

1

Fault 1.

Fault 2.

Fault 3.

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Crankshaft Gear 36 - 1 tooth

Crankshaft Speed/Position Sensor

EST Code 190

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Camshaft Gear 36 + 1 tooth

Camshaft Speed/Position Sensor

EST Code 342 (Speed and timing Sensor 2)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Crankshaft Sensor Resistance

between 1 and 2

Camshaft Sensor Resistance

between 1 and 2

Run Engine and Measure output

AC Voltage or Frequency from

each Sensor - one at a time

2 1

2 1

Crankshaft Speed/Position

Sensor fly lead

Camshaft Speed/Position

Sensor fly lead

Checking Speed/Position Sensors

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Additional Sensors/Senders

Oil pressure sender

CV18339/3 and adapter 3Y-2888

Coolant temperature sender

CV18338/5 and adapter OE51375

Speed Sensor

CV18338 and Harness

CV18965

Coolant Level switch

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Oil

Pressure

Switch

Temperature

Switch

Coolant Level sensor

Additional Engine Sensors/Senders

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2800 Wiring Diagram

Customer side (Jack 1)

Outputs - may be used to drive lamps or

relays. (0.3 A, 1.0 A and 1.5 A)

Crank terminate should be a relay to

monitor starter motor in the OEM panel

Diagnostic lamp, lights when active fault

code registered, or any of the outputs

are disconnected/open circuit

Inputs - injection disable, RPM select,

digital speed control, raise/lower,

droop/isochronous, etc

For full details of inputs and outputs refer

to the installation manual

(2800,TSL 4262. 2300, TSL 4267)

This drawing for indication only!

Machine Wiring Schematic, All Options

9 Pin Perkins Data

Link Connector

Notes:

Outputs may be used to

drive lamps or relays.

Crank Terminate should be

a relay used to disconnect

the starter motor in OEM

panel start circuit.

Diagnostic lamp lights

when active systemfault

registered

For full details of inputs/

outputs, refer to

Installation Manual

Action Alert

Warning

Diagnostics

Low Oil Pressure

High Coolant Temp

Overspeed

Critical Override

To PWM

Speed Control

ECM

J1/19

J1/20

J1/31

Action Alert Lamp Output

Warning Lamp Output

Diagnostics Lamp Output

J1/28 Oil Pressure Lamp Output

J1/29 Coolant Temperature Lamp Output

J1/30

Overspeed Lamp Output

J1/18

J1/66

J1/5

J1/4

Digital Ground

PWM Input

Ground

+8V

J1/67

D E

Key

Switch

Circuit

Breaker (16A)

Starter

Motor

Start Button

Emergency

Stop Button

5K Analogue

Speed Setting

Potentiometer or

Input fromLoad

Sharer/Synchroniser

A B G F C

Battery

24V DC

+ -

H J

Unswitched Battery Positive

P1 J1

J1/61 Unswitched Battery Negative

J1/63

J1/65

J1/52

J1/53

J1/48

J1/70 Switched Battery Positive

J1/3

J1/17

J1/2

Analogue Ground

Analogue Speed Input

+5V

J1/50

J1/34

J1/42

J1939 Data Link +

J1939 Data Link -

J1939 Screen

J1/8 Perkins Data Link +

J1/9 Perkins Data Link -

J1/55

J1/69

Charging

Alternator

GRD POS

U

P

K

O

N

A

B

B

W

R

B

B

W

R

B

B

B

R

R

R

Y

Y

G

G

N

R

B

680R

680R

This Wiring Supplied By OEM

Shutdown

J1/10 Shutdown lamp Output

G

J1/13 Crank Terminate Output

K

Crank Terminate

(Engine Running

Signal)

Injection Disable

J1/64 Shutdown Emergency Override

K

J1/62 Injection Disable

U

Off - Disabled - Stop

On - Enabled - Run

Off

On

(Disables Oil & Water shutdowns

when on)

Off

On

Unswitched Battery Negative

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Positive

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Negative

Power

Supply to

Service

Tool

Main

Battery

Feed

(Direct

from

starter/

battery)

(ECM latched out)

1500/1800

rpmSelect

Droop/

Isochronous

Fault Reset

J1/56

J1/46

J1/41

1500/1800 rpm Select

Droop/Isochronous

Fault Reset

N

A

Y

1500

1800

Droop

Isoch

O

Raise Speed

J1/7 Raise Speed

O

J1/49 Digital Speed Control Enable

G

J1/59 Lower Speed

P Lower Speed

Enable

Digital

Speed

Control

Disable Digital Speed Control

C

T

PWM

Ground

+8V

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Gen-Set Desired Engine Speed/Load Control

The software in the ECM provides the flexibility to

cater for Four types of control.

Digital Control

Pulse Width Modulated

Analogue Control

CAN J1939 Control

Typical Pressure Sensor

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Digital Speed/Load Control

Enables speed control by digital load-sharing and

synchronizing equipment

The Engine can interface directly with manual

synchronizing selector switches, relays or push buttons

When the ECM is working on Digital Speed Control

there are three inputs that can be used.

Digital Speed Control Enable

Digital Speed Control Ramp Rate

Digital Speed Control Raise/Lower

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Digital Speed/Load Control

Digital speed control (enable/disable)

Lower speed (pushbutton/relay contact)

Raise speed (pushbutton/relay contact)

Digital speed control ramp rate, (default 10 rpm/sec)

This can be adjusted via the Electronic Service Tool

Speed adjustment ranges +150 150 rpm

Machine Wiring Schematic, All Options

9 Pin Perkins Data

Link Connector

Notes:

Outputs may be used to

drive lamps or relays.

Crank Terminate should be

a relay used to disconnect

the starter motor in OEM

panel start circuit.

Diagnostic lamp lights

when active system fault

registered

For full details of inputs/

outputs, refer to

Installation Manual

Action Alert

Warning

Diagnostics

Low Oil Pressure

High Coolant Temp

Overspeed

Critical Override

To PWM

Speed Control

ECM

J1/19

J1/20

J1/31

Action Alert Lamp Output

Warning Lamp Output

Diagnostics Lamp Output

J1/28 Oil Pressure Lamp Output

J1/29 Coolant Temperature Lamp Output

J1/30

Overspeed Lamp Output

J1/18

J1/66

J1/5

J1/4

Digital Ground

PWM Input

Ground

+8V

J1/67

D E

Key

Switch

Circuit

Breaker (16A)

Starter

Motor

Start Button

Emergency

Stop Button

5K Analogue

Speed Setting

Potentiometer or

Input from Load

Sharer/Synchroniser

A B G F C

Battery

24V DC

+

-

H J

Unswitched Battery Positive

P1 J1

J1/61 Unswitched Battery Negative

J1/63

J1/65

J1/52

J1/53

J1/48

J1/70

Switched Battery Positive

J1/3

J1/17

J1/2

Analogue Ground

Analogue Speed Input

+5V

J1/50

J1/34

J1/42

J1939 Data Link +

J1939 Data Link -

J1939 Screen

J1/8 Perkins Data Link +

J1/9 Perkins Data Link -

J1/55

J1/69

Charging

Alternator

GRD POS

U

P

K

O

N

A

B

B

W

R

B

B

W

R

B

B

B

R

R

R

Y

Y

G

G

N

R

B

680R

680R

This Wiring Supplied By OEM

Shutdown

J1/10 Shutdown lamp Output

G

J1/13 Crank Terminate Output

K

Crank Terminate

(Engine Running

Signal)

Injection Disable

J1/64 Shutdown Emergency Override

K

J1/62

Injection Disable

U

Off - Disabled - Stop

On - Enabled - Run

Off

On

(Disables Oil & Water shutdowns

when on)

Off

On

Unswitched Battery Negative

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Positive

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Negative

Power

Supply to

Service

Tool

Main

Battery

Feed

(Direct

from

starter/

battery)

(ECM latched out)

1500/1800

rpm Select

Droop/

Isochronous

Fault Reset

J1/56

J1/46

J1/41

1500/1800 rpm Select

Droop/Isochronous

Fault Reset

N

A

Y

1500

1800

Droop

Isoch

O

Raise Speed

J1/7 Raise Speed

O

J1/49 Digital Speed Control Enable

G

J1/59 Lower Speed

P

Lower Speed

Enable

Digital

Speed

Control

Disable Digital Speed Control

C

T

PWM

Ground

+8V

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2300/2800 Series PWM Speed Control

Intended for use with a customers load-sharing unit

The PWM signal 500 Hz, duty cycle 10-90%

Speed adjustment 24% to +8% (0% is rated speed)

For 50 Hz 1141 to 1621 rpm

For 60 Hz 1369 to 1945 rpm

Typical Pressure Sensor

Note for Calibration:

If the PWM input is selected on the configuration screen but not connected

on the OEMs side, the ECM will default the speed to 1100,

(and log a diagnostic code 91-8)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2300/2800 Series Analogue Speed Control

Speed adjustment 10% to +10% (0% is rated speed)

For 50 Hz 1350 to 1650 rpm

For 60 Hz 1620 to 1980 rpm

Typical Pressure Sensor

Note for Calibration:

If the Analogue input is selected on the configuration screen but not

connected on the OEMs side, the ECM will default the speed to 1100,

(and log a diagnostic code 1690-8)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2300/2800 Series Analogue Speed

Adjustments

Resistive track

potentiometer

Provide linear voltage

output (0.5v to 4.5v)

Two series resistors

keep voltage away

from fault region

V

o

l

t

a

g

e

o

/

p

4.5V

-10%

+10%

0.5V

Fault Region

Fault Region

1500/1800 RPM

Rated Speed

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Engine Speed/Ratings Selection

Engine Rating,Duties,Speed can be set within limits set by the torque maps

The rating of the Engine is selectable via the EST in Configuration

The Function will be selected at the time of manufacture or in service via the

Electronic Service Tool.

For example: 2300 Series -

2306C-E14TAG2, 2306C-E14TAG3

The ECM has torque limit maps:

1500 rpm prime power

1800 rpm prime power

1500 rpm base load - continuous

1800 rpm base load - continuous

1500 rpm standby maximum power

1800 rpm standby maximum power

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2800 Series Engine Protection

There are three alarm levels provided which are defined as:

Level 1 - Operator Warning

To warn the operator or machine control system of a possible

condition within the ECM control system that requires the operators

attention.

Level 2 Action (called De-rate or Alert)

To inform the operator or machine control system to take action to

enable the proper control of the system (i.e. to externally de-rate or

reduce speed). This is normally used by the OEM to stop the engine.

Level 3 Shutdown

To inform the operator or machine control system that the ECM has

shutdown due to an operating condition reaching an unacceptable

level; or if in the critical override condition, that the product is now

operating in a condition outside of its scope of supply and may cause

injury or be damaged in such a way as to invalidate the warranty

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Protection Device Warning Action Alert Shutdown

High Coolant Temp

Low Oil Pressure

Engine Over-speed

Inlet Manifold Air Pressure

High Inlet Manifold Air Temp

High Fuel Temp

There is not a warning, alert, shutdown on atmospheric it purely logs a

diagnostic code, the diagnostic lamp comes on, the oil pressure is then

invalid and we trigger the oil pressure lamp and the shutdown

Warnings, Action Alert and Shutdown

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2800 Series Lamp Outputs

The ECM provides individual outputs to drive warning lamps

and/or relays to indicate each of the following fault conditions:

Active Fault Codes (Diagnostics)

High Coolant Temperature

Low Oil Pressure

Over-speed

Level 1 (Warning)

Level 2 (Action Alert)

Level 3 (Shutdown)

Lamp Outputs.

The outputs have a maximum current value as below.

Shutdown and Crank Terminate = 1.5 amps.

Action Alert and Warning = 1 amp.

Diagnostics, Oil Pressure, Coolant Temperature, Overspeed = 0.3 amps.

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Customer Outputs

Machine Wiring Schematic, All Options

9 Pin Perkins Data

Link Connector

Notes:

Outputs may be used to

drive lamps or relays.

Crank Terminate should be

a relay used to disconnect

the starter motor in OEM

panel start circuit.

Diagnostic lamp lights

when active system fault

registered

For full details of inputs/

outputs, refer to

Installation Manual

Action Alert

Warning

Diagnostics

Low Oil Pressure

High Coolant Temp

Overspeed

Critical Override

To PWM

Speed Control

ECM

J1/19

J1/20

J1/31

Action Alert Lamp Output

Warning Lamp Output

Diagnostics Lamp Output

J1/28 Oil Pressure Lamp Output

J1/29 Coolant Temperature Lamp Output

J1/30

Overspeed Lamp Output

J1/18

J1/66

J1/5

J1/4

Digital Ground

PWM Input

Ground

+8V

J1/67

D E

Key

Switch

Circuit

Breaker (16A)

Starter

Motor

Start Button

Emergency

Stop Button

5K Analogue

Speed Setting

Potentiometer or

Input from Load

Sharer/Synchroniser

A B G F C

Battery

24V DC

+

-

H J

Unswitched Battery Positive

P1 J1

J1/61 Unswitched Battery Negative

J1/63

J1/65

J1/52

J1/53

J1/48

J1/70

Switched Battery Positive

J1/3

J1/17

J1/2

Analogue Ground

Analogue Speed Input

+5V

J1/50

J1/34

J1/42

J1939 Data Link +

J1939 Data Link -

J1939 Screen

J1/8 Perkins Data Link +

J1/9 Perkins Data Link -

J1/55

J1/69

Charging

Alternator

GRD POS

U

P

K

O

N

A

B

B

W

R

B

B

W

R

B

B

B

R

R

R

Y

Y

G

G

N

R

B

680R

680R

This Wiring Supplied By OEM

Shutdown

J1/10 Shutdown lamp Output

G

J1/13 Crank Terminate Output

K

Crank Terminate

(Engine Running

Signal)

Injection Disable

J1/64 Shutdown Emergency Override

K

J1/62

Injection Disable

U

Off - Disabled - Stop

On - Enabled - Run

Off

On

(Disables Oil & Water shutdowns

when on)

Off

On

Unswitched Battery Negative

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Positive

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Negative

Power

Supply to

Service

Tool

Main

Battery

Feed

(Direct

from

starter/

battery)

(ECM latched out)

1500/1800

rpm Select

Droop/

Isochronous

Fault Reset

J1/56

J1/46

J1/41

1500/1800 rpm Select

Droop/Isochronous

Fault Reset

N

A

Y

1500

1800

Droop

Isoch

O

Raise Speed

J1/7 Raise Speed

O

J1/49 Digital Speed Control Enable

G

J1/59 Lower Speed

P

Lower Speed

Enable

Digital

Speed

Control

Disable Digital Speed Control

C

T

PWM

Ground

+8V

- Negative

+ Positive

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Injection Disable/Critical Override

When critical override has been enabled in the service tool - the switch

when 'open' allows the protection to be over ridden, the switch when closed

enables the normal protection - the diagram reads the opposite. The idea

was that if you've enabled a feature to over ride protection and the wire

drops off then the fail safe results in you being able to run to destruction.

Critical Override Not Recommended, ignores oil pressure, coolant

temperature, atmospheric pressure shutdowns when on

Machine Wiring Schematic, All Options

9 Pin Perkins Data

Link Connector

Notes:

Outputs may be used to

drive lamps or relays.

Crank Terminate should be

a relay used to disconnect

the starter motor in OEM

panel start circuit.

Diagnostic lamp lights

when active system fault

registered

For full details of inputs/

outputs, refer to

Installation Manual

Action Alert

Warning

Diagnostics

Low Oil Pressure

High Coolant Temp

Overspeed

Critical Override

To PWM

Speed Control

ECM

J1/19

J1/20

J1/31

Action Alert Lamp Output

Warning Lamp Output

Diagnostics Lamp Output

J1/28 Oil Pressure Lamp Output

J1/29 Coolant Temperature Lamp Output

J1/30

Overspeed Lamp Output

J1/18

J1/66

J1/5

J1/4

Digital Ground

PWM Input

Ground

+8V

J1/67

D E

Key

Switch

Circuit

Breaker (16A)

Starter

Motor

Start Button

Emergency

Stop Button

5K Analogue

Speed Setting

Potentiometer or

Input from Load

Sharer/Synchroniser

A B G F C

Battery

24V DC

+

-

H J

Unswitched Battery Positive

P1 J1

J1/61 Unswitched Battery Negative

J1/63

J1/65

J1/52

J1/53

J1/48

J1/70

Switched Battery Positive

J1/3

J1/17

J1/2

Analogue Ground

Analogue Speed Input

+5V

J1/50

J1/34

J1/42

J1939 Data Link +

J1939 Data Link -

J1939 Screen

J1/8 Perkins Data Link +

J1/9 Perkins Data Link -

J1/55

J1/69

Charging

Alternator

GRD POS

U

P

K

O

N

A

B

B

W

R

B

B

W

R

B

B

B

R

R

R

Y

Y

G

G

N

R

B

680R

680R

This Wiring Supplied By OEM

Shutdown

J1/10 Shutdown lamp Output

G

J1/13 Crank Terminate Output

K

Crank Terminate

(Engine Running

Signal)

Injection Disable

J1/64 Shutdown Emergency Override

K

J1/62

Injection Disable

U

Off - Disabled - Stop

On - Enabled - Run

Off

On

(Disables Oil & Water shutdowns

when on)

Off

On

Unswitched Battery Negative

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Positive

Unswitched Battery Negative

Unswitched Battery Positive

Unswitched Battery Negative

Power

Supply to

Service

Tool

Main

Battery

Feed

(Direct

from

starter/

battery)

(ECM latched out)

1500/1800

rpm Select

Droop/

Isochronous

Fault Reset

J1/56

J1/46

J1/41

1500/1800 rpm Select

Droop/Isochronous

Fault Reset

N

A

Y

1500

1800

Droop

Isoch

O

Raise Speed

J1/7 Raise Speed

O

J1/49 Digital Speed Control Enable

G

J1/59 Lower Speed

P

Lower Speed

Enable

Digital

Speed

Control

Disable Digital Speed Control

C

T

PWM

Ground

+8V

+ 24 Volts

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

2800 Series Switch Inputs

1500/1800 rpm Selection

Switch to ground to select 1800 rpm. Enabling of this input is controlled

via the Electronic Service Tool (EST)

Droop/Isochronous

Switch to ground for droop governing. Enabling of this switch input and

Percentage droop is set using the EST

Fault Reset

This switch is used for clearing faults after an engine shutdown, switch to

ground for fault reset.(Faults cleared by turning the Ignition Switch off/on)

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Electronic Fault Diagnostics

Electronic Service Tool (EST)

Electronic Diagnostic Device (EDD)

Generic Engine Monitor (GEM)

Diagnostic Manual TSD 3453

Trouble Shooting Guide (TSG)

Perkins Technical Marketing Information (PTMI)

Workshop Manual TSD 3450

Installation Manual TSL 4262

Proprietary Information of Perkins Engines Company Limited 2006 - All Rights Reserved

Perkins Confidential Green

Electronic Fault Diagnostics

Generic Engine Monitor (GEM 2200)

Part Number 2800A003

Compact Robust Module, connects via J1939 CAN

Several Languages

Analogue Gauges

Digital Readout

Graphs

Active Diagnostic Codes

Audible Alarm

12/24 Volt Operation