Escolar Documentos

Profissional Documentos

Cultura Documentos

Carbide End Mill Feeds and Speeds TuffCut XR 177 Metric

Enviado por

Алексей ЗубковDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Carbide End Mill Feeds and Speeds TuffCut XR 177 Metric

Enviado por

Алексей ЗубковDireitos autorais:

Formatos disponíveis

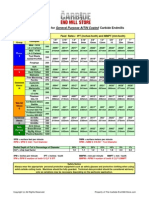

End Mills Technical Information

Series 177/179 Metric

Slotting

Coolant

Workpiece

Material

Group

25% Axial 50% Axial

Examples

1 x Diameter Axial Depth

Proling

Small Radial Depth ===========> Largest Radial Depth

1% of

5% of

10% of

15% of

20% of

30% of

50% of

Dia.

Dia.

Dia.

Dia.

Dia.

Dia.

Dia.

Steels

Technical Information

Stainless

M

Steels

Special

Alloys

Cast

Irons

Free Machining

Low Carbon

Medium Carbon

Alloy Steels

High Strength Alloys

Structural Steels

Die/Tool Steels

Free Machining

Moderate Stainless

Difcult Stainless

PH Stainless

Cobalt Chrome Alloys

Duplex (22%)

Super Duplex (25%)

High Temp Alloys

Titanium Alloys

Gray Cast Iron

SG Iron

Ductile Cast Iron

Malleable Iron

MMS

Type

x

x

x

x

x

x

x

x

x

x

x

150

150

90

75

75

150

60

90

75

60

40

45

40

30

45

55

120

105

90

90

Preferred

Possible

x Not Possible

150

150

90

75

75

150

60

90

75

60

40

45

40

30

45

55

120

105

90

90

730

730

335

150

150

730

120

150

150

105

75

75

75

60

75

125

450

365

150

120

SMM

620

620

290

130

130

620

115

140

115

95

75

75

75

55

75

115

400

320

140

110

685

685

310

140

140

685

115

145

115

100

75

75

75

60

75

120

430

345

145

115

565

565

260

130

130

565

110

135

110

90

70

70

70

55

70

105

360

295

130

105

500

500

240

120

120

500

110

130

105

90

70

70

70

50

60

100

335

275

130

105

Examples

Stainless

Steels

Free Machining

Moderate Stainless

Difcult Stainless

PH Stainless

Cobalt Chrome Alloys

Duplex (22%)

Super Duplex (25%)

Special Alloys

Steels

10

12

16

18

25

.066

.066.083

.078.088

.088.129

Should the Calculated

Spindle Speed be more than

your actual Spindle Max.,

Use Formula Below:

Calculated Feed x Spindle Max.

.005

.010

.017

.025.040

.033.053

.040

.005

.010

.017

.025.040

.033.053

.040

.066

.066.083

.078.088

.088.129

High Temp Alloys

.002

.005

.020

.012.020

.017.027

.017.033

.025.040

.025.043

.027.045

.030.050

Gray Cast Iron

SG Iron

Ductile Cast Iron

Malleable Iron

.005

.010

.017

.017.040

.025.055

.038.071

.045.083

.060.088

.071.099

.060.127

Titanium Alloys

Cast Irons

150

150

90

75

75

150

60

90

75

60

40

45

40

30

45

55

120

105

90

90

Spindle Max.

mm/Tooth

Free Machining

Low Carbon

Medium Carbon

Alloy Steels

High Strength Alloys

Structural Steels

Die/Tool Steels

380

380

180

105

105

380

90

115

95

75

60

60

60

45

55

80

250

215

115

100

If axial depth is less than the ball diameter, the speed

is gured using the effective cutting diameter.

Tool Diameter (mm)

Workpiece Material

Group

Series 177/179 Metric

Air

Max

Example: Prole Milling

1) Select Material from chart.

2) Select Tool Size.

3) Select feed per tooth.

4) Figure percentage of clutter Diameter Radial Cut Depth.

5) Select Chip Load Factor for Radial Depth.

6) Multiply Chip Load Factor x Feed per Tooth.

7) Answer: New Feed per Tooth.

8) RPM x New Feed per Tooth x number of Teeth = mm/min

(Millimeters per Minute)

Example:Slotting

1) Select Material from chart.

2) Select Tool Size.

3) Select feed per tooth from chart.

4) Multiply Feed per Tooth x Number of Teeth x RPM.

5) Answer: mm/min (Millimeters per Minute)

Calculated Speed

During Prole Milling less

than 50% of the cutter

diameter radial depth,

the actual chipload at the

cutting edge is less than

the programmed chip load.

Below are Chip Load factors

depending on Radial Depth

Percentage. Multiply your

inches per tooth by the factor

before guring your IPM.

Radial Depth in

Percentage of

Cutter Diameter

50%

30%

Increase Chip

Load Factor

20%

15%

10%

5%

1%

M.A. Ford Phone: 800-553-8024 or 563-391-6220 email: sales@maford.com www.maford.com

1.00

1.10

1.20

1.40

1.80

2.30

5.00

222

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Fanuc 5 AxisDocumento192 páginasFanuc 5 AxisKiên Trung NguyễnAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- ShopWare Webinar 2021 Mill Only Rollout CondensedDocumento18 páginasShopWare Webinar 2021 Mill Only Rollout CondensedАлексей ЗубковAinda não há avaliações

- Mastercam 2017 Overview & Introduction Presenter: Matt SumpDocumento41 páginasMastercam 2017 Overview & Introduction Presenter: Matt SumpАлексей ЗубковAinda não há avaliações

- Carbide End Mill Feeds and Speeds General Purpose AlTiNDocumento1 páginaCarbide End Mill Feeds and Speeds General Purpose AlTiNАлексей ЗубковAinda não há avaliações

- 101 - Beginning FeatureCAMDocumento23 páginas101 - Beginning FeatureCAMАлексей ЗубковAinda não há avaliações

- 102 - Features and SetupsDocumento23 páginas102 - Features and SetupsАлексей ЗубковAinda não há avaliações

- Rexroth IndraMotion MTX Micro MTX Micro Trainer Milling - First StepsDocumento58 páginasRexroth IndraMotion MTX Micro MTX Micro Trainer Milling - First StepsАлексей ЗубковAinda não há avaliações

- Mastercam 2019 How To Tips PDFDocumento374 páginasMastercam 2019 How To Tips PDFАлексей Зубков100% (1)

- 102 - Snapping and GeometryDocumento41 páginas102 - Snapping and GeometryАлексей ЗубковAinda não há avaliações

- 100 - Introduction To FeatureCAMDocumento6 páginas100 - Introduction To FeatureCAMАлексей ЗубковAinda não há avaliações

- PS2010 Wireframe ModellingDocumento223 páginasPS2010 Wireframe ModellingАлексей ЗубковAinda não há avaliações

- 101 - Intro To 5-Axis PositioningDocumento24 páginas101 - Intro To 5-Axis PositioningАлексей ЗубковAinda não há avaliações

- Delcam CopyCAD ProDocumento74 páginasDelcam CopyCAD ProАлексей Зубков100% (1)

- PS2010 - Modelling ConceptsDocumento244 páginasPS2010 - Modelling ConceptsАлексей ЗубковAinda não há avaliações

- PS-Delcam Crispin SoleDesignDocumento86 páginasPS-Delcam Crispin SoleDesignАлексей Зубков100% (1)

- PowerINSPECTv5 TrainingNotesDocumento170 páginasPowerINSPECTv5 TrainingNotesАлексей Зубков67% (3)

- Customising Power SHAPE For Your ApplicationDocumento234 páginasCustomising Power SHAPE For Your ApplicationАлексей Зубков100% (2)

- Fanuc O Series Lathe Parameter ManualDocumento174 páginasFanuc O Series Lathe Parameter ManualАлексей Зубков100% (3)

- Fanuc Operator Manual 31iDocumento174 páginasFanuc Operator Manual 31iClaudintoshAinda não há avaliações

- Post Processor ListDocumento2 páginasPost Processor ListDannish R Lailan100% (2)

- MastercamX DesignDocumento128 páginasMastercamX DesignАлексей ЗубковAinda não há avaliações