Escolar Documentos

Profissional Documentos

Cultura Documentos

STD Insp Procedure (Wirebrushed)

Enviado por

benjiy800 notas0% acharam este documento útil (0 voto)

8 visualizações2 páginasSurface Preparation

Título original

Std Insp Procedure (Wirebrushed)

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoSurface Preparation

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

8 visualizações2 páginasSTD Insp Procedure (Wirebrushed)

Enviado por

benjiy80Surface Preparation

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 2

STANDARD INSPECTION PROCEDURE (WIREBRUSHING)

A. BEFORE WIREBRUSHING

WHAT TO INSPECT

STEELWORK

B. DURING WIREBRUSHING

WHAT TO INSPECT

MEASURE AND

RECORD WEATHER |

‘CONDITION

INSPECTION OF >

WHAT TO LOOK FOR

i Condition of Rust - Grades A, B,C, D

Ti. Oilor grease - solvent wipe in

accordance with SSPC- SPI

ii, Sharp edges, weld slag - grind off or

chip off

WHAT TO LOOK FOR

Measure and record weather condition - dew

point, relative Inumidity, steel surface

temperature. No wirebrushing shall be

allowed if steel temperature is not at least 3°C

above dew point

~

Standards achieved - visual comparison using

INSPECTION OF a

NSPECTIONOF |e Sesh Pra Sind 813150 89011

1988

NOTE

1 No wirebrushing to be allowed if relative humidity is above 85% (Whirling

Hygrometer may be used) and steel surface temperature (using Magnetic Contact

Thermometer) is less than ¥C above dew point (using Dew Point

Caleulator/Chart),

Wirebrushed steel surfaces are preferably primed within 6 hours at normal

weather condition provided that no abrupt change in weather conditions (rust

blooming)

Wirebrushed surfaces left uncoated overnight shall receive a complete light

wirebrushing the next day before coating

NIPPON PAINT (M) SDN. BHD. (7516-1

Lot -17, Taman Perindusran Subang Utama, Jalan SU 4, 40300 Shah Alam, RO. Box 7027, 40700 Shah Alan

Selangor Darul Ehsan, Malaysia, Tl 603-51250888 Fax: 602-51914849

Email: ta@msia.sippanpaint.com

[A MEMBER OF THE NIPSEA GROUP

STANDARD INSPECTION PROCEDURE (WIREBRUSHING)

AFTER WIREBRUSHING

WHAT TO INSPECT WHAT TO LOOK FOR

CHECK WEATHER > No coating to be applied if steel temperature is

CONDITION less than 3°C above dew point

INSPECTION OF p> |i Sharp edges wo be removed by

STEELWORK Sanding down/grinding.

i, Dust free surface - t Blow off

dust

iii, Dust/potiution free environment t0 be

applied when wirebrushing work is

carried out nearby.

WITHIN 6 HOURS

S OF PAINT

| CHECK APPLICATION

| TOOLS/SKILL OF

PAINTER

ARTER APPLICATION AND WHEN DRY

Application tools, technique used, oil spots,

over spray, dry spray, continuity of film build

in coat, drying time, wet film thickness, etc.

PHYSICAL CHECK ON

DRY PAINT FILM

>

Dry film thickness, misses and coating defects,

including blisters, cracking, bubbling, flaking

and/or lifting etc.

NIPPON PAINT (M) SDN. BHD. (7516-4)

Lot +17, Taman Perindustian Subang Utama, Jlan U4, 40300 Shah Alam, PO. Box 7027, 40700 Shah Alam

Selangor Darul Ehsan, Malaysia. Tel 60351250888 Far: 603-51914849

Email: psa iponpaint com

|A MEMBER OF THE NIPSEA GROUP

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- SOP - Chill Water Chemistry Management Rev ADocumento12 páginasSOP - Chill Water Chemistry Management Rev Abenjiy80Ainda não há avaliações

- Yamaha Av ReceiverDocumento20 páginasYamaha Av Receiverbenjiy80Ainda não há avaliações

- Anaerobic Digestion of SewageDocumento7 páginasAnaerobic Digestion of Sewagebenjiy80Ainda não há avaliações

- Aviation Safety World Magazine - Oct06Documento68 páginasAviation Safety World Magazine - Oct06Harry NuryantoAinda não há avaliações

- Application of Ponding Systems in The Treatment ofDocumento10 páginasApplication of Ponding Systems in The Treatment ofbenjiy80Ainda não há avaliações

- Additive 166Documento2 páginasAdditive 166santoshkumartata1Ainda não há avaliações

- Safety Signage StandardizationDocumento13 páginasSafety Signage Standardizationbenjiy80Ainda não há avaliações

- Grundfos LiteratureDocumento36 páginasGrundfos Literaturebenjiy80Ainda não há avaliações

- Cable GlandDocumento2 páginasCable Glandbenjiy80100% (1)

- 05 CDM Specialist Training Rev01Documento18 páginas05 CDM Specialist Training Rev01benjiy80Ainda não há avaliações

- 22 MOE ReportDocumento9 páginas22 MOE Reportbenjiy80Ainda não há avaliações

- Guiding Your Way To Correct Chiller PipingDocumento5 páginasGuiding Your Way To Correct Chiller Pipingbenjiy80Ainda não há avaliações

- CDM Chapter 2Documento16 páginasCDM Chapter 2benjiy80Ainda não há avaliações

- Bomba BLESS SeminarDocumento5 páginasBomba BLESS Seminarbenjiy80Ainda não há avaliações

- Boiler MaintenanceDocumento36 páginasBoiler Maintenancebenjiy80Ainda não há avaliações

- Felda Palm Oil Mill ContactDocumento4 páginasFelda Palm Oil Mill Contactbenjiy80Ainda não há avaliações

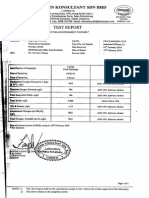

- Test Report: Chemsain Konsultant SDN BHDDocumento1 páginaTest Report: Chemsain Konsultant SDN BHDbenjiy80Ainda não há avaliações

- Biogas From Sewage Sludge To Be Supplied As City Gas: 2010.02.03 Wed - Posted by JfsDocumento1 páginaBiogas From Sewage Sludge To Be Supplied As City Gas: 2010.02.03 Wed - Posted by Jfsbenjiy80Ainda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)