Escolar Documentos

Profissional Documentos

Cultura Documentos

Ashrae Laboratory Design Guide PDF

Enviado por

errenmay91%(23)91% acharam este documento útil (23 votos)

8K visualizações225 páginasTítulo original

ASHRAE LABORATORY DESIGN GUIDE.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

91%(23)91% acharam este documento útil (23 votos)

8K visualizações225 páginasAshrae Laboratory Design Guide PDF

Enviado por

errenmayDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 225

ASHRAE

Laboratory

Design

Guide

American Society of Heating, Reftigerating and Air-Conditioning Engineers, Inc.

© 2001, American Society of Heating, Refrigerating and Air-Ci Engineers, Inc. (werwashrae.org). For

personal use only. Additional reproduction, distribution, or transmission in either print or digital form is not permitted

‘without ASHRAE’s prior written permission.

ASHRAE Laboratory

Design Guide

SRS apmeaueO paused 8 Buna owosnoait, 4 ON

‘quo on sono 0p LOH HOR 90 IN LUPIN O} Postos OPE Poy

This publication was prepared under ASHRAE Research Project 969. Ir was sponsored by TC 9.10,

About the Authors

Jan BD. Melntosh, PhD. is a recent Ph.D. graduate in mechanical engineering from the University of Wiscon.

sin—Madison and ts a member of ASHRAE and ASME. While working on his Ph.D. dissertation, he completed an

eight- monthresearch internship at Stemens Building Technologies —Landis Division, where he gave business and tech-

nical presentations toaid in the marketing of potential product concepts related to fault detection and diagnosis in HVAC

subsystems. Currently, he ts with Farnsworth Group, Inc.. and was the lead engineer in change of research and devel

‘opment ofthis publication,

Chad B. Dorgan, P-E.,Ph.D.,1s3 licensed professional engineerin Wisconsin, South Carolina, Oregon, and California

and Is a recent Ph.D. graduate in indoor air quality from the University of Wiscansin—Madison. Between 1989 and

1993, he coordinated a 60-person operationsand maintenance section for the United States Air Force. Asan engineering

teclinician, he was involved inthe analysisand optimization of over 30 large commercial and industrial facilities, includ

ing a Large enamel oven complex in Wisconsin and several auto manufacturer's facilites in Michigan. As part of these

studies, several publications for EPRI were developed, including EPRI's Cold dar Disiribution Design Guide, Field

Evaluation of Cold Air Dismibution Spstems, and Detailed Field Evaluation of a Cold Air Distribution System. Since

1993, he has led engineering activities at Farnsworth Group, Inc. (formerly Dorgan Associates)

Charles E,Dorgan, PE: Ph.D, has been invatved in refrigeration, air-conditioning, and energy projects since 1960.

A professional engineer since 1964, he is registered in Wisconsin, Ohio, Kansas, and South Carolina. He isan ASHRAE

fellow. He received his Ph.D. in mechanical engineering from the University of Wisconsin—Madisan in 1979. He has

‘authored or contributed to more than 25 books and more than 100 articles and other publications, plus various educa

tional presentations and engineering reports. Since 1980, he has had partial appointments at the University of Wis-

consin, while working for three different consulting firms, including Dorgan Assoctates.

Any updates/errata to this publication willbe posted on the

ASHRAE Web site at worwashrae org'pablicationspdate:,

on

100

BYUHSY fa panqiasia ‘paaused 8 Cunvomiey 10 vorRnpoider

quo nn" pve o1.0} LOOP HOR NOUN (UPC) Pos Oy FORE POR

ASHRAE Laboratory

Design Guide

lon B.D. Mdntosh

Chad B. Dorgan

Charles E. Dorgan

w

a, American Society of Heating, Refrigerating

iaY>/” and Air-Conditioning Engineers, Inc.

4 on

2

Pat

1uad #1 Bunsen 10 uorpapoidos

102 vo 1 LEM O} Po eeu

0 pat

i

fa pan

PURO

ISBN 10: 1-883413-97-4

ISBN 13: 978-1-883413-97-2

©2001 American Society of Heating. Refrigerating

and Air-Conditioning Engineers, Inc,

1791 Tullie Circle, NE.

Ailania, CA 30825,

‘wwrw.ashrae.org,

All rights reserved.

Printed in the United States of America on 10% post-consumer waste,

Cover design by Tracy Becker.

ASHRAE has compiled this publication with care, bat ASHRAE has not investigated, and ASHRAE expressly disclaims

any duty to investigate, any product, service, process, procedure. design othe like that may be described herein. The

‘appearance of any technical data or editorial material in this publication does not constitute endorsement, warranty, or

guaranty by ASHRAE of any product, service, process, procedure, desiga, or the lke. ASHRAF does not warrant thatthe

{Information in the publication is free of errers, and ASHRAE does aot necessarily agree with any statement or opinion in

this publication. The entire risk ofthe use of any information inthis publication is assumed by the user.

[Na part of this book may be reproduced without permission in writing from ASHRAE, except by a reviewer who may

{quote brief passages or reproduce illustrations ina review with appropeiate credit: nor may any part of this book be repro

duced, stored in a reieval system, or transmitted in any way of by any means electronic, photocopying, recording, or

cother—without permission in writing from ASHRAE, Requests for permission should be subraited at wwwashae.org/

permissions

ASHRAE STAFF

Special Publications Publishing Services

Mildred Geshrwiler Barry Kurian

editor Manager

Erin S. Howard Jayne Jackson

Assistant Fdtor Production Assistant

Christina Johnson

Eduortal Assistant

Publisher

Meter W.Stephen Comstock

Secretary

ByaNsy Karamar payed s Buncoms 0 vornooida Jeary oN

gue 950"§ PEON DH LOO VO 902 WN LPS OF Pos OH UI POR OMESD

Table of Contents

Adowedgments.

Chapter 1 Inttoduction

Overview. a

‘Organization. ss

Chapter? Background

Oveniew no

Laboratory Types.

Laboratory Equipment,

References

Chapter. laborotory Panning

Overview...

Risk Assessment. Sosa

‘Identification and Understanding of Hazards.

Laboratory Codes, Standards and References

Integration of Architecture and Engineered Systems,

Development of Planning Documents.

References... rst

Bibliography...

Yay Mapapa 8 panies turamin 1 vorenpcntos ge ON

quo oxn Hee DF LOT OPIN 80 OLN LAMM CH PR U2 LOR POLES,

SHRAE obumta Design Guide

Chopier4 Design Process

Overview .

Design Process ci

Special Space Considerations

References coe

Chapter 5 Exhaust Hoods

Overview

(Chemical Fume Hoods

Perchloric Acid Hood...

Biological Safety Cabinet

Other Hood Types “

Hood Safety Certification and Continous Monitoring,

Selection of Exhaust Hoods

References.

Chapter 6 Primary Air Systems

Zone Air Distribution ....

Zone Heating.

‘Exhaust Air System.

Supply Air System

Duct Construction. a

Energy Efficiencies .......

References.

Chopter7 Process Cooling

Overview. e

‘Types of Water Cooled Loads.

Water Treatment and Quality Requirements

‘Temperature and Pressure Requirements

‘Pumping System Configurations. 7

References. “= etary

Chopier8 Ai Treatment

Overview.

Requirements.

Scrubbing

‘Condensing.

References.

ieSY Kapaa paula’ stun 1 vrEnpcitas gy ot

yuo sn ¢ paeONOI Dh LOTITO 00 WEMMO} Poe oy Le PORTO

Ghogier 9 haust Stack Design

QVETVEW on nennnnnene nnn

Elements of Stack Design...

Dispersion Modeling Approach ..

References 2 2

Chapter 10. Energy Recovery

Overview. 7

Alir-to-Alir Heat Recovery.

Woater-o-Air Heat Recovery...

Selection Parameters...

References

Bibliography.

Chapter 11. Contols

Overview. -

Equipment Control...

Room Control... 0

(Central System Emergency Situations

References 7

Chapter 12 Airflow Pattems and Air Balance

Overview.

Aiflow Pattems

Testing, Adjusting, and Balancing

Laboratory Testing Requirements

References z “

Chapter 13 Operation and Maintenance

Overview . 7 -

Decontamination of Existing Laboratories

‘Maintenance of Equipment and Systems.

(Cost Information ... “

Training ..

Reference..

Chapter 14 Laboratory Commissioning Process

Overview. .

‘The Commissioning Process

Planning Phase

Design Phase. .

‘Construction Phase...

ielSY Mapepaie9 panied s tunuomin 1 vornpontos ge oN

Poweutac

quo 080 $eaeoo OF LOVOPIOZ WO IEW WENA} PaURDS PLO

ISHRAE ebony Design Gude

Chapter 15 HVAC System Economics

Overview. s

Initial Price of System een

Life Cycle Cost ANALYSIS. ocnniminnnnn

Chapter 15 Microbiological ond Biomedical Laboratres

Overview... a

Biological Containment

Animal Overview... 7

Design of Laboratory Animal Areas

ARP EN ono

References...

Amototed Bibliography.

Index

SYUNSy Aa para eG, pamuiedw Oungonin 0 vormoode ary oN

wad

‘yuo oer tsaeoo OF LO LOPIOZ UO HOT WuESIAN) Poe uo BuOPeU

Acknowledgments

BRSY a pape patie | unsonie 0 wlEnpcada ey ot

yuo sn teen Dh LITO HL 00 1 WENEMON Poe soy URE PERIOD

‘This guide was developed through a cooperative effort of the Famsworth Group, Inc.

formerly known as Dorgan Associates, and laboratory industry experts. The input of the

ASHRAE Project Monitoring Subcommittee, chaired by John Mentzer (Giffels Associ-

ates, Inc.) and including members Pete Gardner, Joim Varley. Bob Weidner, and Randall

Lacey, was instrumental in achieving a successful guide. Special thanks to Jack Wunder

forhis detailed review of the draft guide and access to the laboratories at the University of

Wisconsin-Madison

‘The input provided by several key people, including designers, manufacturers, and

others, was invaluable in making the guide whole. These include Todd Hardwick, Otto

Van Geet, Victor Neumm, Carl Lawson, Greg De Luga, Geoftiey Bell, Luis Solarte,

Daniel Ghidoni, Patrick Chudedke, Edward Fiance, Robert Haugen, Tom Begley, Bob

Parsons, and Gary Butler

‘Dorgn Associates’ staff members who deserve recognition for their contributions

inchide Svein Momer, Ph.D. and Zachary Obert for their detailed input on writing various

sections of the guide and endless hours of reviewing background material for ensuring

fechmical accuracy of the guide. Chad Grindle’s efforts in creating and editing the Inm-

reds of graphics required to make the guide understandable and useful are appreciated.

Sincere thanks go to Joan Dorgan for proofieading. Finally, we would have never finished

the guide without the tireless efforts of Suzanne Bowen in word-processing and prooftead-

ing fo ensure consistency in formatting. and general legibility was maintained

Rpyrgtied ateit tant to Winn Mi econ 7014.0. Icon ne ony

No kirber reproduction or networking is permed, Ont buted by ASHE

Chopter 1

Introduction

OVERVIEW

‘The American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (ASHRAE), commis-

sioned this design guide in response to the need for a comprehensive reference miamual for the planning, layout, and

design of laboratories. Its intended that the information in this guide assist engineers, owners, and system operators

in determining the needs of their Inboratory facility and how to best match these needs to mechanical system options.

‘The Guide is written in a manner that progresses from general to specific to reach a wide target audience of

designers, architects, engineers. owners, operations and maintenance personnel, and others in the heating, ventilating,

sir-conditioning, and refrigerating (HVACR) industry. The beginning chapters of the Guide present general back

‘ground information and prescribed desizm frameworks, whereas the later chapters are more specific, providing

detailed design and application information.

‘A primary benefit of this structure is that many types of readers can use the Guide. Whereas an owner may only

read the first fo chapters, an engineer may focus on the design chapters.

‘To improve the comprehension of the material for those unfamiliar with laboratory design, the guide is organized

around a typical project. progressing through the basic steps of planning, design. construction, and operation and

maintenance (OSM). This Guide consists of sixteen chapters.

ORGANIZATION

* Chapter 2, “Background” provides basic background information on laboratories including their various

types and typical equipment found in them The intent of this chapter is to provide a basic understanding of

laboratories, their importance, as well as their different fictions and needs

Chapter 3, “Laboratory Planning” describes the many important issues that are addressed during the plan-

ning phase ofa laboratory project. At the very core of this phase is the need to ensure the utmost safety for

the laboratory occupants via risk assessment and hazard analyses while achieving experimental integnity.

good comfort and indoor air quality, the capacity to meet operating loads, and successful integration of

architecture ancl engineering systems. These Various important considerations are then carefully documented

in the owner's program of requirement and the owner's design intent.

Chapter 4, “Desizn Process” outlines the design process with guidance provided to designers and engineers

on the key steps in meeting or exceeding the owner's design intent. Also included in this chapter is a review

of special space design considerations forthe different system types encountered in a laboratory.

+ Chapter 5, “Exhaust Hoods” details the operability, types, and applications of exhaust hoods.

BRSY a pape patie | unsonie 0 wlEnpcada ey ot

yuo sn teen Dh LITO HL 00 1 WENEMON Poe soy URE PERIOD

ASHRAE Lobutay Design Guide

Chapter 6, “Primary Air Systems” describes

the many EAC system options that are avail-

able for conditioning and contaminant

removal, including supply systems, room or

space air diffusing, exhaust systems, duct con-

struction, and energy efficiencies

(Chapter 7, “Process Cooling” examines the if.

ferent system options available to meet supple-

mentary process cooling needs. This includes

the types of water-cooled loads found in labo-

ratories, water treatment and quality, tempera-

ture and pressure requirements, and pumping

system configurations

Chapter 8, “Air Treatment” presents several

methods of treating the air as it is either

expelled to the outside environment or drawn

into the laboratory space from the outside.

Chapter 9, “Exhaust Stack Design” deals with

the final conduit through which air is expelled

and diluted into the environment ~ exhaust

stacks. Required elements for good exhaust

stack design in addition to modeling techniques

available for design verification are described.

Chapter 10, “Enerzy Recovery” addresses the

recovery of the temperature humidity content

of the exhaust air or other sources of energy

that would othenwise be wasted, to realize eco-

nomic savings. The two main energy recovery

technologies discussed are air-to-air and water-

to-air heat recovery. In addition, key parame-

ters are presented that are used to properly

select heat recovery options

Chapter 11, “Controls” discusses control for

constant volume fume hoods, variable volume

fame hoods, and other exhaust equipment.

Room control discussion includes the theory of

room control, outside air needs, minimum ven-

tilation air changes per hour, control stability,

variable and constant volume strategies, con-

trol of critical spaces, and building pressuiza-

tion.

Chapter 12, “Airflow Pattems and Air Bal-

ance” provides an understanding of airflow

‘pattems throughout the laboratory environment

and how they need to be maintained in a spe-

cific direction and velocity to protect against

malicious pollutants or contamination. This is

followed by descriptions of the proper air and

hydronic balancing and testing procedures.

Chapter 13, “Operation and Maintenance

details how to properly operate and maintain

laboratory systems to ensure the contimual

safety of occupants, quality of laboratory

experiments, and efficiency of HVAC and lab-

‘oratory equipment, To this end, this chapter

discusses the training needed for O&M person

nel and laboratory users. In addition, operating

‘costs and the importance of continual fume

hood and biological safety cabinet testing and

certification is also addressed

‘Chapter 14, “Laboratory Commissioning Pro-

‘ces5" introduces the quality method known as

the commissioning process, which commences

‘during the planning phase and follows through

to the design, construction, acceptance, tum-

‘over, and operation phases of the laboratory

building project. In so doing, the commission-

ing process ensures that the diverse require-

ments for the laboratory and the owner's

sdesign intent are met.

‘Chapter 15, “HVAC System Economics” cov-

rs both the initial costs (costs associated with

planning. design, and construction) and life-

‘oycle costs (costs associated with operation and

maintenance) of the laboratory facility.

Although more emphasis is often given to the

initial cost due to budgetary constraints, this

chapter also considers the life-cycle cost in

designing the laboratory. This is important

since a substantial investment is required to

effectively operate and maintain the laboratory

systems and equipment over a lift span of 15 to

30 years,

‘Chapter 16, “Microbiological and Biomedical

Laboratories” provides specific information

about laboratories that specialize in biological

‘containment and that house animal areas. Due

to the importance of containing and controlling

Diohazards and product protection within these

special laboratories issues such as system reli-

ability, redundancy, proper space pressuriza-

tion, envelope design, and sanitation are

addressed.

Reference Sources

American Society of Heating, Refrigerating

cand is-Conditioning Engineers, Inc.

ASHRAE is an intemational professional society

‘with more than 50,000 members worldwide. The Soci-

ety was organized for the sole purpose of advancing the

arts and sciences of heating, ventilation, air-condition.

‘ng, and reftigeration for the benefit of the public. The

Society achieves these goals through sponsorship of

research, standards development, contiming education,

‘and publications. For additional information. contact the

Society a:

BYUSY pane. panied 8 bunsoniy 0 vornpoides ry

pou

Agus oun tsar OF LOOP IOZ 00 IW LHPSIMO} Poets eee

American Society of Heating, Reffigerating

‘and Air-Conditioning Engineers, Inc

1791 Tullie Cucle, NE

Atlanta, GA 30329-2305

Tel: (404) 636-8400

Fax: (404) 321-5478

Infemet: wwwashrae org

Building Officials and Code

Administrators International, Inc.

Building Officials and Code Administrators Inter-

national, Ine. (BOCA), is a nonprofit association that

hhas been establishing and enforcing building codes

since 1915. The association curently has over 16,000

members fully dedicated to the development and

enforcement of codes that benefit the public safety and

health For additional information contact BOCA at

‘Building Officials and Code

Administrators Infemational, Inc

4051 W. Flossmoor Ra

Country Club Fills, 160478

Tel: (708) 799-2300

Fax: (708) 799-4981

Intemet: www bocai org

Centers for Disease Control and Prevention

The Centers for Disease Control and Prevention

(CDO is a federal institation whose primary goal and

pledge is “to promote health and quality of life by pre-

venting and controlling disease, injmy, and disabibty.”

Toachieve this pledge. the CDC uses federal and private

fimding for research and development in several fields

and sciences at its 11 different laboratories and loca-

tions. For additional information the CDC may be con-

tacted at

(Centers for Disease Control and Prevention

1600 Clifton Road, NE

Atlanta, GA 30333

Tek: (BOO) 311-3435

Intemet: wor ede gov

Institute of Environmental Sciences

‘and Technology

‘The Institute of Environmental Sciences and Tech-

nology (EST). founded in 1953 as a nonprofit organiza

tion, is an intemational society in the area of

contamination control and publishes recommended

practices for testing cleanrooms, HEPA/ULPA filters,

and clean air filtration systems. For additional informa-

tion, contact IEST at:

Institute of Environmental Sciences and Teclnology

‘940 E. Northwest Highway

Mount Prospect, IL 60056

Tel: (847) 255-1561

Fax: (847) 255-1699

Intemet worwiest org

Institute of Laboratory Animal Resources

TLAR, or the Instiule of Laboratory Animal

Resources, has been a national leader in the research,

publication, and collection of information pertinent to

‘animal care and use inthe laboratory setting since 1952

For additional information contact ILAR at

Institute of Laboratory Animal Resources

2101 Constitution Avene. NW

‘Washington, D.C. 20418,

Tel: 200) 334-2590

Fax: 202) 334-1687

E-mail: ITAR@mas.ecu

Intemet: www nas eduiclsilarhome nsf

‘National Insrinutes of Health

The National Institutes of Health (NTH) is a feder-

ally fmded laboratory dedicated to the research and

development of medicine to aid the health of people

around the world. Founded in 1887, the NIH fimds

rational and intemational research in numerous medical

fields to accomplish this dedication to health. For addi-

‘ional information contact the NIH at

‘National Institutes of Health

Bethesda, MD 2089?

Tel: 201) 496-4000

Research funding E-mail: grantsinfo@nih gov

Intemet: wewnih gov

National Fire Protection Association

‘The National Fire Protection Association (NFPA) is

‘a intemational leader in the development of fire, elec-

trical, and life safety for the public. This nonprofit,

member association was founded in 1896 to develop

consensus codes and standards, as well as training

research, and education in fire and other hazard protec-

tions in various buildings, NFPA has over 67,000 mem

bers and is associated with 80 national and professional

‘organizations from across the globe. For more informa-

tion contact the NFPA at:

‘National Fire Protection Association

1 Batterymarch Park

PO. Box 9101

Quincy, MA 02269-9101

“Tek: (617) 770-3000

Fax: (617) 770.0700

Intemet: www nfpa org

National Reseasch Council

‘The National Research Council (NRC) was formed

by the National Academies of Science in 1916 to bridge

the gap between the science and technology communities

and the federal goverment. Today, the NRC continues

‘his initiative by supplying information and advice tothe

federal. and public sectors on the cument issues and

3

BYUISY Ma paPeneD pated 9 tunsony 0 woRnpode aay ot

Po bulde

yuo o8n tea OF LOO PIO 0 AW LaPAAO} Pow sos

Você também pode gostar

- IEQc1 CreditFormDocumento2 páginasIEQc1 CreditFormerrenmayAinda não há avaliações

- Wets 2002.1002 - 10 13Documento1 páginaWets 2002.1002 - 10 13errenmayAinda não há avaliações

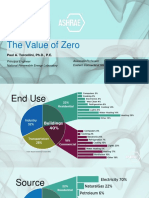

- The Value of Zero: Paul A. Torcellini, PH.D., P.EDocumento23 páginasThe Value of Zero: Paul A. Torcellini, PH.D., P.EerrenmayAinda não há avaliações

- The Team of Net Zero: Philip Macey, AIA, National Director CollaborationDocumento19 páginasThe Team of Net Zero: Philip Macey, AIA, National Director CollaborationerrenmayAinda não há avaliações

- FaucetDocumento2 páginasFauceterrenmayAinda não há avaliações

- Ventilation FundamentalsDocumento24 páginasVentilation FundamentalsSomnath SenAinda não há avaliações

- EAc1 CreditFormDocumento2 páginasEAc1 CreditFormerrenmayAinda não há avaliações

- EAp2 CreditFormDocumento13 páginasEAp2 CreditFormerrenmayAinda não há avaliações

- Guia VRF LGDocumento24 páginasGuia VRF LGYves CamelotAinda não há avaliações

- KVSHoods CatalogDocumento32 páginasKVSHoods Catalogerrenmay100% (1)

- Weus 10021001 025Documento1 páginaWeus 10021001 025errenmayAinda não há avaliações

- Metraflex: For Pipes in MotionDocumento1 páginaMetraflex: For Pipes in MotionerrenmayAinda não há avaliações

- Siesmic Protection Ufc 3 310 04Documento128 páginasSiesmic Protection Ufc 3 310 04irastemhemAinda não há avaliações

- Guide to Development Requirements on GuamDocumento169 páginasGuide to Development Requirements on GuamerrenmayAinda não há avaliações

- Water CloserDocumento1 páginaWater ClosererrenmayAinda não há avaliações

- Complete CatalogsDocumento272 páginasComplete CatalogserrenmayAinda não há avaliações

- 30rb 18pdDocumento106 páginas30rb 18pdLouie DupayaAinda não há avaliações

- UDF400 - DFO Field Start-Up GuDocumento16 páginasUDF400 - DFO Field Start-Up GuerrenmayAinda não há avaliações

- Fuel Pipe Friction ChartDocumento7 páginasFuel Pipe Friction CharterrenmayAinda não há avaliações

- SS-3002 Series: Drop in LavatoryDocumento1 páginaSS-3002 Series: Drop in LavatoryerrenmayAinda não há avaliações

- Hvac l1 2013 CepsDocumento48 páginasHvac l1 2013 CepserrenmayAinda não há avaliações

- Aquaboost VS: Pressure BoostersDocumento2 páginasAquaboost VS: Pressure BoosterserrenmayAinda não há avaliações

- BRAQBSTDocumento8 páginasBRAQBSTerrenmayAinda não há avaliações

- IOM AquaBoost en USDocumento48 páginasIOM AquaBoost en USKrish DoodnauthAinda não há avaliações

- Fire Protection Drawings 10-02-08Documento2 páginasFire Protection Drawings 10-02-08errenmayAinda não há avaliações

- Team Usa Medium Pattern Flier WebDocumento1 páginaTeam Usa Medium Pattern Flier WeberrenmayAinda não há avaliações

- Hydr Valve 60554Documento7 páginasHydr Valve 60554errenmayAinda não há avaliações

- Vav PRC011 en - 07162013Documento146 páginasVav PRC011 en - 07162013errenmay100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)