Escolar Documentos

Profissional Documentos

Cultura Documentos

Audit Checklist - Blasting Painting1

Enviado por

Angel Angeleye100%(4)100% acharam este documento útil (4 votos)

3K visualizações6 páginasPainting Audit checklist

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOC, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoPainting Audit checklist

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOC, PDF, TXT ou leia online no Scribd

100%(4)100% acharam este documento útil (4 votos)

3K visualizações6 páginasAudit Checklist - Blasting Painting1

Enviado por

Angel AngeleyePainting Audit checklist

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOC, PDF, TXT ou leia online no Scribd

Você está na página 1de 6

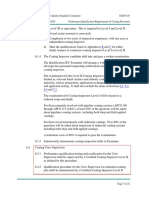

QUALITY AUDIT CHECKLIST

Client: MPN (FMS) Title: QA/QC AUDIT Contract No:

A!it No:

"#$%&#" (13-02)

A!itor: FIELD MAINTENANCE SE'(ICE A!it Sco)e: *LASTIN+ , PAINTIN+

Date: "-/#./"#$% A!itee: *IL INTE+'ATED SYSTEMS

LTD

Location: *IL FA* YA'D /

/FFICE0 E*ANA

Ite1

No

'e2erence

Doc1ent

Qe3tion Co1)liance Co11ent3 / Fin!in43 / /53er6ation /

/57ecti6e E6i!ence Ye3 No

1.0 Paintin4 Proce!re (Doc No. & rev)

Very area of reference

Are documents used for painting activities approved; i.e. MS

!"# #rocedure etc; Verify samp$es of eac% document.

&.0 !s t%e copy of #ro'ect (ine (ist avai$a)$e to t%e #ainting

Supervisor*.

.

+.0 Verify t%at paint materia$s are in $ine ,it% M#N specifications

and re-uirements.

!ncoming inspection reports product )atc% ana$ysis (certificates

/ certificates of conformity).

0.0 Are )aint 1aterial3 )re3er6e! in accor!ance 8it9

1an2actrer3: 1anal/!ata 39eet3 /3)eci2ication3

/MSDS/MPN +lo5al Practice3;

1or e2amp$e. minimum storage temperature re-uirement;

i.e.+&34 in ,eat%erproof )ui$ding etc etc.

5.0 Are paint materia$s stored )y type* Are consuma)$es issued on

a 1!16 )asis (7# notes8 o$dest paint of eac% particu$ar type

s%a$$ )e used first).

9.0 Are unidentified paint materia$s stored on site or in stores*

:.0 Are measuring e-uipment .

Ade-uate

#age 1 of 0

:.0

(contd)

4a$i)rated or verified at specified interva$s or prior to use*

!dentified to ena)$e ca$i)ration and tracea)i$ity*

Are records of ca$i)ration resu$ts and verification

maintained*

!s t%e e-uipment stored in secure area after eac% inspection*

;.0 Are personne$ conducting/performing painting operations

and/or ,or< activities e2perienced and -ua$ified*

Verify -ua$ification matri2

=.0 Are too$ )o2 meetings %e$d* Verify ,or< permit system >S?

induction for ne, %ires and ,or< procedures for ,or< ,it%in

confined space*

Are records <ept*

10.0 !s @$ast 4$eaning ?-uipment and its maintenance suita)$e to ac%ieve

product conformity*

Air compressor (verify mo)i$iAation certificates survey certs;

@$ast #ots air de$ivery %oses 6perators air mas< )reat%a)$e

air$ines 1i$ters & #o,er )rus%.

11.0 Verify evidence of re8)$asting if after )$asting painting is not carried

out on t%e same day due to unforeseen circumstances.

Verify records of suc% occurrence*

1&.0 >o, does personne$ invo$ved in painting activities verify t%at Air

4ompressor used for painting activities.

!s free from ,ater & oi$ and is e-uipped ,it% ade-uate separators

and traps*

!s contro$$ed to de$iver air temperature up to 11034*

1+.0 Are e-uipment used for measurement and testing ca$i)rated and t%at

t%e ca$i)ration records are avai$a)$e for e-uipment suc% as.

>ygrometers

Surface #rofi$e 7auges

4ontact temperature gauge

>o$iday detector / D1" gauge / Ad%esion "ester

10.0 Verify t%at @$asting & #ainting documents used are t%e current

versions

((ist app$ica)$e documents)

#age & of 0

In3)ection < Te3t Plan (ITP)

Verify document num)er and approva$ status of !"#.

15.0 !s t%ere a proper and documented Spoo$ Be$ease note or c%ec<$ist in

use*

Verify t%at records of spoo$ re$ease notes are maintained.

19.0 Are specifications of paint materia$s used in accordance ,it% M#N /

pro'ect re-uirements*

@$asting 7rit materia$s

#aints / consuma)$es

19.0 !s painting tria$ test on samp$e p$ates carried out for eac% paint type

and for eac% manufacturer )rand*

*la3tin4

1:.0 @$asting records

>o, is )$ast profi$e measured

C%at )$ast medium is used

1;.0 Are records of metro$ogica$ conditions re-uired )y t%e procedure /

paint manufacturer monitored and recorded*

Be$ative >umidity D ;5E

Stee$ surface temperature is +34 a)ove de, point

1=.0 Surface preparation. Fua$ity Be-uirements ac%ieved*

!s t%e minimum surface finis% grade of Sa &81/& )eing met* !s t%is

resu$t recorded to assure

$eve$ of surface c$ean$iness

correct materia$s (so$vents) used*

Pri1er A))lication

&0.0 Ceat%er / environmenta$ reports.

Verify t%at records of ,eat%er conditions at t%e time of primer coat

app$ication

$ocation of item primed

Ade-uate cover (if re-uired); !s %eating app$ied or provided

Be$ative %umidity D ;5E

Stee$ surface temperature is +34 a)ove de, point

Verify records of t%e time interva$ from )$asting to primer coating

app$ication

&1.0 #aint mi2ing ratio & pot $ife record

Verify t%at paint mi2ing ratio recommended )y t%e manufacturer are

fo$$o,ed

#age + of 0

Detai$s of ratio and time; pot $ife

4orrect paint & t%inner

#age 0 of 0

&&.0 #rimer paint app$ication report/record.

Verify t%at t%e fo$$o,ing records are indicated

.met%od of app$ication;

C1" & D1" readings;

Stage of coating;

!nter8coat interva$

>o$iday test ad%esion test (if re-uired)

Inter1e!iate Coat A))lication

&+.0 Verify t%at records of ,eat%er conditions at t%e time of intermediate

paint coat app$ication

Be$ative %umidity D ;5E

Stee$ surface temperature is +34 a)ove de, point

&0.0 Verify t%at t%e app$ication of intermediate coating conforms to t%e

paint manufacturerGs minimum over8coating time

Final Coat A))lication

&5.0 Verify t%at records of ,eat%er conditions at t%e time of intermediate

paint coat app$ication

Be$ative %umidity D ;5E

Stee$ surface temperature is +34 a)ove de, point

&9.0 1ina$ painting report/record

Verify contro$ of painting records

Acceptance of reports (signing off)

"racea)i$ity

&:.0 Verify t%at t%e app$ication of t%e fina$ paint conforms to paint

manufacturerGs minimum over coating time

&;.0 Verify t%at t%e fina$ paint t%ic<ness conform to t%e minimum and

ma2imum D1" re-uired )y t%e specification / manufacturer

&=.0 Verify t%at paint ad%esion test resu$ts meet t%e re-uirements

+0.0 #aint Becords / Documentation

Are reports of )$asting and painting avai$a)$e tracea)$e and

retrieva)$e

+1.0 N4B 4$ose 6ut

Verify t%e effectiveness of t%e corrective and preventive actions of

N4BsG issued )y M#N particu$ar$y on

#oor paint app$ication

Materia$s

Si4natre AUDIT/': AUDITEE:

#age 5 of 0

#age 9 of 0

Você também pode gostar

- Duties of Tank InspectorDocumento1 páginaDuties of Tank InspectorJawed AlamAinda não há avaliações

- API 510 Certification Exam Study Plan PDFDocumento3 páginasAPI 510 Certification Exam Study Plan PDFJayeshAinda não há avaliações

- 0901b80380959cc7 PDFDocumento2 páginas0901b80380959cc7 PDFikan100% (1)

- CBT 3Documento9 páginasCBT 3SUNIL RAJPUT100% (1)

- Painting Method StatementDocumento10 páginasPainting Method StatementYusufAinda não há avaliações

- 172 Tank Settlement Report PDFDocumento1 página172 Tank Settlement Report PDFarkaprava ghosh100% (1)

- 1C.cv - Talha Abdullah (Painting Crew Supervisor)Documento2 páginas1C.cv - Talha Abdullah (Painting Crew Supervisor)Mohamed Reda100% (2)

- Audit Checklist Blasting PaintingDocumento4 páginasAudit Checklist Blasting PaintingEyoh EffiongAinda não há avaliações

- CBT 25Documento6 páginasCBT 25SUNIL RAJPUTAinda não há avaliações

- Interzone 485 - Application GuidelinesDocumento7 páginasInterzone 485 - Application GuidelinesBon Panganiban100% (1)

- Vacume Box Test ProcedureDocumento5 páginasVacume Box Test ProcedureFarhan Sheikh100% (3)

- Coating Interview QuestionDocumento1 páginaCoating Interview QuestionMatthew Baker100% (3)

- Painting Procedure GlobalDocumento15 páginasPainting Procedure GlobalUbed KudachiAinda não há avaliações

- CBT 8Documento5 páginasCBT 8SUNIL RAJPUTAinda não há avaliações

- CBT 02-20Documento3 páginasCBT 02-20Manoj Kumar100% (1)

- Resume For Painting InspectorDocumento3 páginasResume For Painting InspectorMITHUNAinda não há avaliações

- CBT 19Documento3 páginasCBT 19SUNIL RAJPUTAinda não há avaliações

- SAIC-M-1018 Leak Proof Testing-Final InspectionDocumento1 páginaSAIC-M-1018 Leak Proof Testing-Final InspectionLegend AnbuAinda não há avaliações

- Qstns 1Documento29 páginasQstns 1Shawn Leo100% (2)

- DFT RulesDocumento4 páginasDFT RulesSalahuddin Farooqui100% (1)

- CBT 22Documento16 páginasCBT 22SUNIL RAJPUTAinda não há avaliações

- MNT - QC - BP - 001 Blasting & Painting ReportDocumento1 páginaMNT - QC - BP - 001 Blasting & Painting Reportsivagnanam sAinda não há avaliações

- Revision Questions PA 10 Specific Page 23-12Documento2 páginasRevision Questions PA 10 Specific Page 23-12Bayu Falen100% (2)

- Paint Inspection Checklist I PDFDocumento1 páginaPaint Inspection Checklist I PDFanush_swaminathan0% (1)

- Painting & Coating-1Documento17 páginasPainting & Coating-1sattanathan07100% (10)

- Painting and Coating Inspector Interview QuestionsDocumento7 páginasPainting and Coating Inspector Interview Questionsவிஷ்ணு ராஜசெல்வன்100% (2)

- Bgas 1Documento25 páginasBgas 1Manoranjan Nayak60% (5)

- 4516 TTI Coating Inspector Transition 0317.2Documento4 páginas4516 TTI Coating Inspector Transition 0317.2Mohamed NouzerAinda não há avaliações

- Painting Inspection Report Angle Bars PDFDocumento1 páginaPainting Inspection Report Angle Bars PDFpstechnical_43312697Ainda não há avaliações

- Painting - Training PPT 1Documento24 páginasPainting - Training PPT 1vijay padale80% (5)

- Blasting and Painting ProcedureDocumento9 páginasBlasting and Painting ProcedureAhmad FadlullahAinda não há avaliações

- Muhammad Shoaib, S Resume (API 510-API 570-API 653)Documento6 páginasMuhammad Shoaib, S Resume (API 510-API 570-API 653)Muhammad Shoaib33% (3)

- CBT QuestionsDocumento20 páginasCBT Questionsmohammed amjad ali100% (1)

- Painting ReportDocumento1 páginaPainting Reportbaidu1980Ainda não há avaliações

- CBT 12Documento7 páginasCBT 12SUNIL RAJPUT100% (1)

- BGAS PaperDocumento9 páginasBGAS PaperMuhammad AsifAinda não há avaliações

- Shell Plate Dimension CheckDocumento7 páginasShell Plate Dimension Checksetak0% (1)

- 3855 ICorr Coating Inspector Assessment Guidelines 0821Documento6 páginas3855 ICorr Coating Inspector Assessment Guidelines 0821aliAinda não há avaliações

- Coating Crew SupervisorDocumento4 páginasCoating Crew Supervisorimtiaz100% (1)

- Abrasive BlastingDocumento1 páginaAbrasive BlastingRísês Ãfröz67% (3)

- Quality Control Checklist: Structural Steel Painting ChecklistDocumento8 páginasQuality Control Checklist: Structural Steel Painting ChecklistDilhara WickramaarachchiAinda não há avaliações

- Blasting & Painting Ops ProcedureDocumento12 páginasBlasting & Painting Ops ProcedurekolaaruAinda não há avaliações

- PDS Hempadur Hi-Build 45200 en-GBDocumento2 páginasPDS Hempadur Hi-Build 45200 en-GBvitharvanAinda não há avaliações

- Paint Inspection:: Daily Coating Inspection ReportDocumento1 páginaPaint Inspection:: Daily Coating Inspection ReportEhsan KhanAinda não há avaliações

- Hempel'S Galvosil 15780: DescriptionDocumento2 páginasHempel'S Galvosil 15780: DescriptionEngTamer100% (1)

- Painting and Coating Inspector InterviewDocumento8 páginasPainting and Coating Inspector Interviewkumar100% (2)

- CIP Session I Quiz-4Documento5 páginasCIP Session I Quiz-4munna100% (6)

- BGAS Short NotesDocumento2 páginasBGAS Short NotesSameh Amin80% (5)

- Apcs 113a Rev 3 Pid ApprovalDocumento19 páginasApcs 113a Rev 3 Pid ApprovalMedel Cay De Castro50% (2)

- Procedure of Apcs-113cDocumento8 páginasProcedure of Apcs-113cNoman AhmedAinda não há avaliações

- CBT 06.02.2020Documento3 páginasCBT 06.02.2020Nidhin Joseph100% (1)

- Painting Inspection ReportDocumento1 páginaPainting Inspection Reportعبداللة العبداللةAinda não há avaliações

- Sandblasting ProcedureDocumento3 páginasSandblasting ProcedureFs100% (2)

- Coating PaintingDocumento8 páginasCoating Paintingdeva0170% (2)

- DW Horizontal AbovergroundDocumento3 páginasDW Horizontal AbovergroundMohammed EljammalAinda não há avaliações

- Bechtel France S.A.S.: Reliance Petroleum Limited Jamnagar Export Refinery ProjectDocumento22 páginasBechtel France S.A.S.: Reliance Petroleum Limited Jamnagar Export Refinery Projectravi00098Ainda não há avaliações

- Audit Checklist - Material ControlDocumento4 páginasAudit Checklist - Material ControlAngel Angeleye100% (1)

- Illinois VOC and LEED 2009 LimitsDocumento5 páginasIllinois VOC and LEED 2009 LimitsspecmasterAinda não há avaliações

- Cswip Plant Inspector Competence/Experience Log: Level 2 PrequalificationDocumento16 páginasCswip Plant Inspector Competence/Experience Log: Level 2 PrequalificationSigit BintanAinda não há avaliações

- Audit Checklist - Material ControlDocumento4 páginasAudit Checklist - Material ControlAngel AngeleyeAinda não há avaliações

- Designing Effective Powerpoint Presentations: Victor Chen ErauDocumento52 páginasDesigning Effective Powerpoint Presentations: Victor Chen ErauSharminYameenAliAinda não há avaliações

- KK Cake Deco BrochureDocumento8 páginasKK Cake Deco BrochureMichelle FabeneAinda não há avaliações

- Msds Etanol 2005Documento7 páginasMsds Etanol 2005Puput Trisnayanti Inanto PutriAinda não há avaliações

- Pipe Threads - StandardsDocumento5 páginasPipe Threads - StandardsAngel AngeleyeAinda não há avaliações

- Audit Checklist - Material ControlDocumento4 páginasAudit Checklist - Material ControlAngel Angeleye100% (3)

- Slinging Tubulars, Scaffold, BeamsDocumento3 páginasSlinging Tubulars, Scaffold, BeamsAngel AngeleyeAinda não há avaliações

- Washing Machine ManualDocumento44 páginasWashing Machine ManualAngel Angeleye100% (1)

- Welding Basics 1Documento63 páginasWelding Basics 1Lutfi IsmailAinda não há avaliações

- Adhesion Testing Methods For PaintingDocumento3 páginasAdhesion Testing Methods For PaintingAngel AngeleyeAinda não há avaliações

- Filler Material Selection GuideDocumento32 páginasFiller Material Selection GuidemaknileAinda não há avaliações

- Filler Material Selection GuideDocumento32 páginasFiller Material Selection GuidemaknileAinda não há avaliações

- Filler Material Selection GuideDocumento32 páginasFiller Material Selection GuidemaknileAinda não há avaliações

- Aws A2.4 Weld Symbols PDFDocumento2 páginasAws A2.4 Weld Symbols PDFbastonspestalode67% (3)

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Documento2 páginasWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- Hand Safety Training-FINALDocumento37 páginasHand Safety Training-FINALAngel AngeleyeAinda não há avaliações

- Audit Checklist - Material ControlDocumento4 páginasAudit Checklist - Material ControlAngel Angeleye100% (1)

- Tables of Flange PDFDocumento5 páginasTables of Flange PDFAngel AngeleyeAinda não há avaliações

- 03-01 Material TraceabilityDocumento1 página03-01 Material TraceabilityAngel AngeleyeAinda não há avaliações

- Glossary of HSE TermsDocumento20 páginasGlossary of HSE TermsAngel AngeleyeAinda não há avaliações

- Safety Talk - Pinch PointDocumento8 páginasSafety Talk - Pinch PointAngel AngeleyeAinda não há avaliações

- Tables of Flange PDFDocumento5 páginasTables of Flange PDFAngel AngeleyeAinda não há avaliações

- Audit Checklist - Material ControlDocumento4 páginasAudit Checklist - Material ControlAngel AngeleyeAinda não há avaliações

- Audit Checklist - Material ControlDocumento4 páginasAudit Checklist - Material ControlAngel AngeleyeAinda não há avaliações

- Biblical Names and Their MeaningsDocumento58 páginasBiblical Names and Their MeaningsKumina Issachar0% (1)

- Project Quality Plan.Documento27 páginasProject Quality Plan.Adeel RazzaqAinda não há avaliações

- Project Quality Plan.Documento27 páginasProject Quality Plan.Adeel RazzaqAinda não há avaliações

- Project Quality Plan.Documento27 páginasProject Quality Plan.Adeel RazzaqAinda não há avaliações

- Biblical Names and Their MeaningsDocumento58 páginasBiblical Names and Their MeaningsKumina Issachar0% (1)

- $ - KS Driving ManualDocumento76 páginas$ - KS Driving ManualFerris BuhlerAinda não há avaliações

- Total Phenolic and Flavonoid Contents of Srikaya (Annona Squamosa L.) Leaf Fermented ExtractsDocumento14 páginasTotal Phenolic and Flavonoid Contents of Srikaya (Annona Squamosa L.) Leaf Fermented ExtractsAhmad HidayahAinda não há avaliações

- Supercritical CO2: Properties and Technological Applications - A ReviewDocumento38 páginasSupercritical CO2: Properties and Technological Applications - A ReviewXuân ĐứcAinda não há avaliações

- Correlated Optical Convolutional Neural Network With "Quantum Speedup"Documento27 páginasCorrelated Optical Convolutional Neural Network With "Quantum Speedup"jaccneeAinda não há avaliações

- BS en 00480-2-2006Documento14 páginasBS en 00480-2-2006Shan Sandaruwan Abeywardene100% (1)

- Kinetic Energy Recovery SystemDocumento2 páginasKinetic Energy Recovery SystemInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- Teacher PPT - Scientific RevolutionDocumento13 páginasTeacher PPT - Scientific Revolutionapi-441776741Ainda não há avaliações

- GGDocumento8 páginasGGGaurav SharmaAinda não há avaliações

- Winter Intership SyllabusDocumento14 páginasWinter Intership SyllabusAjayAinda não há avaliações

- TM 9-4110-241-23PDocumento41 páginasTM 9-4110-241-23PwwwsurvivalebookscomAinda não há avaliações

- Soil Mechanics PowerpointDocumento239 páginasSoil Mechanics PowerpointEdcel Angelo TomasAinda não há avaliações

- College Level Math Practice TestDocumento17 páginasCollege Level Math Practice TestHarsha Kasaragod100% (1)

- Trigonometric Substitution: Jzfa20Documento12 páginasTrigonometric Substitution: Jzfa20Samuel SmallmanAinda não há avaliações

- Xii Chemistry MCQ (Haloalanes & Haloarenrs)Documento7 páginasXii Chemistry MCQ (Haloalanes & Haloarenrs)SanjanasanjuAinda não há avaliações

- 125 Tractor: (Specifications and Design Subject To Change Without Notice)Documento5 páginas125 Tractor: (Specifications and Design Subject To Change Without Notice)Gary LarsonAinda não há avaliações

- Wa Wa40-3 Komatsu s3d84Documento2 páginasWa Wa40-3 Komatsu s3d84james foxAinda não há avaliações

- 1st Mid-Term Test (Add Maths f4)Documento5 páginas1st Mid-Term Test (Add Maths f4)Jarnice Ling Yee ChingAinda não há avaliações

- Lorian Meyer-Wendt - Anton Webern - 3 Lieder Op.18Documento136 páginasLorian Meyer-Wendt - Anton Webern - 3 Lieder Op.18Daniel Fuchs100% (1)

- Translating Mathematical PhrasesDocumento16 páginasTranslating Mathematical PhrasesApple Jean Yecyec AlagAinda não há avaliações

- Chapter26to29-Bolt Tightening TorqueDocumento36 páginasChapter26to29-Bolt Tightening TorqueEnam SembilanAinda não há avaliações

- Rockschool Popular Music Theory Syllabus 2015 18Documento33 páginasRockschool Popular Music Theory Syllabus 2015 18Archit AnandAinda não há avaliações

- A) I) Define The Term Variable Costs Variable Costs Are Costs That Change With The Quantity of Products SoldDocumento2 páginasA) I) Define The Term Variable Costs Variable Costs Are Costs That Change With The Quantity of Products SoldAleksandra LukanovskaAinda não há avaliações

- Question Bank - PolyDocumento16 páginasQuestion Bank - Polyمحمود صابرAinda não há avaliações

- Transom Analysis ComparisonDocumento38 páginasTransom Analysis ComparisonRifky NetriadyAinda não há avaliações

- AUTOSAR SWS UDPNetworkManagementDocumento103 páginasAUTOSAR SWS UDPNetworkManagementStefan RuscanuAinda não há avaliações

- ElcometerDocumento228 páginasElcometerMohammedMudassirAinda não há avaliações

- SM 89Documento36 páginasSM 89Camilo RamosAinda não há avaliações

- G12 NCERT Unit-14 BiomoleculesDocumento15 páginasG12 NCERT Unit-14 Biomoleculescherryakila05Ainda não há avaliações

- Abnormal Labour: Perceptor: Dr. Nurul Islamy, M. Kes., Sp. OGDocumento54 páginasAbnormal Labour: Perceptor: Dr. Nurul Islamy, M. Kes., Sp. OGramadhiena destia100% (1)

- MMM - Unit 1Documento133 páginasMMM - Unit 1Ahmed Raza MokashiAinda não há avaliações

- BMTC 132Documento16 páginasBMTC 132Deepak Chaudhary JaatAinda não há avaliações