Escolar Documentos

Profissional Documentos

Cultura Documentos

Tema Fouling

Enviado por

Ibrahim0 notas0% acharam este documento útil (0 voto)

12 visualizações8 páginasTema Fouling

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoTema Fouling

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

12 visualizações8 páginasTema Fouling

Enviado por

IbrahimTema Fouling

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 8

FLOW INDUCED VIBRATION SECTION 6.

\V-19 DESIGN CONSIDERATIONS

‘Many parameters acing independerty or in conjunction wit ech cer can alate How induced

‘ation araiysiaGne must be cogent of tse parametars and tel oles shold bo

‘counted for nthe veral het exchange dos

19.4 TUBE DIAMETER

se ofthe targos reasonable tube lamer consent with practical thermal and hyraule

‘eign eonomies is destatle. Largo dumstrs ereavo the moment cf ora, Norby

‘Sacvolymoraasing the siineas ofthe botox e gen length

\v-12.2 UNSUPPORTED TUBE SPAN

“The uncupporte tb span i the most sgnllcat ctor atoctng induced vbations. The

Shorter tl tube span, te goats resize to vtston

Sunatmanca ences ercencemns ree

Sees ctraesre oe catecceec ma

ee gr eee pee em

Seu al onion neacncen mungaramnateies

Scr ter sy tg ere cr

Slane edic ati using spe othe sae hel ade tow tate ar posi

=

“No tubes inwndow tow arangement tales provige suppor to al ubes st al bale

‘Deaton and alse perm the ust co male mermesin Suppor wear sect tho

‘Sonsion velco wlsredusing the untuppored tube Span

v9.9 TUBE TCH

Larger pt to tubo arate aie prowl neeaoed gamer areas which resultin

reduced rostow vlosiy fora ghia wrupported tbe span ra reduced unsupported

{be pan fora gon eros oct.

“Th increased tube to tube spacing reduces the eood of mid. span cols damage snd

‘so creases the hydra ras cotton gon in gure 7.11.

1-134 ENTRANCE/EXIT AREAS.

Entrance and ex areas ae gonrayreaognled tobe partic susceptbitodarragein

‘iraton prone exchangers

‘alba othe spancin coat shold be noted at Compl wit Paragraph

HGESEOS Se ek ech toa toc wom ow nsuce veralon a ho

‘vence/ex regione ofthe bundle

Conseraton may be gen tote use pare suppors oes waupoated ie spans

‘rte errane oxtreglone. Suficrt lubed space ay Nave to be povided atthe sh

‘ret out connections to reduce errarco/exaveloctes. Impingement plates shoudl be

“bedand postioned rose att ort este the area evalabior flow. The woe ot

‘dtbson ale can be an elletve mens of lometng entranco/emt vets by allowing

{he shel side fd to entero ho bund st several oct

1V-19.5U.BEND REGIONS

Suscoptty of U-ends to damaging vation may be reduced by aptinum locaton of

Sdiscen banks into stags tgs ao ue of 9 spec bond supper Seve

‘ecceraton may so be ven to protein the bones rn Now duced vbrtion by

Sppropratyocaing the sol comcton and/or adjacent Pais

\V-18.6 TUBING MATERIAL AND THICKNESS

“Te natural equency of an unsuppored tube spans fected bythe eleste modulus ofthe

‘Ue Tigh wands of ate model nbs n fare slows nd tustente aess sioys

Provide greater resitancs to vbraory Sexng than matorals such as alurium and rads

{heather et mod abe atakrgy on wal sess et he Garang

‘Standards Of The Tubular Exchanger Manufacturers Association 121

SECTIONS FLOW INDUCED VIBRATION

122

\V-10. BAFFLE THICKNESS AND TUBE HOLE SIZE

Increasing the bate thickness and reducing the moo bale Moe clearance increases the

‘fsem Gapping sen Paragraph and rduceste rage te force Sees ce

The formule nthe secon donot quanttatvely account forthe eet of ncreesing the

bathichness, or tghoning oneal hole Cearance *

¥V-12. OMISSION OF TUBES

‘Omission of tes at prdetermine cia aati wan the bute may be employed to

‘educe baton peri. For inane, tubes csi on Dale caine como

“experience excessive damage lt vieation pron ints: orfoa, sale ome! tubes.

‘dog bat et ines may Be scaagecus

13.9 TUBE AXIAL LOADING

‘The heat exchanger designer must recognize the potential avers impacton vation by

Soper moro ace presage oneal conton Ts

igual eignlicant fo tubes engi ps, oad tubeshoetSxchangore whee the et fuk

init dd tae ral ts a aoe exchargee Tee oan

‘pansion fin in sush casos may esis fecucon ofthe tube compose sess ey

Paaganh is) m ‘

\VelA SELECTED REFERENCES

(1) Singh KP and Sce, "Mechanical Design OtHea Exchangers And Presure Vessel

(” Botan heres bias Chay eHNG: oe

(@ attousi. MP, Flow Induced Viration OF Cyincical Sutures: AReiow Of The

State Sethi! wat Ontersiy, Het spor No 01 (sel

(©) Banington,€, A, "Esperance Wah Acoustic Verto In Tubular Exchanges, Chena

Engineering Progress, VO. 62, No. Y (873)

(@) Barrington, EA, "Cure Exchange: Acoustic iat, Hytrocarbon Processing, (uy, 1976)

) Chan, S. and Chung, Ho, Design Guide or Cleiaing Hyeraaynamie Mas, Pat: Cxcular

(© Spinel Sucre Aina Natoal above Rep Ne ARCS ess

(Chung, H, and Chen, 8.8. "Design Gul For CacuatingHyodyamic Mass, Pat I

NNoneleui Gyinarical Snicturs" ne, Ropar Nos ANL ET 48

(© Mg, Flow indees Vranas xcenger th Sal Sip’, ASME HTD, Vol @

(7 ita, SS. Tow toucgs raon OF Crear Cyndncal Structures, Argonne National

Sabot Ropon No. ANL-CT-ss ot "

(©) Tinker... "Genera Discussion Of Heat Tranafer, sation OF Mechanical Engineers, pp

GP, Landon 851.

(@) Gorman, Dara, "Foe Vibration Anayes OF are & Shae’ Jn Wily & Sons, (1975)

(10 Fairey... Goyer GD, Ol. 7 Lae “Dann of Muspan ea Exchange

‘Tube art n Gases, Pow induced Vian (1935), ASME PVP Vo fos, ete) pp OTST

(1) Petigray, Ms, Taylor, C.K, 88, Vibration of Tube Bunces In Two Phase Coss Fw:

Pant yarodyramie Mase and Banging, 1060 itematonal Symgosian on low relacee

“ibration and Noe Volume 2 Tne Pest Veoreland Piping Dsisan ASME: pp 78108

(12) Goonars, 1, “Fuldelaie Vbvation OFT Arrays Excted By Crocsow, Fow Induced

‘ieation in Haat Cechangors, ASME, New York 18°)

(18) Qhon,§.8, "Design Guide For Caldating The Inia Fow Velocity OF Tube Aaysin

(2 Srsttowe’ Argonne Netendl braun) ARL STON iS) "

(14) esol, Joseph, ‘How induces Vibra n Heat Exchangers - A Practical Lol, Presented

‘the th Nato Het aster Conterence, Dewar (HT

(95) Monat P.M, Art Lowery. "Hpérodyraic neta Coeflents Fe A Tube Suroundd By

igh Tubes! ASME paper No 7920 ar Second hehoral Congress On Prosaute Vases Ard

Piping, San Feretece

(10) WRC Butn 99, dated February 1804

‘Standards Of The Tubular Exchanger Manufacturers Association

RECOMMENDED GOOD PRACTICE SECTION 10

Planned Geaning Method And Desk Frequency

ti mportar hat the cleaning method be planed a the design stage of the neat

‘exchanger, Consdarationsin dosgn ivivng cleaning are wiatork vib done

{ixne fine, buns removed or paca whether ki ivoWe corte fds, te.

‘Roast. Glosrances calving and piping io must bo eansidored to pti ease

‘Searing. The cleaning method ay rue spetlefeyrequomerts which chou bo

freorporata nthe doaign

1) Flaco The Moro Fouting Fd On Te Tube Sido

“Ther ar wo bert romain the moe fouling hon habe sie, Ter es

rah oF slagrar fw regons cr the tubs cide, ana, t's gery easier

{olen toto sil then the shed ade fs oon posae to lonn tha te ae wh

{he exchanger in place wile maybe neccesary ia remove he bundle ocean th shal

RGP-T-2.22 ECONOMIC CONSIDERATIONS.

Planned fouling prevtion,rantananes and caning make posable lowe lowances for

fouling, but da ecve a coimmamont to ong cow.‘ amour ané Requeney ol

‘Geantig varios conersly wit user ano operon.

“The most slgnticant parameters Incved in dang upon the amount fouling alowance

{ht snow be proved ere te operational an econo factors tl crange ih in

New fd reir, changing St coee ad crag cots Grr eng rocbhes

ld ine degree of paoac for longer periods of beng on seam shouldbe some of he ems

‘luni in detarfing an approrratefoulng essiance Faturetoincde fe eeonomic.

‘onaieratlons may loa to uaceseary monaary penalise for fouling

Compan concerad shox ong canny monic he peorance oth bat

‘xcangore fo stash foung sence an doveop ther oem gusines or eternning

‘he appropiate fing rexrtrice fo specy hon purchasing new equipment

Almost eory source of calng water needs to be ead before ts used for haat exchanger

‘Sopige. "Tha weatmert ranges rom sinpo gaa salon to coral blog felng 10

‘bstandalrentment of bien vt 0 rende tsukabio ruse. The amoure of eatinant

ay benno ste sine cvtng rat bape a=

{etncigy, the quaity of water can be improves To tne pot that fouling shoud bs under

‘onto 36 Yang a fon vets aro rained a ouace temperatures coils

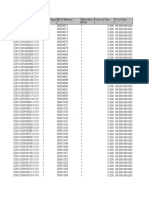

RGP-1-2.4 DESIGN FOULING RESISTANCES (HR FT2°F/Btu)

‘epypn tenga enin eaine eennaiinen

‘oyna eee at ae ae

Feazonaie bien betwen sacra end caning These vluns dt recogni tng

stupcat rc Ca ae

‘Standards Of The Tubular Exchanger Manufacturers Association 285,

ECTION 10 RECOMMENDED GOOD PRACTICE

206

Fouling Resistances For industria Fluids

oie

Fos ora fone

Foal O66 [0.008

“Transformer OF fooot

Engine ube OF fooor

[Guero oF _ [ooo

| Ga Ana Varo

Manutecured Gas foie

Engine Exhaust Ga foo

‘Steam (Now-01 Boating) 2.008,

haust Steam (04 Bearing) fours aa0e

Retigerart Vapors (Bearing) foo.

‘Compressed Air [o00t

‘Ammonia Vapor [o008

(602 Vanor ooo

‘Ghose Vapor oe.

‘Coal Fue Gas foo.

‘Natural Gas Fas Gas 08

Tia:

Moin Haat Tranter Sate coord

Fefrigerar igus [0008

Hyer Fk fooor

Industrial Organic Hest Tanefor adla [0002

“Ammonia Liquid on

‘Ammonia gu (01 Beara) feos

‘Calcium Chorge Scions [ooo

‘Sodium Gtiorde Sokions| [oon

60 a Leis ooo:

‘Gorne Gaui 2

Methanol Sousions foo

Ethanol Sutons| 08

Ethylene yea! Sokiions| [aoe

‘Standards Of The Tubular Exchanger Manufacturers Association

RECOMMENDED GOOD PRACTICE

Fouling Resistances For Chemical Processing Steams

SECTION 10

Gases And Vapor:

eid Gases foneaa00s

Salon Vapors 001

‘Stable Overhead Produce 001

Lis

‘MEA And DEA Solaions oa

‘DEG And TEG Solutions fo.02

‘Satie Side Draw And Bote Product [ooo

Caustic Suions loon

Vegsabie Ole [000

Fouling Resstances For Natural Gat-Gasotine Processing Streams

‘Gases And Vapors

aural Gas [ooorano

‘Overhead Products 001-0002

Tau:

ean OF aoa

ich OF [o0or-0002

Natural Gace And guid Parlour Gases fooor 000

Standards Of The Tubular Exchanger Manufacturers Association 287

ECTION 10 RECOMMENDED GOOD PRACTICE

288

Fouling Resistances For Ol Retnery Steams:

‘Crude And Vacuum Unk Geees And Vapors

_Airospherie Tower Overhead Vapors [oar

Light Napihas [oor

| Vacsum Overead Vapare [o.oo

(rode And Vacuum Luis

rue OF

‘010 250°F 25010 560°F

veLoorTY FY/SEC yeLociry Fr/se0

Day [doe | eooa | ~ooo2 | ~.o0d | anna | —a00e

sate | 000s | 0002 | oo | ome | a004 | 0.004

ss 10450" “60°F and over

veLocmy FT/SEC yeLociry FT/SEC.

[as Ey az] 24 =

‘oRY | 0002 | ~o.003 | ~o.008 | aans | 0.008 | —a.000

‘sat= [0006 [0.005 | 0.005 | ~a007 | 0006 | ~o.one

“Assumes desaing @ approx 250°F

Gasotna foe

‘Naphtha Ae Light Datiates (o.oo 0008

Kerosene [o.o080.000

get Gas OF [o.oa20.009

Heavy Gas OF [.008 0.006

Hey Fuel Ol [0.005 0007

pat And Resi

‘Vacuum Tower Some foie

‘Aamoephere Tower Soom 0.07.

{Gradling And Goling Unt Streams

‘Overhead Vapors oo

ight Cycle OF o.cooa00s

Heavy Cyte OF o.cos0.004

Light Goker Gas OF o.cos..004

Heavy Coker Gas OF 0.000.005

Batioms Stuy OF (45 F/See Minera) 0.09,

Light Liguid Products ooo

‘Standards Of The Tubular Exchanger Manufacturers Association

RECOMMENDED GOOD PRACTICE SECTION 10

Fouling Resstances For OllRetineryStreams- continued

(tai Reforming, Hydrocracking And Hydrodesuizaton Seams

| —_eformer Charge as

eformer Event TT o.005—

Hydrecacker Chaige And Baan aon +d

ecyie Gas 001

Hydrodesutureaton Oharpe Ard EMuani™ [o.002

‘Overhead Vapors [o008

guid Product Overs0°APL fooot

Liquid Product 90-60° APA oo

“Depending cn charg, characlartes and storage history, charge recance

nay bean as a al eee

git Ends Procesing Steams

‘Ovens Vapors And GS5e5 008

Ligue Produc acon

‘Absorption Ol [aca o008

‘Aiylation Trace ei Seam foo

Rebolr Seas [oovea 0

[ibe O1 Processing Svea

Feed Stock foe

Solvent Feed i ono

Salven fo0or

aract™ 008

afin [ooo

sph o.006

Wee Sina fo.

Precautions mus

Te aka to rover wax option on col ube wale

Virose

‘Overiad Vapor 008

Visbresker Botoms oro.

Napitha Hycotreater:

Feed 08

fluent fo.

Naphthas fo.

‘Overhead Vapors [ooo

‘Standards Of The Tubul

F Exchanger Nanutacturers Association

280

ECTION 10

RECOMMENDED GOOD PRACTICE

Fouling Resstances for Ol Retinery Streams.

[Gatti ryaro Desutzor: _ |

‘charge

[etter

HIT. Sep. Overhead —

‘Siipper Charge

Liquid Preucts =

HEAlky Units — _

‘Allele Geprop Batons, an Fact. Ovid a

Al Other Process Sears ooo

Fouling Resistances For Water

Heats un To24g"E zag to aon"

Temperature Of Water 15°F Over 125°F

_ Witer Veloiy F/See_| Water Velooty FSee

ane Loss [Over [Sard ties [Over

[Se 20005 Joo0es foo: [0.001

Bracksh Water ‘one Joo: Joos |o.on2

‘Goalng Tower And Anfcld

Spray Pond: _

‘Treated MakeUp [0001 [anor [once [oa

Unireated 008 Joos [oocs [0.008

(iy Or Wal Water ‘001 Jooo: [ooce [o.oaz

iver Water:

io oee ooo! Joos Joa

‘Average | o.n8Joooe—Jo.oce | o.008|

Has (Over 16 Graine/Gai) | 0.008 [oon _fo.oes | .005

Engine Jacket oot Joo; [oor o.oo

Diatled Or Cased Cycle

Condensate o00s Jooos foows [anos

Treated BoterFesdwater [0.001 [aco0s [ooci [oot

Baler Blowdown ove [oove —[ooce [o.ooe

{th heating medium temperate is over 400° F andthe cooling medium is known oslo these

ratings should be madined accordingly.

290 Standards Of The Tubular Exchanger Manufacturers Association

Você também pode gostar

- Penjelasan Umum PDFDocumento32 páginasPenjelasan Umum PDFIbrahimAinda não há avaliações

- Valuation Document Action Plans and Materials ListDocumento837 páginasValuation Document Action Plans and Materials ListIbrahimAinda não há avaliações

- OPTIMASI DATADocumento17 páginasOPTIMASI DATAchandraiyahAinda não há avaliações

- Formulir Aplikasi Asean Chartered Professional Engineer: Indonesia Monitoring CommitteeDocumento5 páginasFormulir Aplikasi Asean Chartered Professional Engineer: Indonesia Monitoring CommitteeInatAinda não há avaliações

- Mast C101 20190906Documento397 páginasMast C101 20190906IbrahimAinda não há avaliações

- Panduan Pengisian PDFDocumento16 páginasPanduan Pengisian PDFIbrahimAinda não há avaliações

- Valuation Document Action Plans and Materials ListDocumento837 páginasValuation Document Action Plans and Materials ListIbrahimAinda não há avaliações

- Buku Manajemen OperasiDocumento414 páginasBuku Manajemen OperasiNur CholiqAinda não há avaliações

- Form PKBDocumento19 páginasForm PKBIbrahimAinda não há avaliações

- Manajemen Operational Pertemuan I PDFDocumento20 páginasManajemen Operational Pertemuan I PDFIbrahimAinda não há avaliações

- Bakuan KompetensiDocumento25 páginasBakuan KompetensiahsanmuafaAinda não há avaliações

- FAIPDocumento21 páginasFAIParif.tuoAinda não há avaliações

- Continuing Education Form OptimizationDocumento19 páginasContinuing Education Form OptimizationIbrahimAinda não há avaliações

- Manajemen Operasional Manajemen Operasional: Bab 1 - Pengantar Manajemen Operasi Bab 1 - Pengantar Manajemen OperasiDocumento33 páginasManajemen Operasional Manajemen Operasional: Bab 1 - Pengantar Manajemen Operasi Bab 1 - Pengantar Manajemen Operasinindi rahmasariAinda não há avaliações

- Form Registrasi SKADocumento4 páginasForm Registrasi SKARobbie BieberAinda não há avaliações

- Export PlpoDocumento85 páginasExport PlpoIbrahimAinda não há avaliações

- Bakuan PKBDocumento17 páginasBakuan PKBirbasukirahardjocesAinda não há avaliações

- Formulir Aplikasi PDFDocumento16 páginasFormulir Aplikasi PDFIbrahimAinda não há avaliações

- Ekma5310 TM PDFDocumento3 páginasEkma5310 TM PDFIbrahimAinda não há avaliações

- OSM Inovasi Bisnis WiratmanDocumento3 páginasOSM Inovasi Bisnis WiratmanIbrahimAinda não há avaliações

- CPD Standard ActivitiesDocumento19 páginasCPD Standard ActivitiesKristian Dwi SancokoAinda não há avaliações

- Modul1 Ekma5309-M1 PDFDocumento31 páginasModul1 Ekma5309-M1 PDFKusnadiAinda não há avaliações

- Dasar Manajemen InvestasiDocumento34 páginasDasar Manajemen InvestasisingatesAinda não há avaliações

- ISO Technical Codification PDFDocumento170 páginasISO Technical Codification PDFMayo de la Paz0% (1)

- Biaya2015 PDFDocumento5 páginasBiaya2015 PDFSenos SudrajatAinda não há avaliações

- Ekma5312 TM PDFDocumento2 páginasEkma5312 TM PDFIbrahimAinda não há avaliações

- Ekma5311 DiDocumento3 páginasEkma5311 DijustilhamAinda não há avaliações

- Ekma5208 TM PDFDocumento3 páginasEkma5208 TM PDFIbrahimAinda não há avaliações

- Ekma5310 M1 PDFDocumento11 páginasEkma5310 M1 PDFIbrahimAinda não há avaliações

- MO1-PengantarMODocumento44 páginasMO1-PengantarMOEndang SusilawatiAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)