Escolar Documentos

Profissional Documentos

Cultura Documentos

Ijct 12 (1) 105-107

Enviado por

gkreddi0 notas0% acharam este documento útil (0 voto)

17 visualizações3 páginas1) The document examines the effect of gamma radiation on the viscosity of solutions of galactomannans with different galactose to mannose (G:M) ratios.

2) It was observed that galactomannan with the highest G:M ratio of 1:1 (fenugreek) resisted depolymerization the most when exposed to gamma radiation, while the galactomannan with the lowest ratio of 1:4 (locust bean) showed the greatest reduction in viscosity.

3) The reduction in viscosity indicates that gamma radiation causes depolymerization through breaking of glycosidic bonds between sugars, producing lower molecular weight products rather than rupturing sugar rings.

Descrição original:

IJCT 12(1) 105-107

Título original

IJCT 12(1) 105-107

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documento1) The document examines the effect of gamma radiation on the viscosity of solutions of galactomannans with different galactose to mannose (G:M) ratios.

2) It was observed that galactomannan with the highest G:M ratio of 1:1 (fenugreek) resisted depolymerization the most when exposed to gamma radiation, while the galactomannan with the lowest ratio of 1:4 (locust bean) showed the greatest reduction in viscosity.

3) The reduction in viscosity indicates that gamma radiation causes depolymerization through breaking of glycosidic bonds between sugars, producing lower molecular weight products rather than rupturing sugar rings.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

17 visualizações3 páginasIjct 12 (1) 105-107

Enviado por

gkreddi1) The document examines the effect of gamma radiation on the viscosity of solutions of galactomannans with different galactose to mannose (G:M) ratios.

2) It was observed that galactomannan with the highest G:M ratio of 1:1 (fenugreek) resisted depolymerization the most when exposed to gamma radiation, while the galactomannan with the lowest ratio of 1:4 (locust bean) showed the greatest reduction in viscosity.

3) The reduction in viscosity indicates that gamma radiation causes depolymerization through breaking of glycosidic bonds between sugars, producing lower molecular weight products rather than rupturing sugar rings.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 3

Indian Journal of Chemical Technology

Vol. 12, January 2005, pp. 105-107

Notes

Effect of gamma radiation on solution

viscosity of galactomannans: Influence of

galactose : mannose ratio

Roshan Issarani & B P Nagori*

Lachoo Memorial College of Science & Technology,

Shastri Nagar, Jodhpur, India

Received 17 June 2004; revised received 1 October 2004;

accepted 14 October 2004

Various seed galactomannans differ from each other in G:M

ratios, molecular weight and fine structure, w.r.t. the distribution

of galactose side groups on the main chain. In the present

investigation, galactomannan samples of fenugreek, guar and

locust bean having different G:M ratios of 1:1, 1:2 and 1:4

respectively, were exposed to different doses of gamma radiation.

Dispersions of the resulting products were prepared and their

viscosities were measured. A considerable fall in their viscosities

was noted. The lower viscosity is obtained due to the production

of lower molecular weight products, indicative of depolymerization. It was observed that galactomannan having the

highest galactose : mannose (G:M) ratio of 1:1 resisted depolymerization the most in comparison to the galactomannan

possessing the lowest G:M ratio of 1:4.

Keywords: Depolymerization, gamma irradiation,

mannas, locust bean, fenugreek, guar.

galacto-

IPC Code: G05D 24/00

Galactomannans are found as reserve food material in

the endosperms of leguminous plant seeds. Galactomannans consist of -(1-4)-mannose backbone having

-(1-6)-galactose side chains. Various seed

galactomannans differ from each other in galactosemannose (G:M) ratios, molecular weight and fine

structure, w.r.t. the distribution of galactose side

groups on the main chain1-7.

The unusually high viscosity of galactomannans is

in a way a limitation for their use in both food and

non-food industries. The limitations of using these

gums in their native forms (i.e. non-deploymerized

form) include:

(i) The quantity of high viscosity gum employed as

food additive (0.1% of bulk) is too insufficient

to make it effective dietary fibre (12 - 28 g/day).

________________

*For correspondence (E-mail: bpnagori@sancharnet.in;

Fax: 0291-2433919)

(ii) In dairy products, it provides a thickening that is

very unnatural.

(iii) High viscosity gum does not work well in

pharmaceutical applications like coating of

granular and spray dried products.

(iv) An ideal viscosity builder should have a fast rate

of hydration and should maintain a consistent

viscosity under variable shear rate and

temperature. This is not possible with a very

high viscosity gum product.

(v) It is the low molecular weight galactomannan

that finds application in preparation of adsorbents for chromatography.

Hence, there is a need to modify them by

depolymerization to offset this limitation and suit the

requirements. Various methods8-17 of modifying the

native gum include enzymatic, acid catalyzed

hydrolysis and thermal methods.

In the present study, a novel method of

depolymerization of galactomannans was conceived

involving the use of gamma rays. The effect of

gamma radiation on depolymerization of galactomannans having different G:M ratio was studied.

Experimental Procedure

The galactomannans of guar (GG), fenugreek

(FGM), and locust bean (LBG), were obtained from

M/s Sunita Minechems, Jodhpur.

Six samples of each galactomannan, contained in

Borosil glass tubes were exposed to different doses of

gamma radiation ranging from 0 - 40 Kgrays. 1.5%

(w/v) aqueous dispersions of the gamma irradiated

galactomannan samples were prepared using a

mechanical stirrer at 1500200 rpm. Their viscosities

were determined using Synchrolectric Brookfields

Viscometer spindle no. 4 at 25C.

Results and Discussion

It is evident from the data given in Table 1 that the

reduction in viscosity is least in the case of galactomannan having the highest G:M ratio of 1:1 i.e. FGM.

On the other hand, the reduction in viscosity on

depolymerization in case of LBG is highest among

the three galactomannans which correlates with its

INDIAN J. CHEM. TECHNOL., JANUARY 2005

106

Table 1Viscosities of 1.5% (w/v) aqueous dispersions of different galactomannans exposed to different doses of gamma radiation

S. No.

Viscosity of galactomman (cps)

G:M ratio

Radiation dose

(Kgrays)

1

2

3

4

5

6

7

0

5

10

15

20

30

40

Guar

1:2

Fenugreek

1:1

Locust bean

1:4

9100 986

1100 97

185 22

35 4

10 7

-

3850 350

1450 127

910 100

360 44

100 13

30 4

09 5

2850 223

150 12

50

The data indicates mean S.D. of triplicate determinations.

Sufficient viscosity was not produced; hence viscosity could not be determined.

lowest galactose-mannose ratio of 1:4. The same

corollary is extendible in case of guar having a G:M

ratio of 1:2, which shows a fall in viscosity which is

intermediate between the above two galactomannans.

In Fig.1, log values of the viscosities are plotted

against the gamma radiation dose. If a straight line is

drawn, through the points, then slopes can be worked

out which will give a direct measure of the rates of

depolymerization in the three galactomannans. The

slopes are found to be 0.065, 0.147, and 0.29 for

fenugreek, guar and locust bean gums, respectively.

The lower negative value of slope in case of FGM

indicates its resistance to depolymerization, followed

by GG and the highest negative slope value in case of

LBG indicates its relatively easier depolymerization.

The above fact is also confirmed by other

observations, when depolymerization was carried out

by acid hydrolysis method. It was observed that

fenugreek galactomannan took the longest time for

complete hydrolysis, requiring 30-35 min. This was

followed by guar, requiring a time of 15-18 min and

the least time of 10-12 min was required by locust

bean for complete hydrolysis.

In order to ensure that on exposure of gums to

gamma radiation only galactose and mannose are

obtained and that the ring of galactose and mannose is

not ruptured, the following experiments were carried

out. 1% (w/v) aqueous dispersions of depolymerized

galactomannans were prepared and centrifuged to

remove any insoluble matter. The depolymerized (low

molecular weight) galactomannans were precipitated

from aqueous solution by adding 70% ethanol and the

precipitated galactomannans were collected by

Fig.1Plot of log viscosity of 1.5 % (w/v) dispersions of

galactomannans versus different doses of gamma radiation (mean

values of triplicate determinations).

filtration, washed with acetone, dried and weighed.

The TLC of the filtrate was performed using mannose

and galactose as reference. Two spots were obtained

having Rf value of 0.62 and 0.36 corresponding to

mannose and galactose, respectively. This proves that

these sugars remained intact and did not undergo ring

rupture. Further, the breaking of glycoside bonds

requires much less energy compared to the rupture of

pyranose ring in sugars. Depolymerization involves

breaking of glycosidic (sugar-sugar) bond. This is

preferred over pyranose ring rupture when gamma

radiation, which possesses sufficient energy to break

the glycoside bond, is being employed. The

galactomannans have an abundance of adjacent OH

groups in cis position, due to which they enter into

ISSARANI & NAGORI: EFFECT OF GAMMA RADIATION ON SOLUTION VISCOCITY OF GALACTOMANNANS

complex formation with a number of ions like Ca2+,

Cu2+, Al3+, Ti2+, and Sb3+. However, the most noted

interaction takes place with the borate ion18, resulting

in considerable increase in viscosity. The increase in

viscosity was also observed on addition of borax to

the prepared dispersions of gamma irradiated

depolymerized galactomannans.

Viscosity depends on the molecular weight and the

chain length of polymers. The viscosities of dispersions prepared using the gamma-irradiated galactomannans showed a considerable fall in comparison to

the viscosities of dispersions prepared using native

galactomannans. This indicates the formation of lower

molecular weight polymers. Thus, the products of

depolymerization of galactomannans on exposure to

gamma radiation include depolymerized low

molecular weight galactomannans, galactose and

mannose.

It is concluded that galactomannans can be

depolymerized by exposure to gamma radiation to

yield low viscosity galactomannans and that a

galactomannan with the highest G:M ratio resists

depolymerization in comparison to a galactomannan

with a lower G:M ratio.

Acknowledgments

The authors acknowledge Dr. A. K. Vadhawan,

Head of Ravi, the gamma radiation plant at Defense

107

Lab, Jodhpur for providing the plant facilities for the

present study. The authors also acknowledge Dr. N.

K. Mathur, Ex-president, Association of Carbohydrate

Chemists and Technologists of India, for providing

guidance for the study.

References

1 Kapoor V P, Milas M, Taravel F R, & Rinaudo M,

Carbohydr Polym, 25 (1994) 79.

2 Eileen H & Whistler R L, J Am Chem Soc, 70 (1948) 2249.

3 Ahmed Z F & Whistler R L, J Am Chem Soc, 72 (1950)

2524.

4 Swanson J W, J Am Chem Soc, 71 (1945) 1510.

5 Raffique C M & Smith F J, J Am Chem Soc, 72 (1950) 4634.

6 Montgomery S F R, Chemistry of Plant Gums and Mucilages

(Reinhold Publishing Corpn, New York), 1959.

7 Mathur N K, Chem Week, 39 (2000) 161.

8 Chistafell C & Boral E A, US Pat., 3 300 473, 1967.

9 Gupta A K & BeMiller T N, Phytochemistry, 29 (1990) 853.

10 Mathur N K, Gum Stabilizers for Food Industry, Vol. VII

(Oxford University Press, Oxford), 1993, 149.

11 McCleary B V, Phytochemistry, 18 (1979) 757.

12 Dea I C M & Morrison A, Advances in Chemistry and

Biochemistry of Carbohydrates, 31 (1975) 241.

13 Marrs W M, Gums and Stabilizers for Food Industry, Vol.

IV (Oxford University Press, Oxford), 1988, 391.

14 McCleary B V, Carbohydr Res, 92 (1981) 269.

15 Mathur N K & Mathur V, Chem Week, 40 (2001) 153.

16 Mathur N K & Mathur V, Chem Week, 40 (2001) 141.

17 Yamatoya K, IFI NR, (1994) 15.

18 Mathur N K & Mathur V, J Chromatogr A, 685 (1994) 360.

Você também pode gostar

- Pressure Cell Assisted Solution Characterization of Polysaccharides. 2. Locust Bean Gum and Tara GumDocumento7 páginasPressure Cell Assisted Solution Characterization of Polysaccharides. 2. Locust Bean Gum and Tara GumJosimar Aguilar FlorezAinda não há avaliações

- Ahmad 2001Documento9 páginasAhmad 2001Himew BraidAinda não há avaliações

- Properties of Chemically Modified Gelatin Films: Brazilian Journal of Chemical EngineeringDocumento9 páginasProperties of Chemically Modified Gelatin Films: Brazilian Journal of Chemical EngineeringMuhammad Rizky AKAinda não há avaliações

- FTIR Alg BeadDocumento11 páginasFTIR Alg BeadKani RapeeAinda não há avaliações

- J Foodhyd 2014 02 001Documento7 páginasJ Foodhyd 2014 02 001Virnanda SyafiraAinda não há avaliações

- Jian 2015Documento8 páginasJian 2015Koreab KoeenAinda não há avaliações

- 水凝胶表征 食品方向Documento10 páginas水凝胶表征 食品方向sheng caoAinda não há avaliações

- Materials: A Study of The Synergistic Interaction of Konjac Glucomannan Alkaline ConditionsDocumento15 páginasMaterials: A Study of The Synergistic Interaction of Konjac Glucomannan Alkaline ConditionsLavenderAinda não há avaliações

- 5 ParkDocumento13 páginas5 ParkJanay BátizAinda não há avaliações

- J.Mol Cat 2004Documento6 páginasJ.Mol Cat 2004Saravanamurugan ShumugavelAinda não há avaliações

- Synthesis and Characterization of Maleic Acid and Sodium Methallyl Disulfonate New Copolymer: Application As A Barium Sulfate Scale InhibitorDocumento10 páginasSynthesis and Characterization of Maleic Acid and Sodium Methallyl Disulfonate New Copolymer: Application As A Barium Sulfate Scale InhibitorAri WijayaAinda não há avaliações

- 1 s2.0 S0141813018360719 MainDocumento9 páginas1 s2.0 S0141813018360719 MainPaulo CedeñoAinda não há avaliações

- Easychair Preprint: Kholoud Al-Ajlouni, Paul D. Fleming and Alexandra PekarovicovaDocumento17 páginasEasychair Preprint: Kholoud Al-Ajlouni, Paul D. Fleming and Alexandra PekarovicovaKholoud Al-AjlouniAinda não há avaliações

- Yang 2012Documento6 páginasYang 2012Deepak Kumar SinghAinda não há avaliações

- Al-Hassan y Norziah 2012Documento10 páginasAl-Hassan y Norziah 2012AlexRiveraAinda não há avaliações

- Helga Son dd009Documento37 páginasHelga Son dd009Sol AngelAinda não há avaliações

- Enhanced Malachite Green Removal From Aqueous Solution by Citric Acid Modified Rice StrawDocumento6 páginasEnhanced Malachite Green Removal From Aqueous Solution by Citric Acid Modified Rice StrawÖmer LaçinAinda não há avaliações

- MODIFICATION OF THE RHEOLOGICAL BEHAVIOUR - Deeb Abu Fara & Basim Abu Jadayel - 2013Documento7 páginasMODIFICATION OF THE RHEOLOGICAL BEHAVIOUR - Deeb Abu Fara & Basim Abu Jadayel - 2013DeebAinda não há avaliações

- 7 - CinéticaDocumento8 páginas7 - CinéticaAlejandro PérezAinda não há avaliações

- Zhao 2003 - Fuel Processing TechnologyDocumento9 páginasZhao 2003 - Fuel Processing TechnologyGipsy Abril Peña RamirezAinda não há avaliações

- Optimization Of The Immobilization Process Of Β-Galatosidade By Combined Entrapment-Cross-Linking And The Kinetics Of Lactose HydrolysisDocumento10 páginasOptimization Of The Immobilization Process Of Β-Galatosidade By Combined Entrapment-Cross-Linking And The Kinetics Of Lactose HydrolysisDevi PutriAinda não há avaliações

- 4 PBDocumento13 páginas4 PBShierly ShafrillaAinda não há avaliações

- Synthesis of Glycerol Mono-Laurate From Lauric Acid and Glycerol For Food Antibacterial AdditiveDocumento8 páginasSynthesis of Glycerol Mono-Laurate From Lauric Acid and Glycerol For Food Antibacterial AdditiveRikardo LumbantoruanAinda não há avaliações

- Yarnpakdee 2015 Ekstraksi AgarDocumento10 páginasYarnpakdee 2015 Ekstraksi AgarAmpun Bang JagoAinda não há avaliações

- Temperature Influence in Cornstarch Gelatinization For Froth FlotationDocumento5 páginasTemperature Influence in Cornstarch Gelatinization For Froth FlotationRougeeeAinda não há avaliações

- Structural and Rheological Characteristics of Alginate From Sargassum Cristaefolium Extracted by Twin Screw ExtruderDocumento17 páginasStructural and Rheological Characteristics of Alginate From Sargassum Cristaefolium Extracted by Twin Screw Extrudersugiono sugionoAinda não há avaliações

- 13 Kabouris Etal WER 2009Documento10 páginas13 Kabouris Etal WER 2009ibrahim3318Ainda não há avaliações

- The Effect of Graphene Dispersion On The Mechanical Properties of Graphene/epoxy CompositesDocumento12 páginasThe Effect of Graphene Dispersion On The Mechanical Properties of Graphene/epoxy CompositesVansala GanesanAinda não há avaliações

- Polymer: Changgang Xu, Xuegang Luo, Xiaoyan Lin, Xiurong Zhuo, Lili LiangDocumento8 páginasPolymer: Changgang Xu, Xuegang Luo, Xiaoyan Lin, Xiurong Zhuo, Lili LiangMathilda PasaribuAinda não há avaliações

- Chemical Engineering and Processing: Process Intensi FicationDocumento9 páginasChemical Engineering and Processing: Process Intensi FicationAmrutAinda não há avaliações

- Influence of Initial PH On Gelation Kinetics of Texturized Passion Fruit PulpDocumento6 páginasInfluence of Initial PH On Gelation Kinetics of Texturized Passion Fruit Pulpramon SilvaAinda não há avaliações

- Lech 206Documento5 páginasLech 206trangAinda não há avaliações

- Graft Copolymerization, Characterization, and Degradation of Cassava Starch-G-Acrylamide/itaconic Acid SuperabsorbentsDocumento17 páginasGraft Copolymerization, Characterization, and Degradation of Cassava Starch-G-Acrylamide/itaconic Acid SuperabsorbentsCaty CerasAinda não há avaliações

- Dutta 2016Documento11 páginasDutta 2016suranjoyAinda não há avaliações

- Innovative Complex Coacervates of Gelatin and Sodium Carboxymethyl Cellulose For Cinnamaldehyde Delivery: Impact of Processing Conditions On Characteristics and BioactivityDocumento10 páginasInnovative Complex Coacervates of Gelatin and Sodium Carboxymethyl Cellulose For Cinnamaldehyde Delivery: Impact of Processing Conditions On Characteristics and BioactivityMamta AgarwalAinda não há avaliações

- Antioxidant Properties of Garcinia Mangostana L (Mangosteen) RindDocumento6 páginasAntioxidant Properties of Garcinia Mangostana L (Mangosteen) RindCristover FernandoAinda não há avaliações

- Effects of Kappa-Carrageenan On The Physico-Chemical Properties of Thermoplastic StarchDocumento8 páginasEffects of Kappa-Carrageenan On The Physico-Chemical Properties of Thermoplastic StarchMaria PanganibanAinda não há avaliações

- Pga DLSJ ReviewDocumento6 páginasPga DLSJ ReviewjenniAinda não há avaliações

- Radiation Induced Degradation of Sodium Alginate and - 2017 - Arabian Journal oDocumento8 páginasRadiation Induced Degradation of Sodium Alginate and - 2017 - Arabian Journal olucian_lovAinda não há avaliações

- Effects of Polysaccharides Upon The Functional Properties of 11 S Globulin of Broad BeansDocumento8 páginasEffects of Polysaccharides Upon The Functional Properties of 11 S Globulin of Broad BeansJose perezAinda não há avaliações

- Alginate Based New Materials: Kurt Ingar Draget, Gudmund Skja K-Bræk, Olav SmidsrødDocumento9 páginasAlginate Based New Materials: Kurt Ingar Draget, Gudmund Skja K-Bræk, Olav SmidsrødEsteban ArayaAinda não há avaliações

- Sugar CarobDocumento6 páginasSugar CarobЛуизАпазаТ.Ainda não há avaliações

- Stability and Reusability of Cyclodextrin GlucanotDocumento8 páginasStability and Reusability of Cyclodextrin GlucanotWilfried HlouedjeAinda não há avaliações

- Asus Ux303ua Ub ADocumento4 páginasAsus Ux303ua Ub ALUIS XVAinda não há avaliações

- 2009 John C - Municipal Digestion UntitledDocumento10 páginas2009 John C - Municipal Digestion UntitledJulio ReyesAinda não há avaliações

- Extrusion Processing of Wheat Gluten Bioplastic: Effect of The Addition of Kraft LigninDocumento11 páginasExtrusion Processing of Wheat Gluten Bioplastic: Effect of The Addition of Kraft LigninXuan Phuong HuynhAinda não há avaliações

- Dialnet-AdsorcionEfectivaDeTartrazinaPorBiomaterialModific-8637738 AmarilloDocumento12 páginasDialnet-AdsorcionEfectivaDeTartrazinaPorBiomaterialModific-8637738 AmarilloAlexa RiveraAinda não há avaliações

- Sadhukhan - 2016 - Green Reduction Manga e Batata - FenolicosDocumento11 páginasSadhukhan - 2016 - Green Reduction Manga e Batata - FenolicosLuana DemosthenesAinda não há avaliações

- Process Biochemistry: Rukiye Yavas Er, Arife Alev Karag OzlerDocumento10 páginasProcess Biochemistry: Rukiye Yavas Er, Arife Alev Karag OzlerEcAinda não há avaliações

- Alginate Properties and Applications Updated 12608Documento7 páginasAlginate Properties and Applications Updated 12608Wasif RazzaqAinda não há avaliações

- Synthesis of Mercaptoalkyl Glucosides (Edited)Documento16 páginasSynthesis of Mercaptoalkyl Glucosides (Edited)Susan Del Rosario-ArcoAinda não há avaliações

- Barnacle Cement ProteinDocumento7 páginasBarnacle Cement ProteinVIGNESHAinda não há avaliações

- Synergistic Effect of Tannic Acid and Modified Atmospheric Packaging On The Prevention of Lipid Oxidation and Quality Losses of Refrigerated Striped Catfish SlicesDocumento10 páginasSynergistic Effect of Tannic Acid and Modified Atmospheric Packaging On The Prevention of Lipid Oxidation and Quality Losses of Refrigerated Striped Catfish SlicesSajid DijasAinda não há avaliações

- Mechanical Properties, Hydrophicity and Aw of Starch-Gum FilmsDocumento9 páginasMechanical Properties, Hydrophicity and Aw of Starch-Gum FilmsCarolina AyalaAinda não há avaliações

- Starch-Gelatin Edible Films Water Vapor Permeability and Mechanical Properties As Affected by PlasticizersDocumento10 páginasStarch-Gelatin Edible Films Water Vapor Permeability and Mechanical Properties As Affected by Plasticizersazfar_mmas4206Ainda não há avaliações

- 1 s2.0 S0272884223005655 MainDocumento20 páginas1 s2.0 S0272884223005655 MainafrizalsatyapAinda não há avaliações

- Synthesis of Metal Organic Framework (MOF) Based Ca Alginate For Adsorption of Malachite Green DyeDocumento15 páginasSynthesis of Metal Organic Framework (MOF) Based Ca Alginate For Adsorption of Malachite Green Dyeasdigistore101Ainda não há avaliações

- ScribdDocumento9 páginasScribdSrinivas ReddyAinda não há avaliações

- SPE 164135 Mechanical and Thermal Stability of Polyacrylamide-Based Microgel Products For EORDocumento11 páginasSPE 164135 Mechanical and Thermal Stability of Polyacrylamide-Based Microgel Products For EORLeopold Roj DomAinda não há avaliações

- Glycochemical Synthesis: Strategies and ApplicationsNo EverandGlycochemical Synthesis: Strategies and ApplicationsShang-Cheng HungAinda não há avaliações

- Madhuri RMGDocumento1 páginaMadhuri RMGgkreddi100% (1)

- Seminar MagazineDocumento20 páginasSeminar Magazinegkreddi100% (1)

- Component List: Neuwall Movable&Partitions SolutionDocumento9 páginasComponent List: Neuwall Movable&Partitions SolutiongkreddiAinda não há avaliações

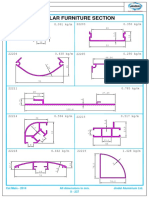

- 25) Modular Furniture SectionDocumento26 páginas25) Modular Furniture SectiongkreddiAinda não há avaliações

- (CDMM) : Certified Digital Marketing Master CourseDocumento29 páginas(CDMM) : Certified Digital Marketing Master CoursegkreddiAinda não há avaliações

- Country Sales District Sales Organization Distribution: Period Division 011/2015 11Documento3 páginasCountry Sales District Sales Organization Distribution: Period Division 011/2015 11gkreddiAinda não há avaliações

- Specification SheetDocumento5 páginasSpecification SheetgkreddiAinda não há avaliações

- Fenugreek As Dietary FibreDocumento4 páginasFenugreek As Dietary FibrePriyadarshini Mh100% (2)

- 7Documento6 páginas7Joenetha Ann Aparici100% (1)

- Common Core Content and Training Objectives For Basic AIS Training - Phase 2 - SpecialistDocumento82 páginasCommon Core Content and Training Objectives For Basic AIS Training - Phase 2 - SpecialistjlferreiraAinda não há avaliações

- Engleza Referat-Pantilimonescu IonutDocumento13 páginasEngleza Referat-Pantilimonescu IonutAilenei RazvanAinda não há avaliações

- Maya Deren PaperDocumento9 páginasMaya Deren PaperquietinstrumentalsAinda não há avaliações

- Lightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationDocumento2 páginasLightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationAnas BasarahAinda não há avaliações

- 2 Design of DOSAGE DESIGNDocumento16 páginas2 Design of DOSAGE DESIGNMarjo100% (1)

- View All Callouts: Function Isolation ToolsDocumento29 páginasView All Callouts: Function Isolation Toolsمهدي شقرونAinda não há avaliações

- Virtual WorkDocumento12 páginasVirtual Workdkgupta28Ainda não há avaliações

- 220245-MSBTE-22412-Java (Unit 1)Documento40 páginas220245-MSBTE-22412-Java (Unit 1)Nomaan ShaikhAinda não há avaliações

- Pathophysiology of Myocardial Infarction and Acute Management StrategiesDocumento11 páginasPathophysiology of Myocardial Infarction and Acute Management StrategiesnwabukingzAinda não há avaliações

- Nikos MIDI Pack - Chord Progression GuideDocumento5 páginasNikos MIDI Pack - Chord Progression GuideSamuel ThompsonAinda não há avaliações

- Fuzzy Gain Scheduled Pi Controller For ADocumento5 páginasFuzzy Gain Scheduled Pi Controller For AOumayAinda não há avaliações

- Note!: Rear Shock Absorber For YAMAHA N-MAXDocumento4 páginasNote!: Rear Shock Absorber For YAMAHA N-MAXAdityaArnas0% (1)

- A Comparative Study of Public Private Life Insurance Companies in IndiaDocumento5 páginasA Comparative Study of Public Private Life Insurance Companies in IndiaAkansha GoyalAinda não há avaliações

- Teaching Trigonometry Using Empirical Modelling: 2.1 Visual Over Verbal LearningDocumento5 páginasTeaching Trigonometry Using Empirical Modelling: 2.1 Visual Over Verbal LearningJeffrey Cariaga Reclamado IIAinda não há avaliações

- LP32HS User Manual v1Documento52 páginasLP32HS User Manual v1tonizx7rrAinda não há avaliações

- Claim of FactDocumento11 páginasClaim of FactXeb UlritzAinda não há avaliações

- Highlights ASME Guides Preheat PWHT IDocumento4 páginasHighlights ASME Guides Preheat PWHT IArul Edwin Vijay VincentAinda não há avaliações

- Test Physics Chapter# 12,13,14 (2 Year) NameDocumento1 páginaTest Physics Chapter# 12,13,14 (2 Year) NameStay FocusedAinda não há avaliações

- Very Narrow Aisle MTC Turret TruckDocumento6 páginasVery Narrow Aisle MTC Turret Truckfirdaushalam96Ainda não há avaliações

- Vitamins - CyanocobalaminDocumento12 páginasVitamins - CyanocobalaminK PrashasthaAinda não há avaliações

- Acting White 2011 SohnDocumento18 páginasActing White 2011 SohnrceglieAinda não há avaliações

- KLA28 ProductsapplicationpresetDocumento2 páginasKLA28 ProductsapplicationpresetcarxmozAinda não há avaliações

- Niveshdaily: From Research DeskDocumento53 páginasNiveshdaily: From Research DeskADAinda não há avaliações

- Case Study - Suprema CarsDocumento5 páginasCase Study - Suprema CarsALFONSO PATRICIO GUERRA CARVAJALAinda não há avaliações

- DIR-819 A1 Manual v1.02WW PDFDocumento172 páginasDIR-819 A1 Manual v1.02WW PDFSerginho Jaafa ReggaeAinda não há avaliações

- Catheter Related InfectionsDocumento581 páginasCatheter Related InfectionshardboneAinda não há avaliações

- Caterpillar Cat C7 Marine Engine Parts Catalogue ManualDocumento21 páginasCaterpillar Cat C7 Marine Engine Parts Catalogue ManualkfsmmeAinda não há avaliações

- The Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDocumento30 páginasThe Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDusen VanAinda não há avaliações

- Volvo BL 71 ManualDocumento280 páginasVolvo BL 71 ManualAlberto G.D.100% (2)