Escolar Documentos

Profissional Documentos

Cultura Documentos

Alloy 001

Enviado por

MuhammedHafis0 notas0% acharam este documento útil (0 voto)

97 visualizações51 páginaswps

Título original

ALLOY-001

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentowps

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

97 visualizações51 páginasAlloy 001

Enviado por

MuhammedHafiswps

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 51

ce /LE/T

HyCO / NH, INDUSTRIAL GASES PLANT PROJECT | RYN tS

HyCO / AMMONIA INDUSTRIAL GASES PLANT PROJECT

WELDING PROCEDURE SPECIFICATION | SITE MASTER ]

| SA-eoShe

AL JUBAIL 10 PROJECT, KSA | tau amy |

cec-pee ve

JHP PROJECT

DOCUMENT TITLE: WPS-1099-ALLOY -001GTAW+SMAW

GROOVE+FILLET

DOCUMENT No. CCC-Q-PP-1045 (WPS-1099-ALLOY-001+PQR-GUP-018)

To further submission.

AB Document acepted ss final

PO Incorporate comments and

‘esubmi documert CCC Project No. 1099

Lilie wa raewan

a: 22.AUg 2013. pu END

mato

77 0.082015 | Revel va UNDE commen ezzan—TAnDaN [tai Sha

05082013 [woe oraproal waza —[Annw | Fiat

Rev | Date ‘Status Description _ Prepared Reviewed ‘Approved

HyCO / NH; INDUSTRIAL GASES PLANT PROJECT ONS! fMU000-1001,

Revo: a

EA ALJUBAIL 10 PROJECT, KSA Ea ar

WELDING PROCEDURE SPECIFICATION ASME IX, | ProlectNo: 2410APwn

ASME B31.3 Page 2ofa

Welding Procedure Specification No.: WPS-l098-ALLOY- RevNo 1 Date: 06.08.2013,

oot

Supporting POR No.: _PQR-GUP-O18 Rev.No: 0 Date:

Welding Process(es): _GTAW+SMAW Type: _MANUAL

throat anual acne or Serta) |

JOINTS: (QW-402)

Joints Design: Butt welds Fillet Welds (Shop/Field) Dera

Backing: ‘Yes for fillet Refer Page 3 for Joints Design

Backing Material (Type): _GTAW for SMAW

BASE METALS (QW-403)

P-No. 3 Group No. 1 To P-No. 3 Group No. 1

on

Specification Type & Grade: _A335Gr. Pi, A204 Gr A. or Equivalent

To Speciation Type & Grade: _AB35Gr. Pi, A204 Gr A. or Equivalent

Chem. Analysis & Mech. Properties N/A = rier ineerereeratill

‘To Chem. Analysis & Mech. Properties N/A

Thickness of Test Coupon: 22" 20mm

Base metal thickness range Qualified Groove: _5 mmto19mm Fillet _All(Equa leg length)

Deposited Weld Metal Range Qualified Groove: GTAW Smm max and the rest is SMAW Fillet All (Equal leg length)

4mm

Pipe Diameter Range Groove: _ALL Fillet _ All (Equal leg length)

Service Class:

FILLER METALS: (QW-404)

PROCESS GTAW sMaw

FNo: 6 4

ANo.: 2 a

‘Spec No. (SFA) 5.28 55

[AWS No (Class). ERBOS-G EPMIRSALIES REE

Size of Filler Metals a 274 Wi Se 2.53.2mm

Electrode-Flux (class) NA NA

Consumable Insert

EN 10204-3.1 certification Is

otherwise agreed with Linde.

Approved PREPARED BY CCC

Name IAZZAM, Name

Sign vol? — Sign

Date 3-3 —Jold| ate

HyCO / NH; INDUSTRIAL GASES PLANT PRoJEcT | Femme FM-1052-1001

Revo: 1

eaA ALJUBAIL 10 PROJECT, KSA pect cp-1099.100

WELDING PROCEDURE SPECIFICATION — ASME IX, | Project No: 2410aPwN

ASME 831.3 Page 30f4

Welding Procedure Specification No. ‘WPS-1099-ALLOY-001 RevNo:

POSITION: (QW-405) POST WELD HEAT TREATMENT (QW-407)

Position(s) of Groove: ALL ‘Temp Range: NA

Welding Progression: ‘UPHILL Time Range: NA

Position(s) of Fillet: ALL GAS (QW-408)

PREHEAT (QW-406) Shielding Gas: _Argon (GTAW only)

Preheat Temp ASME 831 3Table 40°CMin;for metaltemp 420M | fprcheated to at least 79°C

{eropane torch)

Inter-pass temp: Tao'twax——S~™S*w Rat TOtois

Preheat Maintenance: NA Niu of ree Gas Backing N/A

{he preheat & iter ‘Trailing Shielding Gas Composition N/A -

‘thermocouples /temp

{Continuous or special heating where

ELECTRICAL CHARACTERISTICS: (QW-409)

Current (AC/DC) oc Polarity: GTAW (-VE), SMAW (+VE}

‘Amps (Range) See table below Volts (Range) See table below

‘Tungsten Electrode Size and Type

Mode of metal transferforGMAW = _ N/A

Electrode Wire speed Range: NA,

TECHNIQUE: (QW-410))

String or Weave bead: String /Weave, Max weave width: 2.5 x wire dia for GTAW, 2.5 x Electrode dia for MAW

Orifice or Gas cup size: Uptogmm _

Initial & Inter-pass cleaning ire brush and chipping hammer

Method of back gouging _ _

Oscillation

Contact Tube to work distance

Multiple or single-pass (per side)

Multiple or single electro«

Travel Speed (Range)

Peening: ‘None

Remarks: 1) Treat Consumables as per QCP-1099-101 3) When welding outdoor, suitable protection shall be provided. 2} Complete the root pas andi

possible, cary out completion of weld without interruption.) During welding avoid displacement, shock, vibrations and stresses 4) Al

‘GTAW equipment shal be fitted with high frequency starting unit, pre and post low and crater eliminating slope out control. 5) For detalls of,

assembly of enforced pad-weld preparation, branch placed on run pipe refer to Linde Specification AAR'SP-1010 issue 02

For Socket/flet, mi

Weldtaverts) | Process Sa peat [ray amare | Votan | "ren | ss rn

oo craw mass | 24 oct) ns.9 910 5560 2

vor raw Ero 2a ect) 1030 osu 3590 12

Fut sMaw evowat | 32 ete) 135-120 aaa Toss 153

car smaw | e7oiear | 32 ete) 160-165 2325 120-125 1.68

FormNo; _ FM-1099-1001

HyCO / NH; INDUSTRIAL GASES PLANT PROJECT

Revo: 1

eaA AL JUBAIL 10 PROJECT, KSA | Serres

WELDING PROCEDURE SPECIFICATION — ASME IX, | Project No: 2410APWN

ASME 831.3 Page 4ofa

Welding Procedure Specification No.:_ WPS-1099-ALLOY-001___RevNo.. 2

Other Notes: The welding to comply with the Project Specific Requirements

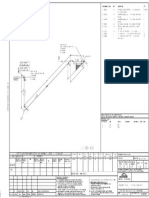

DETAILS:

3240.8mm

aa

—

‘ 1.6t0.30mm

X= 116 for Pipe Dia 250,

1.6mm max

k

i Ruwais General Utilities Plant Prj. 1203 |

Form No 71000, Reve

Page bof 2

PROCEDURE QUALIFICATION RECORD

tm accordance with : ASME IX. & TRU 201

Dates 12

Prossdure Qualification PQR- GUP-o18

WPS No “WPS/PQR_GUP -018

Welding Peacestes) GTAW./SMAW.

“Types (Manual, Automatic, Semi-AUto) _

Joins \ SF ES rae

Sand SSUES

AAI a

ty

} ao Asses

' Sve 5: [S30 a Ponan=

Fig 4. 22 B—F0na Fig 13

Base Metals Post Weld Heat Treatment

Material Spee. 15 M3 - 15. Ma} ‘Temperature NA

Typeor Grade: {ASISGEPI) - (ABISGePD) |

Po. 3 Topo 3 Wold Time Nin |

‘Thickness of Test Coupon 20mm

Diameter of Test Coupon $5omm 2) Other

omer Nia

Ga

Filer Metals Type of Gas or Gases ARGON

SFA Speciication S.sist Composition of Gas Mixture 99.99% PURE

[AWS Classification ERAOS-G/E Other WA

Filler Metal Fo. an 11-12 DPN

Meld Metal Analysis A-No, 22 Electrical Characterstis

Siee of Fille Mota: 2.4mm @/SMAW.2.513250

Other: A Cursent De.

Weld Metal Ti Potority "ne (way Resp ELAN URCRR

Amps: WG utsuoxan woas9 Volls: Rastasaneat

Position: Tungsten Electode Size 2.4 mm

Position of Grease ra +s Other: 2% THORIATED

Weld Progression (Uphill, Downbilt):—_ UPHL Technique?

Other Nin Travel Speed AW. $5.10 mein’ SAAN 55.1 nina

String or Weave Bead STRING & WEAVE

Proheat Temp MIN 100°C (5 Mod) Multipass or Single pas (Per Slide}: _ MIULTIPASS |

Iatespass Ten 300° C Mas Eloetodss SINGLE

Other Nia

= = = a el

toi6-1G XLS.

a Ruwais General Utilities Plant Prj, 1203 |

4 x

PROCEDURE QUALIFICATIE

SEF ATTACHED MTS REPORTS:

AD 51142, ADS1113 See ee

width Thickness eer hime Tae Typeot

Specim Total Load|Tensile Strength| Failure &

No KN, Nine? Location

Guided - Bend Tests

Type und Figure No.

Toughness Tests

oa ae Te] Tapas [Tae EP Trap Weare

No._| Location Type Temp _| Values [FoShear] Miz | “Break [No Br

Le

|

f—t

Fillet - Weld Test

Result -Satisfacton Yes No

Macro - Results

Other Tests

Type of Test

Deposit Analysis

Other

D.C ANCHANIL 16811 W-020

Weldors's Name LW. SINGH Badge No._17416_ Stomp No __W- 024

ap 51112

Tests conducted by MTS - Abu I Laboratory Test No AD 51113

We certify that the statements in this record are correct and thal the teat welds were prepared, welded &

tested in accordance with the requirements of Section IX of the ASME Code & TRD 201

BILL Mz FARLANE

Stamp Name Stam

Signature

Pare

045-26 NLS.

ww

conrontion

Procedure Qualifieation Recoré No. t

weldls

Process ¢

fuwais General Utilities Project

Base Metal : 15 M03 (DIN 17175)

rele

Proposal

GTAW/SMaw

(ASTM A335 TYPF 1)

No. 1203

Joint Design according w Figures Nos.

4& 19 0IN 8551)

Welding performance qualification +

TQ/E-Rilg

Quality requirements =

DIN 8363 PART 3

ill & Material +

DIN Classification

(AWS Classification }

au

Q Bieesn.,

ust GTAW SG MO 1.5424/D1N 8575 .

bHet tt

(ER 80 S-G/ AWS) wa J is

Electrode - E Mo B20 He og... |

(E7018- Al) fie 1

Welding Position O/q eGrsc) Se 15-30mm

Proheating Minimum 100° ¢ (for 15 Mo3 Only)

loterpass temperature ¢ 300" € May

‘ure NA

WELDING DA’

Filler Ma Number Current Speed] Auxiliary

Welding | Layer | DAN AWSCClassit. [Diameter| Pass] Bead] Type Polar | A v material

Process im

Taw |ROoT | SGMoERSOSG | 24 | 1 | 1 =) | 18-129 [9125] 3570 [Argon 99.9%|

SMAW |TILLING| EM B20: 118-Al] 25 2 | toto | 21.28] 55.65 ]s- 12 real

SMAW |FILLING] € Mo B20 7018 - a1] 3.25 = (4) | 113 130 | 21-25 | 60-190]

Approved. _CCC Stamp

Name BILL Me BAmtLANE

SIGN.

DATE

Ww

+ Fomufscturee

AS RUN SHEET

wes: Gor els POR: pArfee L DATE: 2D -0b- 35

Proce

Material

Diameter

Thickness pone

Consemabie eG S254 .€ CIR Es

Fier metal sie

B.No

a5 75

iB fit

nef

tary

ie}

DAE LuKse a

Welder Name* gy wLeup LDA yo -poy

Taye] Precns Fuller Metal (Current Position [Shielding

vot 2M Gass _| Dia (om Auep Ee Jt

hee | av 2 Pe a

eres | 24> 1Rcem

cee ae

Paoisle

DEPT a

SAEED! XLS.

A Vv

General Utilities Project No. 1203

ste

AS RUN SHEET

Wes the BY FoR

Preeess Zima

| Material

Diameter

Thickness

Conserable

Frills metal size

} Bos”

} tomaticturer

weidervone DDS LUE tadge Wor 14601

@ Fon Wie

Wore pave] Poem [Plea Ta Tam [elding [PPD

i Ciass__| Dia (mam) | Type Pole | Amp Ranac] LJ tin, pr risiyay

Ferepai pe ve [sige niai2te7| BE- 66

Ee

1k

BONE

Tide,

135-140) 2

130-134

een) | 65e70

—___.\55-60

180-135"! “Wee

- leo tes" 135

tef-n0 | 1325

- Hea 179. Pee

We!

r

ae ?

WS -Gur-ele

Ww. 020 |

wee org

Ns — 7.9 Peo

SE > soem

Bo 1A egpra

ae ee

8 ceeded erm |

a

Wns AR8 Ere 1D

RWTOV Aniagentechnik GmbH

Zuerkennung VP 05-95

Geschatts.-Nr:

Hersteller

tocar

Pratgrundlage:

Profgegenstant

Werkstatfe bra. Gruppe

eens rae OP

Wank {rm}

Bur

Tomperatur (°C):

Tempera

Schweibverfahren:

‘ian procure

Nahtform

Rimalooe

wmesser >= frm

Schweipzusatze

Markenbezelernung:

Nommbezeichoung

Hiltsstorte

‘gchwieiBposition:

Wena poston

Warmenachbehsnctung:

Bemerkungen:

PQR/GUP/018-2G

RWTGV

License VP 05-95

Auttrags-Nr.

232332/ 01

C.C.LC, Ruwais

TRD 201 Part 1, Edition June 1989

Pipe, butt weld

Group I, II ace. to VDTUV-Merkblatt 451-67/10

15 up to30 mm

279.5 mm to O

-10 up to permissible base material temperature

GTAW/SMAW

"VW". groove ace. to DIN 8551

GTAW - wire & Electrodes

BOEHLER DMO - IG / BOEHLER FOXDMoKb

SG Mo/ E Mo B20

Shielding gas acc. to DIN 32526-11

26

None

er Antragstelier hat aufgrund verliegender Prifergebnisse nachgewiesen, dal erin der Lage ist,

‘Schweiarbeiten gemas den 0.9. Vorschriften und Angaben durchzutunren,

[peerapce win sot el outs appa hs mantel Rec ae to prom meta Se we scoring oh

Bei Anderungen des Schweibvertahren oder Schweidbedinguagen sowie bei Erweiterungen hinsichtich der

Werksloffe, Zusalzwerkstoffe, Abmessungen der Werksticke oder der Wirmebehandlung ist eine

ultigkeitsbaginn

Semana eeeL,

SS ecient tmnt

07.05.1995

Die Galigket dieser Zuerkennung dchtet sich nach der 0.9. Prifgrundiage baw. endet am 05.08.1996

Abu Dhabi 15/06/95,

Re aeee euPEn i onsen remeron rasearey abled eat

Cited ?

Dér Sachverstinuige

‘des RWTLV oN.

eg

RWTCY Aniagentectese GH

Bericht

liber eine Verfahrenspriifung Nr. VP 05-95

Procedure Test Report No. VP 05-95

Geschatts-n PQR/GUP/O18-2G Auftrags-Ne 232532 / 01

Hersteller: CCIC, Ruwais Werks

‘Auftrag vor: 08.03.1995

Profgrunclage:, TRD 201 Part 1, Edition June 1989

Pautgegenstanc: Pipe, butt weld

Werkstote 15 Mo 3 acc. to DIN 17172

Wandalcke nm} 28 mm reduced to 20 mm

Durohmesser fmm 359mm

‘Sehwelsvertanren: GYAW/SMAW

Nantform: "V". groove acc. to DIN 8551

Schweiszusatze GTAW wire / Electrodes

Markenbezeichnung ROEHLER DMO - IG /BOEHLER FOXDMoKb

Nommbezeichnang SG Mo / E Mo B20

Hitsstote: Shielding gas ace. to DIN 32526-11

SchweiSpastion: 2G

‘etn poston

Warmenachbehandhing ‘None

Bemerkungen: =

Ergebnis der Prisfung Die gestelten Anforderungen sind ert

Datum ger letzten Prifung 07.05.1995

Dai inet

Z LOL.

= Strata

eRe

| RWIEV

I *,\ 0, box 4s050

\a Races

Abu Dhabi 15/06/95

Dieser Bericht enthat

Buiter 3 pnlagen

RWTSV

Bedingungen der ProbeschweiBung VP 05-95

Conditions of Test Weld VP 06-95

funeags cs 232332/01 gat 2 ven 3

recat PQRIGUP/018-26

technische Gitewere(Grnderst)adnconee ser

Pick sec Tay Rea A |

vert fom | isaae | sua Bereshing

ce | om Lim? [nome | ow | 9 | om

1SMo3 -DINIIT2 T [Congitudinaliy/O.D. 539 x 28| 539.8 .

eat 25897 weld | mm

ores ens)

cherie Anay (Gunde cure

tai | -@ [| mm [P| = ]-@ | Ww | aw [ay

L 0.105 | 0.15 0.96 | O.01F | 0.008 | 0.03 002 0.06 - = -

Prat [Seni Waar | Wana Sa Seiwa Sa

i ane Fein | tage | Seg werenen | poston | earenang

3G] Bask, Archon | OB] OF =i] GTAW?] 26

SMa

Lwsinn | os fo | os craw? 26.

SMAW

schveticaen wospiat

mar ra aan] ean [pa “Ve vasa] Bama

woe. on ara Mil toral | rene | barn | Woes |e

Trnse | Marketing Jour | Lage ]oupe a Sane | Sa | tts

a es essa te ened eccee eee

= atv |<

7S) HOERCER DMOTIG BaP = peas a aa

© ‘8-12 Limin|

BOEMLER FOxDMoxs 25] 2 | 2 |2lrsaz0)ores -

es]

worsen soxpatoxy | 325 | a= | 3 |'2]asoaso late ,

+)

“TWseSchweiigeschwindighel vice eee?”

RWTCY Anlagentechnix Gm

SSUESEUBYIEG TSMR (Son ean case tebe 8579 680 RWisv

Ergebnisse der Priifung VP 05-95

Results of the Test VP 05.95,

umagesse fon 232332/ 01 fat oven 3 vente 5

rutgeaenstand sxe:

Probenauftllung/ rex pee seca

Zesstiungsteie Prifuna mondestaneweneg Accepted

Prutbereich tex we

Aolorderungen fosters DINS4 111, DIN

Batund temic Acceptable

“Zugversuch quer 2ue Nah (IN $0 120, Rundaugprebe (ON £0 126)

Proseni | Abmessung | Fah] Rm] 10 x 2] saenage | —eraensearationg —)

Pos. Cersens | pO Bemeriung |

SSochon rom Nim? | ire? | mem % % wearer we Remene|

“Rafoesnrngan ng oon 20

sis | asax206 | - | sat z é “c

sx0 | asaxio7 | - | sas : es c

Faitverauen (18 $0 123) /Bea wa Biegedorn una 3 en

Warzaliage- Gegering

Brobe-Nr. [Biegewiniel | Bruchbeurisiong | Biegedahnong | Probes, [Biegewinkel] Bruchbeurtelung | Blegedchnung

[outros | eccmaae | teem | secracanan | uPox | ceoyanye | teseware | Serampaargec

secemnne | Grad Lo segerants | Grad bo

ean’ | Sere ee ce one

180 se f 180 alee

Kerbechlagbiegeversuch (DIN 5019880 122) ‘Anforderunsen: oom

Probe-Nr. | Pruftemp. | Kerblage | Kerbschiagzahigholt Breitung f “| Bemerkung/Bruchaussehen

wpos. | “teawen | towhpnsen ‘aoas ren ist Brochanteita) |" nomsraresaree satu

x seule tem? ciate

‘Schwelagutanalyse eatin (8)

Probe, | © a ? = @ >

Prowerianven: Vickers hardness method

Coercana Grundverkrtot

Mabrogetige nia factory ihoagetiiye renee

Sonstige Protungen

Bemnernungen

a Sy pS ol ys ol

MIS INTERNATIONAL HOLDINGS LTD.

TAAL Na 2 ACld = oY GANT ED» aba = pg = ad = OM

P.0,Box 9191 - Ab Dhabi -U,A.E,-Tel:02- 582945 - Fax:02-S84S15

TEST CERTIFICATE

nt: Consolidated Contractors Intemational Company MTS Ref

Ruvais

GUP Project

Contact: Mr. 8. MFarlane

ADSI12 :Revo

Order N*

Date Reported: 08/06/95

ASME IX & TRD 201 Annex 1 & DINSO120 PI.t & DIN 50121

Description: WPS/PQR GUP O18 Postion : 26

22° Diameter x 20mm thk Bult Welded Pipe

Material ; 1$Mo3

spetification / Code :

TENSILE TEST ae __ Test Specification : ASME IX/DIN50120~

Mark | Type [Dimensions] Aree JIGL] YL] YS) UTL | UTS] EL | RoA] Comments

* mine | mm? Yom | and | aumet | aN toe Ae

Ba Saawe EERAT | ET =P} =| Face

$59__[ Ciossweld [282x197 | 496.0 | — [=| [= | = GS Frecure

(BEND TEST = +s Test'Sbecification ASME IX

Tare Type Bend Angle | Former Diameter Result Comments

*

840_| Face Band Ta a Receprabie

bai Root Bend 180" x Acceptable

BEND TEST ot APIs Test Specification : DIN 50121. x

Mark Type Bend Angle] Former Diameter Rowult Comments

#

’42_| Side Bend | 80? a Acceptable

843_| Side Bend 180" I EN Acceptable

Kile

Odie

Page Lof 4 ADSILI2 Rye

Client : Consolidated Contractors International Company, Ruwais

Description: WPS/ POR GUP 018 : 26

MACROEXAMINATION Test Specification : ASTM E340

Wak aye asian Resuls 1 Comman

?

wa Weis Section “WE Aszeplabie | i aera

HARDNESS SURVEY fe _. Test Specification : ASTM E92

‘Mark | Position Type Load Results. | Comments

2

ae WA Vers [0g See altached repo t

Certicate Comments: em #’s 838 & 839: Tensile fractured Ina duce manner,

Tesing Winessed by: TwW/Chijoda / Coie Tested by: tain Deon

One sunonaQietetes. Sy

signature a= thorized Signer

re

wo eve NCD JOFNSO

aaaac Mitte :

Page 2ot 4 ADSINZ Reve

Client

Description

Load

Mark #

[| VICKERS HARDNESS REPORT |

Consolidated Contractors International Company, Ruwais,

WPS / POR GUP 018 : 23

10k

aad

TOCATION SPACING | _A-A’ (GAPY

PM 2mm 205

PM 198

PM 195

HAZ 345

HAZ 37

HAZ 333

WELD EQUAL 254

WELD EQUAL 247

WELD EQUAL 232

HA OSmm 308

HAZ 0.5mm 276 243

HAZ OS 262 216

PM ‘2mm 182 202

PM ‘2mm 195 198

Pu ‘amr 185 798

Tested by: lain Dixon

Date Tested

Authorized Signature

&

Page ot 4 boa,

Consolidated Contractors International Company, Ruvials

tient

Description WPS /PQR GUP 018: 26

Magnification: ~x25

Macro # 844

ADSII2 Reve

UVTLY Antagentechrik Gmbh

TRURNTSDS mato oT BS-258 ele 8579 80 RWiuv

Zuerkennung VP 06-95

License VP 06-95

Geschatts.-Ne: PQR/GUP/O18-SG Auuftrags-Nrs 23233201

Heraeler: C.CIC,, Ruwais

Prafgrundiage TRD 201 Part 1, Edition June 1989

Brafgegenstands Pipe, butt weld

Werkstoffe baw. Gruppe: Group 1, II ace, to VDTUV-Merkblatt 451-67/10

Wandaleke (mm) 15 up to 30 mm

Durctimasser >= (mm 279.5 mm to

Temperatur (10): -10 up to permissible base material temperature

Sehweidverfahren: GTAW/SMAW

‘Retin precere

Nantiorm "V"- groove acc. to DIN 8551

Schweinzusatze GTAW - wire & Electrodes

Markenbezeichnung: BOEHLER DMO - IG / BOEHLER FOXDMoKb

Normbezelcnnung SG Mo / E Mo B20

Hitsstote Shielding gas acc. to DIN 32526-11

‘Schweiapositon: 5G

Warmenachbehandlung None

Bemerkungen: -

Der Antragstelier hat aufgrund vorliegender Prifergebnisse nachgewiesen, dab erin der Lage ist,

‘Schweidarbeiten gema den o,9. Vorschriften und Angaben durchzufihren,

In segvaren hho ening te ets 2pean hes eared hah os pune ne acatng Wo he above reqasrens and

Bei Anderungen der Schweitverféhven oder Schweibbedingungen sowie bei Erweterungen hinsichtlich der

Werkstotfe, Zusatzwerkstufle, Abmessungen der Werksticke oder der Warmebehandlung Ist elne

entsprechende Erganzung erfordertic.

Erase ceo eligi rats Has ewenne eagle etl mata, dro tn pst oe

Giltigneitebeainn: 0705 1995

Die Gutigk cieser Zuerkenung cet ich nach der 9.8. Prijrunalag baw. endet am 09.08 1906

Lilbler, >

Der Sachverstandige

des RWTOV eV.

Abu Dhabi 15/06/95

Pojeese

WTLY Anlagentechrik Grit

Bericht

Uber eine Vertahrenspriifung Nr. VP 06-95

Procedure Test Report No. VP 06.95

Geschitts-Nr. POR/GUPIOIS-SG Autteags-Nr: 232332/01

Hessel: C.CLC,, Ruwais Yeerke-i

‘ufrag vor: 08.03.1995

Prafgrunciage:, ‘TRD 201 Part 1, Edition June 1989

Prufgegenstand: Pipe, butt weld

Werkstotte: 15 Mo3 ace, to DIN 17172

Wandaleke {mm} 28 mm reduced to 20 mm

urehmesser {rin}: 359 mm

Sedweigveranren GTAW /SMAW

Nantform: 'V"= groove acc. to DIN 8551

Schweitzusitze GTAW wire / Electrodes

Markenbezeichnung BOEHLER DMO - IG / BOEHLER FOXDMoKb

Nommbezeichnang SG Mo | E Mo B20

bisstote Shielding gas acc. to DIN 32526-11

Schweigposition 5G

‘een penn

Warmenachbehsndhing None

Bemerkungen

Ergebnis der Pratung Die gesteiten Anforderungen sind ert

Datum der letzten Pratung: 07.05.1995

at ere a

Mhbbee ee >

.

Dor Sachyerstindi

des RWTUV eV.

‘Abu Dhabi 15/06/95

Dieser Bericht enthuilt.

RWICV Anlagantectnik Gmeit

Bedingungen der Probeschwei&ung VP 06-95

Conditions of Test Weld VP 06-85

Aunrags-Nr 232332 /01

Bit 2 van 5.

Geschits-hr, PQR/GUPIO1S-5G

Hechanische Gitewots (Grundwerketlte ecw goons ea reat

PrUBIUGk se Reh Re [A ay

Worketott or Cr Bemertung

wes ne We Seanad | reel] ree) |e tena

1SMo3 -“DINT7172 [1 lCongitudinally|OD 89x28) —. | 3308] ~~

Heat: 25397 welded mim

(for test only)

Chenache Any (OrundweratelN metre ben

Pru ] | si | mm |p s ]e@ ps >e@ ] a yw

| fee

T Os a q =

sivefahren vate me sen pene

rifatick | Schweiter Welder Nahivorberetung seonaansater —] Schwelts | Schwoit>

Me Name | Zeichen] Form] stegabstand veitanren | position | Semerkung

50] Basi Anchanit | 020 04 GTAW | 3G

SMAW

L.W. Singh on | ow 03 ~3 |oraw/| so

SMAW

Schweiddaten eng tome

Sciweiaaueate Baan] Bier Ve) Worwain- | Bemerkana

cn ‘cra femininy [temperatur | Renee

burch| Lage |Raupe | act Austin. [brsen | taste

reser ‘a Hinge | wnersore |" astee

36 BOEHLER DMO-IG | 24 | 1 [7 90-120 | 9-12 | > = | aro aI

oO 8 Limin,

BOEHLERFOxDMokb | 25 | > fa [2 {risrsofarae 2

io

BOEHLER FOXDMokb 3+ [= |rsosolaraa}

eo

‘TesScinmiigeachoindighaiiesang - _

Bemerkungen

WTEY Anlagentectnik Gob

elton 102011 828-0 f Teves {02011 825-2868 M1

18579 680

RWT6V

Ergebnisse der Priifung VP 06-95

Resuilts of the Test UP 08.95

nuttage Ne lower m 232332 /01 Blatt /onee 3 vonra 3

Peatgegenstand dae

Zerstirungeteete Prafung savers

Pratvertaheen Yaseg mont

Pruteerich te

sexsna Accepted

‘Anforderungen DIN 54.111, DIN 856 BS,

Befund acne: Acceptable

Zugyersuch quer zu Haht (OW 30120), Rundeugprobe (IN 30 125)

Frosch aiessoas | Rah] —Ra |] Be]

Seon | Mewes’ | mz

sent | om | wien? | wo? |_mm | x | x

‘Anforderungem /Revarenens 430. T

se | asanzar | - | sis ‘o

sv | asaxea| - | oor] - | - ‘e

Faiverach ON 59a Bigrionrenanamm ode) eR

Delage Zugzone rela Gegaringein unaue

Probert. [Biegennk!] Srciavarshng | iegdahmang_| Prove [Siegeninkal] Brucbeureiing | Biegeashning

rien [sooteas!| os emony || seayenemt (| cron | wemasgs|| vee! | wrasse

aie to Sie to

a er os, air

so | isa | Acowpmbie | st | aso -|-

Kermachinghiegpversuch (ON 60 195150 172) Anforderungen: 0180” bu

Probe | Fatnp | Ketiage | Keractingaingnet | Braking my | Seneiunatrecaaseren |

tien | "towne | comps | ““Segerenme | xastometamensy | wmemntcacecsee

ic Joute fem? emt pigeon

Schwsiguanae iesraencnat) :

Pobeic| © [| 8 | wm |e [= [|e | w]e

Higeprting alae Tileaiens Vihar andes netiod

Sereno oeaies Grinduattt

etgrnerscung Aaa

sonsgePtingen orem

eureshungen

Sd A Sd Gs yl

MTS INTERNATIONAL HOLDINGS LTO.

SU OALONS GSU = AY AARTE S aale pg aig = IM ge

P.0.Box9 191 + AvuDhabi-U.A.E. Tel. :02-5823a5 - Fax :02- 534515,

Client = Consolidated Contractors Intemational Company MTS Ref: ADS1112. :Revo

Ruwais

GUF Project

Contact: Mr. 8. MFariane Order N®

Date Reported: 08/08/95

‘Specification ‘Code: ASME IX & TRO 20 Annex 1 & DINS0120Pt.1 & DIN 50121

Description: WPS /PQR GUP 018 Position : 8G

22" Diameter x 20mm thk Butt Welded Pipe

Material : 15Mo3

[TENSILE TEST “= Test Specification : ASME IX/DIN50420

Wak Type [Dimensions] Areg [IGL] VL | Ys] UTL | UTS] EL [ROA] Comments

# mim | met fron | a [nt | an |’ | 8 ||

G6 | Crosswald | BSAKT | SSH | = | | | as [erasure

847_| Cross-weid [25.2x 202 | 509.0 [= [= = 265 | 521_| TG Fracture

"BEND TEST, Raven _ Test Specification : ASME IX i

‘atk Type | Bend Angle Former Diameter ‘Comments

*

43 | Face Bend | 760 x Aesaprabie —

249| Root end | 190" a (Aceepiabie i

BEND TEST. Test Specification: DIN 60121.

‘Mark Type ‘Bend-Angle | Former Diameter Result Comments

* |

350_| Side Band Tae El Receptabla —

25 Side Bend 100" t at ‘Acceplable

Page 1 of 4 AD SEIS 6)

The contents of i roar are gaisnd by the tems and candhions @

client Consolidated Contractors Intemationat Company, Ruwals

Description: WPS/ POR GUP 018 : 5

MACGROEXAMINATION ie ‘Test Specification : ASTM E340.

Mark Type Position Resurs Comments

#

52 Weld Section | WA ‘Acceptable 38 allached macroaragh

HARDNESS SURVEY = Test Specification : ASTM E92 —

Wark | Position | Type] Load Results ‘Comments

#

a53-| NA Vickers | 10Kg ‘See attached report -

Certificate Comments: tem #'s 848 & 847 : Tensiles fractured in a ductile manner.

Testing Witnessed by: TuV/Chiyoda /CCIC Tested by: Iain Dixon

Date Tested 07/08/95

Signature: Authorized Signature

eee

whi

Page ? of 4 ADSI Reve

Client

Description

Mack #

| _VICKERS HARDNESS REPORT

Consolidated Contractors Intemational Company, Ruwais

WPS/ POR GUP 018: 5

10K9

352

LOCATION SPACING | AA(CAP) | B-8' (ROOT)

PM 2mm 497 198

PM ‘2mm, 194 201

Pu 2mm 192 205

HAZ 0.5mm. 260 220

HAZ ‘O.5mm 262 222

HAZ 0.5mm 262 220

‘WELO- EQUAL 254 192

‘WELD EQUAL 260 | 182

WELD EQUAL 258 {207

HAZ 0.5mm. 249 220

HAZ 0.5mm 238, 217

HAZ ‘O.5mm 240 | 220

PM 2mm 201 205

PM. 2mm. 201 195

PW ‘2mm. 201 197

Tested by: Iain Dixon

Date Tested :

Authorized Signature

Page 3 of 4

ant

Description

Magnification

Macro #

Consolidated Contractors Intemational Company, Ruwais

WPS/ POR GUP 018: 5a

= x25

852

AD SHIN

Rev

i 8 Sika Sh |

ASGS Saclété Générale de Surveillance S.A. ore _ Fo f 1 _F.

WORLD LEADER IN INSPECTION SERVICES

2 rnoe ost Des UAE 7 leuel

au Berge. Pan 379024 Te: 40682 SGS08 EM reronr i=. £2 jo1g |

Be erst Ru Brae Telos 288050 Poe fe sezhz, Yi 2089 ALA EN

Soin Tacoeasts on ee

: SROIOGRAPHIC -NSPECTION REPORT -

ENT Apnece ENGINEER wos ne, 12-3

‘tRAGTOR CHiy ODA

Soeccurnon: R7_ OF PAR TEST Courente

Garion secTiOn @uwhisr Sup section: Bury

SPEGTONGODETRD_Dp|[ATEGWOIE Syjst [1 Did STin— [RUNTPE Hy [sorcene PE

SET ry [OEE FF Tid vENEY > 3 [Se y

ore | WELoNG PROTES oR oR

asme D 67a ) SMAW 2a"

wecowem fo WELOERE —T onanscrsroo. ne ewan ae ee

PAR - 26 waaj2¢ [wes GuP-ore-| o- Sn cm |

= 260 Cho cs

9-40 ch ea

| 40-129 f1m =

12) Ch a

. cr Jsp-115 (0) em a

aR -~ 56 wadle4 | wes = Gu? piel p30 ¢ [ee

= Ba- 60 cy ea

= Fo cry ce

40-129 cm Eahtfare tig | =

120 -)S0 cra -

ISV-1DS (6) crm —

_ J ete

a SUS

cl ~

—— . t

ARBREVATIONS

LE. ONSPaSiraen oh: Bgegienese FE: ERELERiinete

Se ese seeres |e cores eke: Mamatmanessere?

% euteetiarecsn eased encae PS RESET cost

Someta te 2 Se is: MURA Sat

ie aR

(Stn

—T —Teniieen'g SiGNATURE ~ *)

we eee wis KLAUS Ma LA

mae ov) RATSY

Auftrags-Nr./Order No. 577 788/01

Siegen, 18 10.94 Fu/fKa

Bescheinigung / Certificate

ber die Tellbaupriifung an tangsnahtgeschweiften Rohren

on the partial construction testing on longitudinal welded tubes

zur Verwendung als Druckbehilterteile / to be used ae pressure vessel parts

Besteller/Customer, Deutsche Babcock Italiana $.P.A.

Kom -Nr./Com. No. 5470

Hersteller Erndtebriicker Eisenwerk Werks-Nr.: 34 134

Manufacturer 1D-57339 Erndtebriick Work No

Prufgegenstand: —_lingsnahtgeschweifite Rohre

Test object’ longitudinal welded tubes

Anforderungen: — AD-Merkblatter

Requirements:

Umfang der Lieferung / Size of delivery

[Poane. [Stickam Gegensiand Schmelze Nr | Prove.tr |

[nom no [number ot Aicle _ Hest Ne | Spec. No |

| |

| langsnabigeschweiies Rebrfongitudns! welled tube |

ja 1 |9559 28 x 12000 mem 26036 | 61994

| 1 9 559 28 x 12000 min 25807 | 88282

Werkstoff / Material: 15 Mo 3

SchweiBverfabren: beidseitig UP

Welding Procedure double sided SAW

Schweifnahtwertigkeit 10

Joint Factor:

Warmebehandlung. keine ne

Heat treatment: without eee

Ergebaie der Prufungen: Die gestellien Anforderungen bind-erfille

Test results The requirements are fulfilled

Kennzeichnung des Rohres Kom, Rohe-Nr et

Marking of the tube: Com, Tube-No Wy

RWTUV e. V. Anlnge / Annex

C

Arbeitspeifungsbericht Ne. / Report PT No 5695

rN Ronigentericht / Report of X-ray examination

Eucker Quasty COMA Roige

of Sachivérstandige/Expert Ergebnis der Prufungen fLest result

a APZ-Ausgangsblech / Certificate sheet

DEUTSCHE BAR STK SAR MARCO

nt / Report olteasonic examination

Bescheinigung Uber Wasserdruckpenbel

Contratato Centificate of Hudlrostatic test

Checked by

ee ae

RWTsV

Ergebnis der Pritungen/Test results Anlage/Annex 1

(Beiblacs Rir geschweilte Kessel- und Druckbehalterteile) __Auftrags-Nr. 57/ 788/01

(Supplement for welded boiler and vessel components) Order No.

1. Abnahmepriifzeugnis Uber die verwendeten Bauteile wurde erbracht

Inspection certificate for the used parts was submitted

2 Besichtigung und Ausmessung: ohne Beanstandung

Visual inspection and measurement ‘no objection

3. Wasserdruckversuch: 80 bar / 15 se

Hydrostatic test

4. Arbeitsprifung bei der Herstellung der Schweifinahte wurde gemaB

Anlage durchgefthrt

Production test during the welding of the seams was carried out in

iv accordance with the annex

Schweilfnahtwertigkeit / joint efficiency: v= 1,0

Xray examination

100 % der Nahtlange eee

of the longitudinal welds 100 % of seam length

Befund siehe Anlage

Test finding: see annex

6 Bescheinigung des Lieferwerkes dber Schweilidaten wurde gemals

Anlage erbracht.

Manufacturers's certificate of weld data was submitted in accordance

with the annex

Die vom Herstellerwerk eingesetzten SchwelBer sind in der entsprechen-

den Prifgruppe der EN 287 oder den maflgebenden Richtlinien geprift

‘The welders employed by the manufacturer are qualified in accordance

with the examination class of EN 287 or with the applicable regulations.

RWTUV e. V.

x >

Eucker

Town GET) 2378.

bs 30134 XLS

WRK cat

ERNDTEBRUCKER EISENWERK

Offshore Constructions

Onoed 29.094 i Starkwandige Stat

Deutsche Babcock Italiana S.p. A

20H Fray Laura Tos Starandige St

Vin Livernese, 600 lan i Stecpes with heavy

| wallthiekness, longitudinal welded

157017 Tonbolo (Pisa ceenonene

Siainons Stetsipes

rohre,

Sarsneos

Dispatchnote Our Order-No, PartNo, Ourref—_Lrndtebetick|

34 134 Gesamt _wey-ha___21. 09.1994]

[Your Order [Bex S470

Terms of Payment Net cash in DM for payment 30 days following the date of invoice

\ ihe goods delivered by us remain ou property! ll payment hasbeen effected.

[Tems of delivery ei threm Werk

Delivered to. Deuische Babcock Raliana Sp A

Viz Livor +, 600 - §7017 Tombolo (Pisa) Italien

Devers by Spediton Bald - Fe

[Your VAT-Ne TT ONS7481001 "Statistical Code-No 73053100 |

iiuty-free delivery within the European Community ace. to § 6A USTG (ie turnover law) |

Stahlrohre, LN-geschweifit, ans Lagerblech hergestellt

\Material 15 Mo 3, DIN 17155, AD-W)

the other terms eee our order-confirmation Date of our crdcontension (01.08.1994

[re [Rem] tube | od | wall | te te] ike! T

fmm | mm | mn | m total ai

| | )

Hextrakosten ir Lieferung fret Pisa |

| DEUTSCHE BABTOCK SAN Ml |

UAL CONTRO

Toke 1

onectes by

Abnalmiedabumene

"| ERNOTEBROGKER EISENWERK

‘GmbH & Co.

Exndtebrick 1

West Germany

Abnahmepriifzeugnis

Works Test Certificate

Certificat de contréle par 'usine

DIN 500¢9.3.1 8

WerkeNe, 34 138

Works No,

Rolerence usine

Cert-No. 34 134/0

Besteerrvensercore

Deutsche Babcock Italiana S.>|

Ereougrislown : UP lingenantgeechwoie Sta

Eovoclers roars wonegut sevens nel pee

Becton pea er esom soe wetmmene

Beatos Ne

EUTSCHE BABCOGRS Cormme

ITALIANA 5. |

000879 29.094 |

ae Tren

5470

sence DIS 1717 ! ! &

vieisot 15 Ho 3 soonmegitene Ta

= tem (me

ER |Gh >= [eS] & | = Se | ee

L 4. 359 28 12000 26056 61994 80 /230/93/00287

uz | a | se | 22 | 12000 | 25897 | s62se 20 | ase

| |

I

) 4

i}.

‘Rantgenprifung Long. velds 100% x-ray-tested acc Beschichiung: —_ |

Secures (oR 3 om. -

Uraschaiprotong: UT:

amination ely

MPUFE-Pratung:

Erotebrick t,den 19,09, 199.

yack ace, vo SEL 072/77

a

Bericht

ber eine Arbeitsprifung Nr, 5695

Procedure Test Report No.

= ReparaturschweiSung -

Geschatts-Nrs Auttrags-Nr: $77 788/01

Hersteller Emdtebriicker Eisemwerk Werks-Nr: 34134

Sennen 57339 Emdtebrick ie

09.09.94

Prifgrundiage: TRD 201, AD-Merkblatt HP 2/1

Bralgegenstand: Probeplatte

Werkstotte: 15 Mo 3 DIN 17155, AD-W1

Wapicke (mm 28

Qurchriesser {mm}: $59

UP. Lage Badsicherung: MAG wird kompl. ausgefrast

Nation HeNabe

‘Schweizusdee UP

Markenbezelchnung: Draht’ $2 Mo Drabt. Union I Mo,

MAG

Normbezeichnung: Pulver: OP 121 TT. Gas: Argon 82%; COz 18%

SchwelSposition. waagerecht

‘Ration =

Avsrtzung det 28si9en 100%

Betsennunapanos

Warmenachbehandiuny :

Gegenstand / ow: Schmelaen-Nr: 25897 Probe-Nr: 86282

Bemerkungen: Die Erweiterung avf den ungeglthten Zusatnd

Bem bestehenden

Verfahrensprifung Nr, 2686, Prif-Nr, 25 901 142/8 erfolgt durch die

Axbeitsprilfung Nr. 5695, PrifNr. 577 788/01

Ergebnis der Prifung: Die gestelien Anfarserungen sind eral

Qatum der ietaten Profung. —-

DRUTSCHE PA

BCE TT

OIA Geniront

ALUOTICIBIAL

Siegen 29.09.94 /Bi |

Dieser Bericht enthait

restros

RWG

Ergebnisse der Prifung Nr.

Results of the Test

uta Jom es 57778801 fut 2 vont 2

Prgegenstand snc Frobeplate rns

Proveauteling ratseemewins: —AD-Mcebat HP 2/4 faite §

Zesbvngsile rng on tem og Pos

Puvetiens tomy mene ‘Ducchstranlng ta

Palen neon: Schvceirahi und Ubergang | mae

Aaordrungen orton AD Mesa HP 53 Mie Fev

roan he kena Fee | '

Aatage sean: Ronigenahre s

“Zugversueh quer 2u¢ Naht (DIN 50 120) und Pifung des Grundwerkstoftes*

Pane ay [Rat] a]

Sree oon conne

Scenes [mm | we? | wm? | mm | x | x | Soe semagacesinmee

Taforderuigen ines | a

Ss | 2ossaT@ 30 | ae |

asaseanas 50 | ow |

Rpea |

9,90 su | 79 | 50 2 so} +300°C |

FaaconechiGn oe Repro erwnaans d= Ba =

| Seamccaee Corsutdiae aemnsaueem ]

Probe-Nr. [Biegewinke! |Bruchbeurteilung | Biegedehnung | ProbeNr. |Biegewinkel | Bruchbeurteilung | Biegedchnung

whee" [eevee | vanace "| Setwerenc |utor” |store | tee’ | setae |

fete | one | mere | spp | an S |

[_spemen | Seareee fet mm | 4 [| Sere | Oven Limm | ow |

5695 180) ‘ohne Ann - 5695 180 chne Ann [= =

wo |Sheane |. | we eweams | > |

| j

[Le al |

ebcnagbepeeroc ONE HD a

Tes] reno. |_Rebuge | —eachagazet | ort ie —| Benungfchaarhen

titees | mere’ | sonense | “Sturnegn | nant awctimes) | “wontnomeestneen

scour |“. dae eerily

5695 RT s 154178156 ~ 7

eeu oenremar ~ -

race f © | * | | [= pe >= p> | @ >]

ses [0,106 | 01s | 0,96 | 0.018 “005 | 0,02 | 048 | 006 ~

|

Pideprbung (Aniage: = Peuvedtaheens

comets doe gomtngisas =

Sldgnantereuchung Ange

Makrogetige tear ohne Reanstandang Mikrogetugetowment =

Sonstige Prufungen rome ims:

Bemeikungen: =

ERNOTEBROGKER ElseNwerk | Abnahmepriifzeugnis

Werkat, 34 134

GOAL FS Works Test Certificate Works Na,

Erdibrick 1 Gertiticat de contrdle par'usine | Réerense wine

West Germany DIN s0049-3.1 8 Cert-Ne. 34 134/0

Besteerrvchnechee Beslan: 5470

Deutsche Babcock Italiana S.p.A No cccomnande

Ezeugistom: UP ingrarigeschneiie Stahkchve |

elo ecaentenveaal |

|

Aotorderangen: DIN 17175, Heysteberzichen |

Wensint” 15 Ma 3 Apeatmepitsiomol, [WE

rd Re

we Tiamang Desa a wan]

to | os, RS Teen) ae atic wisi | Ta

fon | nu Perec | r= scl | et 9. Cert.-to,

|

1a | ia | ss9 | 28 | 12000 | 26056 80 20/93/0087

1? 1 | 559° | 28 | 12000 | 25297 | 80 730/93/00287

| |

|

v1

| t

{

j

| |

}

\éntgenprifung: Long. welds 100% x-ray-tested acc. Sescrichtun

een aaa ti. HP 5/3. Seg ° o

Unaschatinulung: UT-Lamination check acc. to SE 072/77.

ese uracon

mapur-Protung)

rope -

‘Wena tt aorersorneenra hoatne ares aaron niente eo

Ematebrick 1,den 19.09.1904

Tisaaioripessa | ashy roan |

Sgonouw | Nacho"

ep2aiyisfeee| zest

comets) om |

ict gana

Sie me

Ys da Te +e

v] ae at

ATIOWANOYSSYW OND ONNINdLHOIS U3EN AHOIIA *00 8 HqUID

os-20 wos 4AOd3U TOULNOS ~VNOISNAWIG ONY TYNSIA | Imuasiy Jeyonsga}pusz

4 ok

: t somaya ania

[agen age seu es eat Bee

To Tt

| fos

ross so

See ee

|

jioat || er | eer | ar ace fr zweae" | diese feos

5a

Notisod o1a8 YanwieNo1/3uNisoNyT WHO 30"1 ! 5 =

- _ : Be We py ee | 2 | ss x 2 + 900 | 80 bar || 1S see !

Pf cesses

|

|

|

|

|

|

|

[Fin / coMPARY / STE

UNTERSCHRIFT / SIGNATURE

7 xo

Protocollo nr. ALLY /i99ant

TELEFAX

gage

Errcistoer

Reoura Toxin

ERNDTEBRUCKER

EISENWERK GmbH & Co.

r Ceara acon

osoresza21| Kes

BABC@ck

DEUTSCHE BABCOCK

ITALIANA SpA.

[cow

| Betin 16.09, 1998

~ ~ |

Fem etolge iow Sic ita fopense osoweBaz8-3

Hof

a ‘Our order $470/15.600 - Your job EW Nr. 34.134

Piven Your fax dated September 9, 1994

Tomes eee pagina (lus oussi) > trpremision icyou ae nisin wy Pape pease al

Seapreeteateelten hace fevsesiotien — |__| Patees Gowrnnung nen voto acs in em iasprer

Sem Deck) oo Est 7

See amie

SARUVORNO

‘Stobitmente Tombole (F)— Telelae —_ |

V2 Livornese, 609 ds0Be525-6

Tel esgreezee!

Telorsov0e |

DUE BRRUUCE TAWA Sp

"ALOR

Rortifind Tras Geny

Dear Sir,

referring to your fax dated September 9, 1994, we confirm you herewith that PWHT is not

required for our pipes so that the relevant delivery time can be reduced.

a

i

:

3

i

&

i

‘

:

2

3

;

i

i

fr

;

Werkstofflabor GmbH

Sohiiehtermannstrase 4a Talafen (9 23.23) 51006.

: Telotax

8628 6°85, 5 27201 (02329) 5t007

|

Priifbericht: mechanische Prifungen

Wom-Fes /Oe no Cien Probe estno TD Kunden der

sae 3068 027

Wwerkstor- Mater “Apmessung-Oimension (me) Schmelee Hest ne: 25897

iso ve Bron ni-Pateno. 85282

WN WPS no WFO ‘Warmabehandhong Heat Voniment

Souusnavon 0 70) Saher tr Wal re

Specteavon

Gagiewecn Veraie ear ON BOE 7 S010 7 SOA

Pope] baa ] tw | AempA | in | A erage | Tene

Peston’ | amenten |S sfongation ae

| ea | ten | es ie

Wertorderung. io] lar

Neca Bie wie | [a

S-0 % 26.95x 27.60] 539.8 | ow

| se 26.960 27.43 ws. w

st 9 so ms | rma] mo | m | 2s

i

‘Bregeversuch - Bend test: DIN $0121 Dorn® - mandrel: axe | Owr-test:

robeniane | Eroebris [Lo mm) |F ges. si] Probeniage | Ergebnis [Us im) Je ges (| Pobenane [Tema °e [area

Remsen | Resse |e Lists: | Boston |e em feaey | Bone yee

a oot) T

te bo: &

Rt is: ¢

a tie =

Geechigbegees-inonc eal.TGo IN SOS 7 soe

vwertoeurg._inelwe singe veces itomeiaanee Teme *

SENET Shes fetes ee Se he

Probeioge | loves | at] Poser | Proveniage | deus | mt | anew | Fopenioe | loves | mt

ec erie | “5” | PSSSaSe atti | “ta | "Pose ove

aa Set] FS [ees | BBS PY lace a

$0 1

decktae | ES

Seer” | ES

j

|

|_| |

Bemerkung. fakroschl iff: Hakro: Frei von Rissen ~ Schlacken indefehlera. ‘Scnitte (Sich),

BEETS. 1 mcoshtts Wabroetne Fret vor Bisson» Seblacken ~ Bidet Foor” (Sie

| se ste $77 190 fo:

Here, 39.09.1556 LUISE BARCOCK HALIATIA Spa |

RTD Werkstoffiabor GmbH coma conconan |

0-44928 Horno ALCOMIGINAGE

3 ‘See reiiind Tree th

75 ; 2 ene

wo fB] AZ ores

fro taser — ness by

G/B = Grundwerket Base

= Unergang Fusionure

ome

wezitne —

5 = Sehwaidesvieis

Miarmebariol Zane/Heat atected tone

(O= Quer/Tranaverse = Langs/Langiuaine

P= Preset

J Ganciqung ex Pron i mrrugeasne vera wercen

anweie: le Potegeanitse bet ahen sn austen gl Pr'goeen

oma

Priifbericht: chemische Analysen

1 Order 0. Cent

‘estan Motors

hos

‘aamessung-Dimension irm)

Werkstofflabor GmbH

Schichieniaanstrae 4a Telefon (02323) 51006

24620 Herne Telefax (02323) 51007

pavgig0z27200

Pighe-Ne Test 90 “OWL, Kunden -Order no

3598 9403)

‘Schmelte- Heal no 25897

S-

Sehwoiterivel8

GNF ~ Grundverksl /Basemat

te Blech Ni. Plate no 86282

| APN = WPS ne: Ve. - POR no ‘Warmebehanciuna-Heat leatment -

vein

‘Soetitnation: TRO 201 - ‘Schweifler-Ne - Welder no.

‘Speciation

Cchemicne Anaysen = Chem

hist aat ec | s f[m| er] s|wlalalmimwi[m|{aln]v la

“resin. | pe

| i

Saliw, (nin T t 1

ste. |eax | |

sess |s “0.206 0.15 | 0.96 | 0.010.008 05 feos fore 0.02

| | \

| \ |

| | |

! | 1 |

proben-Ne| at |B ca | No | oz | | Pe | an | we Poe |Ccusni) No#V| AUN | Cars

"esto. | Toe to | an

| a

seta, tn. |

sothe. fax

\se0s |b 0.330

| | |

- | \ ——

Bonenang. HN S10 S17 350 7

Inert

Vieme, 15.09.1998 Serres

4 i, DEMITHE EABCUCK HTAUIANA Sp,

ATO Warkstoifiabor Gmbr, Ess Reonneniv

D-afeze’ Hes OHISINALS

| Sun fod Teun Cony

lom uve} YAstscn Uniersehet

low ustorton — Valngesed by

Technlscher Oberwachungs-Verein

Saarland 6.¥. 919495

Tw

CUDg EROPER OE CAEUNIELES DE CONTREXE

Abnabmepritzeugnis (DIN 50049-3.1 4 ) pata = mansions 70/93/0287

ritestio Nea?

Inspection Cartificate Tol-— Pat — Parte — Pata: v

Gertitical de Réception (EX 10208 ~ 3.24)

Cortificato Collaudo Materialt

Benalie — Quraner — Azbenur — Commitarts

Nr. — Bhaat No — Page-No — Pago:

Ne Ge Secarmant ~

Universal Eisen u.Stanl as

Duisburger Str.26, #1960 Neuss

Hoenater — Mentactiree — Fabennt ~ Prost

Ne der Dillinger HUttenwerke

66748 Dillingen

Progrienicd — Arle — Predot — Prodoco

Blech, warogewalzt

Prtigunelagen/averterangan Tecate! requramenia/Damand — S

037.6030

renlon uchlques/Eaigences — Noma eartoto/ Regie:

PRO 101,TRB100/ AD-Merkbl. H 1

Warkcit — Matanal — Matteo — Matera: eiaprchand — according to — wart — atsondoy Ausgabe — Elton — Edtione

15 Ho 3 DIN 17155 10-83

Uslaruntand — Bais ef debary —

st — Maing pres

Keenstung = Marking — Margo

Wrst! — Maiadal —

Mauiey — Matar

rnd of he manatecsre

Murgce du hbrcant— Marcio da predutre

DARE

15 Ho 3 7

1 Suantnagn— tapers ane. apf

Sa ee cen aL

“Se

Unlarg dar Ustanng — Ena ital detiany — Ute dnstnn — Doeriloo dot ena

Ere] ~ Probe Fi.

lueer of ind —— Article — Ddatgnation du produit — Tipe él prov Jet He

OF ° Crea We Ebpoovene

pon [one

aos | 2 siech 28,00 x 2500 x 12600 ma

|

|

Jha

Zune Anglen — Adonai amuha — Aeon ovarvtn — Owen

Toleranzen; DIN BN 10029 K1.B/92

J Anlodarangen sin Anvagan afl — The raquvamona are fle at par Annan —

Fata sone onto eg

y Sulzbach

(Ont — Leeson — Low — Local)

AdsSchu

bie come Goalie

Bet “Ke guse

‘Prim —

93

= oem

Ine. (grod.) Arnal

Gone

neva

corr PON VIE OEM TRsahat dete Prove

3 Pratungen Technischer Oberwachunge-Verein

SAARLAND «V.

Aagste:t

lane

230/93/00287

20| 270 | 440-| 20

|$3e

_ se a

m0,

che Zaagha eucbnget fare

tov suabieqe Eo i

| hod

| = foseredtne | |

[| [DRBEESEESScestuershene) | |

| fad > fegpsssutesssepverste™) | | | '

| prutergppndssp, siehe b.2) abbahmeprafprptokot t -/anthee | 2

| , , |

1 |

| usbagen|zu dep Profungen

Besientdguhg undl Hapkaherbie, ohnk Brahstaheun

i ,

2. senbizinabyst dhech en erectarers] | |anthoe| 2

en Heretblibr

i i ;

3. Werkptof tvpregchbiuhseprituns

anipge] 2

Va ae

Marc’

Sulzback 26. August 93

(On = Laction = Liaw ~Lecaial {Orlum = Onl =O)

sn wxo wine Ina. (gred.) Amold

ee ere nn neemenencrensl ser

i Bee DIBIMNILLIN HFONITUG

ao egspaboue. C

BNIWERSAL

LeavensaL SEU SUN GMI POSTHACH ON A wUOENEUEE EISEN UND STAHL GMBH__

ULTRASCHALL-PRUFBERICHT adie waraness

Ultrasonic Testreport a Beker

lierr Luteler 225

eesTELLER: Exndtebricker Eisenwerke |,urrmacs.na, 594013964

joie “GmbH & Co.Brnéteprick — [tment

SESTELLNA: 34134 EFERUNG vom:

Proton nace _ Prager [ysu=2 usk-6

teat | {lesen hist t

7) [erent [seeaw | [seear jezsn TJentoeeics | BU ams |,

on [seaano"[ [wsesan | Teasn TT To ]seie i inms |

‘oertachenninand | Wala 7a one 15d koppaimine: Wasser Tene DC Ooo 1

Serie: cons fo Sees ese Foeve i

Gerticustendhg, [St [9C) Sulenbeiamecnase| | Regavionrenser FSS [ERSBSOS em)

Scometsenies [K2—]AVG-Siala [Lespavaten et eas wate [Zi i

PRUFDEFUND

ce "Ramesses Sse Probe uss [Paci Race Randers rn] eves

. Loo wt

1[2ex2sooxi2000 Pg z RET [is ne 3 2col = 5

| |

T

|

UNIVERSAL

FISEN UND STAHI. GMBH

neuss, den 2+ & 04

t

4

a

; tebad TU

Technischer Oberwachungs-Versin Ti

cEOC Saarland @.V.

‘coUBGUE EUROPE OCB OMOANIGES DE CONTROL SAARLAND

Abnahmepritzeugnis (DIN 50049-3.1 A ) att — lnrtea ls 20/93/0028"

Inypecton Cancale ay s0204 — 3.34) aaron 7

CertHlicat de Réception . Blatt, — Sheet No — PageNo — Pag-o =

Cortificato Collaudo Matoriall

aoe a serar — Aavtae —- Comrlterte ‘Berar, — Order No — Noe commande —

Novator

Universal Eisen u.Stahl AG VOCS" S aq sit/s3 6.4.93

Duisburger Str.26, 41460 Neuss Ree ern ntl

= Manalogacer — Fate — Prodamere Wthacie, Wert No — No ul

Re"der ofTiinger kuttenverke

S748 DAllingen 037.6030

Prolarsenwtind — Arla — Prod — Prodebo

Blech, warngewalzt

Faleundisgni Anrcarengea —-Tacioal aqutemerta/Oumand — Sphcteon tacholguee/ Egon

TRO 101,7RB100/ AD-Merkbl. Wd

Noma 4: eanvolio/ Regt

Wisattt — Maietal — Mata — Matec

snapredhond — accent to — whant —

25 Ho 3 DIN 17155 10.83

tice — Efaione

= Sine @ torture

rn Making procean — Prachdt dlaborain — Procadinento i elaborvona

Kanraschnang —; Marlng — Maguage — Puronabirs

= tiatecatbn — Brad of be mantener DAR BL

Margue du falcant — Marae dsl produtore

varaatt — Mi

15 Ho 3

Brechm.-Art

Schr. -Hr. /Probe-Nr

Liang dee Usteung ~ Era el casa dliary — Ute deep — Deserve 0

Fane) Sasa Fae

turbo | Gepenitend — Ante —~ Diagraion pra — Tos pret rte

ot |Noeie pee ie epee

t -

cos | 1 Blech 28,00 x 2000 x 12000 na 26056 63961

1 Blech 28,00 x 2500 x 12000 mm zeoss >| 61896

uciiscne

co

one eens

|

|

|

|

Zohan Angeben — Adon rena — Aspe

Toleranzens DIN BN 10028

rmarsint — Onsoraione

KL.B/94

ingen in Ie Anapas. aol — Tha agua

eae SORE ye 93 ecu

(On = Lecrton — Unu — Lact ‘Baton — Date — Di

7 @ Des) ing. (arse) Armold

Ds garatan Aale

4 a4 lila 48 per Annas ==

<> rgeba du pettangan Technischer Odsrwachungs-Verein

Rewuttate ces eeats SAARLAND a.

asia "

conten oO Petes Wont

aogier

Bia

230/93/00287

1 Prove macoaniche

armas Sone te

regrecie

nan

|e cc | BAF] wont [SPB] sta ts Loh bem.

po a wpe a

a

Mecha

TOV Saarland

he |

|

| i

? | - gblegevershiche) | \

| | ~ hagpeugversven! ; ito |

Proter Je, Lise b.2}aspenneprotrsfsoxoby | | - ie z.ata.al

wsjasen| se dep Pettunsy |

>) Hatkehterlel Les | [ena Bhahseadual

2. sen hyse dusdy den btersce lier: aja-a}.2

3. Wer! Jexvbchstungaprifung Hurch en Herstel2 pz |

| | antbage| 2}. 1-2] 2

: in|

iain

Sulzbach 2. August 4g 93

(On Lezttion = Las Lacats Iatum = Oxi = Dats}

‘na. (rd) Arnold

cra a OO eS VAY 7 7 nme

cufer! © —! Wt v Ty owes 9 ua ryan ones @

OE

‘9 IH)SLNRC

a8 peers

vroren-soumensoag smeeneeL

AL TeV s0Re “ee

1 te ct om

8

bree ae

“y SS SOIPIANILLIH BFONITUT . ~

“ie so wecompecobstage . 5 .

oon ee san ue SHAS EAE “EISEN UNO STAHL GMBH

ULTRASCHALL-PRUFBERICHT Whe Wiese BiShews

Ultrasonic Testreport oe

case ia

BESTELLEN Exndtebricker Eisenwerke |AUCTRAGS.NA:n94013904

—_ Erndtebriick a

BESTELLNA: 34134 LuEFERUNG VOM

| Pratuna nach seLoraTT TE paper wa

oe Fie Ree} Esme

Proton: pseeah | {See 47 BZSN T {| Protereich: 1 60__mms

ae Senor _lwswen | Tease | I ce a

‘Obertachengustand: | waarauh / 49 | Koope'mitas sor / Be [Oat ow i

ee eed iene 1 {

ier A eT ERSTE OEE

fae ten est} }

{ PRUFBEFUNO

es] eee apd tas Paneer aroma

1 et t i

= Sessa = a rc Ct —= _

1| 2ex2000x12000 feegee | [zaco| »~ 13

| | - L

i | |

| L

g @

| UNIVERSAL

EISEN UND STAHL GMBH

Você também pode gostar

- PR-UPP-TCC-WIS-QC-014: Above Ground Steel Piping Pressure Test ProcedureDocumento1 páginaPR-UPP-TCC-WIS-QC-014: Above Ground Steel Piping Pressure Test ProcedureMuhammedHafisAinda não há avaliações

- Black Spots On DSS WeldsDocumento4 páginasBlack Spots On DSS WeldsMuhammedHafisAinda não há avaliações

- Tie in Joint Welding Gold Weld SpecDocumento1 páginaTie in Joint Welding Gold Weld SpecMuhammedHafisAinda não há avaliações

- Tie in Joint Welding (Gold Weld) SpecDocumento8 páginasTie in Joint Welding (Gold Weld) Specrepository1100% (2)

- SKMBT 28316102714300Documento2 páginasSKMBT 28316102714300MuhammedHafis100% (1)

- 332 2Documento1 página332 2MuhammedHafisAinda não há avaliações

- Adhoc Appointments - 20.12.2017Documento1 páginaAdhoc Appointments - 20.12.2017MuhammedHafisAinda não há avaliações

- Tie in Joint Welding (Gold Weld) SpecDocumento8 páginasTie in Joint Welding (Gold Weld) Specrepository1100% (2)

- BLR - MD Pgdia Ppt.. 2014..Documento26 páginasBLR - MD Pgdia Ppt.. 2014..MuhammedHafisAinda não há avaliações

- Field Hydrotest (Restrained)Documento5 páginasField Hydrotest (Restrained)MuhammedHafisAinda não há avaliações

- Field Hydrotest (Restrained) PDFDocumento5 páginasField Hydrotest (Restrained) PDFMuhammedHafisAinda não há avaliações

- Fiberstrong and Wavistrong Flange GuideDocumento46 páginasFiberstrong and Wavistrong Flange GuideMuhammedHafisAinda não há avaliações

- AG+Piping+Test+Pack CompressedDocumento61 páginasAG+Piping+Test+Pack CompressedMuhammedHafis67% (3)

- 1ug L-ZL 10 1-1003-847.001 1.0Documento1 página1ug L-ZL 10 1-1003-847.001 1.0MuhammedHafisAinda não há avaliações

- 1ug L-ZL 16 1-1605-838.001 1.0Documento1 página1ug L-ZL 16 1-1605-838.001 1.0MuhammedHafisAinda não há avaliações

- Copy of QC Folder Spine (檔案封條)Documento11 páginasCopy of QC Folder Spine (檔案封條)MuhammedHafisAinda não há avaliações

- Tie in Joint Welding (Gold Weld) SpecDocumento8 páginasTie in Joint Welding (Gold Weld) Specrepository1100% (2)

- t15b03-0102 - 0painting Specification For Whb&Steam DrumDocumento36 páginast15b03-0102 - 0painting Specification For Whb&Steam DrumMuhammedHafisAinda não há avaliações

- Galvocoat 16380Documento2 páginasGalvocoat 16380MuhammedHafisAinda não há avaliações

- 1ug L-ZL 15 1-1502-832.001 1.0Documento1 página1ug L-ZL 15 1-1502-832.001 1.0MuhammedHafisAinda não há avaliações

- 1ug L-ZL 96 1-9602-105.001 2.0Documento1 página1ug L-ZL 96 1-9602-105.001 2.0MuhammedHafisAinda não há avaliações

- 1ug L-ZL 92 1-9201-101.003 2.0Documento1 página1ug L-ZL 92 1-9201-101.003 2.0MuhammedHafisAinda não há avaliações

- 1ug L-ZL 16 1-1605-837.001 1.0Documento1 página1ug L-ZL 16 1-1605-837.001 1.0MuhammedHafisAinda não há avaliações

- 1ug L-ZL 15 1-1503-831.001 1.0Documento1 página1ug L-ZL 15 1-1503-831.001 1.0MuhammedHafisAinda não há avaliações

- 1ug L-ZL 16 1-1605-836.001 1.0Documento1 página1ug L-ZL 16 1-1605-836.001 1.0MuhammedHafisAinda não há avaliações

- 1ug L-ZL 16 1-1606-841.001 1.0Documento1 página1ug L-ZL 16 1-1606-841.001 1.0MuhammedHafisAinda não há avaliações

- 1ug L-ZL 16 1-1605-836.001 1.0Documento1 página1ug L-ZL 16 1-1605-836.001 1.0MuhammedHafisAinda não há avaliações

- 1ug L-ZL 10 1-1003-846.001 1.0Documento1 página1ug L-ZL 10 1-1003-846.001 1.0MuhammedHafisAinda não há avaliações

- PunchlistDocumento1 páginaPunchlistMuhammedHafisAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)