Escolar Documentos

Profissional Documentos

Cultura Documentos

Factors Influencing The Grinding Efficiency

Enviado por

recaiDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Factors Influencing The Grinding Efficiency

Enviado por

recaiDireitos autorais:

Formatos disponíveis

Factors influencing the grinding efficiency

- Ventilation

- Moisture

- Water injection

- Coating

- Grinding Aid

- Product addition:

limestone

slag

Slegten grinding course

Factors influencing the grinding efficiency

Ventilation

Purpose:

Fluidization / progress of the material

Removal of fine particles

risk of coating

Cooling of the material

coating / gypsum dehydration

Usual ranges of ventilation:

Air speed

Amount of air:

Open circuit : 0.8 to 1.2 m/sec

Open or closed circuit:

Closed circuit: 1.2 to 1.5 m/sec

0.3 to 0.45 Nm3/kg

Slegten grinding course

Factors influencing the grinding efficiency

Ventilation

Comparison between m/sec et Nm3/kg:

AIR FLOW

0,70

0,60

0,45 Nm3/kg

Quantity in Nm3/kg

0,50

0,3 Nm3/kg

0,40

0,7 m/sec

0,30

1,0 m/sec

0,20

1,2 m/sec

0,10

1,0

1,8

2,0

3,0

4,0

5,0

6,0

7,0

1,5 m/sec

Mill diameter in m

Slegten grinding course

Factors influencing the grinding efficiency

Ventilation

Limits

Open circuit

The filter product goes directly to the finished product.

Open or closed circuit

A high ventilation

can result in a transportation of uncrushed particles from Cpt 1 to Cpt 2

can have a bad influence on the material level in Cpt 1

is necessary if fresh feed is moist

In general, it is necessary:

.

to limit to 20-25 m/sec at mill feed entrance

.

to limit to 15 - 25 m/sec in the diaphragms

.

to provide a feeding chute with air passage

.

to provide an isolation device at mill

Slegten grinding course

discharge

Factors influencing the grinding efficiency

Inlet Chute

Ventilation

Slegten grinding course

Factors influencing the grinding efficiency

Moisture

Influence of the moisture on the ginding efficiency

Slegten grinding course

Factors influencing the grinding efficiency

Moisture

Solutions to high moisture

-

Use hot clinker

Control rejects temperature (closed circuit)

Work at high circulating load

Dry the material

Slegten grinding course

Factors influencing the grinding efficiency

Water injection

Purpose

EFFECT OF TEMPERATURE ON GYPSUM DEHYDRATION

Maintain the outlet temperature

< 105 C (115 C

max)

130C

80

Dehydration of gypsum

in the mill: short stay

not too bad effect

In the silo: long stay

extremely serious

DEHYDRATION %

dehydration of gypsum

140C

120C

coating

150C

100

60

110C

40

20

0

0

10

20

30

40

TIME OF EXPOSURE (minutes)

Slegten grinding course

Factors influencing the grinding efficiency

Water injection

Rules :

Cpt 1

If clinker temperature > 80 C at mill inlet ---> max 1 % H20 (on fresh feed)

The water has to be dropped on the fresh feed or at mill inlet

No spray, just drop

Cpt 2

The water has to be sprayed close to 2nd Cpt inlet

The water can be sprayed from intermediate or outlet diaphragm

A PID regulation and a security device has to be foreseen

Slegten grinding course

Factors influencing the grinding efficiency

Water injection

Slegten grinding course

10

Factors influencing the grinding efficiency

Water injection

Thermal balance

KW

AIR

WATER

AIR

Equilibrium: IN = OUT

WATER

MATERIAL

FEED

Shell

3 parameters:

.

Mill outlet temperature

. Necessary amount of water

.

Mill ventilation

Also take into account: thermal balance on the separator

Slegten grinding course

11

Factors influencing the grinding efficiency

Water injection

Thermal balance

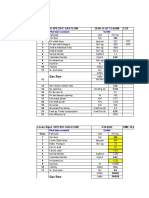

Example of calculation - Open Circuit

Basis

4m x 13m

2900 kW

97 t/h

Feed temp: 90 C

Air and water temp: 15 C

3

Air amount through mill: 26900 Nm /h

Cement temperature: 105 C

IN

Energy

Material

Air

Water

2900 kW x 0,85 x 860 Kcal/kW / 97000 kg cem

0,19 kcal / kgC x 90C

3

3

0,31 kcal / Nm C x 26900 Nm /h x 15C / 97000 kg cem

1597 l/h x 15C / 97000 kg cem

OUT

Shell

Cement

Air

Water

750 Kcal / m h x 188 m / 97000 kg cem

0,19 kcal / kgC x 105C

3

3

0,31 kcal / Nm C x 26900 Nm /h x 100C / 97000 kg cem

1597 l/h x [ 537 kcal/kg + 100 kcal/kg + 0,44 kcal/kgC x(100C - 100C) ] / 97000 kg cem

= 21,85 kcal/kg cem

= 17,10

= 1,29

= 0,25

40,49

= 1,45

= 19,95

= 8,60

= 10,49

40,49

Slegten grinding course

12

Factors influencing the grinding efficiency

Water injection

Thermal balance

Feed: 102C

PROCESS AND THERMAL FLOW-SHEET

194 t/h

recirculated air:

135 000 m 3/h

18 980 m 3/h

FAN

at 86C

BAG FILTER

Process:

dp filter:

18 980 m 3/h

150 mmWG

HD

FAN

fresh air:

feed/air ratio:

15 000 m 3/h

1,29 kg/m 3

78C

at 15C

SEPARATOR

at 91C

CYCLONE

300 m m WG

material flow:

air flow:

A/F= 2

Fines: 91C

Process:

filter product

air-material flow:

150 000 m 3/h

97 t/h

155 858 m 3/h

at 91C

500 m m WG

dp cycl:

dp sep:

100 mmWG

250 mmWG

Product:

97 t/h

3000 Blaine

at 86C

E

L

E

V

A

T

O

R

MILL FILTER

Tails: 92C

FAN

97 t/h

dp filter:

impact

150 mmWG

flow meter

clinker

add.1

add.2

Design:

47 000 m 3/h

400 m m WG

add.3

at 90C

26 908 m 3/h

at 15C

43 649 m 3/h

at 91C

dp mill: 200 mmWG

MILL

ch.1

ch.2

air speed: 1,34 m/sec

FRESH FEED:

T/H:

C:

%H2O:

Clinker

92,15

90

Gypse

4,85

18

15

w ater injection:

0 l/h

86,4

0,75

tot fresh feed: 97

Company:

Plant:

15,0% false air

2900kW

105 C cem ent

filter product

475 l/h

Mill:

Separator:

SD 100

Slegten grinding course

13

Factors influencing the grinding efficiency

Water injection

Thermal balance

% of each component IN and OUT heat balance

according to mill (30 kWh/t - 1,2 m/s - clinker 100C)

60%

50%

40%

30%

IN :

% energy

IN :

% material

IN :

% air

IN :

% water

OUT : % shell

OUT : % cement

OUT : % air

20%

OUT : % water

10%

0%

1,8 2 2,2 2,4 2,6 2,8 3 3,2 3,4 3,6 3,8 4 4,2 4,4 4,6 4,8 5 5,2 5,4 5,6 5,8 6

Diameter (m)

Slegten grinding course

14

Factors influencing the grinding efficiency

Water injection

Thermal balance

Water requested in % according to mill

for different air speeds - 30 kWh/t - clinker 100 C

3,0%

2,5%

2,0%

0.7 m/sec

1 m/sec

1.2 m/sec

1.5 m/sec

1,5%

1,0%

0,5%

0,0%

1,8 2 2,2 2,4 2,6 2,8 3

3,2 3,4 3,6 3,8 4

4,2 4,4 4,6 4,8 5

Diameter (m)

5,2 5,4 5,6 5,8 6

Slegten grinding course

15

Factors influencing the grinding efficiency

Coating

Definition:

Agglomeration of fine particles (on lining and/or on grinding media)

grinding efficiency decrease

Reasons:

*

Overgrinding (often in O.C., fine cement grinding and limestone addition)

Too high outlet temperature in Cpt 2 ( > 110 C at mill outlet)

Fresh feed moisture

Solutions:

*

limit the fines

good mill ventilation

good separator

Avoid outlet temperatures > 105 C (ventilation, water injection, separator)

Use grinding aids

If coating is due to moisture, dry by hot clinker, hot rejects or hot gas

Slegten grinding course

16

Factors influencing the grinding efficiency

Grinding Aids

Purpose :

fight coating

produced Blaine is directly

proportional to grinding efficiency

in theory, grinding efficiency

(cm2/j) constant

in reality, not constant because of

agglomeration negative

effects

Mill efficiency (cm2/j)

Rittinger Law :

Rittinger

With

G.A.

Without

G.A.

Mill outlet fineness SSB (m2/kg)

Slegten grinding course

17

Factors influencing the grinding efficiency

Grinding Aids

Function principles:

Coating : due to static electricity on the generated areas

make them stick together

G.A.:

contain components which neutralize cement grain

superficial charges

decrease these electrostatic forces

better grinding efficiency

production gain 5 - 30 %

Disadvantage: high price

Slegten grinding course

18

Factors influencing the grinding efficiency

Grinding Aids

Slegten grinding course

19

Factors influencing the grinding efficiency

Grinding Aids

Other advantages:

.

Improve cement flow

One can use finer ball charge

.

Easier cement transport to silos

.

Allow a higher amount of additional

Silo buildcomponents

up elimination other than clinker

Improve product quality

* Optimize cement particle size distribution

* Improve cement strengths 1, 2 and 28 days

Way of use:

GA sprinkled on fresh feed (diluted with water)

In general .01 % to .08% are added (250 gr/t)

Quantity (and efficiency) increase with Blaine fineness

Slegten grinding course

20

Factors influencing the grinding efficiency

Slag grindability

Slag

Thionvilloise (100 %

laitier)

Thyssen (100 % laitier)

Sidmar (100 % laitier)

Atlantic (100 % laitier)

Ssang Yong (100 %

laitier)

Nittetsu (100 % laitier)

Slegten grinding course

21

Factors influencing the grinding efficiency

Slag

Clinker grindability

Consommation spcifique (kWh/t)

Consommation spcifique (kWh/t)

Slag grindability

Surface spcifique Blaine

Surface spcifique Blaine

Slegten grinding course

22

Factors influencing the grinding efficiency

Slag Vs Clinker: Grindability

Slag

Slegten grinding course

23

Factors influencing the grinding efficiency

Slag

Properties of slag grinding:

- Beneficial on kWh/t if slag < 15 %

- Moisture problems (if slag not dried)

- Higher wear (balls / liners)

Slegten grinding course

24

Factors influencing the grinding efficiency

Slag

slag influence - increase of the spec.grinding energy vrs slag

content and blaine

100

90

80

70

20%

60

40%

100%

50

Log. (100%)

Log. (40%)

40

Log. (20%)

30

20

10

0

2200 2400

2600 2800

3000 3200

3400 3600

3800 4000

4200 4400

4600 4800

5000 5200

5400 5600

blaine

Slegten grinding course

25

Factors influencing the grinding efficiency

Limestone

- prone to coating

- increase artificially the Blaine value

- mind slot sizes and moisture

Slegten grinding course

26

Factors influencing the grinding efficiency

Limestone

Influence of the pozzolana on the specific grinding energy

Source Holderbank

80

70

60

kWh/t (mill shaft)

50

100% clinker

95% cl + 5 % gypsum

40

85%cl.+ 5% gyp.+ 15% poz.

75%cl.+ 5%gyp.+ 20% poz.

65%cl.+5%gyp.+30% poz

30

20

10

0

2000

2500

3000

3500

4000

4500

blaine

Slegten grinding course

27

Você também pode gostar

- Ilara RM - CS P.11002 - P.12610 - 15092021 - 18092021 - Technichal ReportDocumento16 páginasIlara RM - CS P.11002 - P.12610 - 15092021 - 18092021 - Technichal ReportBen100% (1)

- Raw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesDocumento3 páginasRaw Mill Heat Balance Without WHR: Sn. Parameters Units ValuesRamachandrarao MaddaliAinda não há avaliações

- V SK VSK: Focus On EfficiencyDocumento8 páginasV SK VSK: Focus On EfficiencyGerman Gabriel Anaya VegaAinda não há avaliações

- Cement raw material gas flow balance sheetDocumento4 páginasCement raw material gas flow balance sheetAli Hüthüt100% (1)

- Ball Mill GrindingDocumento78 páginasBall Mill GrindingFran jimenezAinda não há avaliações

- Raw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Documento6 páginasRaw Mill Nozzle Ring Area 8/6/2019 11:02: 4.47 m2 m2 m2 m2 m2 3.57 m2Bùi Hắc HảiAinda não há avaliações

- Dokumen - Tips - Vertical Raw Mill Heat Balance SolutionDocumento3 páginasDokumen - Tips - Vertical Raw Mill Heat Balance SolutionRamadhani AhdiyakaAinda não há avaliações

- 15th NCB Technical PaperDocumento10 páginas15th NCB Technical PaperSalah RomdaniAinda não há avaliações

- Atox 20 Coal Mill Critical Interlock SheetDocumento6 páginasAtox 20 Coal Mill Critical Interlock SheetValipireddy NagarjunAinda não há avaliações

- Mill Fan Efficiency CalculationDocumento8 páginasMill Fan Efficiency Calculationsam abusiAinda não há avaliações

- Cement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Documento17 páginasCement Grinding Vertical Roller Mills Versus Ball Mills 1654248086Salah Romdani100% (1)

- Fan Flow - CementDocumento5 páginasFan Flow - CementharikrushnaAinda não há avaliações

- ZeiselDocumento98 páginasZeiselGirne100% (1)

- BM TrompcurveDocumento1 páginaBM Trompcurveniladri.jagatyAinda não há avaliações

- Atox 45 Raw Mill Critical Interlock SheetDocumento6 páginasAtox 45 Raw Mill Critical Interlock SheetValipireddy NagarjunAinda não há avaliações

- Presep Air Separator VTP enDocumento6 páginasPresep Air Separator VTP enBrunoAinda não há avaliações

- Grinding and Classifying Technology For Slag: Replacement Factors DryingDocumento6 páginasGrinding and Classifying Technology For Slag: Replacement Factors DryingGerman Gabriel Anaya Vega100% (1)

- Flow Calculation SheetDocumento24 páginasFlow Calculation SheetTOULASSI-ANANI Yves Lolo50% (2)

- Operating Manual for Slag Grinding UnitDocumento41 páginasOperating Manual for Slag Grinding UnitPushpendra Kumar KushwahaAinda não há avaliações

- Study of The Grinding Balls Distribution Inside The MillDocumento2 páginasStudy of The Grinding Balls Distribution Inside The Millsempatik721Ainda não há avaliações

- Annex 16.1 & 16.2: Mill calculation plant dimensions and filling degree formulasDocumento2 páginasAnnex 16.1 & 16.2: Mill calculation plant dimensions and filling degree formulasIrfan AhmedAinda não há avaliações

- Example of Cement Mill QuestionnaireDocumento5 páginasExample of Cement Mill QuestionnaireIrfan AhmedAinda não há avaliações

- Nozzle Ring Area of Raw MillDocumento6 páginasNozzle Ring Area of Raw MillThaigroup CementAinda não há avaliações

- Cooler Air Flow Vs Kiln FeedDocumento2 páginasCooler Air Flow Vs Kiln FeedBùi Hắc HảiAinda não há avaliações

- Mass Balance PDFDocumento5 páginasMass Balance PDFElai MacabitAinda não há avaliações

- Ball - Mill - Finish Mill Ball Charge CalculationDocumento3 páginasBall - Mill - Finish Mill Ball Charge CalculationVijay Bhan50% (2)

- Ball Mill CalculationsDocumento7 páginasBall Mill CalculationsSSAC PVT.LTD.100% (1)

- VRM Heat and Mass BalanceDocumento1 páginaVRM Heat and Mass BalanceRajeshRockAinda não há avaliações

- High-Efficiency Cyclone: Machine Manual En-22330.003-BDocumento31 páginasHigh-Efficiency Cyclone: Machine Manual En-22330.003-BRahmat YusufAinda não há avaliações

- Raw Materials Granulometry and Ball Charge DesignDocumento11 páginasRaw Materials Granulometry and Ball Charge DesignKaran_Agarwal_4807100% (2)

- Fan Curves Explained: Power, Speed, Pressure & VolumeDocumento1 páginaFan Curves Explained: Power, Speed, Pressure & VolumeVijay BhanAinda não há avaliações

- Technical Specification of VSK PDFDocumento28 páginasTechnical Specification of VSK PDFmaran.suguAinda não há avaliações

- Loesche Round Table VICATDocumento20 páginasLoesche Round Table VICATrecaiAinda não há avaliações

- Comminution 2Documento159 páginasComminution 2Kumar RajeshAinda não há avaliações

- 05 RP - Process Know HowDocumento25 páginas05 RP - Process Know Howaff bear100% (2)

- VRM Fan ..Documento2 páginasVRM Fan ..harikrushnaAinda não há avaliações

- Gebr. Pfeiffer Brochure Passion For Grinding enDocumento28 páginasGebr. Pfeiffer Brochure Passion For Grinding enRollerJonnyAinda não há avaliações

- Ball Mill Sizing CalculatorDocumento6 páginasBall Mill Sizing CalculatorHoàng HùngAinda não há avaliações

- High VM Coal With 3% SulphurDocumento1 páginaHigh VM Coal With 3% SulphurIrshad HussainAinda não há avaliações

- Loesche Grinding Plants for Coal GasificationDocumento45 páginasLoesche Grinding Plants for Coal GasificationMaxim Polevoy100% (1)

- Diagnostic Study For Cement Mill OptimizationDocumento9 páginasDiagnostic Study For Cement Mill OptimizationHilmy MuhammadAinda não há avaliações

- VRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Documento2 páginasVRM-Fill Data Only in Yellow Cells: Total Feed (MT) Clinker (MT) Gypsum (MT) Slag (MT)Sahadeb Manna100% (1)

- Precalciner Kiln Systems ExplainedDocumento39 páginasPrecalciner Kiln Systems ExplainedMohamed Saad100% (1)

- Annexure 1 Mass Flow RajashreeDocumento3 páginasAnnexure 1 Mass Flow RajashreeKenny RuizAinda não há avaliações

- Ball Top Size Diameter CalculationDocumento1 páginaBall Top Size Diameter Calculationsempatik721100% (1)

- Cement Separator & Ball Mill OptimizationDocumento29 páginasCement Separator & Ball Mill OptimizationAdelezzat OmranAinda não há avaliações

- Calciner Technology in AF Firing PDFDocumento22 páginasCalciner Technology in AF Firing PDFJohn GiannakopoulosAinda não há avaliações

- 26 00 Special Cases and Experiences EDocumento9 páginas26 00 Special Cases and Experiences EDiego AlejandroAinda não há avaliações

- Compare kiln capacities and specificationsDocumento1 páginaCompare kiln capacities and specificationsgvrrAinda não há avaliações

- VRM Cement Pre-grinding System OptimizationDocumento21 páginasVRM Cement Pre-grinding System OptimizationShariq KhanAinda não há avaliações

- 11.30 DR Stefan Seemann, KHD Humboldt Wedag GMBHDocumento15 páginas11.30 DR Stefan Seemann, KHD Humboldt Wedag GMBHMohd AliAinda não há avaliações

- MBT CalculatorDocumento2 páginasMBT Calculatorsempatik721100% (1)

- Air Slide Data SheetDocumento2 páginasAir Slide Data SheetTECHCONS Consulting and Engineering Pvt LtdAinda não há avaliações

- Kiln Heat Balance 1Documento33 páginasKiln Heat Balance 1Bùi Hắc HảiAinda não há avaliações

- Loesche Seminar VCM Study Dec03Documento132 páginasLoesche Seminar VCM Study Dec03stelios nikoladosAinda não há avaliações

- Factors Influencing The Grinding EfficiencyDocumento27 páginasFactors Influencing The Grinding Efficiencynoelbaba71100% (1)

- Ball Mill OptimizationDocumento82 páginasBall Mill OptimizationRashek_119588% (16)

- Polycom Process-CalculationDocumento42 páginasPolycom Process-Calculationdarkcorsair100% (4)

- Styropor Processing Guide - Rev3Documento3 páginasStyropor Processing Guide - Rev3NurettinAlpAinda não há avaliações

- Compressed Air Filters and Water Separators: Intelligent Air TechnologyDocumento6 páginasCompressed Air Filters and Water Separators: Intelligent Air TechnologyOliver CambelAinda não há avaliações

- Krystowczyk Get in Line 2017Documento4 páginasKrystowczyk Get in Line 2017grameshkreddy2013Ainda não há avaliações

- Krystowczyk Get in Line 2017Documento4 páginasKrystowczyk Get in Line 2017grameshkreddy2013Ainda não há avaliações

- Rawmaterial GrindingDocumento28 páginasRawmaterial Grindinggrameshkreddy2013Ainda não há avaliações

- FLSmidth CrossBar Cooler v2 PDFDocumento8 páginasFLSmidth CrossBar Cooler v2 PDFgrameshkreddy2013Ainda não há avaliações

- Imp DataDocumento6 páginasImp Datagrameshkreddy2013Ainda não há avaliações

- 1 - Cement AF ChallengeDocumento30 páginas1 - Cement AF Challengegrameshkreddy2013100% (1)

- FLSmidth CrossBar Cooler v2 PDFDocumento8 páginasFLSmidth CrossBar Cooler v2 PDFgrameshkreddy2013Ainda não há avaliações

- Pfeiffer MPS Vertical Mill PDFDocumento8 páginasPfeiffer MPS Vertical Mill PDFgrameshkreddy20130% (1)

- Shaft AlignmentDocumento7 páginasShaft AlignmentAmitanshu SharmaAinda não há avaliações

- FLS Burners PDFDocumento42 páginasFLS Burners PDFgrameshkreddy2013Ainda não há avaliações

- Fan CurvesDocumento13 páginasFan CurvesgravatomAinda não há avaliações

- FLS Burners PDFDocumento42 páginasFLS Burners PDFgrameshkreddy2013Ainda não há avaliações

- Lubricants For Cement ProductionDocumento21 páginasLubricants For Cement Productiongrameshkreddy2013100% (1)

- Clinker Microstructure and Grindability PCA Literature Review by Linda M. Hills SN2967Documento15 páginasClinker Microstructure and Grindability PCA Literature Review by Linda M. Hills SN2967tkrapkat100% (2)

- Electrodes EquivalentDocumento15 páginasElectrodes Equivalentgrameshkreddy2013Ainda não há avaliações