Escolar Documentos

Profissional Documentos

Cultura Documentos

A2XS (FL) 2Y 1x 500RM - 50 110kV IEC 60840

Enviado por

Anonymous LNdiNQTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

A2XS (FL) 2Y 1x 500RM - 50 110kV IEC 60840

Enviado por

Anonymous LNdiNQDireitos autorais:

Formatos disponíveis

Page 1 of 3

(x)

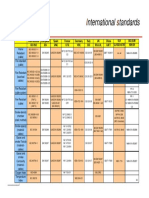

Diameters are calculated values and subject to manufacturing tolerances

TECHNICAL SPECIFICATION

A2XS(FL)2Y 1x500RM/50 64/110 (123) kV IEC 60840

D E S C R I P T I O N UNIT DETAILS

CONSTRUCTION DATA U

o

/U/U

m

64/110 (123)kV

Conductor

material

number of wires

No

Aluminum

56

Nominal cross sectional area mm

2

500

Conductor diameter and tolerance mm 25.7

+0.4

Min./ Nom. thickness semi-conducting XLPE on conductor / diameter mm / 0.6 / 1.0 / 27.5

Insulation thickness XLPE nominal mm 13.0

Insulation thickness: minimum at a point mm 11.7

Diameter over insulation nominal mm 53.9

Min. / Nom. thickness semi-conducting XLPE on insulation / diameter mm / 0.6 / 1.0 / 55.5

Thickness of semi-conducting swelling tape No x mm 2 x ~ 0.35

Metallic screen

Copper wires

Copper equalizing tape

mm

2

No x mm

No x mm x mm

50

60 x 1.04

2 x 10 x 0.18

Mean diameter over metallic screen mm 58.7

Thickness of semi-conducting swelling tape No x mm 2 x ~ 0.35

Thickness of aluminum foil mm 0.2

Diameter over aluminum foil mm 60.4

Nominal outer sheath thickness / min. mm 3.1 / 2.53

Approximate overall diameter completed cable (D

e

) mm 66.7

Weight of complete cable (approx.) kg/km 4532

DELIVERY DATA

Diameter of wooden drum

type

m 3.2

32

Maximum length per drum m 1500

Weight of heaviest reel, including cable kg 8670

The picture is informative only

not in scale

APPLICATION

Laying in ground

(wet or dry locations)

Laying in air

Laying in ducts

Highest permissible conductor

temperature

Continuous operation 90C

Overload 105C

Short circuit 250C

( duration max 5 s )

Laying is possible without any special

measures at natural cable temperatures and

ambient temperature not lower than -5C,

with Tele-Fonika supervising

CONSTRUCTION

(x)

Round, stranded and compressed

aluminum conductor. Class 2.

Extruded semi-conducting

conductor screen

Insulation XLPE dry cured

Extruded semi-conducting

insulation screen

Semi-conducting swelling tapes

Metallic screen:

copper wires screen and

copper equalizing tapes

Semi-conducting swelling tapes

Longitudinal aluminum foil

Sheath Black HDPE

MARKING

TF KABLE, product name, date of

manufacture, standard, meter marking

Page 2 of 3

(x)

Diameters are calculated values and subject to manufacturing tolerances

ELECTRICAL DATA at 50Hz

Maximum D.C. conductor resistance at 20C

Maximum A.C. conductor resistance at 90C

/km

/km

0.0605

0.0792

Maximum D.C. metallic screen resistance at 20C /km 0.358

Maximum D.C. aluminum foil resistance at 20C /km 0.673

Operating inductance

trefoil formation

flat formation

(*)

mH/km

mH/km

0.379

0.564

Induction reactance

trefoil formation

flat formation

(*)

/km

/km

0.119

0.177

Capacitance F/km 0.193 (+ 8 %)

Capacitance reactance k/km 16.49

Impedance

trefoil formation

flat formation

(*)

/km

/km

0.143

0.194

Zero sequence reactance /km 0.066

Max. electric stress at conductor screen / (at insulation) kV/mm 6.98 / 3.60

Dielectric losses (tg = 0.001) per phase W/m 0.248

Partial discharge test at 1.5Uo pC 5

Charging current per phase A/km 3.88

Charging power kVA/km 248

Earth fault current per phase A/km 11.64

MECHANICAL DATA

Recommended min. bending radius for laying m 1.67

Recommended permissible bending radius at final installation m 1.00

Maximum permissible pulling force: kN 15.0

SHORT CIRCUIT CURRENTS

Maximum permissible thermal short-circuit ( IEC 60949 )

Current for 1.0 sec.

Phase conductor 90 250C

Metallic screen 80 350C

kA

kA

47.8

10.5

AMPACITY

(**)

Bonding of the metallic screens Cross-bonded

in earth

trefoil formation

in air

trefoil formation

A

A

521

763

TESTS

AC Test voltage ( 2.5Uo; 30min)

Partial discharge test

kV

kV

160

96

Marking: TF-Kable 5 A2XS(FL)2Y 1x500RM/50 64/110kV IEC 60840 2013

(*)

Distance between cable axes laid in flat formation D

e

+D

e

mm (for information)

(**)

Current rating guideline (Calculated with Cymcap 5.3 based on IEC Pub. 60287 and the following conditions)

Ground temperature 20C

Laying depth 1.2 m

Ground thermal resistivity 1.5 Km/W

Load factor 1.0

Air temperature 35C

Page 3 of 3

(x)

Diameters are calculated values and subject to manufacturing tolerances

Cross-bonded In Earth

Cross-bonded In Air

Date: 2013-03-25; MM13116

Prepared by: Micha Mallach

Você também pode gostar

- High Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YDocumento3 páginasHigh Voltage Power Cables 2XS (F) 2Y - A2XS (F) 2YNeven Ahmed HassanAinda não há avaliações

- Mathcad - Fiabilitatepals1Documento6 páginasMathcad - Fiabilitatepals1Florentina S FlorentinaAinda não há avaliações

- NA2XS2Y, A2XS2Y: Manta Din Polietilena (PE)Documento2 páginasNA2XS2Y, A2XS2Y: Manta Din Polietilena (PE)Adrian Ioan POPAinda não há avaliações

- Tipuri de Stalpi PDFDocumento81 páginasTipuri de Stalpi PDFLevi StrausAinda não há avaliações

- Vent Ozone Destroyer Type Docat: Ozono Elettronica Internazionale S.R.LDocumento3 páginasVent Ozone Destroyer Type Docat: Ozono Elettronica Internazionale S.R.LDiego FernándezAinda não há avaliações

- Fotovoltaica Situatie Avize ATRDocumento121 páginasFotovoltaica Situatie Avize ATRespeleitorAinda não há avaliações

- 011 - 2008 - Medium Voltage (36 Ka) Surge ArrestersDocumento10 páginas011 - 2008 - Medium Voltage (36 Ka) Surge Arresterse09341Ainda não há avaliações

- Earthing & Lightning Protection Solutions CatalogueDocumento12 páginasEarthing & Lightning Protection Solutions CataloguesofyanshahAinda não há avaliações

- Stalp 110 KVDocumento1 páginaStalp 110 KVVirgil CiobanuAinda não há avaliações

- 20kV DesignDocumento13 páginas20kV DesignVladimir ĐorđevićAinda não há avaliações

- DLTC 2011 LowresDocumento8 páginasDLTC 2011 LowresSalvador FayssalAinda não há avaliações

- Moeller Datasheet EMR4 W500 1 D 290183Documento4 páginasMoeller Datasheet EMR4 W500 1 D 290183Marcio RangellAinda não há avaliações

- Snow/Wind Load RomaniaDocumento20 páginasSnow/Wind Load RomaniaJacopo FrancesconAinda não há avaliações

- Cable Sheath Bonding Application Guide Companion PDFDocumento45 páginasCable Sheath Bonding Application Guide Companion PDFskylimit.skylimitAinda não há avaliações

- SKM 2019 Price ListDocumento7 páginasSKM 2019 Price ListDaniel CamargoAinda não há avaliações

- Cables For Use in ATEX or IEC Applications For Zone 1 and Zone 2Documento4 páginasCables For Use in ATEX or IEC Applications For Zone 1 and Zone 2asimozmaAinda não há avaliações

- NTE 007-08-00 Normativul Retele Cabluri Cu AnexeDocumento144 páginasNTE 007-08-00 Normativul Retele Cabluri Cu Anexelionascu1970100% (1)

- Standard eDocumento1 páginaStandard edragos.dimitriuAinda não há avaliações

- Windtest: Kaiser-Wilhelm-Koog GMBHDocumento2 páginasWindtest: Kaiser-Wilhelm-Koog GMBHDamodharan ChandranAinda não há avaliações

- Oferta Generala Philips Lighting LuminairesDocumento326 páginasOferta Generala Philips Lighting LuminairesGigiese100% (2)

- Norme Deviz W2 Linii El Joasa TensiuneDocumento1.821 páginasNorme Deviz W2 Linii El Joasa TensiuneStefan RosioaraAinda não há avaliações

- E670 - Arc Suppression CoilsDocumento12 páginasE670 - Arc Suppression CoilsgfgfgAinda não há avaliações

- XLPE Insulated Power CableDocumento1 páginaXLPE Insulated Power CableMeng Xiao ZhangAinda não há avaliações

- BRILUM - IluminatDocumento121 páginasBRILUM - IluminatFilipescu Radu100% (1)

- Ingesco Pdc.E Lightning Rod: OperationDocumento2 páginasIngesco Pdc.E Lightning Rod: Operationmazu_bzAinda não há avaliações

- SUN2000-185KTL-H1 Output Characteristics Curve: Huawei Technologies Co., LTDDocumento6 páginasSUN2000-185KTL-H1 Output Characteristics Curve: Huawei Technologies Co., LTDSav SashaAinda não há avaliações

- Tangent Amp-50 - Service ManualDocumento4 páginasTangent Amp-50 - Service Manualadrian100% (1)

- Calculations Sag Tension LineDocumento5 páginasCalculations Sag Tension LineANANDAinda não há avaliações

- Home Building Management Systems ETS Project SetupDocumento53 páginasHome Building Management Systems ETS Project SetupBogdan BolboreaAinda não há avaliações

- ACSR Power Cables GuideDocumento2 páginasACSR Power Cables GuideueberschallAinda não há avaliações

- 1 LL Ip 4 1 95Documento158 páginas1 LL Ip 4 1 95arc10Ainda não há avaliações

- 10194601-DS-0201 - B - SubstationDocumento48 páginas10194601-DS-0201 - B - SubstationCarlosAinda não há avaliações

- torKVA To Amps (A) Conversion CalculaDocumento4 páginastorKVA To Amps (A) Conversion CalculaYashiro AlvaradoAinda não há avaliações

- Convertizor de Frecventa Delta ManualDocumento25 páginasConvertizor de Frecventa Delta ManualdanimihalcaAinda não há avaliações

- Calculate grounding resistance with vertical rods and connecting stripDocumento2 páginasCalculate grounding resistance with vertical rods and connecting stripPopa Mihai DanielAinda não há avaliações

- Types of BondingDocumento5 páginasTypes of Bondingsaipavan999Ainda não há avaliações

- Mainboard KT600-A ManualDocumento75 páginasMainboard KT600-A ManualRamidavaAinda não há avaliações

- High Voltage CableDocumento9 páginasHigh Voltage CableZuhdi Che RahimAinda não há avaliações

- LED Color Characteristics Fact SheetDocumento4 páginasLED Color Characteristics Fact SheetiddrxAinda não há avaliações

- Relee MediasDocumento50 páginasRelee MediasnorakutyAinda não há avaliações

- 20 Mvar Capacitor BankDocumento9 páginas20 Mvar Capacitor BankFarah Diba Pos-PosAinda não há avaliações

- Argo Ae2mi40ah - B PDFDocumento102 páginasArgo Ae2mi40ah - B PDFNIkica BukaricaAinda não há avaliações

- Calculating cable capacity for ENEL's 220kV 1200mm2 cableDocumento4 páginasCalculating cable capacity for ENEL's 220kV 1200mm2 cableAnonymous 1mTA19lAinda não há avaliações

- BTS-200 High Power Battery Capacity Test SetDocumento4 páginasBTS-200 High Power Battery Capacity Test SetKarim SenhajiAinda não há avaliações

- DatasheetsDocumento37 páginasDatasheetsAna Milagros MH100% (1)

- ZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Documento5 páginasZTT Et Expressway Tacsr'Aw TW Conductor 22 - Xj10296Benjamin SalinasAinda não há avaliações

- SET Ingenieros Technical Specification for 2XS(FL)H-GC-WTC 1x500RM/180 40/69 (72.5)kV CableDocumento3 páginasSET Ingenieros Technical Specification for 2XS(FL)H-GC-WTC 1x500RM/180 40/69 (72.5)kV CableedwinljbAinda não há avaliações

- 3c Cu Xlpe PVC 6.35 (11) KV Heavy Duty CwsDocumento2 páginas3c Cu Xlpe PVC 6.35 (11) KV Heavy Duty Cwsgari_monsantoAinda não há avaliações

- APPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDSDocumento4 páginasAPPENDIX A.1 - Ojas Infra - Chichester SS - MV Cable TDSSanjay GadhaveAinda não há avaliações

- Instrumentation Cable: ApplicationDocumento2 páginasInstrumentation Cable: Applicationbakien-canAinda não há avaliações

- Ts 240 SQMM Cable JSPLDocumento4 páginasTs 240 SQMM Cable JSPLAnonymous vcadX45TD7100% (1)

- BCC.23120008Documento2 páginasBCC.23120008abdulkawi alasharyAinda não há avaliações

- Technical Submittal For MV - Cable Data SheetsDocumento4 páginasTechnical Submittal For MV - Cable Data SheetskhaledelgamalAinda não há avaliações

- Cal-Mn Dastur T2117 Rev 2Documento4 páginasCal-Mn Dastur T2117 Rev 2Shubham BaderiyaAinda não há avaliações

- PO1541 - Ojas Infra - GSF MV TDS-v1.1Documento16 páginasPO1541 - Ojas Infra - GSF MV TDS-v1.1Sanjay GadhaveAinda não há avaliações

- XLPE Insulated Power Cable SpecificationsDocumento3 páginasXLPE Insulated Power Cable SpecificationsStefanBogdanAinda não há avaliações

- Cable TriadaDocumento4 páginasCable TriadaRaymundo Maldonado AlvarezAinda não há avaliações

- FB 02ys (ST) Yqy FLDocumento1 páginaFB 02ys (ST) Yqy FLbakien-canAinda não há avaliações

- Single Core Cables To BS 6622Documento10 páginasSingle Core Cables To BS 6622rose chenAinda não há avaliações

- Vito PDFDocumento366 páginasVito PDFAnonymous LNdiNQ100% (1)

- Certificare Noark2Documento1 páginaCertificare Noark2Anonymous LNdiNQAinda não há avaliações

- Prescriptie Energetica IT (S) 18-86Documento95 páginasPrescriptie Energetica IT (S) 18-86Anonymous LNdiNQAinda não há avaliações

- TT 110kV Pentru Servicii Interne StatiiDocumento4 páginasTT 110kV Pentru Servicii Interne StatiiAnonymous LNdiNQAinda não há avaliações

- Prescriptie Energetica IT (L) 12-86Documento184 páginasPrescriptie Energetica IT (L) 12-86Anonymous LNdiNQAinda não há avaliações

- Prescriptie Energetica IT (L) 12-86Documento184 páginasPrescriptie Energetica IT (L) 12-86Anonymous LNdiNQAinda não há avaliações

- Prescriptie Energetica IT (S) 11-89Documento49 páginasPrescriptie Energetica IT (S) 11-89Anonymous LNdiNQAinda não há avaliações

- Fibre Optic LinesDocumento23 páginasFibre Optic LinesAnonymous LNdiNQAinda não há avaliações

- Iproeb SF-162.2008Documento18 páginasIproeb SF-162.2008Anonymous LNdiNQAinda não há avaliações

- Prescriptie Energetica IT (H) 6 88Documento58 páginasPrescriptie Energetica IT (H) 6 88Anonymous LNdiNQAinda não há avaliações

- Iproeb SF-162.2008Documento18 páginasIproeb SF-162.2008Anonymous LNdiNQAinda não há avaliações

- PIC For BeginnersDocumento147 páginasPIC For Beginnersapi-3695801100% (45)

- Comfort 220 Installation GuideDocumento56 páginasComfort 220 Installation GuideAnonymous LNdiNQAinda não há avaliações

- Adss IproebDocumento1 páginaAdss IproebAnonymous LNdiNQAinda não há avaliações

- Power Control and Protection Products - June - 2013Documento35 páginasPower Control and Protection Products - June - 2013Anonymous LNdiNQAinda não há avaliações

- Pag 437-472Documento36 páginasPag 437-472Anonymous LNdiNQAinda não há avaliações

- Datasheet Trio 20.0 - 27.6 TL en (1) InvertorDocumento4 páginasDatasheet Trio 20.0 - 27.6 TL en (1) InvertorAnonymous LNdiNQAinda não há avaliações

- Catalogo General CubigelDocumento86 páginasCatalogo General CubigelgladysAinda não há avaliações

- The Clap SwitchDocumento10 páginasThe Clap SwitchCM-A-12-Aditya BhopalbadeAinda não há avaliações

- Implementing an Automated Power Factor Corrector for an Induction MotorDocumento5 páginasImplementing an Automated Power Factor Corrector for an Induction MotorPratik ManmodeAinda não há avaliações

- Rajasthan PET Chemistry 1997 Exam with Detailed SolutionsDocumento34 páginasRajasthan PET Chemistry 1997 Exam with Detailed SolutionsYumit MorwalAinda não há avaliações

- Analysis of Dielectric ResponseDocumento221 páginasAnalysis of Dielectric ResponsearunjothiAinda não há avaliações

- CMOS Neural Amplifier Measures Spike Amplitudes <40Documento4 páginasCMOS Neural Amplifier Measures Spike Amplitudes <40Alex WongAinda não há avaliações

- Fabrication of TransistorsDocumento10 páginasFabrication of TransistorsDurga PrasathAinda não há avaliações

- Low Voltage Audio Power AmplifierDocumento9 páginasLow Voltage Audio Power AmplifierJuan V Castro SotoAinda não há avaliações

- Ipc-9800 Manual (6064)Documento108 páginasIpc-9800 Manual (6064)visitorAinda não há avaliações

- Doble - Acceptance and Maintenance Testing For Medium-Voltage Electrical Power CablesDocumento23 páginasDoble - Acceptance and Maintenance Testing For Medium-Voltage Electrical Power CablessulemankhalidAinda não há avaliações

- CET Power - User Manual - Bravo - 7.4Documento52 páginasCET Power - User Manual - Bravo - 7.4Hoàng HảiAinda não há avaliações

- Capacitive TransducersDocumento5 páginasCapacitive TransducersKhairunnisa Abu KhairAinda não há avaliações

- Inverter and Multilevel Inverter - Types, Advantages and ApplicationsDocumento19 páginasInverter and Multilevel Inverter - Types, Advantages and ApplicationsSUNIL MANJHIAinda não há avaliações

- Lecturer Tutorial Sp025 20212022Documento135 páginasLecturer Tutorial Sp025 20212022faris zainuddinAinda não há avaliações

- Design of Tesla's Two-Phase Inductor: Đorđe M. Lekić, Petar R. MatićDocumento8 páginasDesign of Tesla's Two-Phase Inductor: Đorđe M. Lekić, Petar R. MatićJosé Antonio NevesAinda não há avaliações

- Induction Generator Theory and ApplicationDocumento8 páginasInduction Generator Theory and ApplicationDiego Nicolás López-RamírezAinda não há avaliações

- SSC Je Ee 2016 2Documento119 páginasSSC Je Ee 2016 2Yaswanth DandiboinaAinda não há avaliações

- 10Documento14 páginas10Ajmal FarooqAinda não há avaliações

- Emtl Question Bank Imp QsDocumento9 páginasEmtl Question Bank Imp QsSri MurthyAinda não há avaliações

- AN10009 Differential Terminations Rev1.2Documento18 páginasAN10009 Differential Terminations Rev1.2eppramod3271Ainda não há avaliações

- 10 MHz Reference Oscillator Circuit DesignDocumento7 páginas10 MHz Reference Oscillator Circuit Designnaveen jaiswalAinda não há avaliações

- SSP 204 EspDocumento64 páginasSSP 204 Espภูเก็ต เป็นเกาะAinda não há avaliações

- Ipdf Sitop DC Ups Batterybrochure enDocumento26 páginasIpdf Sitop DC Ups Batterybrochure enBruno ZagoAinda não há avaliações

- Circuit Stepper Motor DriverDocumento17 páginasCircuit Stepper Motor DriverkalpicoAinda não há avaliações

- CSEE UM71 AF Jointless Track Circuits - Set-Up, Test and CertificationDocumento8 páginasCSEE UM71 AF Jointless Track Circuits - Set-Up, Test and CertificationAmir EshaghiAinda não há avaliações

- Modelling Underground Cables High Voltage TransmissionDocumento11 páginasModelling Underground Cables High Voltage TransmissionjagayaAinda não há avaliações

- Editor - Juan A. Martinez-Velasco - Transient Analysis of Power Systems - A Practical Approach (2020, John Wiley & Sons) - Libgen - LiDocumento610 páginasEditor - Juan A. Martinez-Velasco - Transient Analysis of Power Systems - A Practical Approach (2020, John Wiley & Sons) - Libgen - LiDDdivyaAinda não há avaliações

- Interference Suppression PCX2 335M Film Capacitors (100 )Documento7 páginasInterference Suppression PCX2 335M Film Capacitors (100 )eduinnAinda não há avaliações

- Manual de Servicio K LED43FHDRST2Documento2 páginasManual de Servicio K LED43FHDRST2Hamza Abbasi AbbasiAinda não há avaliações

- Service Manual: MVC-CD200/CD300Documento132 páginasService Manual: MVC-CD200/CD300ricahard61Ainda não há avaliações