Escolar Documentos

Profissional Documentos

Cultura Documentos

Popular Mechanics - DIY Fly Cutter

Enviado por

sonofsilasDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Popular Mechanics - DIY Fly Cutter

Enviado por

sonofsilasDireitos autorais:

Formatos disponíveis

N ovices'’ C orner

Fly-cutting

F LY-CUTTING is usually carried out with a

single-point tool mounted in a holder for

gripping in the lathe mandrel chuck, or the tool

may be carried in an arbor running between the

lathe centres, or, again, a cutter frame attached to

the lathe saddle may be used for this purpose.

Although the fly-cutting tool is not primarily

intended for removing large amounts of metal, it

has, nevertheless, the advantages that it is easily

and cheaply made of high-speed steel to any Fig. I . An easily made fly-cutter with two tool

required shape, and when blunted it can be positions

readily resharpened by straightforward grinding

and oilstoning. steel. Two tool housings are provided ; the

Milling cutters, on the other hand, are relatively axial mounting of the tool will serve for all

costly and need special grinding equipment for ordinary facing work, but when cutting against an

resharpening. Again, by using a fly-cutter, overhanging shoulder the tool is mounted

sharpened on an oilstone, a very tine, chatter- obliquely in the second tool housing.

free finish can without difficulty be given to the This obliquely-placed hole is best drilled at

work, whereas in light lathes a good finish is not the outset and before the bar is cut to the finished

always obtained with the ordinary milling cutter, length. If the work is set at an angle of 15 deg.

especially when the teeth have become slightly for drilling this hole, the drill will be deflected

blunted. and the drilling will be out of line even if the

drill does not break in the process. To give

Making a Fly-Cutter guidance to the drill point at starting, a hole of

A simple form of fly-cutter head for mounting 1/4 in. diameter at its mouth is first drilled at the

in the self-centring chuck is illustrated in Fig. I. back of the part with a centre drill and with the

work held horizontally in the machine

2BA FOR ALLEN SCREWS vice. Next, a drilling guide, made of

mild-steel 1/8 in. in thickness, is

clamped to the work, as shown in the

illustration. The guide is positioned

with its 1/4in. diameter guide hole

exactly over the centre hole already

drilled in the work. When the work

has been set in the vice to an angle

of 15 deg., a letter D drill is put right

through, and the drilled hole is then

finished to size with a 1/4 in. diameter

reamer. Work the reamer in care-

fully, turning it always in a forward

direction and at the same time apply-

ing plenty of cutting oil. The second

or axial tool housing can now be

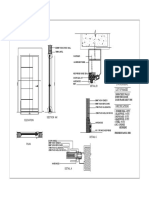

Fig. 2. Showing the details of the fly-cutter parts drilled and reamed, and the central

hole for mounting the shank is

The self-centring chuck can be used for this drilled with a letter P or a 21/64 in. diameter

purpose, as with a single-point tool there is, of drill and then tapped 1/8 in. B.S.F.

course, no need for the holder to be truly centred ; The shank fitted to the cutter head is shown

but if a milling cutter does not run truly, cutting made from a piece of 1/4 in. Whitworth nut-size

will be intermittent and the bulk of the work will hexagon bar, as this gives the finished tool a

fall on a few teeth only ; in fact, an eccentrically secure mounting in the three-jaw chuck. If

mounted milling cutter will behave rather like a preferred, a round shank can be used, and a

fly-cutter, but has none of its advantages. tommy hole is drilled across for screwing the head

The head illustrated was made from a short into place ; in addition, the backward projecting

length of 5/8 in. x 1 in. mild-steel and is intended end of the cutter-bit then abuts against one of the

to carry cutter-bits of 1/4 in. diameter high-speed chuck jaws and so prevents slipping. When

827

THE MODEL ENGINEER DECEMBER 20, 1951

hexagonal material is used, the shoulder

formed on the shank should be machined so

that the head, when screwed firmly home,

lies with the tool housings in line with the

flats of the hexagon ; this allows the tool

shanks to pass between the chuck jaws when

the fly-cutter is in use. The curved surfaces

at the two ends of the head are machined

by gripping the shank in the chuck and

Fig. 5. A fly-cutting attachment for large work

fitted so that the cutting pressure forces the tool

against its housing and not against the screws

themselves. The tool just described, when

mounted in the self-centring chuck, will cut on a

fixed radius of about 5/8 in., but to machine a larger

area the head is unscrewed from the shank and

then attached either to the lathe driver-plate or to I;

the faceplate with a single clamp-bolt, as is

shown in Fig. 4.

Other Forms of Fly-Cutters fc

Fig. 3. Showing the method of using the drill 0

guide to form the oblique tool housing Another way of mounting a tool to machine on

an extended radius is to use a device like that b

illustrated in Fig. 5. Here, a cast base with a

then using a knife tool to take light cuts until an P

even finish is obtained. To complete the work, 0

the Allen grub-screws for securing the tools are

put in and, after the front and back faces of the E

head have been finish turned, the side surfaces of

the head and the shank are filed to a good finish.

It should be noted that the clamp-screws are

z

U

tl

cl

A

tl

a;

C.

Si

Fig. 6. Constructional details of the large fly-

cutter

T-slot at back and front is bolted to the lathe

faceplate, and the toolholder can then be set in the

1

front T-slot to any radius required, provided

that there is space enough in the lathe bed gap.

:

A square tool is fitted and, as it is a difficult e

matter to file a square hole with its sides flat, a il

grub-screw is inserted at the far end of the f

housing so that the tool can obtain an even a

Fig. 4. The fly-cutter head attached to the lathe bearing and will not tend to rock when secured

driver plate by the clamping-screws.

828

THE MODEL ENGINEER DECEMBER 20, 1951

the cutting thrust is limited to the distance

between the two screws, instead of being for the

full length of the housing ; moreover, the

pressure then falls on the screw threads and not

on the solid metal of the head.

Cutter-bits

The tools carried in the fly-cutter head are

formed on the same principles as are used for

grinding lathe tools ; that is to say, adequate

clearances must be given at the cutting edges,

and the amount of rake will depend on the material

being machined. To obtain a really good finish

when fly-cutting a flat surface, the rounded tip of

the tool should be honed on an oilstone until the

cutting edge is made perfectly smooth and

regular.

The speed at which these cutters should be run

is, again, in accordance with ordinary turning

practice, and it matters little in adjusting the

Fig. 7. A fly-cutter for use in a large lathe

The fly-cutter illustrated in Fig. 7 was made

for use in a large lathe and is capable of carrying

out quite heavy machining.

The tool-bits fitted are 3/8 in. in diameter and, as

before, both axial and oblique housings are

provided. As will be seen, the cutter when set

obliquely lies at a more obtuse angle than in the

previous tools ; this enables the tool housing to

be more easily drilled, as a flat drilling surface

I

Fig. 8.

1 i? 0 B

Fly-cutter tools. A, a front tool ; B,

can be filed without materially reducing the a tool for undercutting a shoulder

length of the tool housing. As this tool was

used for taking heavy cuts, a flat was ground on cutting speed that, here, the work is stationary and

the under side of the tool to give a bearing for the the tool is revolving. For example, if, when

clamp-screws and prevent the cutter’s turning. machining mild-steel, a high-speed steel cutter

As previously mentioned, it is advisable to fit revolves on a radius of I in., the tool will travel

the clamp-screws so that they hold the tool-bit approximately 1/2 ft. at each revolution, and a

against a solid face, but in this instance the cutting speed of 100 ft. a minute will, therefore,

clamping-screws have been put in on the reverse be obtained with the lathe set to run at 200 revs

side. This means that the clamping area to resist a minute.

VICE WORK

H ERE is a tip to those who find difficulty

in maintaining the work-piece close to the

parallels when

tightened the canting action forces the piece

downwards.

The secret is

placed in a vice. I to have the con-

A square-

1 1 tact edge of the

edged s t r i p i s strip which

interposed be- touches the work

tween the piece lower than thar

and the loose which is against

jaw, as shown. the loose jaw.-

When the jaw is H. T. TROTMAN.

829

Você também pode gostar

- Lathe Cross-Sli Olders.: " DuplexDocumento3 páginasLathe Cross-Sli Olders.: " Duplexjohnboy183100% (1)

- 3 in 1 MachineDocumento5 páginas3 in 1 Machinemarandan85100% (1)

- Simple Boring BarDocumento3 páginasSimple Boring BarMike Nichlos100% (1)

- MotorBoys MembersOnly PlanBookDocumento113 páginasMotorBoys MembersOnly PlanBookriofeliz100% (1)

- Micro Machine Shop Mods EtcDocumento488 páginasMicro Machine Shop Mods Etcsbarnett38@100% (4)

- Tramming A MillDocumento13 páginasTramming A Millva3ttn100% (2)

- Measuring and Marking Metals for Home Machinists: Accurate Techniques for the Small ShopNo EverandMeasuring and Marking Metals for Home Machinists: Accurate Techniques for the Small ShopNota: 4 de 5 estrelas4/5 (1)

- Motor Whittle V8 PDFDocumento39 páginasMotor Whittle V8 PDFBorralla Cinza100% (1)

- Series 7 Lathes: Technical Support Explaining Changewheel Sets For Lathes With Changewheel Driven LeadscrewsDocumento8 páginasSeries 7 Lathes: Technical Support Explaining Changewheel Sets For Lathes With Changewheel Driven LeadscrewsTomas MalyAinda não há avaliações

- V Po-To 3Documento60 páginasV Po-To 3Pierre799es100% (1)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheNo EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheNota: 4.5 de 5 estrelas4.5/5 (2)

- 05 - Milling Operations in The LatheDocumento125 páginas05 - Milling Operations in The Lathej43951048Ainda não há avaliações

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsAinda não há avaliações

- Popular Mechanics - Hobby Lathe#2Documento13 páginasPopular Mechanics - Hobby Lathe#2sonofsilas100% (3)

- Quorn User Manual PDFDocumento31 páginasQuorn User Manual PDFtaiwest100% (1)

- Building: LatheDocumento60 páginasBuilding: LathePierre799es86% (7)

- Practical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsNo EverandPractical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsAinda não há avaliações

- Metal Steel Bending Press PlansDocumento16 páginasMetal Steel Bending Press PlansFrenchwolf42080% (5)

- Lathe Design ADocumento3 páginasLathe Design AFrenchwolf420100% (1)

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingNo EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingNota: 5 de 5 estrelas5/5 (2)

- Mini Tube BenderDocumento4 páginasMini Tube BenderMartin OngAinda não há avaliações

- Bender PlansDocumento15 páginasBender PlansMike Nichlos80% (5)

- Lathes and Lathe Machining OperationsDocumento18 páginasLathes and Lathe Machining Operationssarasrisam100% (1)

- Lathe-Milling AttachmentDocumento4 páginasLathe-Milling AttachmentFrenchwolf420Ainda não há avaliações

- A Modified Vince Gingery PlasticDocumento13 páginasA Modified Vince Gingery PlasticgeppaAinda não há avaliações

- Single Lip Cutter D-BitDocumento2 páginasSingle Lip Cutter D-Bitsjdarkman1930Ainda não há avaliações

- Shaper Gear CuttingDocumento4 páginasShaper Gear Cuttingnevadablue100% (4)

- Lathe Chuck Backplate FittingDocumento2 páginasLathe Chuck Backplate FittingAnonymous iYKTkmhpZ100% (3)

- MyfordDocumento1 páginaMyfordPeanut d. DestroyerAinda não há avaliações

- Mini Milldiy PDFDocumento6 páginasMini Milldiy PDFCelso Ari Schlichting100% (1)

- Tricking Out Asian 9x20 LatheDocumento48 páginasTricking Out Asian 9x20 Lathearanicki8587Ainda não há avaliações

- Gear Cutters 01Documento4 páginasGear Cutters 01Raúl MuñizAinda não há avaliações

- 03 Building A Model Steam Engine From Scratch Chapter 3 192 651Documento16 páginas03 Building A Model Steam Engine From Scratch Chapter 3 192 651schelanko67% (3)

- Vintage Power Tool Plans 1950sDocumento180 páginasVintage Power Tool Plans 1950sPierre799es100% (5)

- How To Build A Fuel LineDocumento15 páginasHow To Build A Fuel LineMech EngrAinda não há avaliações

- Quorn - Part 1-4Documento24 páginasQuorn - Part 1-4catalin9494100% (3)

- Bridgeport Rebuid 1Documento15 páginasBridgeport Rebuid 1wolviak100% (1)

- Quorn User ManualDocumento31 páginasQuorn User ManualGeorge Stright100% (5)

- Mini-Skat 6-Wheel Plans AssemblyDocumento40 páginasMini-Skat 6-Wheel Plans AssemblyВладимир Батманов100% (3)

- Ralph Patterson Tailstock Camlock 2Documento13 páginasRalph Patterson Tailstock Camlock 2supremesportsAinda não há avaliações

- Parts Price List Atlas Milli NG Machine: Atlas Press Company - Kalamazoo 13D Michigan - U.S.ADocumento16 páginasParts Price List Atlas Milli NG Machine: Atlas Press Company - Kalamazoo 13D Michigan - U.S.Ataxmac100% (2)

- Toolpost Attachment For A High Speed Rotary ToolDocumento32 páginasToolpost Attachment For A High Speed Rotary Toolkokisko100% (1)

- Ralph Patterson Diamond Tool HolderDocumento12 páginasRalph Patterson Diamond Tool Holderian_newAinda não há avaliações

- Myford 7 Series - Inspection Sheet PDFDocumento3 páginasMyford 7 Series - Inspection Sheet PDFRichardScribed100% (1)

- 02 - Vertical Milling in The Home WorkshopDocumento49 páginas02 - Vertical Milling in The Home WorkshopSaleem Alhakim60% (5)

- 1946 Rusnok Mill Heads CatDocumento25 páginas1946 Rusnok Mill Heads CatfgrefeAinda não há avaliações

- Mill Keyways On LatheDocumento1 páginaMill Keyways On LatheJim100% (3)

- 04 Foundrywork For The AmateurDocumento49 páginas04 Foundrywork For The Amateurboon1961100% (1)

- 43 Horizontal Steam Engine PlanDocumento4 páginas43 Horizontal Steam Engine Plannevadablue100% (1)

- Popular Mechanics - Milling PracticesDocumento5 páginasPopular Mechanics - Milling Practicessonofsilas100% (1)

- KeycutterDocumento3 páginasKeycutterFrenchwolf420Ainda não há avaliações

- Popular Mechanics - Hobby Lathe#1Documento19 páginasPopular Mechanics - Hobby Lathe#1sonofsilas100% (1)

- Popular Mechanics - Hobby Lathe#2Documento13 páginasPopular Mechanics - Hobby Lathe#2sonofsilas100% (3)

- FittingalathechuckDocumento2 páginasFittingalathechuckFrenchwolf420Ainda não há avaliações

- Hardening Steel in The Home WorkshopDocumento2 páginasHardening Steel in The Home WorkshopManny MenéndezAinda não há avaliações

- Electric StencilDocumento2 páginasElectric StencilFrenchwolf420Ainda não há avaliações

- Popular Mechanics - Curing OvenDocumento4 páginasPopular Mechanics - Curing OvensonofsilasAinda não há avaliações

- Bolt Together LatheDocumento7 páginasBolt Together Lathe69x4Ainda não há avaliações

- Mach 1 Machine Shop TheoryDocumento11 páginasMach 1 Machine Shop TheoryBernie OrtegaAinda não há avaliações

- Practice Test 06Documento9 páginasPractice Test 06Võ Thành HiệpAinda não há avaliações

- Pintura Corporation: The Lena Launch Decision: ProblemDocumento2 páginasPintura Corporation: The Lena Launch Decision: ProblemSounakAinda não há avaliações

- CONVENTIONAL or RAM EDM (DIE SINKER EDM) PDFDocumento4 páginasCONVENTIONAL or RAM EDM (DIE SINKER EDM) PDFjjzoranAinda não há avaliações

- O331245v21 160992A5JG 202001Documento58 páginasO331245v21 160992A5JG 202001xdd broAinda não há avaliações

- FEBRUARY 2022 Surplus Record Machinery & Equipment DirectoryDocumento720 páginasFEBRUARY 2022 Surplus Record Machinery & Equipment DirectorySurplus RecordAinda não há avaliações

- Catalogo SunnenDocumento28 páginasCatalogo Sunnenvictor carvalloAinda não há avaliações

- Stairway Installation InstructionsDocumento5 páginasStairway Installation InstructionsRuben GarciaAinda não há avaliações

- Lab Exercise 3 CarpentryDocumento15 páginasLab Exercise 3 CarpentryAndy BirdieAinda não há avaliações

- WTP - Vw-Beetle Et TrailerDocumento29 páginasWTP - Vw-Beetle Et TrailerDominique Voirin100% (1)

- Kayu Nganjuk AUSTIN MINI 31t8i4Documento13 páginasKayu Nganjuk AUSTIN MINI 31t8i4Mauro Viana0% (1)

- Yellow Discoloration in OakDocumento4 páginasYellow Discoloration in Oakmeans.infoAinda não há avaliações

- Construction Cost Estimate: By: Engr. Erniel Dave A. GuyoDocumento29 páginasConstruction Cost Estimate: By: Engr. Erniel Dave A. GuyoMica Joice FernandezAinda não há avaliações

- 3-4 Wooden Rabbet Plane Plans by Caleb James 3 - 25 - 13 PDFDocumento1 página3-4 Wooden Rabbet Plane Plans by Caleb James 3 - 25 - 13 PDFChrisAinda não há avaliações

- All in One MC 50 (2023)Documento98 páginasAll in One MC 50 (2023)YashuAinda não há avaliações

- BD 7 DraaibankDocumento32 páginasBD 7 Draaibankgerard0502Ainda não há avaliações

- Dimensioning Reference SheetDocumento1 páginaDimensioning Reference SheetLLOSAAinda não há avaliações

- ShopNotes Issue 62Documento39 páginasShopNotes Issue 62qpidoneuro100% (6)

- Acoustic DoorDocumento1 páginaAcoustic DoorNathar ShaAinda não há avaliações

- Tool Life Management PDFDocumento5 páginasTool Life Management PDFsajithAinda não há avaliações

- Timber Lecture Notes: Construction Management Makerere UniversityDocumento50 páginasTimber Lecture Notes: Construction Management Makerere UniversityMugara Waitega PeterAinda não há avaliações

- Husqvarna 340/345/350 Operator's ManualDocumento47 páginasHusqvarna 340/345/350 Operator's ManualArtur MartinsAinda não há avaliações

- Allowable Comppressive Strength Off Philippine WoodDocumento7 páginasAllowable Comppressive Strength Off Philippine WoodAngelica Anne SoquitosoAinda não há avaliações

- Professional Belt Grinding in Manual Trades and Industry.: MetalDocumento40 páginasProfessional Belt Grinding in Manual Trades and Industry.: MetalthuanAinda não há avaliações

- (Black & Decker Complete Guide) Editors of Cool Springs Press - Black & Decker The Complete Guide To Walls & Ceilings - Framing - Drywall - Painting - Trimwork-Cool Springs Press (2015)Documento275 páginas(Black & Decker Complete Guide) Editors of Cool Springs Press - Black & Decker The Complete Guide To Walls & Ceilings - Framing - Drywall - Painting - Trimwork-Cool Springs Press (2015)Antonio Soares100% (4)

- Carpenter 1 SérieDocumento2 páginasCarpenter 1 Sérieroselysobralgimenez2Ainda não há avaliações

- Woodturne:R: Tocame:Ric NDocumento28 páginasWoodturne:R: Tocame:Ric NJason NelsonAinda não há avaliações

- Art Deco ChairDocumento3 páginasArt Deco Chairapi-602237392Ainda não há avaliações

- Report Connection IbsDocumento7 páginasReport Connection IbsAin SherinAinda não há avaliações

- Grading: of Sawn Timber in Europe According To EN 1611-1Documento31 páginasGrading: of Sawn Timber in Europe According To EN 1611-1sant1411100% (1)

- Crochet Impkins: Over a million possible combinations! Yes, really!No EverandCrochet Impkins: Over a million possible combinations! Yes, really!Nota: 4.5 de 5 estrelas4.5/5 (10)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiNo Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiNota: 5 de 5 estrelas5/5 (2)

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveNo EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveAinda não há avaliações

- Crazy for the Storm: A Memoir of SurvivalNo EverandCrazy for the Storm: A Memoir of SurvivalNota: 3.5 de 5 estrelas3.5/5 (217)

- House Rules: How to Decorate for Every Home, Style, and BudgetNo EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetAinda não há avaliações

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthNo EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthNota: 4 de 5 estrelas4/5 (59)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsNo EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsNota: 4.5 de 5 estrelas4.5/5 (2)

- 438 Days: An Extraordinary True Story of Survival at SeaNo Everand438 Days: An Extraordinary True Story of Survival at SeaNota: 4.5 de 5 estrelas4.5/5 (188)

- The Martha Manual: How to Do (Almost) EverythingNo EverandThe Martha Manual: How to Do (Almost) EverythingNota: 4 de 5 estrelas4/5 (11)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNo EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsAinda não há avaliações

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiNo EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiNota: 4 de 5 estrelas4/5 (3)

- The Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerNo EverandThe Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerNota: 4 de 5 estrelas4/5 (23)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Ainda não há avaliações

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestNo EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestNota: 5 de 5 estrelas5/5 (2)

- Modern Embroidery: A Book of Stitches to Unleash CreativityNo EverandModern Embroidery: A Book of Stitches to Unleash CreativityAinda não há avaliações

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeNo EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeNota: 5 de 5 estrelas5/5 (1)

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsNo EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsAinda não há avaliações

- Dream Sewing Spaces: Design & Organization for Spaces Large & SmallNo EverandDream Sewing Spaces: Design & Organization for Spaces Large & SmallNota: 4 de 5 estrelas4/5 (24)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastNo EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastNota: 5 de 5 estrelas5/5 (1)

- Friends: The One with the Crochet: The Official Crochet Pattern BookNo EverandFriends: The One with the Crochet: The Official Crochet Pattern BookNota: 5 de 5 estrelas5/5 (1)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNo EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesAinda não há avaliações

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreNo EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreNota: 5 de 5 estrelas5/5 (5)

- Mind Gym: An Athlete's Guide to Inner ExcellenceNo EverandMind Gym: An Athlete's Guide to Inner ExcellenceNota: 3.5 de 5 estrelas3.5/5 (18)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsNo EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsNota: 4.5 de 5 estrelas4.5/5 (10)

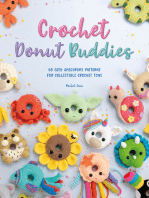

- Crochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysNo EverandCrochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysNota: 4.5 de 5 estrelas4.5/5 (7)