Escolar Documentos

Profissional Documentos

Cultura Documentos

Magnetic Flux Leakage MFL Inspection Limitations

Enviado por

Wigand Junior100%(2)100% acharam este documento útil (2 votos)

909 visualizações30 páginasTrabalho técnico

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoTrabalho técnico

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(2)100% acharam este documento útil (2 votos)

909 visualizações30 páginasMagnetic Flux Leakage MFL Inspection Limitations

Enviado por

Wigand JuniorTrabalho técnico

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 30

Magnetic Flux Leakage (MFL) Inspection Limitations

API 2009 Storage Tank Conference

Presentation

Aaron Lund

Regional Sales Manager of Gulf Coast

HMT Inc.

Dont Discard the Technology and go backwards

MFL is the Best

method to

evaluate a

tank bottom

condition

quickly and

cost effectively

All Limitations

Technology

Human (Training and experience)

Physical

Information on Technology Limitations

A lot of information has been available and presented on in

regards to technology limitations. However, the information

is not common to all brands and types of scanners, so it is

not without some controversy.

API has been trying to quantify these technology limitations

through a task group performing the re-write of nonmandatory Appendix G in API Standard 653 which call for

operator qualification testing and certification. This effort is

on-going but still has not happened thus far.

This presentation will identify most of the physical limitations

and offer some solutions to overcome those physical

limitations

Lets Talk about the Physical Limitations

Tank Bottom inspection preparation

Bottom Plate Lap Welds seams

Bottom Plate Shapes and Sizes (sketch plates)

Shell (corner weld) radius

Patch Plates

Tank Bottom Obstructions (columns / re-pads, internal

piping, etc.)

Edge Settlement

Uneven Bottom Plates peaks and valleys

Thick Reinforced Coating

Thick Annular Plates

Magnet and Sensor location

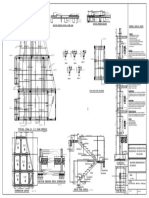

Bottom Plate Lap Weld Seams

Typical Full Sized MFL Scanner

Front to base

sensor = 10

Overall

Length = 36

Bridge Width = 12

Overall scanner width = 14

Limitation Zone

Corner Weld No Scan Zone

Sketch Plate Example

Typical Patch Plate

Typical Column with repad

Floating Roof Leg Striker Pad

Tank Bottom Obstructions

Solutions/Options

Following an informed risk assessment on limitations what

are your best options:

Do Nothing!!

Extensive Visual Exam (should already be standard in

any scope of work)

Vacuum Box Testing (leak detection only)

Helium Testing (leak detection only)

Manual Ultrasonic Scrubs (corrosion locator)

Hand/ Mini MFL Scanner (corrosion locator)

ACFM Crack Detection / Magnet Particle Examination

(surface breaking crack-like indications on welds only)

Patch Plate near lap seam hole/extensive visual exam

Vacuum Box Testing

Helium Testing - Equipment

Helium Testing Weld Seam Scanning

Manual/Mini Scanner Solution

Overall Scanner

length = 9

Front to back of

sensor bar = 6

Hand scanner width = 6

Scanner width = 6

Manual/Mini Scanner for Near Corner Weld

ACFM Crack Detection Equipment

HISTORY

This Technology was introduced in 1991.

The method was initially developed for offshore structures

Since then it has been applied to:

Theme Park Rides

Bridges

Ships

Petrochemical/Refinery Equipment

Tanks

APPLICATIONS

Weld inspection

Detection of Crack-like indications

Depth Sizing

Monitoring Dimensional Propagation

SURFACE PREPARATION

With the Magnetic Particle (MT) and Dye Penetrant Testing

(PT) Methods, the quality of the surface preparation is

critical to the ability of the method to detect

discontinuities.

This level of preparation is not required for electromagnetic

techniques as the method of detection is not based on the

migration of inspection media to the site of discontinuities.

SURFACE PREPARATION-Contd

Reduced surface preparation does not imply no preparation

The presence of ferromagnetic scale will impair the ability

of the method to identify discontinuities

However, the presence of surface rust will not significantly

impair the sensitivity of the test

Coatings-less than .200 does not need to be removed

ADVANTAGES

No set up Calibration required

Single direction deployment unlike MT

Inspection time is reduced

Data can be recorded for later comparison, review, or audit

CONCLUSION

ACFM has proven effective for:

Coated Components

Internal/External Shell-to-Bottom Welds

Internal Lap Welds

Sump Welds

After tank bottom replacement

When Stress Corrosion Cracking is suspected

This techniques provides consistent results - at a lower cost

In Summary

Be aware of real world Limitations that exist everyday

Make an informed risk assessment

Revise or develop a work scope for your inspection vendor

that addresses either:

All tanks

or

Specific to particular tanks based upon tank

characteristics, risk analysis or tank condition

Be informed of the technology/tools that can help

QUESTIONS?

Você também pode gostar

- In-Service NDT InspectionDocumento39 páginasIn-Service NDT InspectionRamakrishnan AmbiSubbiahAinda não há avaliações

- MFL Tank Floor Scanning 2009Documento28 páginasMFL Tank Floor Scanning 2009Justin Diraviraj100% (3)

- MFL ProcedureDocumento5 páginasMFL ProcedureNDTInstructor67% (3)

- Guide Wave Ultrasonic Pipe Test ProcedureDocumento10 páginasGuide Wave Ultrasonic Pipe Test ProcedurejeswinAinda não há avaliações

- Magnetic Flux Leakage Testing System and ServicesDocumento60 páginasMagnetic Flux Leakage Testing System and ServicesAlvaro Paredes100% (3)

- MFL Inspection r4 2Documento54 páginasMFL Inspection r4 2danteleonelmessi100% (2)

- MFL Inspection r4Documento54 páginasMFL Inspection r4Amritesh PandeyAinda não há avaliações

- Sims ManualDocumento76 páginasSims Manualjose ocanaAinda não há avaliações

- Inspection Techniques for Boiler TubesDocumento41 páginasInspection Techniques for Boiler Tubespstechnical_43312697100% (2)

- IRIS Setup Guide - EN PDFDocumento70 páginasIRIS Setup Guide - EN PDFpjhollowAinda não há avaliações

- MFL Techniques for Accurate Wire Rope TestingDocumento59 páginasMFL Techniques for Accurate Wire Rope Testingkingston67% (3)

- HSE - Recommended Practice For MFLDocumento108 páginasHSE - Recommended Practice For MFLMoisés MonteiroAinda não há avaliações

- Internal Rotary Inspection System (IRIS) Tubular TestingDocumento3 páginasInternal Rotary Inspection System (IRIS) Tubular Testingநந்த குமார் சம்பத் நாகராஜன்100% (1)

- TUBE INSPECTION by RFETDocumento8 páginasTUBE INSPECTION by RFETTusar Kole100% (1)

- ARTICLE - Remote Visual Inspection Basics (2010)Documento3 páginasARTICLE - Remote Visual Inspection Basics (2010)Sangameswaran RamarajAinda não há avaliações

- Introduction To Teletest Software: Ashley JolleyDocumento52 páginasIntroduction To Teletest Software: Ashley JolleyAsish desaiAinda não há avaliações

- SED - AUT Brochure Advanced NDTDocumento23 páginasSED - AUT Brochure Advanced NDTannmj17Ainda não há avaliações

- NDT MAGNETIC FLUX LEAKAGE LEVEL IIDocumento102 páginasNDT MAGNETIC FLUX LEAKAGE LEVEL IIsaenal rapi100% (2)

- Silverwing B Scan ReportDocumento46 páginasSilverwing B Scan ReportpjhollowAinda não há avaliações

- MFL PDFDocumento11 páginasMFL PDFJai Patel100% (1)

- Tubing Inspection Using Multiple NDT TechniquesDocumento7 páginasTubing Inspection Using Multiple NDT TechniquesRichard PeriyanayagamAinda não há avaliações

- Remote-Field Testing (RFT)Documento3 páginasRemote-Field Testing (RFT)shahgardezAinda não há avaliações

- RFTDocumento39 páginasRFTGustavo Adolfo Rondon Zabala100% (1)

- Advanced Tube Inspection Techniques and Their SelectionDocumento21 páginasAdvanced Tube Inspection Techniques and Their Selectionvibinkumars100% (1)

- Eddy Current Array TutorialDocumento13 páginasEddy Current Array TutorialsameerAinda não há avaliações

- ANDT InspectionsDocumento98 páginasANDT InspectionsHerris SimamoraAinda não há avaliações

- Rfet Analysis PDFDocumento20 páginasRfet Analysis PDFAfiq Hashim100% (1)

- Selection of NDT Techniques For Inspection of Heat Exchanger TubingDocumento7 páginasSelection of NDT Techniques For Inspection of Heat Exchanger Tubingநந்த குமார் சம்பத் நாகராஜன்100% (1)

- API 1104 PAUT Cal BlockDocumento2 páginasAPI 1104 PAUT Cal BlockWIZKHALIFA100% (2)

- Corrosion Mapping by UT & PADocumento24 páginasCorrosion Mapping by UT & PAInspection Engineer100% (2)

- P-003 Ultrasonic Testing ProcedureDocumento24 páginasP-003 Ultrasonic Testing ProcedureSaheb Yadav100% (2)

- TOFD Full Notes PDFDocumento80 páginasTOFD Full Notes PDFFaiz IshakAinda não há avaliações

- MFL Nava NDT Level III TipsDocumento5 páginasMFL Nava NDT Level III TipsShanmuga Navaneethan100% (1)

- PA-UT Presentation by All NationsDocumento57 páginasPA-UT Presentation by All NationsRamesh mudunuri100% (9)

- Euro NDT PresentationDocumento9 páginasEuro NDT PresentationBetoCordeiroAinda não há avaliações

- Ultrasonic ExaminationDocumento14 páginasUltrasonic ExaminationLiliAinda não há avaliações

- ASME V Art 8 EDDY CURRENT EXAMINATION OF TUBULAR PRODUCTSDocumento20 páginasASME V Art 8 EDDY CURRENT EXAMINATION OF TUBULAR PRODUCTSDiki yunika100% (4)

- Lrut 3Documento62 páginasLrut 3AbinashBeheraAinda não há avaliações

- PAUT of ''CRA WELDSDocumento7 páginasPAUT of ''CRA WELDSDurgamadhaba Mishra100% (1)

- FLOORMAP3Di-R High Speed MFL Floor Scanner with STARS Top & Bottom Defect DiscriminationDocumento6 páginasFLOORMAP3Di-R High Speed MFL Floor Scanner with STARS Top & Bottom Defect Discriminationjose ocanaAinda não há avaliações

- Inspection Manual For PipingDocumento183 páginasInspection Manual For PipingMartin Zaballa100% (3)

- Ultrasonic Thickness Measurement Procedure for Tank BottomsDocumento7 páginasUltrasonic Thickness Measurement Procedure for Tank BottomsShreekanthKannathAinda não há avaliações

- Industrial radiography A Complete Guide - 2019 EditionNo EverandIndustrial radiography A Complete Guide - 2019 EditionAinda não há avaliações

- Non-Destructive Testing: Proceedings of the 4th European Conference, London, UK, 13- 17 September 1987No EverandNon-Destructive Testing: Proceedings of the 4th European Conference, London, UK, 13- 17 September 1987Ainda não há avaliações

- Non-Destructive TestingNo EverandNon-Destructive TestingJ. BoogaardNota: 4 de 5 estrelas4/5 (7)

- Kline MFL LimitationsDocumento13 páginasKline MFL LimitationsJorge PerdigonAinda não há avaliações

- Inspection of Atmospheric Storage Tank BottomsDocumento23 páginasInspection of Atmospheric Storage Tank BottomsrajeshmohanaAinda não há avaliações

- INS - Alternating Current Field Measurement (ACFM)Documento2 páginasINS - Alternating Current Field Measurement (ACFM)Mehmet SoysalAinda não há avaliações

- Nondestructive Examination - 2013Documento97 páginasNondestructive Examination - 2013Armadi Putra100% (1)

- Phased Array Ulatrasonic IntroductionDocumento31 páginasPhased Array Ulatrasonic Introductionerharsingh100% (1)

- 2021-02-23 ICorr Aberdeen Event - Robert Hardy of Tracerco - Delivering Real Time Monitoring of Subsea PipelinesDocumento37 páginas2021-02-23 ICorr Aberdeen Event - Robert Hardy of Tracerco - Delivering Real Time Monitoring of Subsea PipelineshamidrezaettelaieAinda não há avaliações

- Pipe Line Girth WeldDocumento15 páginasPipe Line Girth WeldLương Hồ Vũ100% (1)

- Design For Manufacturability and TestabilityDocumento14 páginasDesign For Manufacturability and Testabilityjagadees21Ainda não há avaliações

- CASE STUDY (002) Bintang Aurora PDFDocumento14 páginasCASE STUDY (002) Bintang Aurora PDFbintangAinda não há avaliações

- Testing and Design-for-Testability (DFT) For Digital Integrated CircuitsDocumento95 páginasTesting and Design-for-Testability (DFT) For Digital Integrated Circuitsnagabhairu anusha100% (1)

- Wellbore Positioning and Quality ControlDocumento34 páginasWellbore Positioning and Quality ControlLaura Corleone SopranoAinda não há avaliações

- Casing Drilling Technical Conference: Overcoming Remaining GapsDocumento19 páginasCasing Drilling Technical Conference: Overcoming Remaining GapsRaul Alberto Miranda Loayza100% (1)

- OLEOBI SchedaTecnica ManifoldDocumento2 páginasOLEOBI SchedaTecnica ManifoldEdwin BonillaAinda não há avaliações

- Fracture Analysis and Corrosion Fatigue (1 of 4) 01-70Documento70 páginasFracture Analysis and Corrosion Fatigue (1 of 4) 01-70Wigand JuniorAinda não há avaliações

- Ferrous Pipeline Corrosion Processes (4 of 4) 231-256Documento26 páginasFerrous Pipeline Corrosion Processes (4 of 4) 231-256Wigand JuniorAinda não há avaliações

- Ultrasonic Emats For Weld InspectionDocumento3 páginasUltrasonic Emats For Weld InspectionWigand JuniorAinda não há avaliações

- Fracture Analysis and Corrosion Fatigue (1 of 4) 01-70Documento70 páginasFracture Analysis and Corrosion Fatigue (1 of 4) 01-70Wigand JuniorAinda não há avaliações

- Ferrous Pipeline Corrosion Processes (3 of 4) 150-230Documento81 páginasFerrous Pipeline Corrosion Processes (3 of 4) 150-230Wigand JuniorAinda não há avaliações

- Battelle Hosts President George W. Bush: Special Edition, April 18, 2005Documento2 páginasBattelle Hosts President George W. Bush: Special Edition, April 18, 2005Wigand JuniorAinda não há avaliações

- Ferrous Pipeline Corrosion Processes (2 of 4) 89-149Documento61 páginasFerrous Pipeline Corrosion Processes (2 of 4) 89-149Wigand JuniorAinda não há avaliações

- Projno107 FinalReview2005 May 4Documento105 páginasProjno107 FinalReview2005 May 4Wigand JuniorAinda não há avaliações

- Ferrous Pipeline Corrosion Processes (1 of 4) 01-88Documento88 páginasFerrous Pipeline Corrosion Processes (1 of 4) 01-88Wigand JuniorAinda não há avaliações

- AE Testing Cryogenic Storage Tank FloorsDocumento4 páginasAE Testing Cryogenic Storage Tank FloorsWigand JuniorAinda não há avaliações

- MULTIPLE CHOICE-ComputationalDocumento5 páginasMULTIPLE CHOICE-Computationaljie calderonAinda não há avaliações

- Installation Instructions For Universal Lightning ArrestorDocumento4 páginasInstallation Instructions For Universal Lightning ArrestorKevin_IAinda não há avaliações

- Flyer - Tego Betain P 50 C - EcocertDocumento2 páginasFlyer - Tego Betain P 50 C - Ecocertrafaeldelperu1982Ainda não há avaliações

- Determination of Fat (Food Analysis)Documento7 páginasDetermination of Fat (Food Analysis)Nabila Husna100% (2)

- Federal Employees' Group Life Insurance Program (FEGLI) Life Insurance Open Season GuidanceDocumento9 páginasFederal Employees' Group Life Insurance Program (FEGLI) Life Insurance Open Season GuidanceFedSmith Inc.Ainda não há avaliações

- Kavya SRPDocumento10 páginasKavya SRPMadhuAinda não há avaliações

- Dulangan National High School: Office of The Guidance CenterDocumento3 páginasDulangan National High School: Office of The Guidance CenteraneworAinda não há avaliações

- Chapter 5 - Bernoulli TheoremDocumento56 páginasChapter 5 - Bernoulli TheoremAfiq IrfanAinda não há avaliações

- Pengaruh Pemberian Simetidin Terhadap Profil Farmakokinetika Parasetamol Dengan Metode High Performance Liquid TAHUN 2020Documento8 páginasPengaruh Pemberian Simetidin Terhadap Profil Farmakokinetika Parasetamol Dengan Metode High Performance Liquid TAHUN 2020hanifah nofilaAinda não há avaliações

- GR 126010 Hernandez Vs Hernandez SHLD Be Legal SepDocumento1 páginaGR 126010 Hernandez Vs Hernandez SHLD Be Legal SepMichael JonesAinda não há avaliações

- Lifting & Moving PatientsDocumento14 páginasLifting & Moving PatientsdylanAinda não há avaliações

- Chapter 03 The Eye and RetinaDocumento10 páginasChapter 03 The Eye and RetinaSimrat WAinda não há avaliações

- Promotion of Tax Culture in Pakistan: Perspective, Prospects and ChallengesDocumento5 páginasPromotion of Tax Culture in Pakistan: Perspective, Prospects and ChallengesRaheel JoyiaAinda não há avaliações

- RD1 Fundic Height MeasurementDocumento3 páginasRD1 Fundic Height MeasurementVillanueva JanelleAinda não há avaliações

- 7 - GravitationDocumento5 páginas7 - GravitationAvik DasAinda não há avaliações

- Gas Laws ExplainedDocumento10 páginasGas Laws ExplainedM Rizki MaulanaAinda não há avaliações

- SV AgreementDocumento3 páginasSV AgreementJanice CuevasAinda não há avaliações

- Zebra XX, Part 2 PDFDocumento3 páginasZebra XX, Part 2 PDFRamona MateiAinda não há avaliações

- Sop Standard Operating ProceduresDocumento3 páginasSop Standard Operating ProceduresTaha SaadanAinda não há avaliações

- Kobalt Spray Gun ManualDocumento39 páginasKobalt Spray Gun ManualChris ReddersenAinda não há avaliações

- How To Build Pyramids and Other Orgone GeneratorsDocumento6 páginasHow To Build Pyramids and Other Orgone GeneratorsGuy Jones100% (2)

- Obw - Jeeves - and - Friends - Short - Stories 2Documento13 páginasObw - Jeeves - and - Friends - Short - Stories 2Victoria AvisAinda não há avaliações

- Key Areas of Risk For Woolworths Ltd.Documento19 páginasKey Areas of Risk For Woolworths Ltd.Allison BestAinda não há avaliações

- Pulkit PPT Steam Turbine3Documento42 páginasPulkit PPT Steam Turbine3Abhishek KumarAinda não há avaliações

- 02 - Motor PDFDocumento80 páginas02 - Motor PDFRenato Assis da SilvaAinda não há avaliações

- Teadit 24 HD: Product InformationDocumento2 páginasTeadit 24 HD: Product InformationАйрат ГараевAinda não há avaliações

- B&S - Immunoassay Market - Global Forecast To 2026Documento36 páginasB&S - Immunoassay Market - Global Forecast To 2026VK KRISHNAMOORTHYAinda não há avaliações

- Causes and Effects of Public Speaking Anxiety among E-MQI FreshmenDocumento47 páginasCauses and Effects of Public Speaking Anxiety among E-MQI FreshmenVi Diễm QuỳnhAinda não há avaliações

- Abdulrahman 4 Bashir Abdirahman Hussein STR .BPNDocumento1 páginaAbdulrahman 4 Bashir Abdirahman Hussein STR .BPNFrancis OdongoAinda não há avaliações

- Dog Training Book Rex in The CityDocumento56 páginasDog Training Book Rex in The CitybebekbuluhAinda não há avaliações