Escolar Documentos

Profissional Documentos

Cultura Documentos

Mycourses

Enviado por

api-295648195Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Mycourses

Enviado por

api-295648195Direitos autorais:

Formatos disponíveis

COMP1017 Computer Applications

Students are introduced to Microsoft applications such as Outlook (email),

PowerPoint, Microsoft Word and Excel. Students learn how to use the Internet

and understand the use of a maintenance management system. Within the

course, students are equipped with job searching techniques, interview skills

and will prepare a cover letter and rsum.

WELD1002 Layout & Fitting 1

Students focus on the use and application of equipment, tools, fasteners and

processes used in fabrication practices in the welding industry. Students will

interpret plans for the actual fabrication of small projects. Students will

develop techniques for layout, fitting, squaring, tacking and fabricating.

SAFE1003 Occupational Health & Safety

Students learn the rights and responsibilities of the various stakeholders

under the Occupational Health and Safety Act (OHSA). Specific topics

associated with the four main types of hazards found in workplaces (physical,

biological, ergonomic and chemical) are covered. Where possible and

practical, in addition to theory-based classes, students are involved in

practical hands-on activities. WHMIS legislation is also introduced.

MATH1027 Technical Math 1 (WELT)

In this course, students demonstrate basic analytical skills and they are

prepared for further studies in mathematics. Topics include basic number

systems and operations, units and measurement, basic algebraic operations,

geometry and solving word problems.

WELD1000 Welding 1

This course focuses on the various fabrication processes. Oxyacetylene

welding, brazing, cutting, Shielded Metal Arc Welding (S.M.A.W.), Gas Metal

Arc Welding (G.M.A.W.) Gas Tungsten Arc Welding (G.T.A.W.) in the flat and

horizontal positions and includes the safety procedures and the electrode

identification will be studied.

WELD1001 Welding Theory 1

Students learn an introduction to the theory and practice of welding,

providing a strong background in the various fabrication processes. The

course will cover oxyacetylene welding, brazing, cutting, G.M.A.W. (Gas Metal

Arc Welding) and S.M.A.W. (Shielded Metal Arc Welding).

WELD1005 Layout & Fitting 2

Students learn the advanced interpretation of drawing and symbols for the

actual fabrication of large projects. Techniques for layout, fitting, squaring,

tacking, welding and fabricating will be practised.

Prerequisite: WELD1002

WELD1006 Metallurgy 1

This course focuses on studying different metals and how they react to

welding, distortion and stress. Students examine types of steel and the

proper welding methods and electrode filler metals to be used. Different

destructive and non-destructive testing will be performed along with an

introduction to welding inspection.

MATH1028 Technical Math 2 (WELT)

Students consolidate the skills in arithmetic, algebra, solving equations,

trigonometry and graphical analysis to solve problems used in technological

applications.

Prerequisite: MATH1027 or MATH1026

WELD1003 Welding 2

Students learn Shielded Metal Arc Welding (S.M.A.W.), Gas Metal Arc Welding

(G.M.A.W.) and Gas Tungsten Arc Welding (G.T.A.W.) in the vertical and

overhead positions. Students also learn different fitting techniques and will

gain the skills and knowledge necessary to prepare them for the Canadian

Welding Bureau Certification at the end of the second semester. Full-size

robot welders and instruction on programming and manipulation associated

with robotics will be introduced.

Prerequisite: WELD1000

WELD1004 Welding Theory 2

Students are introduced to Flux-Cored Arc Welding and Metal-Cored Arc

Welding, Shielded Metal Arc Welding of groove welded joints, robotics,

automation, and production welding processes. Classification of weld faults,

weldability of alloys, and welding codes and standards are explored. Students

participate in the discussion and calculation of structural steel cutting

processes.

Prerequisite: WELD1001

GNED General Education Elective

General Education Courses

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Exam SlidesDocumento7 páginasExam Slidesapi-295647769Ainda não há avaliações

- ExamDocumento1 páginaExamapi-295647769Ainda não há avaliações

- Synopsi 1Documento1 páginaSynopsi 1api-295647769Ainda não há avaliações

- SynopsisDocumento1 páginaSynopsisapi-295647769Ainda não há avaliações

- Bussiness CardDocumento1 páginaBussiness Cardapi-295647769Ainda não há avaliações

- Prospectors Findings: On Community Responses To The Mining SectorDocumento1 páginaProspectors Findings: On Community Responses To The Mining Sectorapi-295647769Ainda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Arita KatalogDocumento58 páginasArita KatalogAhmed Beaet83% (6)

- Joining ProcessDocumento122 páginasJoining ProcessJackson ..Ainda não há avaliações

- Seametrics EF MF TF Pipe Fittings ModelsDocumento23 páginasSeametrics EF MF TF Pipe Fittings ModelsPromagEnviro.comAinda não há avaliações

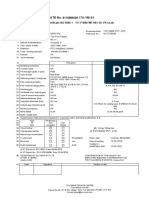

- Certificate No. / 74 / W/ 01: Welder S Certificate ISO 9606-1 111 P BW FM1 RB T 20 PA SS, NBDocumento1 páginaCertificate No. / 74 / W/ 01: Welder S Certificate ISO 9606-1 111 P BW FM1 RB T 20 PA SS, NBDeepak Das100% (1)

- Product Brochure Zincalume1 PDFDocumento2 páginasProduct Brochure Zincalume1 PDFRamius HamdaniAinda não há avaliações

- Astm A572-A572m-06Documento4 páginasAstm A572-A572m-06NadhiraAinda não há avaliações

- A434 03Documento1 páginaA434 03asepoAinda não há avaliações

- TriMarkCatalog Filler MaterialDocumento50 páginasTriMarkCatalog Filler MaterialSuphi YükselAinda não há avaliações

- Thermodynamic Analysis of Zinc Ferrite ZnFe2O4 Formation InsideDocumento16 páginasThermodynamic Analysis of Zinc Ferrite ZnFe2O4 Formation InsideFatemeh RezaeiAinda não há avaliações

- Active Standard ASTM A694 / A694M: Steel StandardsDocumento3 páginasActive Standard ASTM A694 / A694M: Steel Standardshemant_solanki78940% (1)

- Work Shop Layout by MeDocumento1 páginaWork Shop Layout by Mejanrel sedorifaAinda não há avaliações

- Electrode Equivalaent NumbersDocumento2 páginasElectrode Equivalaent NumbersRamdas100% (2)

- Assessing Corrosion in Oil Refining and Petrochemical Processing John Pelton EtalDocumento12 páginasAssessing Corrosion in Oil Refining and Petrochemical Processing John Pelton EtalNabil Al-Khirdaji100% (1)

- Titanium and Titanium AlloysDocumento30 páginasTitanium and Titanium AlloysJay VoraAinda não há avaliações

- Pumps HighPressureDrainage D42AB D53AB DatasheetDocumento2 páginasPumps HighPressureDrainage D42AB D53AB DatasheetMohammad ZeeshanAinda não há avaliações

- List of EN StandardsDocumento22 páginasList of EN StandardsVinay ShrivastavaAinda não há avaliações

- 2012 BSC Junior Paper and AnswersDocumento22 páginas2012 BSC Junior Paper and AnswersBai LiAinda não há avaliações

- 2008 March 4 Acetaldehyde From Ethylene OxidationDocumento4 páginas2008 March 4 Acetaldehyde From Ethylene OxidationameymurudkarAinda não há avaliações

- Improving The Rigidity of Sheet Metal by Embossing and PDFDocumento10 páginasImproving The Rigidity of Sheet Metal by Embossing and PDFalexcus1539Ainda não há avaliações

- Zollern BHW Criteria of JudgementDocumento16 páginasZollern BHW Criteria of Judgementsezio81100% (1)

- BS 1449 PT 1 Sec 1 - 9 1991 Cold Rolled S - S by BS EN 10139Documento12 páginasBS 1449 PT 1 Sec 1 - 9 1991 Cold Rolled S - S by BS EN 10139Fu Ki chunAinda não há avaliações

- Materials For High-Temperature and High-Pressure ValvesDocumento107 páginasMaterials For High-Temperature and High-Pressure ValvesKevin Drumm100% (1)

- Manual de Mantenimiento de Cadenas Table TopDocumento44 páginasManual de Mantenimiento de Cadenas Table TopMiguel Molina MendezAinda não há avaliações

- Stainless Steels 410: MartensiticDocumento2 páginasStainless Steels 410: MartensiticKiranAinda não há avaliações

- Steel Section Design PFCDocumento16 páginasSteel Section Design PFCRajeev SharanAinda não há avaliações

- PRESENTATION Comparison Stud Welding With Spot WeldingDocumento5 páginasPRESENTATION Comparison Stud Welding With Spot WeldingFaiz IshakAinda não há avaliações

- Bodies and Cavities Technical TipsDocumento7 páginasBodies and Cavities Technical TipsMahardika PrananditoAinda não há avaliações

- 1.4404 Material & Low Carbon Austenite Stainless SteelDocumento5 páginas1.4404 Material & Low Carbon Austenite Stainless SteelSM Waqas ImamAinda não há avaliações

- Iso 11970 2016 en PDFDocumento8 páginasIso 11970 2016 en PDFKamal ThummarAinda não há avaliações

- BurrDocumento9 páginasBurrOmsri VinashaAinda não há avaliações