Escolar Documentos

Profissional Documentos

Cultura Documentos

Finitestatemachine

Enviado por

api-241650697Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Finitestatemachine

Enviado por

api-241650697Direitos autorais:

Formatos disponíveis

2012

Brian Greiner

Professor Peter Han ECET365 Embedded

Microprocessor Systems

12/17/2012

Course Project - Robot

1

Contents

Summary ....................................................................................................................................................... 2

Introduction .................................................................................................................................................. 2

Purpose and scope .................................................................................................................................... 2

Sources and methods................................................................................................................................ 3

Report organization .................................................................................................................................. 3

Hardware implementation ........................................................................................................................... 3

Transmitter ............................................................................................................................................... 4

Receiver..................................................................................................................................................... 6

Dragon12 development board and HCS12 ............................................................................................... 9

Continuous rotation servo motors .......................................................................................................... 10

Chassis ..................................................................................................................................................... 11

Hardware issues ...................................................................................................................................... 11

Software implementation ........................................................................................................................... 12

Pulse width modulation .......................................................................................................................... 12

Finite state machine ................................................................................................................................ 13

Software polling ...................................................................................................................................... 14

Phase locked loop ................................................................................................................................... 14

Software issues ....................................................................................................................................... 14

Conclusion ................................................................................................................................................... 15

Project Recommendations ...................................................................................................................... 15

Technical Results ..................................................................................................................................... 15

Critical Thinking Results .......................................................................................................................... 16

Appendix A References ............................................................................................................................ 17

Appendix B Source code .......................................................................................................................... 18

Appendix C PWM State Outputs .............................................................................................................. 21

2

Summary

This report covers the course project for ECET 365. The goal of the course project is to build a remote

controlled PWM operated moving robot. The robot built for this project is detailed in this report. The

hardware is made up of a remote control transmitter built on a bread board, a receiver, also on a bread

board, a development board with microcontroller, four servo motors and a chassis. Four keys on the

remote send data to the receiver. The receiver then sends these key presses to the microcontroller,

which uses this information to control the speed and direction of the servo motors mounted on the

chassis.

The microcontroller is programmed to vary the duty cycle of a PWM signal to the servo motors to

control their speed and direction. The specifics of this PWM duty cycle are determined by logic

implemented in transitioning between the states of a finite state machine. The program polls a valid

transmission pin on the receiver decoder and when this becomes active, uses the new button press to

determine which state to transition to. As timing is important for this implementation, a phase locked

loop is used to maintain the system clock while the robot runs in standalone mode.

Video of the functioning robot may be found at the following link:

http://www.youtube.com/watch?v=Rn6wQefUG_U

Introduction

The course project involved the building and testing of a microcontroller controlled remote activated

robot. The robot receives inputs from a transmitter module and uses these inputs to determine a

direction of travel.

Purpose and scope

The purpose of this project is to demonstrate knowledge of the curriculum learned throughout a series

of electronics and computer engineering courses over the past several semesters at DeVry University.

3

The functioning robot demonstrates knowledge in hardware design, software design and embedded

controller interfacing. Furthermore, creating the robot required skills in both hardware and software

troubleshooting using tools such as an oscilloscope and digital voltage meter to test the hardware and

the Codewarrior IDE to debug the program.

Sources and methods

Several sources were used in the design and implementation of the robot. Primarily the course texts

from the current course and previous courses were used as a basis to plan the software

implementations. These texts are, Embedded Microcomputer Systems Real Time interfacing by

Valvano and, HCS12/9S12 An introduction to software and hardware interfacing by Huang. Also

sourced heavily were the datasheet for the HCS12 microcontroller and the datasheets for the encoder

IC, transmitter module, receiver module and decoder IC used in the project.

Report organization

This report is organized by the individual parts involved in the planning and construction of the robot. It

starts with information on the hardware used to create the robot. This is followed by the details about

the software implementation and finally there is a technical and critical thinking conclusion. The

references, source code and some project documentation are included in the appendices.

Hardware implementation

There are five main components that make the robot work. The first component is a user interface

which encodes and transmits button presses. Secondly, there is a receiver module that receives and

decodes these button presses. Central to these components is the dragon 12 development board

including an HCS12 microcontroller. The microcontroller takes inputs from the receiver and outputs

control to four continuous rotation servo motors. These motors and the development board are

mounted to a chassis.

4

Transmitter

The transmitter is made up primarily of a voltage regulator circuit, four pushbutton switches, a Holtek

HT6014 encoder and an Easy-Link wireless Ultra small Transmitter. Each of the buttons on the

transmitter is wired so that a press of the button creates a path to ground. This is interpreted by the

encoder as a logic low. There are four inputs to the encoder that will trigger the data output to send

the encoded data to the transmitter. The push button switches are each wired to one of these four

inputs. The encoder also has eight lines for addressing, all of which are wired to ground. Furthermore

the encoder has an oscillator input for varying the oscillation using a resistor and the data output lines

to the transmitter. The resistor chosen for the oscillator inputs has a resistance of 1M. According to

the data sheet, with a five volt supply this should create an oscillator frequency of 3kHz, the

recommended frequency for the oscillator. The data output of the encoder is fed into the Ultra Small

Transmitter, which transmits the data using Amplitude shift keying (ASK) at 433.92MHz.

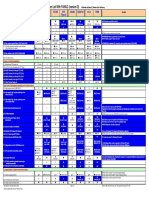

The oscillator frequency resistor is calculated from this chart.

5

The voltage regulator circuitry provides a clean 5V to power the transmitter.

The encoder also has an LED to indicate a transmission.

Wires on the breadboard are color coded for ease of understanding and later troubleshooting. Non-

colored silver jumpers provide the grounding for the address pins. There are four pushbuttons that are

associated with forward, reverse, left and right.

6

For R1, a 1M resistor was chosen. All of the address pins are grounded. Two filter capacitors of 4.7F

and 0.1F are used with the voltage regulator to provide clean power.

Receiver

The receiver is made up of similar components to the transmitter. It also requires a clean 5V power

supply, but instead of constructing one on the bread board, power was sourced from the dragon12

development board, which already has a filtered and regulated 5V supply. The receiver module receives

the ASK signal at 433.92MHz sent from the transmitter and converts to a data stream that will be

interpreted by a decoder IC. The decoder IC, a Holtek HT6034 has a data input line and receives serial

data from the receiver module. Successfully decoded data first causes a valid transmission (VT) pin to

transition from low to high briefly. Following, one of four output lines normally in a logic high state

will latch to a logic low state until different code is received. All address lines on the decoder IC were

grounded to match the encoder. An appropriate resistor, 100k, was chosen to regulate the oscillator to

approximately 91kHz as per the suggestion of approximately 33 times that of the encoder made by the

OSC2

Dout

SW4

SW2

SW1 1 2

SW2 1 2

AD9

AD12

SW3 1 2

1

AD10

AD11

4

SW1 SW5 1 2

TLP434A

3

SW0 SW4 1 2

1

2

SW3 SW7 1 2

7805

1 3

VIN VOUT

C1

TE

OSC1

Vdd

RF Out

SW6 1 2

R1

7

datasheet. The four output lines and the VT pin are wired to the pins associated with port B, bits 0

through 4 on the dragon board.

With a 5V supply a 91k resistor is ideal, but a 100k is available and worked perfectly.

Wires are color coded for ease of troubleshooting. The green wires are the outputs or the oscillator, the

yellow are data inputs, the white is the VT bit and the red and black are power and ground respectively.

8

Here can be seen the impulse on VT (Channel 2) and the corresponding latch to logic low on one output

line (Channel 1) of the receiver. This impulse and latch are used by the microcontroller to decide how to

regulate the PWM on port P.

Here a 100k resistor is used for R1. Clean voltage for the receiver is supplied by the dragon board.

D9

PB0

PB1

1 2

1 2

P

O

R

T

P

6

1 2

1 2

A2

P

O

R

T

P

3

DIN

A6 PB3

OSC1

P

O

R

T

P

0

1 2

RF in

O

S

C

1

GRD

P

O

R

T

P

4

MC9S12DG256

C1

A0

A3

P

O

R

T

P

2

PB7

Vcc

D10

Vdd

1 2

Vss

GRD

A5

C1

P

O

R

T

P

5

Vcc

HT12D

GRD

A7

Linear Out

1 2

Digital Out

PB4

PB6

RLP434

D8

A1

1

A - +

MG1

MOTOR SERVO

1 2

OSC2

O

S

C

2

P

O

R

T

P

1

PB2 D11

PB5

A4

1 2

A - +

MG2

MOTOR SERVO

1 2

7805

1 3

VIN VOUT

R1

VT

9

Dragon12 development board and HCS12

The dragon development board has as a central component, the MC9S12DG256 microcontroller from

Freescale Semiconductors. For this robot the microcontroller takes inputs from port B and outputs

pulse-width modulation (PWM) signals to port P pins 4 through 7. Port P from the microcontroller is also

wired through jumpers to an RGB LED and a speaker on the development board. These jumpers were

removed to prevent loading on the PWM channels. The dragon board also includes an LCD which has a

backlight controlled by a jumper. Since the robot is battery powered and this LCD is not utilized, the

jumper was disconnected. Power for the board was sourced from a 9 volt battery. The servos were

powered by and independent battery connected to terminal block T7. There are four connectors

specifically designed to interface to servo control on the dragon board. These were utilized to control

the four servo motors on the robot.

10

Power is wired from the voltage regulator circuit on the dragon board (terminal block T4) to the

prototyping board where the receiver is constructed. The separate power for the servo motors is

implemented by positioning Jumper J35. Grounds for the servo and development board are connected

together.

Continuous rotation servo motors

Four continuous rotation servo motors designated #900-00008 by Parallax were used as the primary

motion for the robot. These servos have a cable with three lines; they are power (red), ground (black)

and a line for control using PWM (white). According to the data sheet for the servo, a pulse should have

a positive width of between 1ms and 2ms and a negative width of 20ms. A positive width of 1.5ms to

2ms will cause the servo to rotate counter-clockwise with increased speed correlated to the pulse width

while a positive width of 1ms to 1.5ms will cause the servo to rotate clockwise with speed inversely

correlated to pulse-width. The output shaft of these servo motors each has a wheel, which provides the

motion of the robot.

The servos are connected to servo control outputs specifically built into the dragon board for interfacing

with servo motors. The motors are mounted to the chassis, which is a project box.

11

Chassis

The chassis chosen for this project is a simple project enclosure. The size of the chassis needed to be

large enough to accommodate the dragon board and four servo motors. It also needed to be light

enough that it could be carried by the torque specified by the servo motors and modifiable to allow

fitment of the dragon board and servos.

The dragon board is mounted to the underside of the lid of the project box with the antenna from the

receiver fed through a hole in the lid. The servos are mounted to the outside of the chassis with screws.

Hardware issues

The one hardware issue that required the most troubleshooting was simply getting the receiver and

transmitter to work together. Initially the transmitter was wired up incorrectly due to some confusion in

a diagram on the datasheet. Several hours were spent finding this issue that involved taking readings

from many locations in both receiver and transmitter. Finally, communication was established. The

initial design for the chassis had the motors mounted lengthwise. This created poor performance in

12

turning. The wider and shorter wheelbase created by mounting the tires widthwise on the chassis solved

this.

Software implementation

The goal of the program used for this robot was to take inputs from port B, provided by the receiver

module and output PWM control signals to port P, which is connected to the servo motors. The HCS12

already has PWM channels in place that, when configured properly, output to port P. While reading this

section it is helpful to reference the source code in Appendix B.

Pulse width modulation

The pulse width modulation on the HCS12 is controlled by several registers. For this robot a PWM signal

with a period of 20ms and a pulse width of between 1ms and 2ms needed to be created to control the

servos. Four servo motors were driven using the PWM control signals from port P pins 4-7. In order to

control four servo motors using the built in servo interfaces on the dragon board, 8-bit PWM is required,

as concatenating the PWM channels would only allow for two of the interfaces to be utilized. The

function PWMinit() initializes the PWM channel to the required parameters. The 24MHz system clock is

first pre-scaled to 1.5MHz using the value 0x44 on the PWMPRCLK register. Both clocks A and B are then

scaled further to 10kHz by values of 75 on PWMSCLA and PWMSCLB. This gives a period of 0.1ms. The

registers PWMCTL and PWMPOL are set to not concatenate the PWM channels with an initial high output.

To gain a 20ms period for PWM a value of 200 is written to each of PWMPER4, PWMPER5, PWMPER6 and

PWMPER7. The registers for duty cycle, PWMDTY, are initialized to zero. PWME turns on the PWM cannels.

After PWM is initialized the program can regulate the speed of the servo motors simply by changing the

values written to the four PWMDTY registers. The results of these different duty values based on the

current state of the machine can be found in appendix C.

13

Finite state machine

The program is designed using an abstraction known as the finite state machine (FSM). An FSM has

certain states with parameters and may transition to different states based on a time period or external

input. This is a perfect model for this robot as the robot will be traveling in one direction at any given

time and will transition to a different direction based on the inputs from the remote control transmitter.

There are nine states described for this robot. Each of the nine states has a different value for PWM duty

for the left and right wheels of the robot. Each state may transition to up to four other states based on

the inputs to port B.

14

Here is the state diagram that describes the transitions that may occur as a result of the inputs received

from the remote control.

Software polling

For the design of the software, there was a choice between using interrupts and using polling to

determine when the robot may change states. The decoder circuit provides a valid transmission (VT)

output which is fed into port B pin 4. This output pulses when a new button press is received by the

receiver. Since at this time, the only thing the robot may do is change states, it was decided to poll this

pin on port B by using a bit mask. The polling solution keeps the software shorter and easier to

understand than an interrupt driven solution. The software polls port B pin 4 where VT is connected and

when a pulse is detected scans Port B pins 0 through 3. The results of the value read from port B along

with the current state information is used to determine the state to transition to next.

PORT B

Pin 0 Pin 1 Pin 2 Pin 3 Pin 4

LFT FWD RVS RGT VT

Phase locked loop

The final piece in the software design is the phase locked loop (PLL). In order to have the microcontroller

run in standalone mode, a PLL must be used to create and stabilize the 24MHz system clock. The

programming for the PLL can be found in the function init_PLL( ).

Software issues

There were many software issues that occurred. The process for troubleshooting these software issues

was to step through the code one line at a time, watch the results of the changes in the software

variables and while using the Serial monitor, in Codewarrior, observe the output from the PWM

channels on Port P. One particular issue that had to be remedied was an issue related to transitions to

the stopped state. When the robot was in the forward state, a press of the RVS button would

transition through stopped directly to reverse. The problem was found to be that VT stays high for

15

longer than a debounce period and causes a double transition. This was resolved by creating a software

delay of a full half second whenever the robot transitions to a stopped state.

Conclusion

The hardware for the transmitter was assembled on a breadboard with a 9 volt battery connected to the

voltage regulator. The receiver was assembled on the breadboard that is part of the dragon

development board. The dragon board and four servo motors were mounted to the project box chassis.

The software was uploaded using a serial USB cable to the microcontroller. Extensive testing and

troubleshooting took place, but finally the robot was able to drive, and all directions were achieved.

Project Recommendations

The project was well written and allowed for open ended interpretation by students. The ability to add

additional components to the robot such as distance detectors or to use a joystick for control instead of

buttons might make the project more engaging.

Technical Results

There are four 8-bit PWM channels used to control the four servo motors. Through simple programming

the microcontroller was able to take inputs from the decoder module and make decisions as to what to

output to the PWM channels controlling the wheels. There were limitations imposed by the hardware

that could have potentially been designed differently. There are only four purpose built servo controller

interfaces on the dragon board. These are hard wired to port p pins 4 through 7. Because four servos

needed to be driven by these four ports, 16 bit concatenation was not possible. With the 8 bit PWM,

resolution allowed steps in size of the duty cycle of only 0.1ms. These are large steps when considering

the range of the PWM duty cycle only varied by 1ms.

16

Critical Thinking Results

The tools and knowledge gained on both hardware and software in this course and during the

construction of this project create a foundation for a vast array of skills that are applicable in many fields

where technology is implemented today. These skills, including programming embedded controllers and

interfacing with microcontrollers have applications in many industries from computer hardware design,

automotive, pharmaceutical, moving boxes to beer production. Automation, human interfacing and

wireless communication are all elements of the future of technology.

17

Appendix A References

Huang, H. W. (2009). The hcs12 / 9s12: An introduction to software and hardware interfacing. (2 ed.).

Clifton Park, NY: Delmar.

Valvano, J. (2006). Embedded microcomputer system: real time interfacing. (2nd ed.). Mason, Ohio:

Cengage Learning.

18

Appendix B Source code

/******************************************************

*Written and tested by Brian Greiner 12/15/2012

*Week 6 Lab, Final project ECET 365 DeVry University

*Professor Peter Han

*This Program is used with the dragon12 development

*board and the MC9S12DG256 microcontroller

*to controll a robot using PWM

*A receiver module inputs to port B and the

*microcontoller outputs PWM to port p to drive

*servo motors

******************************************************/

#include <hidef.h> /* common defines and macros */

#include <mc9s12dg256.h> /* derivative information */

#pragma LINK_INFO DERIVATIVE "mc9s12dg256b"

const struct State {

int leftCtl; //left PWM duty

int rightCtl;//right PWM duty

const struct State *goTo[4];

};

typedef const struct State sType;

//buttons

#define RGT 0x01 //0001

#define FWD 0x02 //0010

#define RVS 0x04 //0100

#define LFT 0x08 //1000

//state pointers

#define ST &FSM[0] //stopped

#define CL &FSM[1] //circle left

#define CR &FSM[2] //circle right

#define FW &FSM[3] //forward

#define FR &FSM[4] //forward right

#define FL &FSM[5] //forward left

#define RV &FSM[6] //reverse

#define RR &FSM[7] //reverse right

#define RL &FSM[8] //reverse left

sType FSM[9]={ //states

{0,0,{CL,RV,FW,CR}}, //stopped

{20,20,{CL,RV,FW,ST}}, //circle left

{10,10,{ST,RV,FW,CR}}, //circle right

{20,10,{FL,ST,FW,FR}}, //forward

{20,15,{FL,ST,FW,FR}}, //forward right

{15,10,{FL,ST,FW,FR}}, //forward left

{10,20,{RL,RV,ST,RR}}, //reverse

{10,15,{RL,RV,ST,RR}}, //reverse right

{15,20,{RL,RV,ST,RR}}, //reverse left

};

char VT = 0; //valid transmission

19

char foo = 0; //holding port value

char NS = 0; //next state

sType *ptr;

void delay(int);

void PWMinit(void);

void init_PLL(void);

void runWheels(int, int);

void main(void){

DDRB = 0x00; // Port B inputs

PWMinit();

init_PLL();

ptr = ST;

while(1){

runWheels(ptr->leftCtl,ptr->rightCtl);

VT = 0;

while (VT == 0){ //wait for valid transmission

if ((PORTB & 0x10)!=0) {

delay(20); //debounce

VT = PORTB & 0x10;

}

}

foo = ~PORTB & 0x0f; //check which button was pressed

switch (foo){

case RGT: NS = 0;break;

case FWD: NS = 1;break;

case RVS: NS = 2;break;

case LFT: NS = 3;break;

default: break;

}

ptr=ptr->goTo[NS];

if (ptr->leftCtl == 0) delay(500); //pause if stopped for .5 sec

}

}

void delay(int del){ // delay for 'del' msecs

int i,j;

for(i=0; i<del; i++)

for(j=0; j<4000; j++);

}

void runWheels(int leftCtl, int rightCtl){

PWMDTY4 = rightCtl; //Front Right

PWMDTY6 = rightCtl; //Rear Right

PWMDTY5 = leftCtl; //Front Left

PWMDTY7 = leftCtl; //Rear Left

}

20

void PWMinit() {

PWMSCLA = 75; //scale aclock /(75 * 2)

PWMSCLB = 75; //scale bclock /(75 * 2)

PWMCLK = 0xf0; //Ch. 4,5,6,7 source: clock SA,SB

PWMPRCLK = 0x44; //Prescale A & B 2^4

PWMPOL = 0xF0; //Initial HIGH output (left-align) on ch. 4,5,6,7

PWMCTL = 0x00; //8-bit PWM counter, period and duty cycle registers

PWMPER4 = 200; //Channel 4 period value = 20 ms 1/((24MHz/2^4)/(75*2)) *

200

PWMDTY4 = 0; //duty initailly 0;

PWMPER5 = 200; //Channel 5

PWMDTY5 = 0;

PWMPER6 = 200; //Channel 6

PWMDTY6 = 0;

PWMPER7 = 200; //Channel 7

PWMDTY7 = 0;

PWME |= 0xf0; // turn-on PWM ch. 4,5,6,7

}

void init_PLL( ){ // initializes phase-locked loop (hardware)for 24Mhz CPU clock

asm(sei); // for running board standalone w/out Codewarrior

CLKSEL &= ~0x80;

PLLCTL |= 0x40;

SYNR = 0x05;

REFDV = 0x01;

while((CRGFLG & 0x08) == 0){ // wait here for lock

CRGFLG |= 0x08;

}

CLKSEL |= 0x80;

asm(cli);

} // use this function as is

21

Appendix C PWM State Outputs

Forward

Forward Left

22

Forward Right

Stopped

23

Reverse

Reverse Left

24

Reverse Right

Circle Left

25

Circle Right

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Gandarias 2020Documento8 páginasGandarias 2020duonglacbkAinda não há avaliações

- EMotorU3 2017 WebDocumento64 páginasEMotorU3 2017 Webzgregu21Ainda não há avaliações

- 6540 - 250 - 20 DC-servo For Servo MotorsDocumento8 páginas6540 - 250 - 20 DC-servo For Servo MotorsArkady ZabrovßkyAinda não há avaliações

- B-64303EN - 01 Connection Manual Hardware 0i-DDocumento514 páginasB-64303EN - 01 Connection Manual Hardware 0i-DBaldev SinghAinda não há avaliações

- Motoman hp3jcDocumento2 páginasMotoman hp3jcmiguel50% (2)

- Motoare Siemens PDFDocumento996 páginasMotoare Siemens PDFRamiro PetreAinda não há avaliações

- EE208 Lab ManualDocumento38 páginasEE208 Lab Manualsakib shaukatAinda não há avaliações

- BLUE - Quasi-Direct Drive For Low-Cost Compliant Robotic Manipulation ICRA - 2019Documento9 páginasBLUE - Quasi-Direct Drive For Low-Cost Compliant Robotic Manipulation ICRA - 2019Alfredo GalarzaAinda não há avaliações

- Pothole Filler ReportDocumento77 páginasPothole Filler Reportkrishna patil100% (2)

- DC Motors and Stepper Motors PDFDocumento8 páginasDC Motors and Stepper Motors PDFFrank AlvarezAinda não há avaliações

- Chapter One: Smart City SolutionsDocumento27 páginasChapter One: Smart City Solutionssnehal sabnisAinda não há avaliações

- KTA-290 Manual - NOT RSPDDocumento13 páginasKTA-290 Manual - NOT RSPDMagnus Clarkson100% (1)

- AGR Series Stage User's Manual: P/N: EDS139 (Revision 1.01.00)Documento52 páginasAGR Series Stage User's Manual: P/N: EDS139 (Revision 1.01.00)ccf927Ainda não há avaliações

- Blank TaxDocumento1.713 páginasBlank Taxapi-3809838Ainda não há avaliações

- M70-700 (M) Functions Compare With Fanuc-Ver.D (ENG)Documento2 páginasM70-700 (M) Functions Compare With Fanuc-Ver.D (ENG)Syahrul AbidinAinda não há avaliações

- AMETEK Customer GuideDocumento28 páginasAMETEK Customer GuideDis Tant SylphAinda não há avaliações

- RoboticsDocumento18 páginasRoboticslakshmigsr6610100% (1)

- Manual MOVINOR LNDocumento58 páginasManual MOVINOR LNABDOAinda não há avaliações

- Motion Control Drives: SINAMICS Inverters For Single-Axis Drives and SIMOTICS MotorsDocumento308 páginasMotion Control Drives: SINAMICS Inverters For Single-Axis Drives and SIMOTICS Motorsabhi sahdevAinda não há avaliações

- HF SN Manual ServoMotor Mitsubishi PDFDocumento96 páginasHF SN Manual ServoMotor Mitsubishi PDFDiana PitreAinda não há avaliações

- CS Engineer PaperDocumento99 páginasCS Engineer Papermgkvpr100% (1)

- Ed-7273Documento2 páginasEd-7273Benmiloud MarcusAinda não há avaliações

- SCI Volume 25Documento17 páginasSCI Volume 25Karan MAinda não há avaliações

- Disc On 1Documento5 páginasDisc On 1banmethuat2020Ainda não há avaliações

- A Arduino-Info - RobotKitAboutDocumento63 páginasA Arduino-Info - RobotKitAboutzakariiAinda não há avaliações

- Sri Ramakrishna Institute of Technology, Coimbatore-10: Mechatronics QUIZ-1Documento4 páginasSri Ramakrishna Institute of Technology, Coimbatore-10: Mechatronics QUIZ-1Veerakumar SAinda não há avaliações

- CMMS-ST enDocumento12 páginasCMMS-ST enJacpro Automation SacAinda não há avaliações

- Draw Frame: ##Difference Between Card Sliver and Drawn SliverDocumento13 páginasDraw Frame: ##Difference Between Card Sliver and Drawn SlivermdnadimAinda não há avaliações