Escolar Documentos

Profissional Documentos

Cultura Documentos

Bin Duri Kandis Ex Palas

Enviado por

Bm X Breaker0 notas0% acharam este documento útil (0 voto)

75 visualizações11 páginasOnce you upload an approved document, you will be able to read and download this document

Pengadaan Komputer Mainframe Server Oleh Cv Tuah Beusare

Ferdinand Tambunan

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

XLS, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoOnce you upload an approved document, you will be able to read and download this document

Pengadaan Komputer Mainframe Server Oleh Cv Tuah Beusare

Ferdinand Tambunan

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato XLS, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

75 visualizações11 páginasBin Duri Kandis Ex Palas

Enviado por

Bm X BreakerOnce you upload an approved document, you will be able to read and download this document

Pengadaan Komputer Mainframe Server Oleh Cv Tuah Beusare

Ferdinand Tambunan

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato XLS, PDF, TXT ou leia online no Scribd

Você está na página 1de 11

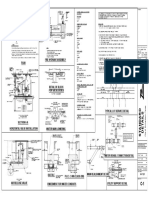

PEMERINTAH REPUBLIK INDONESIA

KEMENTERIAN PEKERJAAN UMUM

DIREKTORAT JENDERAL BINA MARGA

PAKET PELEBARAN JALAN DURI - KANDIS (MYC)

SUMBER MATERIAL : COLD BIN

1. COARSE AGGREGATE (RETAINED NO 4 SIEVE)

Sample 1 Sample 2 Sample 1 Sample 2 Sample 1 Sample 2 Sample 1 Sample 2

Weight of oven dry sample in air A (Gr) 2367 2454 2077 2108 1820.8 1600

Weight of saturated surface dry sample in air B (Gr) 2386 2474 2097 2126 1838 1614

Weight of saturated sample in air C (Gr) 1476 1532 1297 1315 1128 992

Sample 1 Sample 2 Average Sample 1 Sample 2 Average Sample 1 Sample 2 Average Sample 1 Sample 2 Average

Bulk Specific Gravity (Gr/cc) A / (B-C) 2.601 2.605 2.603 2.596 2.599 2.598 2.565 2.572 2.568 0.000 0.000 0.000

App Specific Gravity (Gr/cc) A / (A-C) 2.657 2.662 2.659 2.663 2.658 2.661 2.628 2.632 2.630 0.000 0.000 0.000

Ssd Specific Gravity (Gr/cc) B / (B-C) 2.622 2.626 2.624 2.621 2.621 2.621 2.589 2.595 2.592 0.000 0.000 0.000

Absortion (%) (B-A)/A x 100 0.803 0.815 0.809 0.963 0.854 0.908 0.945 0.875 0.910 0.000 0.000 0.000

2. FINE AGGREGATE (PASSING NO 4 SIEVE)

Sample 1 Sample 2 Sample 1 Sample 2 Sample 1 Sample 2 Sample 1 Sample 2

Weight of saturated surface dry sample in air 500 500 500 500 500 500

Weight of oven dry sample in air A (Gr) 492.3 492 490.8 490.6 492.1 493.3

Weight of picnometer filled with water B (Gr) 1270.1 1225 1225 1270.1 1225 1225

Weight of picnometer filled with saturated water C (Gr) 1575 1532 1531 1575 1529.5 1530

Sample 1 Sample 2 Average Sample 1 Sample 2 Average Sample 1 Sample 2 Average Sample 1 Sample 2 Average

Bulk Specific Gravity (Gr/cc) A / (B+500-C) 0.000 0.000 0.000 2.523 2.549 2.536 2.530 2.515 2.522 2.517 2.530 2.523

App Specific Gravity (Gr/cc) A / (B+A-C) 0.000 0.000 0.000 2.627 2.659 2.643 2.656 2.642 2.649 2.623 2.620 2.621

Ssd Specific Gravity (Gr/cc) 500/(B+500-C) 0.000 0.000 0.000 2.563 2.591 2.577 2.577 2.563 2.570 2.558 2.564 2.561

Absortion (%) (500-A)/Ax100 0.000 0.000 0.000 1.564 1.626 1.595 1.874 1.916 1.895 1.605 1.358 1.482

3. AVERAGE SPESIFIC GRAVITY OF AGGREGAT 4. RESULT TEST

CA 1 MA 1/2 FA + F SAND CA 1 MA 1/2 FA+F SAND

100.00 4.70 0.75 0.00 Bulk Specific Gravity (Gr/cc) 2.603 2.539 2.523 2.523

0.00 95.30 99.25 100.00 App Specific Gravity (Gr/cc) 2.659 2.644 2.649 2.621

Ssd Specific Gravity (Gr/cc) 2.624 2.579 2.570 2.561

Absortion (%) 0.809 1.563 1.888 1.482

FA + Filler SAND

KONSULTAN KONTRAKTOR

Percentage of aggregate retained No 4 sieve (%)

Percentage of aggregate passing No 4 sieve (%)

BINA MARGA

SAND

CA 1" MA 1/2 FA + Filler SAND

CA 1" MA 1/2

CA 1" MA 1/2 FA + Filler

CA 1" MA 1/2 FA + Filler

SNI 03-1969-1990 & SNI 03-1970-1990

PT ADHI KARYA ( PERSERO ) Tbk.

PT ARTERI CIPTA RENCANA

KONSULTAN

SAND

SPECIPIC GRAVITY TEST

KONTRAKTOR

PEMERINTAH REPUBLIK INDONESIA

KEMENTERIAN PEKERJAAN UMUM PT ARTERI CIPTA RENCANA PT ADHI KARYA ( PERSERO ) Tbk.

DIREKTORAT JENDERAL BINA MARGA KONSULTAN KONTRAKTOR

PAKET PELEBARAN JALAN DURI - KANDIS (MYC)

FILLER

SUMBER MATERIAL : COLD BIN

Average

Individual Wt Individual Wt Passing

Inch mm Retained (Gr) Retained (Gr) Retaind (%) Passing (%) Retained (Gr) Retained (Gr) Retaind (%) Passing (%) (%)

1 25.4 0 0 0.00 100.00 0 0 0.00 100.00 100.00

3/4 19.1 0 0 0.00 100.00 0 0 0.00 100.00 100.00

1/2 12.7 0 0 0.00 100.00 0 0 0.00 100.00 100.00

3/8 9.5 0 0 0.00 100.00 0 0 0.00 100.00 100.00

No. 4 4.76 0 0 0.00 100.00 0 0 0.00 100.00 100.00

No. 8 2.88 0 0 0.00 100.00 0 0 0.00 100.00 100.00

No. 16 1.19 0 0 0.00 100.00 0 0 0.00 100.00 100.00

No. 30 0.595 0 0 0.00 100.00 0 0 0.00 100.00 100.00

No. 50 0.297 0 0 0.00 100.00 0 0 0.00 100.00 100.00

No. 100 0.15 0.6 0.6 0.04 99.96 0.7 0.7 0.04 99.96 99.96

No. 200 0.074 5.9 5.9 0.36 99.64 6 6 0.37 99.63 99.63

1634 1613.5

Average

Individual Wt Individual Wt Passing

Inch mm Retained (Gr) Retained (Gr) Retaind (%) Passing (%) Retained (Gr) Retained (Gr) Retaind (%) Passing (%) (%)

1 25.4

3/4 19.1

1/2 12.7

3/8 9.5

No. 4 4.76

No. 8 2.88

No. 16 1.19

No. 30 0.595

No. 50 0.297

No. 100 0.15

No. 200 0.074

BINA MARGA KONSULTAN KONTRAKTOR

SIEVE ANALYSIS TEST

SNI 03-1968-1990

Total Weight

Total Weight

Sieve Size

Sieve Size

Sample 1 Sample 2

Weight Cumulative Weight Cumulative

Sample 1 Sample 2

Weight Cumulative Weight Cumulative

PEMERINTAH REPUBLIK INDONESIA

KEMENTERIAN PEKERJAAN UMUM PT ARTERI CIPTA RENCANA PT ADHI KARYA ( PERSERO ) Tbk.

DIREKTORAT JENDERAL BINA MARGA KONSULTAN KONTRAKTOR

PAKET PELEBARAN JALAN DURI - KANDIS (MYC)

SUMBER MATERIAL : COLD BIN

1" 3/4" 1/2" 3/8" # 4 # 8 # 16 # 30 # 50 #100 # 200

25.4 19 12.7 9.53 4.76 2.38 1.19 0.6 0.3 0.15 0.075

100.00 73.68 22.04 5.12 4.13 3.23 1.99 1.35 1.10 0.92 0.65

100.00 100.00 100.00 76.16 20.41 5.44 3.08 1.76 1.64 1.35 1.00

100.00 100.00 100.00 100.00 95.30 66.86 47.81 34.34 25.31 17.26 9.00

100.00 100.00 100.00 100.00 100.00 76.28 63.00 46.37 24.29 6.83 2.67

100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 99.96 99.63

CA 1 " 31 31.00 22.84 6.83 1.59 1.28 1.00 0.62 0.42 0.34 0.29 0.20

MA 1/2 36 36.00 36.00 36.00 27.42 7.35 1.96 1.11 0.63 0.59 0.49 0.36

FA 23 23.00 23.00 23.00 23.00 21.92 15.38 11.00 7.90 5.82 3.97 2.07

SAND 8 8.00 8.00 8.00 8.00 8.00 6.10 5.04 3.71 1.94 0.55 0.21

FILLER 2 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 1.99

Total Campuran 100.00 100.00 91.84 75.83 62.00 40.55 26.44 19.76 14.66 10.70 7.29 4.84

100.00 100.00 90.00 80.00 56.00 34.60 22.30 16.70 13.70 11.00 8.00

100.00 90.00 71.00 58.00 37.00 23.00 15.00 10.00 7.00 5.00 4.00

Pb = 0,035(%CA) + 0,045(%FA) + 0,18(%FF) + K CA 73.56

FA 21.60

Pb = 5.42 % FF 4.84

K 1

BINA MARGA KONSULTAN KONTRAKTOR

ANALISIS GRADASI KOMBINASI

FINE AGGREGATE

Spec Min

COARSE AGREGATE 1

FILLER

NATURAL SAND

KOMPOSISI CAMPURAN

SPEC GRADASI

Spec Max

MEDIUM AGREGATE 1/2"

UKURAN SARINGAN

Inch

mm

DATA MATERIAL

0

10

20

30

40

50

60

70

80

90

100

0 0 1 10 100

P

e

r

s

e

n

L

o

l

o

s

(

%

)

Ukuran Saringan ( mm )

Grafik Analisis Gradasi Kombinasi

No.200 No.100 No.50 No.30 No16 No.8 No.4 3/8 1/2 3/4 1

PEMERINTAH REPUBLIK INDONESIA

KEMENTERIAN PEKERJAAN UMUM

DIREKTORAT JENDERAL BINA MARGA

PAKET PELEBARAN JALAN DURI - KANDIS (MYC)

SOURCE OF MATERIAL :COLD BIN

AGGREGATE SURFACE AREA

Surface

Area

1 " 100.00 0.41

3/4 " 91.84 0.41 1 x 0.41

1/2 " 75.83 0.41

3/8 " 62.00 0.41 0.41

No.4 40.55 0.41 0.17

No.8 26.44 0.82 0.22

No.16 19.76 1.64 0.32

No.30 14.66 2.87 0.42

No.50 10.70 6.14 0.66

No.100 7.29 12.29 0.90

No.200 4.84 32.77 1.58

TOTAL AGGREGATE SURFACE AREA : 4.67 M2/Kg

Factor

Sieve Size Percent S.A

BINA MARGA KONSULTAN KONTRAKTOR

Passing

PT ADHI KARYA ( PERSERO ) Tbk.

KONTRAKTOR

PT ARTERI CIPTA RENCANA

KONSULTAN

CALCULATION OF AGGREGATE SURFACE AREA

AND

PT ADHI KARYA ( PERSERO ) Tbk.

PEMERINTAH REPUBLIK INDONESIA KONTRAKTOR

KEMENTERIAN PEKERJAAN UMUM

DIREKTORAT JENDERAL BINA MARGA PT ARTERI CIPTA RENCANA

PAKET PELEBARAN JALAN DURI - KANDIS (MYC) KONSULTAN

Specific Gravity Aggregate

SOUESE MATERIAL : COLD BIN

Engineer : Penetration Grade of Bitumen = AC 60/70 No Aggregate oven dry app

Spesific Gravity of Bitument, T = 1.035 a CA 1 2.603 2.659

Date : Calibration Ring, Ring = 26.15 b MA 2.539 2.644

c FA+F 2.523 2.649

Mix To Be Laid At : d SAND 2.523 2.621

Spec Bitument Bulk Sp Gg Eff Sp Gg Max Sp Gr Volume Bulk Absortion Bit % eff AC Flow Marshall Agg Bitument

No Content Of Total Of Total Combined In Air In Water SSD Of Density (% By Wt) BY Mix Eff AC Agg Air Void VMA % Voids Measure Adjust (mm) Qountient Surface Film

Agg Agg Mix Specimen (Gr/cc) Of Tot Mix ( %) Filleds (Kg) (Kg/mm) Area (m

2

/Kg) Thickness(m)

A B C D E F G H I J K L M N O P Q R S T U V

% Bit By Refer Refer Refer From From From Refer Refer From From Refer Refer

Wt Of Mix Note 1 Note 2 Note 3 Lab Lab Lab Note 4 Note 5 Lab Lab Drawing Note 6

4 6.00 2.553 2.602 2.386 1214.7 692.8 1220.8 528.0 2.301 52 1305 4.00

1286.9 730.0 1292.4 562.4 2.288 54 1214 4.10

1270.5 724.0 1276.0 552.0 2.302 48 1117 3.70

2.297 0.72 5.32 11.81 84.56 3.72 15.53 76.02 1212 3.93 308 4.67 11.60

5 6.50 2.553 2.602 2.369 1200.0 685.8 1208.3 522.5 2.297 40 1046 4.50

1230.0 698.0 1236.9 538.9 2.282 43 1046 4.30

1214.0 689.9 1221.0 531.1 2.286 35 879 4.60

2.288 0.72 5.83 12.89 83.80 3.42 16.30 79.05 990 4.47 222 4.67 12.78

1. B = (a+b+c+d+e) / (a/oven

a

+ b/oven

b

+ c/oven

c

+ d/oven

d

)

2. C ={ (a+b+c+d+e) / (a/app

a

+ b/app

b

+ c/app

c

+ d/app

d

) + B } / 2 REMARK

3. D = 100 / { (100-A)/C + A/T } a b c d e f ,

4. J = 100(C-B)/(B*C)*T 31 36 23 8 2 0

5. K = A - (100 - A )/100 X J

6 R = 1000(A-J) / UT(100-A)

If Q > 0,8 then formula shown for D shall not be used

and shall de optained instead ASSTHO T 209 - 74

KONTRAKTOR

PROPERTIES OF HIGH DURABILITY ASPHALT MIXES

( L / O ) x 100 R/T I x K / T

BY THE MARSHALL METHOD

(100-A)I /B 100(D - I) / D L + N

BINA MARGA KONSULTAN

Weight (Gram) Volume % ot Total Stability

E / H

MIX PROPORTION

( % BY WT OF COMB AGGREGATE)

G - F

PT ADHI KARYA ( PERSERO ) Tbk.

PEMERINTAH REPUBLIK INDONESIA KONTRAKTOR

KEMENTERIAN PEKERJAAN UMUM

DIREKTORAT JENDERAL BINA MARGA PT ARTERI CIPTA RENCANA

PAKET PELEBARAN JALAN DURI - KANDIS (MYC) KONSULTAN

SOUESE MATERIAL : COLD BIN

Specific Gravity Aggregate

Penetration Grade of Bitumen = AC 60/70 No Aggregate oven dry app

Spesific Gravity of Bitument, T = 1.035 a CA 1 2.603 2.659

Calibration Ring, Ring = 26.15 b MA 2.539 2.644

c FA+F 2.523 2.649

d SAND 2.523 2.621

Spec Bitument Bulk Sp Gg Eff Sp Gg Max Sp Gr Volume Bulk Absortion Bit % eff AC Flow Marshall Agg Bitument

No Content Of Total Of Total Combined In Air In Water SSD Of Density (% By Wt) BY Mix Eff AC Agg Air Void VMA % Voids Measure Adjust (mm) Qountient Surface Film

Agg Agg Mix Specimen (Gr/cc) Of Tot Mix ( %) Filleds (Kg) (Kg/mm) Area (m

2

/Kg) Thickness(m)

A B C D E F G H I J K L M N O P Q R S T U V

% Bit By Refer Refer Refer From From From Refer Refer From From Refer Refer

Wt Of Mix Note 1 Note 2 Note 3 Lab Lab Lab Note 4 Note 5 Lab Lab Drawing Note 6

1 5.00 2.553 2.602 2.419 1243.6 710.0 1247.8 537.8 2.312

1232.0 705.0 1238.5 533.5 2.309

2.311 0.73 4.31 9.62 85.98 4.48 14.10 68.21

2 5.50 2.553 2.602 2.402 1218.0 700.0 1223.1 523.1 2.328

1236.4 707.7 1240.0 532.3 2.323

2.326 0.73 4.81 10.82 86.08 3.19 14.01 77.20

3 6.00 2.553 2.602 2.386 1230.5 703.0 1233.5 530.5 2.320

1228.0 703.0 1231.0 528.0 2.326

2.323 0.72 5.32 11.94 85.51 2.64 14.58 81.88

1. B = (a+b+c+d+e) / (a/oven

a

+ b/oven

b

+ c/oven

c

+ d/oven

d

)

2. C ={ (a+b+c+d+e) / (a/app

a

+ b/app

b

+ c/app

c

+ d/app

d

) + B } / 2 REMARK

3. D = 100 / { (100-A)/C + A/T } a b c d e ,

4. J = 100(C-B)/(B*C)*T 31 36 23 8 2

5. K = A - (100 - A )/100 X J

6 R = 1000(A-J) / UT(100-A)

If Q > 0,8 then formula shown for D shall not be used 95.5

and shall de optained instead ASSTHO T 209 - 74 98.6515

101.251

MARSHALL PRD

PROPERTIES OF HIGH DURABILITY ASPHALT MIXES

BY THE MARSHALL METHOD

Volume % ot Total Stability

G - F E / H I x K / T (100-A)I /B 100(D - I) / D L + N

BINA MARGA KONSULTAN KONTRAKTOR

MIX PROPORTION

( % BY WT OF COMB AGGREGATE)

( L / O ) x 100 R/T

Weight (Gram)

PT ADHI KARYA ( PERSERO ) Tbk.

PEMERINTAH REPUBLIK INDONESIA KONTRAKTOR

KEMENTERIAN PEKERJAAN UMUM

DIREKTORAT JENDERAL BINA MARGA PT ARTERI CIPTA RENCANA

PAKET PELEBARAN JALAN DURI - KANDIS (MYC) KONSULTAN

SOUESE MATERIAL : COLD BIN

Specific Gravity Aggregate

Penetration Grade of Bitumen = AC 60/70 No Aggregate oven dry app

Spesific Gravity of Bitument, T = 1.035 a CA 1 2.603 2.659

Calibration Ring, Ring = 26.15 b MA 2.539 2.644

c FA+F 2.523 2.649

d SAND 2.523 2.621

Spec Bitument Bulk Sp Gg Eff Sp Gg Max Sp Gr Volume Bulk Absortion Bit % eff AC Flow Marshall Agg Bitument

No Content Of Total Of Total Combined In Air In Water SSD Of Density (% By Wt) BY Mix Eff AC Agg Air Void VMA % Voids Measure Adjust (mm) Qountient Surface Film

Agg Agg Mix Specimen (Gr/cc) Of Tot Mix ( %) Filleds (Kg) (Kg/mm) Area (m

2

/Kg) Thickness(m)

A B C D E F G H I J K L M N O P Q R S T U V

% Bit By Refer Refer Refer From From From Refer Refer From From Refer Refer

Wt Of Mix Note 1 Note 2 Note 3 Lab Lab Lab Note 4 Note 5 Lab Lab Drawing Note 6

1 MARSHALL STANDART PADA KADAR ASPHALT OPTIMUM

5.60 2.553 2.602 2.399 1238.5 706.8 1244.5 537.7 2.303 54 1313 3.15

1243.5 708.3 1248.3 540.0 2.303 50 1216 3.40

1245.0 710.0 1251.0 541.0 2.301 49 1192 3.40

2.302 0.73 4.92 10.94 85.13 4.02 14.96 73.10 1240 3.32 374 4.67 10.67

2 SETELAH PERENDAMAN 24 JAM PADA 60 C PADA KADAR ASPHALT OPTIMUM

5.60 2.553 2.602 2.399 1230.1 703.6 1236.2 532.6 2.310 49 1230 3.30

1244.5 708.6 1249.5 540.9 2.301 46 1119 3.50

1241.8 706.9 1246.8 539.9 2.300 45 1094 3.20

2.303 0.73 4.92 10.94 85.17 3.98 14.92 73.32 1148 3.33 344 4.67 10.67

1147.7 x 100 = 92.54 %

1240.3

3

5.60 2.553 2.602 2.399 1243.0 711.5 1246.5 535.0 2.323

1232.3 705.6 1236.0 530.4 2.323

1235.4 710.0 1238.4 528.4 2.338

2.328 0.73 4.92 11.06 86.08 2.95 14.01 78.94

1. B = (a+b+c+d+e) / (a/oven

a

+ b/oven

b

+ c/oven

c

+ d/oven

d

)

2. C ={ (a+b+c+d+e) / (a/app

a

+ b/app

b

+ c/app

c

+ d/app

d

) + B } / 2 REMARK

3. D = 100 / { (100-A)/C + A/T } a b c d e ,

4. J = 100(C-B)/(B*C)*T 31 36 23 8 2

5. K = A - (100 - A )/100 X J

6 R = 1000(A-J) / UT(100-A)

If Q > 0,8 then formula shown for D shall not be used

and shall de optained instead ASSTHO T 209 - 74

BINA MARGA KONSULTAN KONTRAKTOR

R/T

RETAINED MARSHALL STABILITY AFTER SOAKING 24 HOUR :

MIX PROPORTION

( % BY WT OF COMB AGGREGATE)

PROPERTIES OF HIGH DURABILITY ASPHALT MIXES

BY THE MARSHALL METHOD

G - F E / H

MARSHALL PERCENTAGE REFUSAL DENSITY (PRD)

( L / O ) x 100 L + N

Weight (Gram) Volume % ot Total Stability

(100-A)I /B I x K / T 100(D - I) / D

PEMERINTAH REPUBLIK INDONESIA

KEMENTERIAN PEKERJAAN UMUM PT ARTERI CIPTA RENCANA PT ADHI KARYA ( PERSERO ) Tbk.

DIREKTORAT JENDERAL BINA MARGA KONSULTAN KONTRAKTOR

PAKET PELEBARAN JALAN DURI - KANDIS (MYC)

SUMBER MATERIAL : COLD BIN

1 Bulk Density 2.304 Gr/cc

2 Stability 1260 Kg

3 Flow 3.60 mm

4 Air Voids 4.00 %

5 Void Filleds 73.00 %

6 VMA 15.00 %

7 M, Q 345 KG/mm

8 VIM PRD 3.00 %

9 Asphalt 5.60 %

BINA MARGA KONSULTAN

HOT MIX DESIGN BY MARSHALL METHOD

TEST PROPERTY CURVES

KONTRAKTOR

700

800

900

1000

1100

1200

1300

1400

4.00 4.50 5.00 5.50 6.00 6.50 7.00

S

t

a

b

i

l

i

t

y

(

K

g

)

% Asphalt by Total Mix

STABILITY

1

2

3

4

5

6

7

8

9

4.00 4.50 5.00 5.50 6.00 6.50 7.00

A

i

r

V

o

i

d

s

(

%

)

% Asphalt by Total Mix

AIR VOIDS

50

55

60

65

70

75

80

85

4.00 4.50 5.00 5.50 6.00 6.50 7.00

V

o

i

d

s

F

i

l

l

e

d

s

(

%

)

% Asphalt by Total Mix

VOIDS FILLEDS

2.240

2.250

2.260

2.270

2.280

2.290

2.300

2.310

2.320

4.00 4.50 5.00 5.50 6.00 6.50 7.00

B

u

l

k

D

e

n

s

i

t

y

(

g

r

/

c

c

)

% Asphalt by total Mix

BULK DENSITY

2.0

2.5

3.0

3.5

4.0

4.5

5.0

4.00 4.50 5.00 5.50 6.00 6.50 7.00

F

l

o

w

(

m

m

)

% Asphalt by Total Mix

FLOW

12.0

13.0

14.0

15.0

16.0

17.0

18.0

4.00 4.50 5.00 5.50 6.00 6.50 7.00

V

M

A

(

%

)

% Asphalt by Total Mix

V M A

100

150

200

250

300

350

400

450

500

4.00 4.50 5.00 5.50 6.00 6.50 7.00

M

a

r

s

h

a

l

l

Q

u

o

t

i

e

n

t

% Asphalt By Total Mix

MARSHALL QUOTIENT

0

1

2

3

4

5

6

7

8

9

4 4.5 5 5.5 6 6.5 7

Stability (Kg)

Bulk Density

Air Voirs

Flow (mm)

Voids Filleds (%)

VMA

MQ

PRD

VIM 75 X 2

VIM 400 x 2 Blows

PEMERINTAH REPUBLIK INDONESIA

KEMENTERIAN PEKERJAAN UMUM PT ARTERI CIPTA RENCANA PT ADHI KARYA ( PERSERO ) Tbk.

DIREKTORAT JENDERAL BINA MARGA KONSULTAN KONTRAKTOR

PAKET PELEBARAN JALAN DURI - KANDIS (MYC)

UNIT

1. Abration Test By Loss Angelis ( % ) 29.15 Max 30

2.Coating and Stripping ( % ) > 95 Min 95

3. Specific Gravity Of Bitumen ( % ) 1.033 Min 1.0

%

BY WT OF TOTAL AGREGATE

Coarse Aggregate 1.5" 39 8.50 Cm Hot Bin I 34

Medium Aggregate 36 11.11 CM Hot Bin II 26

Fine Aggregate 17 6.17 CM Hot Bin III 18

Natural Sand 6 1.44 Cm Hot Bin IV 20

Filler 2 Filler 2

Asphalt 5.1 Asphalt 5.10

Aditif 0.3 Aditif 0.30

COMBINED AGGREGATE

SIEVE SIZE 1.5 " 1 " 3/4 " 1/2 " 3/8 " # 4 # 8 # 16 # 30 # 50 # 100 # 200

Cold Bin 100.00 94.89 80.42 65.58 51.49 31.91 20.59 15.66 11.85 9.42 6.22 4.39

Hot Bin 100.00 94.20 80.76 66.10 51.69 31.82 20.45 14.90 11.56 9.27 5.85 4.37

Spec Max 100 100.00 90.00 76.00 66.00 39.50 26.80 18.10 13.60 11.40 9.00 7.00

Spec Min 100 90.00 73.00 55.00 45.00 28.00 19.00 12.00 7.00 5.00 4.50 3.00

AGGREGATE FRACTION BY AGGREGATE

MIX COMPOSITION

% Spec % Spec

Coarse Aggregate Fraction ( CA) 79.41 Coarse Aggregate Fraction ( CA) 79.55

Fine Aggregate Fraction (Fa ) 16.20 Fine Aggregate Fraction (Fa ) 16.08

Filler Fraction ( FF ) (FF) 4.39 Filler Fraction ( FF ) (FF) 4.37

Asphalt Content 5.10 Asphalt Content 5.10

Total 100 Total 100

MARSHALL TEST

DESCRIPTION COLD BIN HOT BIN SPECIFICATION

Bulk Sp Gr By Total Aggregate Gr/cc 2.569 2.569 -

Effective Spgr By Total Aggregate Gr/cc 2.611 2.612

Bitument Content By weight of Mix % 5.1 5.1

Eff. Asphalt Content % 4.520 4.510 4

Absorption Asphalt (% By Wt Total Aggregate) % 0.61 0.62 Max 1.2

Void In Mineral Aggregate ( VMA ) % 14.67 14.72 14

Void In Mix ( Vim ) % 4.57 4.63 3.5 - 5.0

Void In Refusal % 3.25 3.26 Min 2.5

Voids Filled With Bitument ( VFB ) % 68.89 68.57 63

Marshall Stability ( MS ) Kg 2284 2270 Min 800

Retained Marshall Stability After Soaked 24 H at 60 C % 93.59 93.55 Min 90

Marshall Flow ( MF ) MM 4.85 4.80 Min 3.0

Marshall Quotiont ( MQ ) Kg / mm 471 473 Min 250

Aggregate Surface Area M2/ kg 4.09 4.01 -

Bitumen Film Thickness ( BFT ) MMicron 11.19 11.41 Min 7.5

Temperature Mix c 150 150 -

Date : Date : Date :

BINA MARGA QUALITY ENGINEER QUALITY CONTROL

COLD BIN

MIX COMPOSITION

HOT BIN

EMPLOYER CONSULTANT CONTRACTOR

Pangkalan

Bangkinang

Bangkinang

Bangkinang

Semen Type I

Exxon Asia Pasific Pte Ltd

COLD BIN %

MATERIAL OPEN GATE COLD BIN HOT BIN

SOURCES 35 TON/HOURS

SUMMARY TEST RESULT

JOB MIX FORMULA

AC - BASE COURSE

DESCRIPTION MATERIAL TEST TEST RESULT. SPEC.

PEMERINTAH REPUBLIK INDONESIA

KEMENTERIAN PEKERJAAN UMUM

DIREKTORAT JENDERAL BINA MARGA

PAKET PELEBARAN JALAN DURI - KANDIS (MYC)

NOMOR : / EXT / AK / DK(MYC) / / 2011 TANGGAL

KETERANGAN

HASIL TES LAPIS PONDASI

LABORATORIUM AGREGATE KELAS - B

LAPIS PONDASI

AGREGATE KELAS - A

AC - BASE COURSE

AC - BINDER COURSE

AC - WEARING COURSE

BETON KLASS - 400

LAIN - LAIN

MATERIAL SERTIFIKAT

CONTOH

LAIN LAIN

CATATAN

PERMINTAAN UNTUK DISETUJUI UNTUK MENGETAHUI

DISPOSITION DISETUJUI

DISETUJUI DNG CATATAN

TDK DISETUJUI

CATATAN UNTUK DISETUJUI

PT ADHI KARYA ( PERSERO ) Tbk.

KONTRAKTOR

PT ARTERI CIPTA RENCANA

KONSULTAN

DISETUJUI OLEH

PPK 3 (DURI - PEKANBARU)

( SURAT PENGAJUAN )

URAIAN

PT ARTERI CIPTA RENCANA

TRANSMITTAL

DIAJUKAN OLEH

PT. ADHI KARYA (PERSERO)

EDRIZAL ZARKASI

PROJECT MANAGER

DIKETAHUI OLEH

D A R M A W I , ST

NIP. 19750220200502 SITE ENGINEER

( A C - B C )

PT ARTERI CIPTA RENCANA

SATUAN KERJA NON VERTIKAL TERTENTU PELAKSANA JALAN NASIONAL WILAYAH I PROV RIAU

PEKERJAAN KEGIATAN PPK - 3 ( DURI - PEKANBARU)

PAKET

JOB MIX DESIGN

PELEBARAN JALAN DURI - KANDIS (MYC)

No Kontrak : HK.02.03/PPK-DP/50

TANGGAL 30 JUNI 2011

KONSULTAN KONTRAKTOR

CONSULTING ENGINEERS

PT ADHI KARYA(PERSERO)

DIVISI KONSTRUKSI III

PEMERINTAH REPUBLIK INDONESIA

KEMENTERIAN PEKERJAAN UMUM

DIREKTORAT JENDERAL BINA MARGA

BALAI BESAR PELAKSANA JALAN NASIONAL II

ASPALT CONCRETE BINDER COURSE

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- DW95 Series Dishwasher Program and Fault Troubleshooting GuideDocumento56 páginasDW95 Series Dishwasher Program and Fault Troubleshooting GuidepksertzenAinda não há avaliações

- Amm Ata 61 PDFDocumento152 páginasAmm Ata 61 PDFcristianocfs100% (4)

- Kandis Ex PalasDocumento113 páginasKandis Ex PalasBm X BreakerAinda não há avaliações

- deruikirSuper Fast and Easy File Hosting PutLocker isn't just another file hosting site. It allows you to store all your files in one place, manage them, and share them with your friends and family if you choose to. Unlimited Uploads No limits on number of files you can upload Unlimited Downloads Share files to as many people as you want Share Huge Files Our size limits are the highest in the industry Unlimited Storage Store as much content you want Mobile Access Your files are available via your smart phone Leading Security Rest easy - your data is safe with us Get a Free Account Today Get an account today, and enjoy all the features of the site! Awesome file management system No limits on sharing and uploading No time limits on streaming Share files up to 1GB Want MDocumento182 páginasderuikirSuper Fast and Easy File Hosting PutLocker isn't just another file hosting site. It allows you to store all your files in one place, manage them, and share them with your friends and family if you choose to. Unlimited Uploads No limits on number of files you can upload Unlimited Downloads Share files to as many people as you want Share Huge Files Our size limits are the highest in the industry Unlimited Storage Store as much content you want Mobile Access Your files are available via your smart phone Leading Security Rest easy - your data is safe with us Get a Free Account Today Get an account today, and enjoy all the features of the site! Awesome file management system No limits on sharing and uploading No time limits on streaming Share files up to 1GB Want MBm X BreakerAinda não há avaliações

- Specipic Gravity Test: SNI 03-1969-1990 & SNI 03-1970-1990Documento113 páginasSpecipic Gravity Test: SNI 03-1969-1990 & SNI 03-1970-1990Bm X BreakerAinda não há avaliações

- UploooDocumento12 páginasUploooBm X BreakerAinda não há avaliações

- Edit Profile Private Messages Logout My Recent Threads My Recent Posts New PostsDocumento17 páginasEdit Profile Private Messages Logout My Recent Threads My Recent Posts New PostsBm X BreakerAinda não há avaliações

- RubennnDocumento31 páginasRubennnBm X BreakerAinda não há avaliações

- Pave CoolDocumento25 páginasPave CoolBm X BreakerAinda não há avaliações

- Upload A Document For Free Access.: Penaksiran Dan Penilaian Perkembangan Kanak-KanakDocumento6 páginasUpload A Document For Free Access.: Penaksiran Dan Penilaian Perkembangan Kanak-KanakRabani Abd AzizAinda não há avaliações

- Perhitungan Kapasitas Produksi Peralatan: Contri Bute To Scrib Dto Acces S This Docu MentDocumento6 páginasPerhitungan Kapasitas Produksi Peralatan: Contri Bute To Scrib Dto Acces S This Docu MentBm X BreakerAinda não há avaliações

- Perhitungan Alat BeratDocumento21 páginasPerhitungan Alat BeratBm X BreakerAinda não há avaliações

- Upload A Document For Free Access.: Penaksiran Dan Penilaian Perkembangan Kanak-KanakDocumento6 páginasUpload A Document For Free Access.: Penaksiran Dan Penilaian Perkembangan Kanak-KanakRabani Abd AzizAinda não há avaliações

- Adapun Pengujian Yang Dilakukan Terhadap Karakteristik Agregat Antara Lain : A. Analisis Saringan A.1 Analisis Saringan Agregat Kasar Tabel 4.1 Hasil Analisis Saringan Agregat KasarDocumento11 páginasAdapun Pengujian Yang Dilakukan Terhadap Karakteristik Agregat Antara Lain : A. Analisis Saringan A.1 Analisis Saringan Agregat Kasar Tabel 4.1 Hasil Analisis Saringan Agregat KasarBm X BreakerAinda não há avaliações

- Greo About About Scribd Team Blog Join Our Team! Contact Us Subscriptions Subscribe Today Advertise With Us Get Started AdChoices SuprurDocumento7 páginasGreo About About Scribd Team Blog Join Our Team! Contact Us Subscriptions Subscribe Today Advertise With Us Get Started AdChoices SuprurBm X BreakerAinda não há avaliações

- Edit Profile Private Messages Logout My Recent Threads My Recent Posts New PostsDocumento15 páginasEdit Profile Private Messages Logout My Recent Threads My Recent Posts New PostsBm X BreakerAinda não há avaliações

- Laboratory study of Marshall properties and durability of asphalt concreteDocumento84 páginasLaboratory study of Marshall properties and durability of asphalt concreteNana SupriatnaAinda não há avaliações

- Dewi Yuni Akhiriyah: Kreatif Jurnal Kependidikan DasarDocumento14 páginasDewi Yuni Akhiriyah: Kreatif Jurnal Kependidikan DasarBm X BreakerAinda não há avaliações

- terface USB SuperSpeed USB (USB 3.0) port Type A Connector with charging function x 1*4, SuperSpeed USB (USB 3.0) port Type A Connector x 1 Network (RJ-45)Connector 1000BASE-T/100BASE-TX/10BASE-T x 1 Display Output Connector Analogue RGB, Mini D-Sub 15 pin x 1 Headphone Stereo, Mini Jack x 1Documento4 páginasterface USB SuperSpeed USB (USB 3.0) port Type A Connector with charging function x 1*4, SuperSpeed USB (USB 3.0) port Type A Connector x 1 Network (RJ-45)Connector 1000BASE-T/100BASE-TX/10BASE-T x 1 Display Output Connector Analogue RGB, Mini D-Sub 15 pin x 1 Headphone Stereo, Mini Jack x 1Bm X BreakerAinda não há avaliações

- terface USB SuperSpeed USB (USB 3.0) port Type A Connector with charging function x 1*4, SuperSpeed USB (USB 3.0) port Type A Connector x 1 Network (RJ-45)Connector 1000BASE-T/100BASE-TX/10BASE-T x 1 Display Output Connector Analogue RGB, Mini D-Sub 15 pin x 1 Headphone Stereo, Mini Jack x 1Documento4 páginasterface USB SuperSpeed USB (USB 3.0) port Type A Connector with charging function x 1*4, SuperSpeed USB (USB 3.0) port Type A Connector x 1 Network (RJ-45)Connector 1000BASE-T/100BASE-TX/10BASE-T x 1 Display Output Connector Analogue RGB, Mini D-Sub 15 pin x 1 Headphone Stereo, Mini Jack x 1Bm X BreakerAinda não há avaliações

- terface USB SuperSpeed USB (USB 3.0) port Type A Connector with charging function x 1*4, SuperSpeed USB (USB 3.0) port Type A Connector x 1 Network (RJ-45)Connector 1000BASE-T/100BASE-TX/10BASE-T x 1 Display Output Connector Analogue RGB, Mini D-Sub 15 pin x 1 Headphone Stereo, Mini Jack x 1Documento4 páginasterface USB SuperSpeed USB (USB 3.0) port Type A Connector with charging function x 1*4, SuperSpeed USB (USB 3.0) port Type A Connector x 1 Network (RJ-45)Connector 1000BASE-T/100BASE-TX/10BASE-T x 1 Display Output Connector Analogue RGB, Mini D-Sub 15 pin x 1 Headphone Stereo, Mini Jack x 1Bm X BreakerAinda não há avaliações

- terface USB SuperSpeed USB (USB 3.0) port Type A Connector with charging function x 1*4, SuperSpeed USB (USB 3.0) port Type A Connector x 1 Network (RJ-45)Connector 1000BASE-T/100BASE-TX/10BASE-T x 1 Display Output Connector Analogue RGB, Mini D-Sub 15 pin x 1 Headphone Stereo, Mini Jack x 1Documento4 páginasterface USB SuperSpeed USB (USB 3.0) port Type A Connector with charging function x 1*4, SuperSpeed USB (USB 3.0) port Type A Connector x 1 Network (RJ-45)Connector 1000BASE-T/100BASE-TX/10BASE-T x 1 Display Output Connector Analogue RGB, Mini D-Sub 15 pin x 1 Headphone Stereo, Mini Jack x 1Bm X BreakerAinda não há avaliações

- DEWA Regulations For Electrical Installations 2017 Edition PDFDocumento135 páginasDEWA Regulations For Electrical Installations 2017 Edition PDFakhilAinda não há avaliações

- Automation Technology: Full Line Catalog, Volume 3 - Edition 2019/2020Documento564 páginasAutomation Technology: Full Line Catalog, Volume 3 - Edition 2019/2020Serdar AksoyAinda não há avaliações

- Transocean Amirante Rig PDFDocumento2 páginasTransocean Amirante Rig PDFro00tAinda não há avaliações

- Souvenir Book: Skills Work!Documento28 páginasSouvenir Book: Skills Work!r2santuAinda não há avaliações

- M.tech ThesisDocumento59 páginasM.tech ThesisRama Krishna100% (1)

- Artistic Craft Centre (3) Project FileDocumento9 páginasArtistic Craft Centre (3) Project Fileshubham shuklaAinda não há avaliações

- Mae SyllabusDocumento113 páginasMae SyllabusPrashant ChawlaAinda não há avaliações

- Japanese Reports Electrical Fire CausesDocumento55 páginasJapanese Reports Electrical Fire Causesal bauerAinda não há avaliações

- Condensador r410 Ycjd30-60btu TrifDocumento24 páginasCondensador r410 Ycjd30-60btu TrifmeganemesisAinda não há avaliações

- Glass FracturesDocumento4 páginasGlass FracturesKavitha RajaAinda não há avaliações

- Ee3002 IntroDocumento17 páginasEe3002 IntroAnonymous JnvCyu85Ainda não há avaliações

- Cellular Manufacturing in IndustryDocumento8 páginasCellular Manufacturing in IndustrySudheer KumarAinda não há avaliações

- M14 Spring GuidesDocumento4 páginasM14 Spring Guideswatch_sutAinda não há avaliações

- VDI2221Documento8 páginasVDI2221hansen_golsvokAinda não há avaliações

- Job Application Request For Diploma in ElectronicsDocumento2 páginasJob Application Request For Diploma in ElectronicsAnonymous SlZ3VOyWaAinda não há avaliações

- Lecture 2 FoundationsDocumento16 páginasLecture 2 FoundationsAhmet TukenAinda não há avaliações

- BirthtubcleaningDocumento1 páginaBirthtubcleaningapi-419200857Ainda não há avaliações

- PT Kaltimex Energy - Malinau Unit 1 - Wiring Diagram CB Control PCC 3.3 Baseload SystemDocumento1 páginaPT Kaltimex Energy - Malinau Unit 1 - Wiring Diagram CB Control PCC 3.3 Baseload SystemShandy Made HajiAmboAinda não há avaliações

- DC Motor Speed Control Using PID Controller in Lab View: January 2015Documento5 páginasDC Motor Speed Control Using PID Controller in Lab View: January 2015EngidAinda não há avaliações

- Toe-S606-12 1h 15Documento140 páginasToe-S606-12 1h 15mssurajAinda não há avaliações

- Kobuto MBR BrochureDocumento2 páginasKobuto MBR Brochurermon02Ainda não há avaliações

- SGS CTS EU Cosmetic Regulation A4 EN 14 V1 PDFDocumento2 páginasSGS CTS EU Cosmetic Regulation A4 EN 14 V1 PDFDomitian PascaAinda não há avaliações

- Water: City of RichardsonDocumento15 páginasWater: City of RichardsonSnezana RaicevicAinda não há avaliações

- TASKalfa 1800 2200 DP 480 DU 480 PF 480 SM UKDocumento442 páginasTASKalfa 1800 2200 DP 480 DU 480 PF 480 SM UKJoshua WilsonAinda não há avaliações

- 787 Propulsion SystemDocumento7 páginas787 Propulsion SystemAnonymous R0s4q9X8100% (1)

- Manual OLECDocumento138 páginasManual OLECRicardo Nicolau WerlangAinda não há avaliações

- Steering Rack Mitsu Kuda PDFDocumento36 páginasSteering Rack Mitsu Kuda PDFChandra Sutawijaya100% (1)

- SNOA-4: Product DescriptionDocumento2 páginasSNOA-4: Product DescriptionPepe PintoAinda não há avaliações