Escolar Documentos

Profissional Documentos

Cultura Documentos

Jj513 Engineering Design

Enviado por

Dustin AndersonDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Jj513 Engineering Design

Enviado por

Dustin AndersonDireitos autorais:

Formatos disponíveis

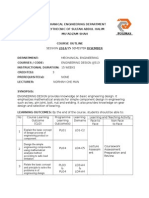

RESTRICTED

JJ513 Engineering Drawing

POLYTECHNICS

MINISTRY OF HIGHER EDUCATION

DEPARTMENT OF MECHANICAL ENGINEERING

COURSE

: JJ513 ENGINEERING DESIGN

INSTRUCTIONAL DURATION

: 15 WEEKS

CREDIT(S)

: 3

PRE REQUISITE(S)

: NONE

SYNOPSIS

ENGINEERING DESIGN provides knowledge on basic engineering design. It

emphasizes mathematical analysis for simple component design in engineering

such as key, pin joint, bolt, nut and welding. It also provides knowledge on gear design

and selection of bearing.

COURSE LEARNING OUTCOMES (CLO)

Upon completion of this course, students should be able to:

1.

explain the basic concept of design process of engineering product or

component. (C2)

2.

design the simple engineering components using mathematical analysis

method according to safe load limitation.(C5)

3.

relate the basic concept and principle to solve the problems in of engineering

design . (A4)

1/9

Version: 080510_1.1_Effective:1 December 2011

RESTRICTED

RESTRICTED

JJ513 Engineering Drawing

SUMMARY

1.0

(45 LECTURE : 00 PRACTICAL)

RTA

(06 : 00)

INTRODUCTION TO ENGINEERING DESIGN

This topic introduces design in engineering, the process

involved, ergonomic factors in design, selection of materials and

the requirements of production specifications

2.0

STRESS ANALYSIS

(12 : 00)

This topic explains the principles of stress, deformation analysis

for several kinds of stresses such as direct stress, shear stress,

torsional shear stress and formulate torque, power and

rotational speed

3.0

DESIGN OF MECHANICAL JOINT

(12 : 00)

This topic explains the design of key, pin joint and bolt and nut

joint. It involves analysis on bolt and nut joint carrying a direct

load or eccentric load. It also explains the design joints of

welding.

4.0

GEAR

(08 : 00)

This topic explains the kinematics of gears, features of different

types of gears and gear trains.

5.0

BEARING

(07 : 00)

This topic explains the types of bearing such as friction bearing,

fluid coated bearing and rolling bearing. It also explains the

method of selecting suitable bearing based on calculation of

dynamic and life load ratio

TOTAL

(45 : 00)

RTA Recommended Time Allocation

2/9

Version: 080510_1.1_Effective:1 December 2011

RESTRICTED

RESTRICTED

JJ513 Engineering Drawing

SYLLABUS

1.0 INTRODUCTION TO ENGINEERING DESIGN

1.1

Understand the engineering design.

1.1.1 Define the meaning of design.

1.1.2 Describe the types of design.

1.2

Understand the designing process.

1.2.1 Explain the primary need.

1.2.2 Define the definition of

problem.

1.2.3 Describe the analysis

process.

1.2.4 Describe the synthesis process.

1.2.5 Explain the systematic process of comparison and

evaluation.

1.3

Explain the design consideration.

1.3.1 Explain the economic and production factor.

1.3.2 Identify the codes and standard are using in

design.

1.3.3 Explain the safety and product liability.

1.4

Explain the ergonomic factors inside design.

1.4.1 Define the ergonomic in relationship between human and

machine.

1.4.2 Explain the relationship of basic ergonomic between human and

machine in the display element.

1.4.3 Analyze ergonomic factors used on simple equipment, such

as micrometer, microscope etc.

1.5

Write the specification in design.

1.5.1 Explain the requirement of design specification.

1.5.2 Analyze the possible specification that can be found

inside general goods, sample pump equipment etc.

1.5.3 Write specification for certain design product.

1.6

Explain the importance of material selection in design.

1.6.1 List types of material.

1.6.2 Describe of the material properties.

1.6.3 Estimate the product cost base on bill of material.

2.0 STRESS ANALYSIS

2.1

Describe the direct stresses

2.1.1 Differentiate between direct tension and direct compression of

stresses.

2.1.2 Determine direct stress in the round bar.

3/9

Version: 080510_1.1_Effective:1 December 2011

RESTRICTED

RESTRICTED

JJ513 Engineering Drawing

2.2

Explain the deformation under direct axial loading

2.2.1 Compute the strain due to a direct axial tensile load or due to

a direct axial compressive load.

2.3

Describe the shear stress

2.3.1 Determine direct shear stresses on a key.

2.3.2 Determine the torsional shear stress formula on a

shaft.

2.3.3 Formulate relationship among torque, power and rotational

speed.

3.0 DESIGN OF MECHANICAL JOINT

3.1

Understand the Key Design

3.1.1 Explain the purpose of the key.

3.1.2 Sketch and name various types of key such as parallel keys,

taper keys, gib-head keys, pin keys, woodruff keys, etc.

3.1.3 Apply mathematical analysis for rectangle and parallel

key based on sheer stress and compressed stress.

3.2 Understand the design of pin joint, bolt, and nut joint.

3.2.1 List the advantages and disadvantages using pin and bolt

and nut as the method of joining.

3.2.2 Analyze the factors of bolt and nut joint failures.

3.2.3 Analyze bolt and nut joints by shearing load.

3.2.4 Analyze bolt and nut joints shearing caused by eccentric

load.

3.2.5 Calculate the bolt size and maximum load.

3.3

4.0

Understand the welded joints design

3.3.1 State the advantages and disadvantages of welded joints.

3.3.2 Sketch the basic symbol for welded joint.

3.3.3 Apply the mathematical analysis for

welded joint.

3.3.4 Determine the weld throat and safe load.

3.3.5 Determine the welded joint size caused by eccentric load.

GEAR

4.1

Explain the kinematics of gears

4.1.1 Recognize the main features of spur gears, helical gears,

bevel gears and worm gears.

4.2 Understand the design of spur gear

4.2.1 List the types of gearing.

4.2.2 Explain the terms that commonly used in gears such as pitch

diameter, circular pitch, diametral pitch, m o d u l e ,

addendum, dedendum, clear ance , outside diameter,

root diameter, whole depth, working depth, tooth

thickness and centre distance.

4/9

Version: 080510_1.1_Effective:1 December 2011

RESTRICTED

RESTRICTED

JJ513 Engineering Drawing

4.2.3 Compute the gear features.

4.2.4 Determine the interference mating spur gear teeth.

4.2.5 Determine the velocity ratio and gear trains.

5.0 BEARING

5.1

Explain the rolling contact bearings.

5.1.1 State the types of bearing.

5.2 Explain the design life bearing.

5.2.1 Explain the relationship between bearing load and life.

5.2.2 Recommend appropriate value for the design life bearings.

5.3 Explain the procedure of bearing selection.

5.3.1 Apply the manufacturers data to specify suitable bearings for a

given application.

5/9

Version: 080510_1.1_Effective:1 December 2011

RESTRICTED

RESTRICTED

JJ513 Engineering Drawing

ASSESSMENT

The course is assessed through coursework.

ASSESSMENT SPECIFICATION TABLE (AST)

ASSESSMENT METHODS FOR COURSEWORK

(CA)

Introduction to engineering

design

Stress analysis

CLO 3

CLO 2

CONTEXT

CLO 1

CLO

Test

Quiz

Discussion

Report

Case

Study

*(2) 30%

*(2) 20%

*(2) 20%

*(1) 30%

Design of mechanical joint

Gear

Bearing

Remark:

CLO1 : explain the basic concept of design process of engineering product or

component.

CLO2 : design the simple engineering components using mathematical analysis

method according to safe load limitation.

CLO3 : Relate the basic concept and principle to solve the problems in of engineering

design .

*(x) refers to the quantity of assessment

6/9

Version: 080510_1.1_Effective:1 December 2011

RESTRICTED

RESTRICTED

JJ513 Engineering Drawing

REFERENCES

Autodesk(2007), Autodesk Inventor Professional 2008, USA.

B.Hawkes, R.Abinett.(1984). The Engineering Design Process.England: Longman.

Cheng, Ron K.C. (2010), Using Autodesk Inventor 6, Thompson Delmar Learning

Mohamad Kassim Abdul Jalil. (2000). Proses dan Kaedah Rekabentuk. Penerbit

Universiti Teknologi Malaysia

Randy H. Shih (2010), An Introduction to Autodesk Inventor 2011 and Auto CAD 2011.

SDC Publications

Robert L.Mott. (2006). Machine Element in Mechanical Design (4th Edition). Singapore:

Pearson Prentice Hall.

Shigley, J.E & Mischke, C.R. (2003). Mechanical Engineering Design (6th Metric

Edition). New York: McGraw-Hill

Ullman, D.G. (2003). The Mechanical Design Process (3rd Ed). New York:

McGraw-Hill.

Yousef Haik. (2003). Engineering Design Process. USA: Prentice Hall.

7/9

Version: 080510_1.1_Effective:1 December 2011

RESTRICTED

RESTRICTED

JJ513 Engineering Drawing

MATRIX OF COURSE LEARNING OUTCOMES (CLO) VS PROGRAMME LEARNING OUTCOMES (PLO)

Compliance to PLO

Course Learning Outcome (CLO)

Explain the basic concept of design

process of engineering product or

component

design the simple engineering

components using mathematical

analysis method according to safe

load limitation.

Relate the basic concept and

principle to solve the problems in

of engineering design

PLO 1

PLO 2

PLO 3

PLO 4

PLO 5

PLO 6

PLO 7

PLO 8

PLO 9

LO-1

LO-2

LO-3

LO-4

LO-5

LO-6

LO-7

LO-8

LO-9

Delivery

Assessment

Quiz, assignment

and Tests

C4

Total

C5

A4

A4

Interactive

Lecture, Exercise

and PBL

Case study &

Test

Case study

Remark :

LD1 Knowledge

LD2 Practical Skills

LD3 Communication Skills

LD4 Critical Thinking and Problem Solving Skills

LD5 Social Skills and Responsibilities

LD6 Continuous Learning and Information Management Skills

LD7 Management and Entrepreneurial Skills

LD8 Professionalism, Ethics and Moral

LD9 Leadership and Teamwork Skills

8/9

Version: 080510_1.1_Effective:1 December 2011

RESTRICTED

RESTRICTED

JJ513 Engineering Drawing

DISTRIBUTION OF STUDENT LEARNING TIME

ACCORDING TO COURSE LEARNING - TEACHING ACTIVITY

9/9

Version: 080510_1.1_Effective:1 December 2011

RESTRICTED

Você também pode gostar

- Structural EngineeringDocumento1 páginaStructural EngineeringApril IngramAinda não há avaliações

- EngineeringDocumento37 páginasEngineeringKAAinda não há avaliações

- Resource Management Plan TemplateDocumento10 páginasResource Management Plan TemplateAnkit ShekharAinda não há avaliações

- Software Quality AssuranceDocumento27 páginasSoftware Quality AssuranceVaishnavo Devi100% (1)

- Siemens' Motor HandbookDocumento20 páginasSiemens' Motor HandbookJerome BaesAinda não há avaliações

- Analysis Report TemplateDocumento2 páginasAnalysis Report Templatemounit121Ainda não há avaliações

- Risk Based PlanningDocumento20 páginasRisk Based PlanningNiel Edar BallezaAinda não há avaliações

- Construction of MRT Feeder Bus Depot and Related Supporting Buildings and Facilities For The KVMRT Project, SBK LineDocumento5 páginasConstruction of MRT Feeder Bus Depot and Related Supporting Buildings and Facilities For The KVMRT Project, SBK LineIkhwan HishamAinda não há avaliações

- Communication Plan TemplateDocumento6 páginasCommunication Plan TemplateHussain ElarabiAinda não há avaliações

- NPR - 7123 - 1B Systems Engineering Process and Requirements PDFDocumento177 páginasNPR - 7123 - 1B Systems Engineering Process and Requirements PDFjaimerheemAinda não há avaliações

- Lecture Slides (Week 3) - Final VersionDocumento45 páginasLecture Slides (Week 3) - Final VersionWeixuan ZhangAinda não há avaliações

- Xdata Management Plan PDFDocumento17 páginasXdata Management Plan PDFAlphaAinda não há avaliações

- Quality: To Meet Product or Service Specifications and ExpectationsDocumento13 páginasQuality: To Meet Product or Service Specifications and ExpectationsmaelikahAinda não há avaliações

- Standard Operating Procedure For Permitting of Development and Infrastructure Projects TR-519Documento30 páginasStandard Operating Procedure For Permitting of Development and Infrastructure Projects TR-519Fenner ElectromechanicalAinda não há avaliações

- A Definition of Business AnalyticsDocumento4 páginasA Definition of Business AnalyticsBalhansAinda não há avaliações

- Quality Register: Project Name: Date: Release: Author: Owner: ClientDocumento3 páginasQuality Register: Project Name: Date: Release: Author: Owner: ClientfarazAinda não há avaliações

- MDR 01 r00 27.03.2019Documento1 páginaMDR 01 r00 27.03.2019CRISTIAN SILVIU IANUCAinda não há avaliações

- LEI Contractor QC Plan574264890Documento32 páginasLEI Contractor QC Plan574264890Marzelino InoferioAinda não há avaliações

- Process Flowcharting For SOP Development, Implementation, Training and MaintenanceDocumento7 páginasProcess Flowcharting For SOP Development, Implementation, Training and MaintenancemmxxmmxxAinda não há avaliações

- MRU-P-001-Management of ChangeDocumento3 páginasMRU-P-001-Management of ChangeSIS AuditorAinda não há avaliações

- Session-2 & 3 Quality - Evolution of QualityDocumento20 páginasSession-2 & 3 Quality - Evolution of Qualitymatten yahyaAinda não há avaliações

- Quality Assessment ProcedureDocumento3 páginasQuality Assessment ProcedureAlina OnţaAinda não há avaliações

- 6ChangeRequestTemplate EPMO 03162009Documento3 páginas6ChangeRequestTemplate EPMO 03162009Phạm TuyếtAinda não há avaliações

- The Program of QmsDocumento16 páginasThe Program of QmsHamza Sharif AdamAinda não há avaliações

- Conformity Assessment (Management System Certification)Documento5 páginasConformity Assessment (Management System Certification)Talal AhmedAinda não há avaliações

- SOA Unit1Documento59 páginasSOA Unit1suganya004Ainda não há avaliações

- EDraw - FlowChart ExamplesDocumento7 páginasEDraw - FlowChart Examplesdmitar stevanovicAinda não há avaliações

- DesignControls Vs IEC62304 MappingDocumento2 páginasDesignControls Vs IEC62304 MappinguclealsepAinda não há avaliações

- Foundation of Quality ManagementDocumento19 páginasFoundation of Quality ManagementAmit VijayvargiyaAinda não há avaliações

- ISO Whitepaper Difference Between A Procedures and Process ApproachDocumento6 páginasISO Whitepaper Difference Between A Procedures and Process ApproachAwadh AlharbiAinda não há avaliações

- CH 2Documento110 páginasCH 2delinquent_abhishekAinda não há avaliações

- A Review of RequirementsDocumento7 páginasA Review of RequirementsPedroSotoAinda não há avaliações

- Work Breakdown StructureDocumento38 páginasWork Breakdown Structureअमित अम्बर गुप्ताAinda não há avaliações

- ITPM Chapter OneDocumento14 páginasITPM Chapter OnegideyAinda não há avaliações

- Training PlanDocumento1 páginaTraining PlanShah ViralAinda não há avaliações

- Clinical Research Organisation CultureDocumento3 páginasClinical Research Organisation CultureZain MalikAinda não há avaliações

- 3 Internal Quality AuditDocumento12 páginas3 Internal Quality AuditJeaneth Dela Pena CarnicerAinda não há avaliações

- Milk RunDocumento161 páginasMilk RunHoussem MoujahedAinda não há avaliações

- Quality Policy PDFDocumento3 páginasQuality Policy PDFSamay NandeshwarAinda não há avaliações

- Design Mee2008 VusDocumento42 páginasDesign Mee2008 VusRajesh RJAinda não há avaliações

- Data Analysis From Theoretical To Implementation Using Excel, Python and FlourishDocumento25 páginasData Analysis From Theoretical To Implementation Using Excel, Python and Flourishmohamed100% (1)

- Assignment of Oosd: Submitted To: Submitted byDocumento13 páginasAssignment of Oosd: Submitted To: Submitted byAmrit VirdiAinda não há avaliações

- Hotel Management System: User Requirements DocumentDocumento7 páginasHotel Management System: User Requirements DocumentRamiz Siddiqui100% (1)

- Project Management Plan Reverse Logistics Midterm PDFDocumento10 páginasProject Management Plan Reverse Logistics Midterm PDFramrammithraAinda não há avaliações

- Health and Safety Compliance: Form HDocumento1 páginaHealth and Safety Compliance: Form HStanley Ng100% (1)

- RTD NM RRP Construction Safety Security Plan PDFDocumento366 páginasRTD NM RRP Construction Safety Security Plan PDFTarun KathpaliaAinda não há avaliações

- Anna University Coimbatore REGULATIONS 2007-08 B.E - Mechanical EngineeringDocumento28 páginasAnna University Coimbatore REGULATIONS 2007-08 B.E - Mechanical EngineeringRaajeshkrishnaAinda não há avaliações

- Resume: Laukesh KumarDocumento2 páginasResume: Laukesh KumarTanuj JoshiAinda não há avaliações

- Schedule Management Plan Form - PMBOK 6th EditionDocumento2 páginasSchedule Management Plan Form - PMBOK 6th EditionMiguel diazAinda não há avaliações

- EOHS Management System Procedure Procedure For Context of The OrganizationDocumento4 páginasEOHS Management System Procedure Procedure For Context of The OrganizationSuresh MuruganAinda não há avaliações

- Procedure - Configuration Management - Rev 0Documento4 páginasProcedure - Configuration Management - Rev 0Venkat BhagavatiAinda não há avaliações

- Manual On Construction RiskDocumento116 páginasManual On Construction RiskMJ KarkiAinda não há avaliações

- Engineering ProductivityDocumento15 páginasEngineering ProductivityGeetha_jagadish30Ainda não há avaliações

- QA QC Excitation PlanDocumento10 páginasQA QC Excitation PlanMihirduttaAinda não há avaliações

- Data OrganizationDocumento20 páginasData OrganizationMDattaAinda não há avaliações

- SCC QMS MANUAL-FINAL Signed 2017 PDFDocumento94 páginasSCC QMS MANUAL-FINAL Signed 2017 PDFAlexis kabayizaAinda não há avaliações

- Lps 01 Hti MST El 005 Point WiringDocumento22 páginasLps 01 Hti MST El 005 Point WiringJomy JohnyAinda não há avaliações

- 08 - Construction Projects Monitoring - Training ManualDocumento28 páginas08 - Construction Projects Monitoring - Training ManualGemechuAinda não há avaliações

- JJ513-Course OutlineDocumento4 páginasJJ513-Course OutlineAwan TornadoAinda não há avaliações

- Road ConstructionDocumento5 páginasRoad ConstructionmetincetinAinda não há avaliações

- Vogue's New Book For Better SewingDocumento171 páginasVogue's New Book For Better SewingMinh NguyenAinda não há avaliações

- HVAC TutorialDocumento115 páginasHVAC Tutorialhungdinhthanh100% (5)

- Global Davit GMBHDocumento8 páginasGlobal Davit GMBHTimothy JacksonAinda não há avaliações

- On PDMSDocumento7 páginasOn PDMSatorresh090675Ainda não há avaliações

- Pe Unit Plan TemplateDocumento3 páginasPe Unit Plan Templateapi-239320998Ainda não há avaliações

- Factual Information and Subjective ContentDocumento44 páginasFactual Information and Subjective ContentCharina Nicole IbascoAinda não há avaliações

- Optics and Lasers in EngineeringDocumento5 páginasOptics and Lasers in EngineeringsenthilAinda não há avaliações

- Application of Chain Drive and It's Selection MethodDocumento21 páginasApplication of Chain Drive and It's Selection MethodYogesh B0% (1)

- MatlaB Lab Manual APDocumento63 páginasMatlaB Lab Manual APVarun SahaniAinda não há avaliações

- Lecture 9Documento26 páginasLecture 9Tesfaye ejetaAinda não há avaliações

- (Myers79) (Hetzel88)Documento43 páginas(Myers79) (Hetzel88)Infomailbox10Ainda não há avaliações

- Noc20-Cs53 Week 04 Assignment 02Documento4 páginasNoc20-Cs53 Week 04 Assignment 02Modicare QuiteAinda não há avaliações

- Chapter 9 - Worksheet1finalDocumento27 páginasChapter 9 - Worksheet1finalTansu Erin ŞarlakAinda não há avaliações

- Baking Enzymes PDFDocumento2 páginasBaking Enzymes PDFOrhan Avur0% (1)

- FRENCH Grade 6 UnlockedDocumento50 páginasFRENCH Grade 6 UnlockedWainaina MuriukiAinda não há avaliações

- Remotivation Therapy (Sammm)Documento4 páginasRemotivation Therapy (Sammm)Sam Venezuelȧ100% (3)

- Signals Systems Jan 2014 PDFDocumento2 páginasSignals Systems Jan 2014 PDFKomalAinda não há avaliações

- E-Learning For Universiti Teknologi Mara Malaysia (Uitm) : Campus Wide Implementation and AccomplishmentsDocumento10 páginasE-Learning For Universiti Teknologi Mara Malaysia (Uitm) : Campus Wide Implementation and AccomplishmentsWan SyahlanAinda não há avaliações

- El Lenguaje Del YogaDocumento149 páginasEl Lenguaje Del YogaMax AlejandroAinda não há avaliações

- Transient Torque Rise of A Modern Light Duty Diesel Engine With Variable Valve ActuationDocumento12 páginasTransient Torque Rise of A Modern Light Duty Diesel Engine With Variable Valve ActuationdheepanasAinda não há avaliações

- Method Statement Riyadh School Project Fire Fighting SystemDocumento3 páginasMethod Statement Riyadh School Project Fire Fighting Systemkhantoseef84Ainda não há avaliações

- Ranjit SinghDocumento8 páginasRanjit SinghRANJIT100% (1)

- BM 2 Operations Management and TQM NewDocumento9 páginasBM 2 Operations Management and TQM NewEly GragasinAinda não há avaliações

- Criteria For SQF Certification Bodies: 7th EditionDocumento12 páginasCriteria For SQF Certification Bodies: 7th EditioncristinaAinda não há avaliações

- A Minor Project Report On ECOKART Student Racing Vehicle 2020 (ARPIT JAMES - 40215611116) (Mail2arpit2010@Gmail - Com)Documento59 páginasA Minor Project Report On ECOKART Student Racing Vehicle 2020 (ARPIT JAMES - 40215611116) (Mail2arpit2010@Gmail - Com)شاہد بشیرAinda não há avaliações

- PsychosesDocumento32 páginasPsychosesAnonymous zxTFUoqzklAinda não há avaliações

- Flsmidth Private Limited: Quality Assurance Plan of Exciter CasingDocumento5 páginasFlsmidth Private Limited: Quality Assurance Plan of Exciter CasingMohammad AdilAinda não há avaliações

- Lesson Plan Template 2017 7 3Documento4 páginasLesson Plan Template 2017 7 3api-424474395Ainda não há avaliações

- NCP On Mental RetardationDocumento20 páginasNCP On Mental RetardationSARITA SHARMAAinda não há avaliações