Escolar Documentos

Profissional Documentos

Cultura Documentos

Thread Supercapacitors

Enviado por

Just4545Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Thread Supercapacitors

Enviado por

Just4545Direitos autorais:

Formatos disponíveis

Smart Science Vol. 2, No. 3, pp.

107-115(2014)

http://dx.doi.org/10.6493/SmartSci.2014.255

Fabrication and Characterisation of Flexible Coaxial Thin

Thread Supercapacitors

Fulian Qiu1,*, David Harrison1,*, John Fyson1 and Darren Southee2

1Department

of Design, Brunel University, London, United Kingdom

school, Loughborough University, Leicestershire, United Kingdom

* Corresponding Author / E-mail: fulian.qiu@brunel.ac.uk, David.harrison@brunel.ac.uk

2Design

KEYWORDS : Supercapacitor, Coaxial thread, Energy storage, Smart electronics, Semi-automatic processing, Carbon ink

Flexible coaxial thin thread supercapacitors were fabricated semi-automatically using a dip coating method. A typical coaxial

thin thread supercapacitor of a length of 70 cm demonstrated a specific length capacitance of 0.3 mF cm-1 (11.2 mF cm-2 and

2.18 F cm-3) at 5 mV s-1, the device exhibited good electrochemical performance with a high volume energy density of 0.22

mWh cm-3 at a power density of 22 mW cm-3. Thread supercapacitors were assembled in series and parallel combinations, the

accepted models for series and parallel circuit combinations were obeyed for two coaxial thread supercapacitors. The thread

shows high flexibility and uniformity of specific length capacitance, one integrated with a commercial solar cell could be

charged and power a LED. The process is simple, robust and easy to scale up to make unlimited length thread supercapacitors

for numerous miniaturized and flexible electronic applications.

Manuscript received: May 11, 2014 / Accepted: June 12, 2014

1. Introduction

coated carbon microfiber as core active material has been reported by

Le [15]. A coaxial single fibre supercapacitor made manually has also

been reported in a previous paper by Harrison et al. It has shown a

good stability and flexibility [17]. In this current paper we move on to

describe ways of making the fibre, and report a series of further

electrochemical studies on longer thin threads to characterise their

performance. We report the development of a purpose-built semiautomatic dip coating setup to facilitate uniform coatings for the

fabrication of long coaxial thread supercapacitors. This is a difficult

procedure to control manually. A range of long coaxial thread

supercapacitors were prepared using this equipment. The charge

storage properties and dynamic stability of a coaxial thread

supercapacitor were fully characterised by cyclic voltammetry,

galvanostatic charge-discharge and electrochemical impedance

spectroscopy. This report also focuses on the potential of the device to

be an alternative power source to rechargeable batteries, by exploring

its power density, combination circuits, capacitance uniformity with

length, and integration with electronics, which have not been

investigated in ref [17]. Power density verses energy density, the

combination circuits (series and parallel) of two coaxial thread

supercapacitors and length dependent capacitance were investigated.

Integration with a commercial solar powered LED was presented.

This kind of coaxial thin thread supercapacitor is flexible and has a

number of potential applications as a wearable power source.

The incorporation of energy storage devices into fabrics has the

potential to offer significant advances. With rapid development of

wearable electronic devices [1-4], wearable, miniaturised, compact,

flexible, and lightweight power sources including batteries, solar

cells and supercapacitors [5, 6] are in high demand. For smart

textiles, the ideal energy storage devices would be weaveable,

knittable and embeddable in order to sustain their functionality

during body movement and on curved surfaces.

As one type of power storage device, supercapacitors have many

advantages over rechargeable batteries as they have higher power

densities, are low cost, easily fabricated, have a long life time, easily

recharged maybe non-toxic and are safe to use [7-9]. Many studies on

supercapacitors have focused on applications in electric vehicles,

hybrid electric vehicles and backup energy sources [10]. Recently,

there has been an emerging interest in fibre supercapacitors, including

those using Chinese ink coated nickel wires, a carbon nanotube-Ti

nanotube fibre supercapacitor integrated with a photoelectrical fibre,

twisted carbon nanotube fibres supercapacitor and two-polymer yarn

supercapacitors using polyaniline nanowire arrays; for all these fibre

devices, only two short fibres were arranged either helically or in

parallel for electrochemical studies [11-15]. In addition,

microsupercapacitors for microelectronic applications have also been

reported [16].

In order to make a simpler more compact device, a coaxial design

might be used. A coaxial fibre supercapacitor using a carbon nanotube

Smart Science

107

Smart Science Vol. 2, No. 3, pp. 107-115(2014)

2. Experimental

m, 120 m, 140 m, 200 m and 300 m (in diameter) were created

for the inner ink layer, the gel electrolyte, the outer ink coating, the

silver paint layer and the PVA gel protective layer respectively.

2.1 Materials

A carbon-based Chinese ink (Li-Tinggui) was obtained from an

art shop, which was comprised of 50 nm diameter carbon

nanoparticles, more details can be found in the coaxial fibre

supercapacitor study [17]. Polyvinyl alcohol (PVA, MW 146,000

186,000, 99+% hydrolysed) and anhydrous phosphoric acid were

purchased from Sigma-Aldrich and used without further purification.

Silver paint was purchased from RS Components Ltd. and a

stainless steel wire (AISI304L Fe/Cr18/Ni10, 50 m in diameter) and

a copper wire (50 m in diameter) both from Advent Research

Materials.

2.2 Preparation of PVA gel electrolyte

PVA powder was dissolved into water (Milli-Q, resistivity, 18.2

M cm at 25C) at 85C with magnetic stirring. A transparent

solution was achieved when PVA particles were fully dissolved.

Phosphoric acid gel electrolyte solution was prepared by dissolving

the required amount of anhydrous phosphoric acid into the PVA

solution [18].

Fig. 2 Schematic of the purpose-built dip coating setup

2.3 Fabrication of a coaxial thin thread supercapacitor (CTSC)

Fig. 1 shows the schematic structure of a CTSC. It consists of a

50 m stainless steel core wire, three active layers, one silver paint

layer and one PVA polymer protective layer. The core wire and silver

paint layer serve as the two current collectors. Three active layers

include two carbon Chinese ink layers and one gel layer between

them. The two ink layers serve as working electrodes for storing

charges; the gel layer serves as a separator and ion conductor.

Fig. 1 Schematic structure of a CTSC

A bobbin wound with the stainless steel wire was fixed onto the

motor and a small weight was clamped to the bottom end of the core

wire, which keeps the wire straight in an up-down alignment. The

motor has a two-direction controller which allows the load to move

up or down. When the coating process was performed, a drop of

coating liquid (or slurry) was applied to the centre of the disc such

that the wire moves through it. During the movement of the core wire

it dragged the liquid with it, the solvent was vapourised and a coating

layer was formed on the wire. Five layers were coated onto the core

sequentially. The thickness of each coating layer can be adjusted by

varying the time the wire is in the liquid drop which is controlled by

motor speed (a motor speed of 0.5 m minute-1 was used throughout

these experiments) and also by coating a number of times through

each drop. The wait time interval is 5 minutes for ink and gel

electrolyte coatings which is sufficient for the coating to dry enough

such that it does not dissolve in the following dip. 10/4/4 times

coatings were performed for three active layers respectively; two

coatings were used for both silver paint layer current collector and

PVA protective layers. In order to minimize the interface between the

electrolyte in 2nd ink layer and silver paint outer current collector, 2nd

ink layer was dried in air for two hours before silver paint coating was

conducted. Silver paint layer was left in air for 12 hours to fully cure.

Chinese ink, 10 wt% H3PO4 / 8.3 wt% PVA gel electrolyte, silver

paint and 10 wt% PVA gel solution were used throughout experiment

for each layer coating respectively. The core stainless steel wire and a

50 m copper wire attached to the silver collector were used for

electrochemical measurements.

2.4 Microscopic characterization

Fig. 2 shows a purpose-built dip coating setup for the preparation

of long coaxial thin thread supercapacitors. This setup consists of

multi-speed controlled motor and Perspex discs of a radius of 1.5 cm.

In the centre of the discs are different sizes of sub-millimetre holes

that were machined using laser cutting. These holes allowed the core

wire through and facilitated the dip coating processes. Holes of 100

An optical microscope (Olympus BHM, Trinocular MTV-3 with

Nikon Coolpix 990 3.34 MP Digital Camera, Japan) was used to

examine the surface morphologies of the cross section structure of the

device. The sample was prepared by sealing the thread in Araldite

and leaving it overnight to solidify. It was then polished using

Smart Science

108

Smart Science Vol. 2, No. 3, pp. 107-115(2014)

sandpaper (P1250, P2500 and P4000) and gamma alumina powder of

size from 1 m to 0.025 m, rinsed using deionised water and

methanol, and then dried in air.

2.5 Solar powered LED lighting

Solar powered garden light was bought from a Poundland shop. It

consist of four 2.2 0.6 cm solar cells in parallel, 1.2 V NiH-M

battery and a LED bulb; there is a circuit inside which amplify

operating voltage to above 1.5 V the minimum voltage required for

driving a LED red. When sunlight is available, the battery is charged.

Otherwise, the battery would discharge and light a LED. For the

lighting test, the battery was replaced by a CTSC.

Fig. 3 (a) Photo of a 70 cm long CTSC on a bobbin and (b) Crosssection optical image of the CTSC

3.2 A coaxial single CTSC characterisation

Electrochemical performance of the 70 cm long CTSC was

studied using cyclic voltammetry, electrochemical impedance

spectroscopy and galvanostatic charge-discharge cycling as shown in

Fig. 4. Fig. 4a shows typical cyclic voltammograms recorded at

different scan rates (5, 20, 50, 100 and 200 mV s-1) between 0 V and 1

V. It can be seen that the charge current increases with scan rate. The

capacitive rectangular CV shape is distorted, and the distortion

becomes more pronounced when scan rate is increased. This might be

explained by the series resistances including gel electrolyte, diffusion

processes in the porous carbon nanostructure, electrical resistance of

the porous carbon network and the wire resistance [19]. No faradaic

processes were noted, which demonstrated the good stability of the

stainless steel wire and the silver paint layer current collectors.

Capacitance can be estimated by equation (1)

2.6 Electrochemical characterisation

Electrochemical measurements were performed using a

VersaSTAT 3.0 (Princeton Applied Research) electrochemical

workstation. A two-electrode setup was used throughout the

experiments. The core stainless steel and a thin copper microwire

embedded in the silver paint layer served as working and counter

electrodes respectively. The working electrode (stainless steel wire)

was kept positive with respect to the counter electrode to prevent

oxidation of the silver current collector. Electrochemical impedance

spectra were determined at open circuit potential using a 5 mV AC

modulation for a frequency ranged from 100 kHz down to 0.01 Hz.

Cyclic

voltammetry,

galvanostatic

charge-discharge

and

electrochemical impedance spectroscopy (EIS) measurements were

used to evaluate the performance of the supercapacitors.

3. Results and discussion

(1)

Where C is the capacitance; i is the current; dV is the rate of

change of sampling potential, v is the scan rate and V is the potential

window. The capacitance as a function of scan rate is shown in Fig.

4b. At 5 mV s-1, a specific length capacitance of 0.3 mF cm-1 was

obtained, and this value decreases sharply before the scan rate reaches

50 mVs-1, and then followed by decreasing gradually with increasing

scan rate further. Length capacitances ranged from 0.3 to 0.024 mF

cm-1 were obtained as scan rate varies from 5 to 200 mV s-1. Areal

and total volume specific capacitances were also calculated, the

surface area is defined only by 1st ink layer (1.9 cm2), and the total

volume includes two ink layers (0.0097 cm3) and gel electrolyte

separator, corresponding specific areal and volume capacitances were

11 to 0.9. mF cm-2 and 2.162 to 0.175 F cm-3 respectively. These

results are higher than those in our previous report [17] and

comparable to those of reported fibre supercapacitors recently [15,

20]. Fig. 4c shows an electrochemical impedance spectroscopy

Nyquist plot performed at 5 mV AC perturbation for a frequency

range of 100 kHz down to 0.01 Hz. An electrical series resistance

(ESR) of 140 was obtained, which originated from wire resistances,

contact resistances between collectors and active carbon material,

electrical resistance of carbon active material and electrical resistance

of gel electrolyte throughout the whole device. The specific length

resistance is 2 cm-1 which is smaller than those reported for

3.1 Structure characterisation

Fig. 3 shows a photo of a 70 cm CTSC wound onto a bobbin

together with 50 m stainless steel wire (a) and the cross-section

image of a typical CTSC (b). From Fig. 3b, it can be seen that the

coaxial thread supercapacitor has a cross-section diameter of about

0.25 mm. A circular geometry and uniformity for each active layer of

ink/gel/ink are observed as shown in Fig. 3b, and the thickness of the

three active layers was measured as 18/10/17.5 m respectively. A

range of thread supercapacitors with different lengths were

manufactured.

Smart Science

109

Smart Science Vol. 2, No. 3, pp. 107-115(2014)

previous fibre supercapacitors [15, 21, 22]. This ESR value is the

partly made up by the inherent resistance of the core which has a

specific resistance of 4 cm-1. No EIS semicircle is observed in the

higher frequency range, which if present would represent a main

contributor to leakage current. The characteristic frequency f0 for a

phase angle of 45 is about 0.04 Hz, at this frequency, the resistive

and capacitive impedance are equal [23]. The corresponding time

constant 0 (= 1/f0) equals 25 s which is longer than the 10 s for a

conventional activated carbon based supercapacitor. A slow diffusion

process is noted as the slope trends upwards from middle to low

frequencies as transmission line model predicts [24]. This is in good

agreement with the results of cyclic voltammetry and chargedischarge measurements. A similar slope trend of Nyquist plots for

gel electrolyte systems has also been reported [25].

mA (a), the tenth cyclic charge-discharge curve on separate runs at

different charging currents from 0.8 mA to 2.5 mA (b), the

capacitance as a function of charge-discharge current calculated from

the discharge curves of the tenth cycles (c) and Ragone plots (d). It

can be seen from Fig. 5a that the charge-discharge curve is welldefined and symmetric; the iR drop is noted at the early stage of the

charging and discharging curves. For a particular cycle, charge and

discharge time decreases as the charge current increases, and the iR

drop increases with increasing current as expected (Fig. 5b). The

capacitance can be calculated using the following equation (2)

(2)

Where t is the discharging time, V is the actual voltage

excluding iR drop of the discharge process and other parameters have

identical meanings as before. The discharge curve was used for the

capacitance calculation. Specific length capacitances ranging from to

0.05 to 0.22 mF cm-1 were obtained for the current varying from 0.4

to 3 mA, corresponding to an areal capacitance range from 1.8 to 7.3

mF cm-2 (2.2 to 0.17 F cm-3) These results are within the reference

ranges for specific length and areal capacitances for carbon based

fibre supercapacitors, 0.02 to 6.3 mF cm-1 and 0.4 to 71 mF cm-2 have

been reported [26, 27]. These scattered values resulted from different

core sizes, cross-section areas and carbon materials employed. All

these references reported only short fibre supercapacitors of a length

less than 10 cm, which are much shorter than those presented in this

report. As shown in Fig. 5c, the capacitance decreases as the charging

current increases. This trend results from delayed charging process by

the slow diffusion at higher currents, the similar trend has been

reported for gel electrolyte super capacitors [28].

Power and energy densities are two important parameters for

evaluating the electrochemical performance of a supercapacitor. Fig.

5d A Ragone plot shows overall performance of the thread

supercapacitor. Energy E stored and power (P) of the CTSC were

calculated by equation (3) and (4) respectively:

0.5

(3)

(4)

It can be seen that the device can exhibit energy density up to 0.2

mWh cm-3 which is higher than those in reference 23 within whole

range of power densities, and comparable to MnO2 fibre

supercapacitor of an energy density of 0.22 mWh cm-3 [29].

Additionally, the device can deliver a power density up to 410 mW

cm-3 which is 3.6 times higher than that of Ref. 15. These results are

attributed to the lower volume of active layers in the device.

In order to study the supercapacitors electrochemical stability,

long term cycling of galvanostatic charge-discharge testing was

conducted for a new 70 cm long CTSC. Fig. 6 shows chargedischarge cycle curves for different cycles at 1.1 mA (a) and the

capacitance as a function of the number of cycles (b). In Fig. 6a, for

comparison, the time was rescaled by subtracting the start time of

Fig. 4 (a) Cyclic voltammograms recoded at different scan rates of 5,

20, 50, 100 and 200 mV s-1, (b) Capacitance as a function of

scan rate, and (c) Nyquist plot recorded at open circuit

potential using a 5 mV AC modulation for a frequency ranged

from 100 kHz to 0.01 Hz for a 70 cm long CTSC

Fig. 5 shows a typical galvanostatic charge-discharge curve

cycling between 0 V and 1 V, first ten cycles at a charge current of 1.0

Smart Science

110

Smart Science Vol. 2, No. 3, pp. 107-115(2014)

each charge-discharge cycle. It can be seen from Fig. 6a that the

charging discharging time is slightly getting smaller as the cycling

progressed; the charge-discharge curves were overlapped after cycles

extended beyond 1500. In Fig. 6b, it can be seen that the calculated

capacitance using equation (2) for the discharge branches of the

cycles decreases gradually with the number of cycles before 1500

cycles was reached; after that, the capacitance keeps almost constant

further with more cycles [21, 25]. 86% of initial capacitance was

retained after 1500 cycles. This demonstrates the viability and

electrochemical stability of the device for many applications.

Fig. 6 Charge-discharge stability test for the 70 cm long CTSC at 1.1

mA. (a) charge-discharge curves for different No. of cycles of

100, 500, 1000 and 1500 and (b) the capacitance as a function

of the number of cycles

3.3 Combination

supercapacitors

circuit

properties

of

two

thread

The single CSTC has limited energy storage ability, and a

limitation of an operating voltage below 1 V as the intrinsic potential

window of PVA aqueous gel electrolyte is 1 V. For devices operating

at a voltage above 1 V with high energy density requirements,

combinations of multiple CTSCs need to be assembled either in

parallel or series, or both. To exploit the applicability of the

combinations of multiple thread supercapacitors, electrical and

electrochemical properties of the basic combination electrical circuits

of two CTSCs were examined. Fig. 7a shows cyclic voltammograms

recorded at 50 mV s-1 for two 70 cm long CTSCs (S1 and S2), which

were fabricated separately, and their series and parallel combination

circuits. It can be seen that two CTSCs show almost identical cyclic

voltammograms with a 1 V potential window, which demonstrates the

coating procedure has good reproducibility. It is also noted that the

cyclic voltammogram cycle areas are doubled for parallel circuits and

one for series circuits; the potential window was extended to 2 V for

the series circuit. Approximated capacitances for series and parallel

circuits would be half and double of one CTSC. These results

illustrated that the accepted models for series and parallel capacitor

combinations were obeyed for the combined circuits of two thread

supercapacitors. No faradaic process was observed for all cases of

electrical circuit indicating the gel electrolytes stability in the system.

To quantify the combination supercapacitors further, galvanostatic

charge-discharge and electrochemical impedance spectroscopy

measurements were employed to investigate the capacitance and

resistance for each case. Fig. 7b and Fig. 7c show Nyquist plots and

galvanostatic charge-discharge curves at charge currents of 0.6 mA

for singles and the series circuit, and 1.2 mA for the parallel circuit.

Fig. 5 (a) Galvanostatic charge-discharge curve (first ten cycles)

recorded at a charging current of 1.0 mA, (b) Galvanostatic

charge-discharge curves (10th cycle) at different charging

currents of 0.8, 0.9, 1.0, 1.5, 2.0 and 2.5 mA, (c) Capacitance

as a function of charging current for the 70 cm CTSC and (d)

Ragone plot from (c)

Smart Science

111

Smart Science Vol. 2, No. 3, pp. 107-115(2014)

Potential windows of 1 V and 2 V were used for two single thread

supercapacitors and parallel circuit, and series circuit respectively.

From Fig. 7b, it can be seen that electrochemical impedance curves

for combination circuits are similar to those of two single coaxial

thread supercapacitors, and the curves are parallel with different real

Z- axis intercepts. This indicated that for all cases ion transport

phenomena are identical, a slow diffusion process in the porous nano

structure dominates. The series resistances were obtained from the

intercept with Real axis (Z) at high frequencies in Fig. 7b, and

capacitances were calculated using the equation (2) from discharge

branches in galvanostatic charge-discharge curves in Fig. 7c.

resistive and capacitive circuits. (The total resistance of resistors in

series is equal to the sum of their individual resistances; the total

capacitance of capacitors in series is equal to the reciprocal of the sum

of the reciprocals of their individual capacitances). For the case of the

parallel circuit, the total resistance and capacitance follow the rules of

total capacitance and resistance in series respectively. Good

agreement was observed for the capacitance; there was a slight

discrepancy for the series resistance, which might be due to lead

connections during the circuits switching.

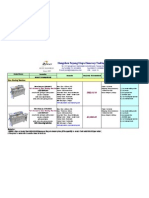

Table 1 Summaries electrical series resistance (ESR) from Nyquist

plots and the capacitances from galvanostatic chargedischarge measurements together with those calculated

using theory for series and parallel circuits.

Circuit

S1

S2

Parallel

Series

Exp.

19.9

20.7

39.5

9.6

C (mF)

Theory

40.6

10.2

ESR ()

Exp.

Theory

15.1

145.5

80.5

74.1

300.5

296.5

3.4 Flexibility and uniformity of a typical CTSC

CTSCs are flexible as shown in Fig. 3, and can be wound on a

bobbin. In order to explore its potential applications as a smart

weaveable energy storage device, its uniformity of capacitance along

the fibre length is a key to predict its energy storage capacity and

verify the feasibility of the semi-automatic processing for scale-up.

Length dependent cyclic voltammetry was performed at 100 mV s-1

for a ~ 60 cm long CTSC initially, and capacitance was calculated;

and then the CTSC was cut short eleven times sequentially by each of

5 cm, and at the same time, cyclic voltammogram was recorded at

100 mV s-1. Fig.8 shows the photo of 11 sequential segments from left

to right cut off from the ~ 60 cm long CTSC (a), typical cyclic

voltammograms for the length of 10, 25 and 52 cm at 100 mV s-1 (b)

and capacitance dependence on length (c). As shown in Fig. 8a, the

thread and its cut sequences are not straight; the segments have

shapes with different curvatures. No intended bending was conducted

during the cutting. From Fig. 8b, similar capacitive shape

voltammograms with different currents for the three selected length

supercapacitors were observed, which demonstrated the

electrochemical stability and flexibility; cyclic voltammograms were

not disturbed by cutting. Calculated capacitances were 0.17, 0.4 and

0.8 mF for 10, 25 and 52 cm long coaxial thread supercapacitors

respectively. As shown in Fig. 8c, the capacitance as a function of the

thread length is pretty linear with fitting slope of 2.010-2 mF cm-1

and a R2 of 0.99, A capacitance intercept of 4.010-2 mF (offset) was

noted which was possibly due to unequal length at the beginning of

the CTSC. These results show that the thread has high uniform

capacity along its length and good flexibility, which is independent of

the thread curvatures. These results demonstrated a potential for the

thread supercapacitors as a weaveable energy storage device. Bending

and length dependent capacitance studies for shorter (< 10 cm) 1D

Fig. 7 (a) Cyclic voltammograms recorded at 50 mV s-1 for two single

supercapacitors and their electrical combinations in series and

parallel, (b) Electrochemical impedance performance of two

single CTSCs and their electrical combinations in series and

parallel using a 5 mV AC modulation for a frequency range of

100 kHz to 0.01 Hz and (c) Galvanostaic charge-discharge

curves of the 10th cycles of each case, for single and series

circuit, 0.6 mA was used, and 1.2 mA for the parallel circuit.

In Table 1, the electrical series resistance (ESR) and capacitance

data from the experiments were tabulated together with values

predicted by the accepted circuit models for series and parallel

Smart Science

112

Smart Science Vol. 2, No. 3, pp. 107-115(2014)

fibre supercapacitors have been reported by deliberately creating

curvatures [20, 30]. Woven supercapacitors were also reported [17,

31]. It is worth noting that this CTSC was tested six months after it

was fabricated.

series combinations of a couple of fibre supercapacitors [15], which

were charged using a potentiostat.

Fig. 9 Solar powered LED lit by a 85 cm long CTSC, (a) Charging by

solar cells and (b) Discharging to light a red LED

4. Conclusion and outlook

Flexible CTSCs were fabricated in a concentric structure of

multiple layer coatings using a purpose-built semi-automatic dip

coating setup. Reproducible thread supercapacitors with circular and

uniform coating layers were achieved. The devices showed a good

specific capacity and electrochemical stability with a high energy

density of 0.22 mWh cm-3 at a power density of 22 mW cm-3, and

displayed high flexibility. Two similar supercapacitors were

assembled in parallel-series patterns; the combination circuits

demonstrated well-defined electrochemical performance. The

accepted models for series and parallel circuit combinations are

obeyed well for both capacitances calculated from charge-discharge

measurements and resistances recorded from electrochemical

impedance measurements. A length dependent capacitance study

demonstrated the device has high uniformity. Mass production of the

thread supercapacitors is feasible by enlarging the semi-automatic

process to a continuous process for commercial applications in

miniaturized and flexible electronic devices. An automatic multiple

layer dip coating process is under design. This design will allow an

unlimited length thread supercapacitor to be produced continuously

by controlling the thickness of each coating layer, the thread winding

speed, the viscosity of each coating slurry and the vaporizing

temperature of the solvent in each slurry.

Fig. 8 (a) Photo of cut segments during length dependent cyclic

voltammetric

measurements,

(b)

Selected

cyclic

voltammograms recorded at 100 mV s-1 for three different

lengths CTSCs of 10, 25 and 52 cm long, and (c) Calculated

capacitance at 100 mV s-1 as a function of CTSC length

3.5 Integration with solar powered device

Solar energy devices have become popular when combined with

low power and voltage LED for home and garden decoration. To

demonstrate the potential applications of this flexible solid-state

energy storage device, we have modified a garden solar LED light by

replacing the 1.2 V NiH-M battery with a 85 cm long CTSC. Fig. 9

shows a setup for demonstration using a 85 cm long CTSC-solar

power charging process (a) and discharging to light a LED (b). A

solar powered garden light was fixed onto one side of a black plastic

box from the inside; the LED bulb protrudes from the side of the box

through a hole in the wall section. When the box is open and facing

sunlight, the CTSC is charged (Fig. 9a); when the box is closed, the

thread discharges and lights the LED red as shown in Fig. 9b. For a

few seconds charge in a bright sunlight environment, it lighted the

LED for 3 s from bright to dim. This result reveals the potential

applications of the flexible, all-solid state coaxial thread in green

energy storage. LED lighting has been reported using parallel and

ACKNOWLEDGEMENT

The research leading to these results has received funding from

Smart Science

113

Smart Science Vol. 2, No. 3, pp. 107-115(2014)

the Powerweave project in the European Union Seventh Framework

Programme (FP7/2007-2013) under grant agreement no. 281063.

[12]

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

D. De Rossi, F. Carpi, F. Lorussi, E. P. Scilingo, A. Tognetti,

and R. Paradiso, Electroactive fabrics and wearable manmachine interfaces, (Wearable Electronics and Photonics,

San

Francisco,

CA,

2005)

pp.59-80.

DOI:

10.1533/9781845690441.59

B. S. Shim, W. Chen, C. Doty, C. Xu, and N. A. Kotov,

Smart Electronic Yarns and Wearable Fabrics for Human

Biomonitoring made by Carbon Nanotube Coating with

Polyelectrolytes, Nano Letters, 8, 4151-4157 (2008) DOI:

10.1021/nl801495p

J. Foroughi, G. M. Spinks, G. G. Wallace, J. Oh, M. E.

Kozlov, S. Fang, T. Mirfakhrai, J. D. W. Madden, M. K.

Shin, S. J. Kim, and R. H. Baughman, Torsional Carbon

Nanotube Artificial Muscles, Science, 334, 494-497 (2011)

DOI: 10.1126/science.1211220

J. Foroughi, G. M. Spinks, S. R. Ghorbani, M. E. Kozlov, F.

Safaei, G. Peleckis, G. G. Wallace, and R. H. Baughman,

Preparation and characterization of hybrid conducting

polymer-carbon nanotube yarn, Nanoscale, 4, 940-945

(2012) DOI: 10.1039/c2nr11580h

K. Jost, C. R. Perez, J. K. McDonough, V. Presser, M. Heon,

G. Dion, and Y. Gogotsi, Carbon coated textiles for flexible

energy storage, Energy Environ Sci, 4, 5060-5067 (2011)

DOI: 10.1039/c1ee02421c

R. A. Davoglio, S. R. Biaggio, N. Bocchi, and R. C. RochaFilho, Flexible and high surface area composites of carbon

fiber, polypyrrole, and poly(DMcT) for supercapacitor

electrodes, Electrochim Acta, 93, 93-100 (2013) DOI:

10.1016/j.electacta.2013.01.062

D. Qu Mechanistic studies for the limitation of carbon

supercapacitor voltage, J Appl Electrochem, 39, 867-871

(2009) DOI: 10.1007/s10800-008-9737-6

M. Conte Supercapacitors Technical Requirements for New

Applications, Fuel Cells, 10, 806-818 (2010) DOI:

10.1002/fuce.201000087

S. Ren, M. Wang, M. Xu, Y. Yang, C. Jia, and C. Hao,

Fabrication of high-performance supercapacitors based on

hollow SnO2 microspheres, Journal of Solid State

Electrochemistry, 18, 909-916 (2014) DOI: 10.1007/s10008013-2332-8

B. Frenzel, P. Kurzweil, and H. Rnnebeck, Electromobility

concept for racing cars based on lithium-ion batteries and

supercapacitors, Journal of Power Sources, 196, 5364-5376

(2011) DOI: 10.1016/j.jpowsour.2010.10.057

A. B. Dalton, S. Collins, E. Muoz, J. M. Razal, V. H. Ebron,

J. P. Ferraris, J. N. Coleman, B. G. Kim, and R. H.

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

Baughman, Super-tough carbon-nanotube fibres - These

extraordinary composite fibres can be woven into electronic

textiles, Nature, 423, 703 (2003) DOI: 10.1038/423703a

K. Cherenack, C. Zysset, T. Kinkeldei, N. Mnzenrieder, and

G. Trster, Wearable electronics: Woven electronic fibers

with sensing and display functions for smart textiles,

Advanced materials, 22, 5178-5182 (2010) DOI:

10.1002/adma.201002159

T. Chen, L. Qiu, Z. Yang, Z. Cai, J. Ren, H. Li, H. Lin, X.

Sun, and H. Peng, An Integrated Energy Wire for both

Photoelectric Conversion and Energy Storage, Angewandte

Chemie (International ed. in English), 51, 11977-11980

(2012) DOI: 10.1002/anie.201207023

Y. P. Fu, X. Cai, H. W. Wu, Z. B. Lv, S. C. Hou, M. Peng, X.

Yu and D. Zou, Fiber Supercapacitors Utilizing Pen Ink for

Flexible/Wearable Energy Storage, Advanced Materials, 24,

5713-5718 (2012) DOI: 10.1002/adma.201202930

V. Le, H. Kim, A. Ghosh, J. Kim, J. Chang, Q. Vu, D. T.

Pham, J. H. Lee, S. W. Kim, and Y. H. Lee, Coaxial Fiber

Supercapacitor Using All-Carbon Material Electrodes, ACS

NANO, 7, 5940 (2013) DOI: 10.1021/nn4016345

J. F. Gu, S. Gorgutsa, and M. Skorobogatiy, Soft capacitor

fibers for electronic textiles, Appl Phys Lett, 97, 3 (2010)

DOI: 10.1063/1.3488351

D. Harrison, F. Qiu, J. Fyson, Y. Xu, P. Evans, and D.

Southee, A coaxial single fibre supercapacitor for energy

storage, Physical Chemistry Chemical Physics, 15, 1221512219 (2013) DOI: 10.1039/c3cp52036f

Z. Liu, Y. J. Zhan, G. Shi, S. Moldovan, M. Gharbi, L. Song,

L. Ma, W. Gao, J. Huang, R. Vajtai, F. Banhart, P. Sharma, J.

Lou, and P. M. Ajayan, Anomalous high capacitance in a

coaxial single nanowire capacitor, Nature Communications,

3, 7 (2012) DOI: 10.1038/ncomms1833

B. E. Conway, W. G. Pell, Power limitations of

supercapacitor operation associated with resistance and

capacitance distribution in porous electrode devices, J

Power Sources, 105, 169-181 (2002) DOI: 10.1016/S03787753(01)00936-3

Y. Fu, X. Cai, H. Wu, Z. Lv, S. Hou, M. Peng, X. Yu, and D.

Zou, Fiber supercapacitors utilizing pen ink for

flexible/wearable energy storage, Advanced materials

(Deerfield Beach, Fla.), 24, 5713-5718 (2012) DOI:

10.1002/adma.201202930

K. Wang, Q. Meng, Y. Zhang, Z. Wei, and M. Miao, Highperformance two-ply yarn supercapacitors based on carbon

nanotubes and polyaniline nanowire arrays, Advanced

materials,

25,

1494-1498

(2013)

DOI:

10.1002/adma.201204598

J. Ren, L. Li, C. Chen, X. Chen, Z. Cai, L. Qiu, Y. Wang, X.

Zhu, and H. Peng, Twisting Carbon Nanotube Fibers for

Both Wire-Shaped Micro-Supercapacitor and Micro-Battery,

Advanced Materials, 25, 1155-1159 (2013) DOI:

Smart Science

114

Smart Science Vol. 2, No. 3, pp. 107-115(2014)

[23]

[24]

[25]

[26]

[27]

[28]

[29]

[30]

[31]

10.1002/adma.201203445

P. Taberna, P. Simon, and J. F. Fauvarque, Electrochemical

characteristics and impedance spectroscopy studies of

carbon-carbon supercapacitors, J Electrochem Soc, 150,

A292-A300 (2003) DOI: 10.1149/1.1543948

R. Signorelli, D. C. Ku, J. G. Kassakian, and J. E. Schindall,

Electrochemical Double-Layer Capacitors Using Carbon

Nanotube Electrode Structures, Proc IEEE, 97, 1837-1847

(2009) DOI: 10.1109/JPROC.2009.2030240

M. F. El-Kady, V. Strong, S. Dubin, and R. B. Kaner, Laser

scribing of high-performance and flexible graphene-based

electrochemical capacitors, Science, 335, 1326-1330 (2012)

DOI: 10.1126/science.1216744

T. Chen, L. Qiu, Z. Yang, Z. Cai, J. Ren, H. Li, H. Lin, X.

Sun, and H. Peng, An Integrated Energy Wire for both

Photoelectric Conversion and Energy Storage, Angewandte

Chemie (International ed. in English), 51, 11977-11980

(2012) DOI: 10.1002/anie.201207023

Y. P. Fu, X. Cai, H. W. Wu, Z. B. Lv, S. C. Hou, M. Peng, X.

Yu, and D. Zou, Fiber Supercapacitors Utilizing Pen Ink for

Flexible/Wearable Energy Storage, Advanced Materials, 24,

5713-5718 (2012) DOI: 10.1002/adma.201202930

M. F. El-Kady, R. B. Kaner, Scalable fabrication of highpower graphene micro-supercapacitors for flexible and onchip energy storage, Nature Communications, 4, 1475 (2013)

DOI: 10.1038/ncomms2446

X. Xiao, T. Li, P. Yang, Y. Gao, H. Jin, W. Ni, W. Zhan, X.

Zhang, Y. Cao, J. Zhong, L. Gong, W. C. Yen, W. Mai, J.

Chen, K. Huo, Y. L. Chueh, Z. L. Wang, and J. Zhou,

Fiber-Based All-Solid-State Flexible Supercapacitors for

Self-Powered Systems, Acs Nano, 6, 9200-9206 (2012)

Y. Meng, Y. Zhao, C. Hu, H. Cheng, Y. Hu, Z. Zhang, G.

Shi, and L. Qu, All-graphene core-sheath microfibers for

all-solid-state, stretchable fibriform supercapacitors and

wearable electronic textiles, Advanced materials, 25, 23262331 (2013) DOI: 10.1002/adma.201300132

J. A. Lee, M. K. Shin, S. H. Kim, H. U. Cho, G. M. Spinks, G.

G. Wallace, M. D. Lima, X. Lepr, M. E. Kozlov, R. H.

Baughman, and S. J. Kim, Ultrafast charge and discharge

biscrolled yarn supercapacitors for textiles and microdevices,

Nature

communications,

4,

1970

(2013)

DOI:

10.1038/ncomms2970

Smart Science

115

Você também pode gostar

- A High-Frequency Isolation (HFI) Charging DC Port Combining A Front-End Three-Level Converter With A Back-End LLC Resonant ConverterDocumento23 páginasA High-Frequency Isolation (HFI) Charging DC Port Combining A Front-End Three-Level Converter With A Back-End LLC Resonant ConverterJust4545Ainda não há avaliações

- Exova Test Certificate 3Documento17 páginasExova Test Certificate 3Just4545Ainda não há avaliações

- LTS350 T95 ManualDocumento28 páginasLTS350 T95 ManualJust4545Ainda não há avaliações

- Structure and Deformation Mechanisms in UHMWPE-fibresDocumento8 páginasStructure and Deformation Mechanisms in UHMWPE-fibresJust4545100% (1)

- Characterisation of Cotton Fibre-Reinforced Geopolymer CompositesDocumento6 páginasCharacterisation of Cotton Fibre-Reinforced Geopolymer CompositesJust4545Ainda não há avaliações

- Julabo - Refrigerated and Heating CirculatorsDocumento66 páginasJulabo - Refrigerated and Heating CirculatorsJust4545Ainda não há avaliações

- Iso7359 1985 PDFDocumento5 páginasIso7359 1985 PDFJust4545Ainda não há avaliações

- Blends of Thermoplastic Polyurethane and PolypropyleneDocumento4 páginasBlends of Thermoplastic Polyurethane and PolypropyleneJust4545Ainda não há avaliações

- Silquest: Product Selection GuideDocumento4 páginasSilquest: Product Selection GuideJust4545Ainda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Tesco, PLC "From Mouse To House"Documento13 páginasTesco, PLC "From Mouse To House"Md IrfanAinda não há avaliações

- How Can The European Ceramic Tile Industry Meet The EU's Low-Carbon Targets A Life Cycle Perspective (Ros-Dosda - España-2018)Documento35 páginasHow Can The European Ceramic Tile Industry Meet The EU's Low-Carbon Targets A Life Cycle Perspective (Ros-Dosda - España-2018)juan diazAinda não há avaliações

- Quotation For Blue Star Printek From Boway2010 (1) .09.04Documento1 páginaQuotation For Blue Star Printek From Boway2010 (1) .09.04Arvin Kumar GargAinda não há avaliações

- Myanmar Power SystemDocumento4 páginasMyanmar Power Systemkayden.keitonAinda não há avaliações

- Falcon 7X CommunicationsDocumento105 páginasFalcon 7X Communicationsjunmech-1Ainda não há avaliações

- Diamond 53 BrochureDocumento3 páginasDiamond 53 Brochuregipanaul100% (1)

- Community Needs Assessments and Sample QuestionaireDocumento16 páginasCommunity Needs Assessments and Sample QuestionaireLemuel C. Fernandez100% (2)

- Server Side - Java - Using Rmi With Apache JservDocumento16 páginasServer Side - Java - Using Rmi With Apache JservTotoAlipioAinda não há avaliações

- Installation of Water HeatersDocumento5 páginasInstallation of Water HeatersLaura KurniawanAinda não há avaliações

- Brady Lecture 6Documento32 páginasBrady Lecture 6TygerGoose0% (1)

- Unist MQL Article - ShopCleansUpAct CTEDocumento2 páginasUnist MQL Article - ShopCleansUpAct CTEMann Sales & MarketingAinda não há avaliações

- Oracle Secure BackupDocumento294 páginasOracle Secure BackupCarlos ValderramaAinda não há avaliações

- Serial NumberDocumento3 páginasSerial NumberNidal Nakhalah67% (3)

- Alimentacion Baterias TiposDocumento11 páginasAlimentacion Baterias TiposjulioclavijoAinda não há avaliações

- Bhopal Gas TragedyDocumento25 páginasBhopal Gas TragedyHarry AroraAinda não há avaliações

- Long+term+storage+procedure 1151enDocumento2 páginasLong+term+storage+procedure 1151enmohamadhakim.19789100% (1)

- Product Handling: Complete Solutions From A Single SourceDocumento24 páginasProduct Handling: Complete Solutions From A Single Sourcemarciojunk100% (1)

- Test Procedure and MethodDocumento1 páginaTest Procedure and MethodkmiqdAinda não há avaliações

- 6802988C45 ADocumento26 páginas6802988C45 AJose Luis Pardo FigueroaAinda não há avaliações

- Redundant Power Supply Installation Guide EP-DCX205Documento38 páginasRedundant Power Supply Installation Guide EP-DCX205Anonymous zLwP4FjLAinda não há avaliações

- Residential Solar System Proposal ExampleDocumento13 páginasResidential Solar System Proposal ExamplehernelandAinda não há avaliações

- Don't Just Lead, Govern: Implementing Effective IT GovernanceDocumento20 páginasDon't Just Lead, Govern: Implementing Effective IT GovernanceWahyu Astri Kurniasari100% (1)

- Introduction To Ada Solo Project: Robert Rostkowski CS 460 Computer Security Fall 2008Documento20 páginasIntroduction To Ada Solo Project: Robert Rostkowski CS 460 Computer Security Fall 2008anilkumar18Ainda não há avaliações

- TPMS - A Learning GuideDocumento14 páginasTPMS - A Learning GuideOrangeElectronicUsaAinda não há avaliações

- High Performance HTP eDocumento14 páginasHigh Performance HTP ejohnny_cashedAinda não há avaliações

- 5 - Balanced and Unbalanced FaultsDocumento117 páginas5 - Balanced and Unbalanced FaultsJuan Manuel VegaAinda não há avaliações

- Kv2ci Oi PDFDocumento142 páginasKv2ci Oi PDFJethro AbanadorAinda não há avaliações

- Conveni Pack Technical Data (LRYCP DY1 R 407C)Documento188 páginasConveni Pack Technical Data (LRYCP DY1 R 407C)HoàngViệtAnhAinda não há avaliações

- Econ 103 - 01Documento3 páginasEcon 103 - 01perrerAinda não há avaliações

- PESTLE Analysis - KenyaDocumento4 páginasPESTLE Analysis - KenyaJoseph0% (1)