Escolar Documentos

Profissional Documentos

Cultura Documentos

PIRT NDT Basic Formulae11b

Enviado por

eldobie3100%(1)100% acharam este documento útil (1 voto)

129 visualizações2 páginasLevel 3 basic

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoLevel 3 basic

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(1)100% acharam este documento útil (1 voto)

129 visualizações2 páginasPIRT NDT Basic Formulae11b

Enviado por

eldobie3Level 3 basic

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

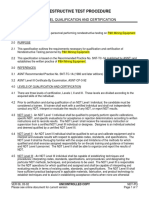

PIRT

NDT LEVEL III

NDT Basic

1. Stress = Load / Initial cross -sectional area

where Stress [psi]

Load [pound]

Initial or original cross-sectional area [sq. inch]

2. Percent elongation = [ (Lf Lo) / Lo ] x 100

where Lf = final gage length

Lo = original gage length

3. N = 2 (n-1)

where N = Number of grains per square inch at 100X magnification

n = ASTM grain size number

4. Fracture toughness of material (K1C)

K1C = stress x ( 3.14 x flaw size )1/2

5. Tensile Strength (TS)

TS = Load / Specimens original cross-sectional area

where TS [psi]

Load [pound]

Specimens original cross-sectional area [sq. inch]

6. Ultimate Tensile Strength (UTS)

UTS = Pmax / Area

= Load to break specimen / Specimens original cross-sectional area

7. Yield Strength (YS)

YS = Load at specified off-set / Specimens original cross-sectional area

PIRT

8. Safety factor = UTS / Allowable design stress

9. Carbon Equivalent (CE)

CE = % C + % Mn/ 6) + % Ni/ 15 + % Cu/ 13 + % Mo/ 14

10. Area of circle = r2 = d2 /4 = 0.7854 x d2

Prepared by:

PRAVEEN INSTITUTE OF RADIATION TECHNOLOGY

(NDT TRAINING DIVISION)

CHENNAI- 600 063

INDIA

www.pirtchennai.com

Tel: +91- 9940167870, 9789094060

E-mail: pirtndt@yahoo.in

2.1

Você também pode gostar

- Industrial radiography A Complete Guide - 2019 EditionNo EverandIndustrial radiography A Complete Guide - 2019 EditionAinda não há avaliações

- Pirt Asnt NDT Leiii Basic QB Solution11bDocumento5 páginasPirt Asnt NDT Leiii Basic QB Solution11beldobie3100% (2)

- Basc QB 2Documento3 páginasBasc QB 2prabhakaran.SAinda não há avaliações

- SSIS VT Procedure Rev 0 25112011Documento14 páginasSSIS VT Procedure Rev 0 25112011Salman KhanAinda não há avaliações

- Basic Total Questions: 135 Time: 4 HRDocumento6 páginasBasic Total Questions: 135 Time: 4 HRprabhakaran.SAinda não há avaliações

- Level III ReferencesDocumento2 páginasLevel III ReferencesCheeragAinda não há avaliações

- Asnt-Tc1a Cambios PDFDocumento20 páginasAsnt-Tc1a Cambios PDFwiAinda não há avaliações

- ASNTDocumento6 páginasASNTlara_rajkumar667Ainda não há avaliações

- NDT-PQ PDFDocumento7 páginasNDT-PQ PDFMiguel RodriguezAinda não há avaliações

- BASIC Q Nov'12 Note: All Answers May Not Be Correct & Need To Be Correct Yourself. Material & ProcessingDocumento4 páginasBASIC Q Nov'12 Note: All Answers May Not Be Correct & Need To Be Correct Yourself. Material & ProcessingSrinivasan Banu AvsAinda não há avaliações

- Asnt Recer RT QB Level IDocumento9 páginasAsnt Recer RT QB Level IkingstonAinda não há avaliações

- NDT MT Formulae11aDocumento3 páginasNDT MT Formulae11aShahidAinda não há avaliações

- BA ExamDocumento7 páginasBA Examalouis0% (1)

- ASNT Level IIIDocumento17 páginasASNT Level IIIryearly100% (1)

- ASNT Level 3 Course BrochureDocumento1 páginaASNT Level 3 Course Brochuresdaniel1979Ainda não há avaliações

- Quizelets PDFDocumento9 páginasQuizelets PDFdiwakarAinda não há avaliações

- Ansa India Information Package Level 3Documento8 páginasAnsa India Information Package Level 3manoj kumar sarojAinda não há avaliações

- LPT Spe QB 2Documento6 páginasLPT Spe QB 2Aruchamy SelvakumarAinda não há avaliações

- NDT Training BrochureDocumento4 páginasNDT Training BrochureSafiq UddinAinda não há avaliações

- SNT-TC-1A Vs cp-189Documento7 páginasSNT-TC-1A Vs cp-189safeer ahmadAinda não há avaliações

- Level III NDT Basic Topical OutlineDocumento2 páginasLevel III NDT Basic Topical OutlineMohamed IbrahimAinda não há avaliações

- Digital Radiography ReportDocumento7 páginasDigital Radiography ReportadityaromasAinda não há avaliações

- Comparison Between Ansi/Asnt CP 189 and Asnt Recommended Practice SNT TC 1ADocumento3 páginasComparison Between Ansi/Asnt CP 189 and Asnt Recommended Practice SNT TC 1AsantanuriniAinda não há avaliações

- Pirt Asnt NDT Leiii RT QB 250 09cDocumento36 páginasPirt Asnt NDT Leiii RT QB 250 09cJose J. Nuñez100% (1)

- Carlos Correia Materials Evaluation Project - ASNT NDT LEVEL III BASIC and UT METHOD ExaminationsDocumento3 páginasCarlos Correia Materials Evaluation Project - ASNT NDT LEVEL III BASIC and UT METHOD ExaminationsJayaneela PrawinAinda não há avaliações

- Basic Examinations ExamDocumento2 páginasBasic Examinations ExamSandro ChiliquingaAinda não há avaliações

- 1975Documento10 páginas1975ibnu.asad984Ainda não há avaliações

- ASNT Level III AnnouncementDocumento4 páginasASNT Level III AnnouncementSelvaraj MaduraiAinda não há avaliações

- Neutron RadiographyDocumento5 páginasNeutron RadiographyMohammed Al-leswasAinda não há avaliações

- Level Iii Prep PDFDocumento2 páginasLevel Iii Prep PDFRamdasAinda não há avaliações

- Astron: MFL Testing Procedure For Tank FloorDocumento16 páginasAstron: MFL Testing Procedure For Tank FloorleonciomavarezAinda não há avaliações

- Ultrasonic ExaminationDocumento14 páginasUltrasonic ExaminationLiliAinda não há avaliações

- Asnt Level III Study NoteDocumento2 páginasAsnt Level III Study NoteDESTINY SIMONAinda não há avaliações

- Paut Calibration Summary Both-Single Side (CS & SS)Documento20 páginasPaut Calibration Summary Both-Single Side (CS & SS)prabhu_trichyAinda não há avaliações

- Neutron RadiographyDocumento29 páginasNeutron RadiographyKaitlyn SmallfootAinda não há avaliações

- NDT PT (NSH Procedure)Documento9 páginasNDT PT (NSH Procedure)Midhun K ChandraboseAinda não há avaliações

- Level III Preparations Study Plan Basic RT and MTDocumento2 páginasLevel III Preparations Study Plan Basic RT and MTjasminnee50% (2)

- Neutron Radiography: What Is NDT?Documento4 páginasNeutron Radiography: What Is NDT?mohamedAinda não há avaliações

- PAUT of ''CRA WELDSDocumento7 páginasPAUT of ''CRA WELDSDurgamadhaba Mishra100% (1)

- Introduction To ECT - OKDocumento57 páginasIntroduction To ECT - OKMan Nguyen TheAinda não há avaliações

- Product TechnologyDocumento138 páginasProduct TechnologyRaja SekarAinda não há avaliações

- Ultrasonic Inspection 2Documento21 páginasUltrasonic Inspection 2pktienAinda não há avaliações

- PT Theory English New 2014Documento44 páginasPT Theory English New 2014CRISTIAN SILVIU IANUCAinda não há avaliações

- Introduction To Ultrasonic Thickness MeasurementDocumento18 páginasIntroduction To Ultrasonic Thickness MeasurementNail Widya Satya100% (1)

- Differences SNTC&CP189Documento15 páginasDifferences SNTC&CP189Ali Alhaik100% (1)

- PT Level IDocumento216 páginasPT Level IhocimtmAinda não há avaliações

- Bio DataDocumento5 páginasBio DataArun KumarAinda não há avaliações

- Question For Basic by GJDocumento53 páginasQuestion For Basic by GJravindra_jivaniAinda não há avaliações

- VPS WP 01 Written Practice Rev 00Documento29 páginasVPS WP 01 Written Practice Rev 00virenckananiAinda não há avaliações

- NDT Forum - NAS410 - EN4179 RT and UT Level 2 and 3Documento1 páginaNDT Forum - NAS410 - EN4179 RT and UT Level 2 and 3Muhammad SyafiqAinda não há avaliações

- ASNT Level II 2011Documento1 páginaASNT Level II 2011Karthik KarunanidhiAinda não há avaliações

- Manual For Liquid Penetrant Testing at Level-2: March, 2017Documento123 páginasManual For Liquid Penetrant Testing at Level-2: March, 2017safeer ahmadAinda não há avaliações

- Changes in ASTM E 1444Documento5 páginasChanges in ASTM E 1444Vicky SinghAinda não há avaliações

- L3 Training Requirements NAS & enDocumento1 páginaL3 Training Requirements NAS & enPrzemyslawAinda não há avaliações

- Radiation Safety Program 2Documento16 páginasRadiation Safety Program 2Ahmed shabanAinda não há avaliações

- NDT Certification Systems:: Written PracticeDocumento3 páginasNDT Certification Systems:: Written PracticeKhaled MeraashliAinda não há avaliações

- SNT TC 1a OverviewDocumento3 páginasSNT TC 1a OverviewNDT Training WorldWideAinda não há avaliações

- Experiment 4 - Testing of Materials in Tension: Engineering Stress (Lbs/inDocumento4 páginasExperiment 4 - Testing of Materials in Tension: Engineering Stress (Lbs/inneel12321Ainda não há avaliações

- Calculation For Lifting Lug On Channel Shell: Provided Thickness Is More Than Required ThicknessDocumento6 páginasCalculation For Lifting Lug On Channel Shell: Provided Thickness Is More Than Required ThicknessErin JohnsonAinda não há avaliações

- Method of Statement For Hydro Test ProcedureDocumento11 páginasMethod of Statement For Hydro Test Procedureeldobie3100% (1)

- Preparation of PartDocumento2 páginasPreparation of Parteldobie3Ainda não há avaliações

- Ogpd-Lrf-Tr-00336 Tie-In Procedure ApproveDocumento2 páginasOgpd-Lrf-Tr-00336 Tie-In Procedure Approveeldobie3Ainda não há avaliações

- NDE PROCESS CONTROL Rev 1Documento15 páginasNDE PROCESS CONTROL Rev 1eldobie3Ainda não há avaliações

- Pene Trant Removal ProcessDocumento3 páginasPene Trant Removal Processeldobie3Ainda não há avaliações

- Dimensional Threshold of FluorescenceDocumento2 páginasDimensional Threshold of Fluorescenceeldobie3Ainda não há avaliações

- Introduction and History of Penetrant Inspection: Capillary ActionDocumento1 páginaIntroduction and History of Penetrant Inspection: Capillary Actioneldobie3Ainda não há avaliações

- PT BM 183 DC 00001 Itp BoilerDocumento5 páginasPT BM 183 DC 00001 Itp Boilereldobie30% (1)

- Developers: Developer FormsDocumento3 páginasDevelopers: Developer Formseldobie3Ainda não há avaliações

- Density or Specific GravityDocumento1 páginaDensity or Specific Gravityeldobie3Ainda não há avaliações

- Common Uses of Liquid Pene Trant InspectionDocumento2 páginasCommon Uses of Liquid Pene Trant Inspectioneldobie3Ainda não há avaliações

- Color and Fluorescent BrightnessDocumento2 páginasColor and Fluorescent Brightnesseldobie3Ainda não há avaliações

- PT BM 183 DC 00008 Preheat ProcedureDocumento5 páginasPT BM 183 DC 00008 Preheat Procedureeldobie3Ainda não há avaliações

- PT BM 183 DC 00007 PWHT ProcedureDocumento7 páginasPT BM 183 DC 00007 PWHT Procedureeldobie3100% (1)

- API 510 PC 20 31 Aug05 Final Open AnswerDocumento1 páginaAPI 510 PC 20 31 Aug05 Final Open Answereldobie3Ainda não há avaliações

- Api 510 Preparatory ExamDocumento13 páginasApi 510 Preparatory Exameldobie3100% (1)

- Pt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and ErectionDocumento5 páginasPt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and Erectioneldobie3100% (1)

- Wps 06Documento2 páginasWps 06eldobie3Ainda não há avaliações

- Wps 06Documento2 páginasWps 06eldobie3Ainda não há avaliações

- I.E.M.S.A.: Welding Procedure SpecificationDocumento2 páginasI.E.M.S.A.: Welding Procedure Specificationeldobie3Ainda não há avaliações

- I.E.M.S.A.: Welding Procedure SpecificationDocumento2 páginasI.E.M.S.A.: Welding Procedure Specificationeldobie3Ainda não há avaliações

- Real Life: Construction Management Guide from A-ZNo EverandReal Life: Construction Management Guide from A-ZNota: 4.5 de 5 estrelas4.5/5 (4)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyNo EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyNota: 4 de 5 estrelas4/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedNo EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedNota: 5 de 5 estrelas5/5 (1)

- A Place of My Own: The Architecture of DaydreamsNo EverandA Place of My Own: The Architecture of DaydreamsNota: 4 de 5 estrelas4/5 (242)

- Building Construction Technology: A Useful Guide - Part 1No EverandBuilding Construction Technology: A Useful Guide - Part 1Nota: 4 de 5 estrelas4/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionNo EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionNota: 4.5 de 5 estrelas4.5/5 (2)

- Estimating Construction Profitably: Developing a System for Residential EstimatingNo EverandEstimating Construction Profitably: Developing a System for Residential EstimatingAinda não há avaliações

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationNo EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettNota: 4 de 5 estrelas4/5 (1)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNo EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesAinda não há avaliações

- Civil Engineer's Handbook of Professional PracticeNo EverandCivil Engineer's Handbook of Professional PracticeNota: 4.5 de 5 estrelas4.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AAinda não há avaliações

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialAinda não há avaliações

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyNo EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyNota: 4 de 5 estrelas4/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideNo Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideNota: 3.5 de 5 estrelas3.5/5 (7)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsNo EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsNota: 1 de 5 estrelas1/5 (4)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsNo EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsNota: 3.5 de 5 estrelas3.5/5 (3)

- Construction Management: Document to Reduce RiskNo EverandConstruction Management: Document to Reduce RiskAinda não há avaliações

- Starting Your Career as a Contractor: How to Build and Run a Construction BusinessNo EverandStarting Your Career as a Contractor: How to Build and Run a Construction BusinessNota: 5 de 5 estrelas5/5 (3)

- An Architect's Guide to Construction: Tales from the Trenches Book 1No EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1Ainda não há avaliações

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishNo EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishNota: 4 de 5 estrelas4/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseNo EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseNota: 5 de 5 estrelas5/5 (3)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesNo EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesAinda não há avaliações