Escolar Documentos

Profissional Documentos

Cultura Documentos

UWO Mechanical Components Design For Mechatronic Systems (MSE 3380) Sample Problems - Solutions v3

Enviado por

Fernando Freitas AlvesTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

UWO Mechanical Components Design For Mechatronic Systems (MSE 3380) Sample Problems - Solutions v3

Enviado por

Fernando Freitas AlvesDireitos autorais:

Formatos disponíveis

MSE 3380

UWO

Sample Problems (v3)

1. [Stress analysis] A sign of dimensions 2.0 m 1.2 m is supported by a hollow circular

pole having outer diameter 220 mm and inner diameter 180 mm as shown in the left and

centre figures. The sign is offset 0.5 m from the centerline of the pole and its lower edge

is 6.0 m above the ground.

(a)

(b)

(c)

A wind pressure against the sign produces a resultant force, , that acts at the midpoint of

the sign (right figure) and is equal to the pressure, , times the area, sign , over which it

acts:

= sign = (2.0 kPa)(2.0 m 1.2 m) = 4.8 kN .

The line of action of is at height = 6.6 m above the ground and at distance = 1.5 m

from the centerline of the pole. Neglecting stress concentrations and the weight of all

components, determine:

(a) the moment of inertia, , polar moment of inertia, , cross-sectional of the pole, pole ,

and the relevant first moment of area for a hollow-semicircle given by,

2

= (23 13 ).

3

(b) the equivalent force-couple system (, , , , , ) at the centroid of the section

of interest.

(c) the normal and shear stress components acting on the element at .

(d) the normal and shear stress components acting on the element at .

(e) the principal stresses, maximum shear stress and corresponding normal stress at

(max , min , max ) geometrically using Mohrs circle.

(f) the principal stresses, maximum shear stress and corresponding normal stress at

(max , min , max ) using any method. Sketch two stress elements (at ) that illustrate

the principal and maximum shear stress states (explicitly identify their orientations).

Bonus: (+1 point) Determine if the pole will yield at using the maximum-distortionenergy (von Mises) criterion given = 60 MPa for the steel used.

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 1/25

MSE 3380

UWO

Sample Problems (v3)

SOLUTION

(a) Let the pole symbol be and the sign symbol be . Thus, we have the second moment

of area (or moment of inertia) with respect to the -axis to their centroids

= 2 d

2 dd

2 2

2

2

2 d

,

12

where = 2.0 m and = 1.2 m

= 0.288 m4

=

ext

2 dext

int

ext

2 dint

2

int

( sin )2 (dd)

0

0

2

( sin )2 (dd)

ext

= sin2 d 3 d

0

int

4

4 )

= (ext

int

,

4

220

180

mm = 0.110 m and ext =

mm = 0.090 m

2

2

63.5 106 m4 = 0.635 dm4

where ext =

and with respect to the -axis to their centroids

= 2 d

2 dd

2 2

2

2

2

=

=

3

,

12

where = 2.0 m and = 1.2 m

= 0.8 m4

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 2/25

MSE 3380

UWO

ext

2 dext

int

ext

2 dint

2

2 (dd)

( cos )

0

0

2

Sample Problems (v3)

int

( cos )2 (dd)

ext

= cos2 d 3 d

0

int

4

4 )

= (ext

int

,

4

220

180

mm = 0.110 m and ext =

mm = 0.090 m

2

2

63.5 106 m4 = 0.635 dm4 =

where ext =

Their polar second moment of area (or polar moment of inertia) are

= 2 d

= ( 2 + 2 )d

= 2 d + 2 d

= +

= (0.8 + 0.288) m4

= 1.088 m4

=

ext

2

2 dext

int

ext

0

0

2

2 (dd)

ext

= d

0

2 dint

int

2 (dd)

3 d

int

4

4 )

= (ext

int

2

= 2 = 2

2 (63.5 106 m4 )

= 127 106 m4 = 1.27 dm4

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 3/25

MSE 3380

UWO

Sample Problems (v3)

The cross-sectional area of the pole is

pole = = ext int

2 )

2

= (ext

int

,

220

180

mm = 0.110 m and ext =

mm = 0.090 m

2

2

12.6 103 m2 = 1.26 dm2

where ext =

The relevant first moment of area for a hollow-semicircle is given by

ext

int ()d ,

int

ext ()d

where () is the thickness in the -axis

ext int ,

ext

int

where is the top (or bottom) portion of the members

cross-sectional area, defined from the section where ()

is measured, and is the distance to the centroid of ,

measured from the neutral axis

Centroid of ext

Centroid of int

ext

int

ext

int

Neutral axis

int ()

ext ()

=[

ext

0 0

( sin )(dd)

0 0 int( sin )(dd)

] ext [

] int

ext

int

ext

= sin d

0

2 d

int

2 3

3

),

= (ext

int

3

220

180

mm = 0.110 m and ext =

mm = 0.090 m

2

2

401 106 m3 = 401 cm3

where ext =

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 4/25

MSE 3380

UWO

Sample Problems (v3)

(b) According to the illustrations and knowing that = 1.5 m and = 6.6 m, the

equivalent force-couple system (, , , , , ) at the point of the section is

(0, , 0, , 0, ) = (0 N, 4.8 kN, 0 N, 7.2 kNm, 0 Nm, 31.68 kNm)

= (0, 4.8, 0, 7.2, 0, 31.68) 103 [S. I. ]

=0

Fernando Freitas Alves

= 0

ffreitas@uwo.ca

= 0

Jan 21, 2015 5/25

MSE 3380

UWO

Sample Problems (v3)

(c) The state of stress at the point is

where

ext

,

given the flexure (bending) due to

ext

=

(4.8 kN) (6.6 m) (0.110 m)

(63.5 106 m4 )

55 MPa

= 0 ,

since no force stress this direction

ext

,

given the torsion due to

ext

=

(4.8 kN) (1.5 m) (0.110 m)

(127 106 m4 )

6.2 MPa

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 6/25

MSE 3380

UWO

Sample Problems (v3)

(d) The state of stress at the point is

where

= = 0 ,

since no force stress these directions

ext

+

,

given the torsion and the transverse force due to

where = and = 2 (ext int )

ext

+

],

2 (ext int )

220

180

where ext =

mm = 0.110 m and ext =

mm = 0.090 m

2

2

=[

(4.8 kN)

(1.5 m) (0.110 m)

(401 106 m3 )

[

+

]

(127 106 m4 )

2 (63.5 106 m4 ) (0.110 m 0.090 m)

7.0 MPa

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 7/25

MSE 3380

UWO

Sample Problems (v3)

(e) Constructing the Mohrs circle, we got that

max

min

max

55.7 MPa

0.7 MPa

28.2 MPa

27.5 MPa (when = )

(f) Once there is no normal stress in the direction studied in the exercise (d), the maximum

shear stress is the same that is already calculated with null corresponding normal stress

and the principal stresses are those that happen when the orientation of the stress

element is 902 = 45 due to the Mohrs circle simplification. Thus, we got

max = | | 7.0 MPa

min = | | 7.0 MPa

max = | | 7.0 MPa

= 0 MPa

max

(at = 135)

(when = )

min

Fernando Freitas Alves

(at = 45)

ffreitas@uwo.ca

max

45

Jan 21, 2015 8/25

MSE 3380

UWO

Sample Problems (v3)

Bonus: According to the Distortion Energy Theory, the distortion energy density in terms

of equivalent (von Misses) stress, VM , is given by

=

1+ 2

3 VM

Knowing that the von Mises stress for a two-dimensional plane stress state can be

defined in terms of principal stresses as

2

2

VM = max

max min + min

and once the stresses at correspond to a situation that only shear stress exists, which

means that

max = min =

we got that the yield stress (critical stress value) is

2 + ( ) + 2 = 3

VM =

which means that the material will yield at if the shear stress reaches 13 0.577

of the yield stress.

Thus, given = 60 MPa,

7.0 MPa

60 MPa

3

35 MPa

respect the maximum-distortion-energy (von Mises) condition and will not yield at .

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 9/25

MSE 3380

UWO

Sample Problems (v3)

2. [Stress-based design] A simply-supported beam is required to support the loads shown,

and the grade of steel to be used has all = 170 MPa and all = 100 MPa. Neglecting the

effect of fillets, stress concentrations, out-of-plane stresses due to the loads and weight of

the bream, determine:

12 kN

6 kN

(a) the reaction forces at the supports.

(b) the maximum magnitudes of the shear force and bending moment.

(c) the required section modulus, min , due to flexure.

(d) the most appropriate standard SI Wide-Flange beam section that should be used from

those listed in the table below.

Shape

Section modulus

[103 mm3 ]

W200 19.3

W150 24

W150 18

W150 13.5

W130 28.1

W130 23.8

W100 19.3

162.0

167.0

120.0

91.1

167.0

140.0

89.5

(e) if the selected beam will fail due to the maximum shear in the web, max

(assume uniform shear stress in the web; note that the table of properties of standard W

sections is attached).

(f) if the selected beam will fail due to the maximum flexural stress on the outermost

surface of the flange, .

Bonus: (+2 point) Determine if the selected beam will fail due to the maximum principal

stress at the web-flange junction, max . Assume uniform shear stress in the web.

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 10/25

MSE 3380

UWO

Sample Problems (v3)

SOLUTION

(a) Defining the reaction forces at each support as illustrated below in the free body

diagram

12 kN

6 kN

and once the beam is static, the sum of every bending moment about any point must be

zero. Thus, about we have

= 0 (6 kN) (2 m) + (12 kN) (4 m) + (6 m) = 0

= 10 kN

Also, this static situation requires that the sum of the forces in all directions must be

zero, we have

= 0

= 0

= 0 + (6 kN) + (12 kN) + = 0

Fernando Freitas Alves

ffreitas@uwo.ca

= 8 kN

Jan 21, 2015 11/25

MSE 3380

UWO

Sample Problems (v3)

(b) Analysing the shear forces across the beam, we have that

= 8 kN,

() = { + (6 kN) = 2 kN,

0m <2m

2m <4m

+ (6 kN) + (12 kN) = 10 kN,

4m <6m

Analysing the bending moments across the beam, we have that

= 8 [kNm],

0m <2m

2m <4m

() = { + (6 kN)( 2) = 2 + 12 [kNm],

+ (6 kN)( 2) + (12 kN)( 4) = 10 + 60 [kNm], 4 m 6 m

Thus, the maximum shear force max and the maximum bending moment max are

max = 10 kN

Fernando Freitas Alves

and

ffreitas@uwo.ca

max = 20 kNm

Jan 21, 2015 12/25

MSE 3380

UWO

Sample Problems (v3)

(c) Knowing the maximum bending moment at 4 m, the correspondent maximum shear

stress at that point is given by

max =

max max

where max is the maximum distance of material of the cross section from the neutral

axis. However, we do not have any information about the cross section of the beam, so

we cannot know . However, we can use the definition of the elastic section modulus

=

max

so that, using the previous equation, we have

max =

max

max

=

max

Once the maximum bending moment was calculated in the last exercise and maximum

shear stress allowed was given, i.e. max = all = 170 MPa, the required minimum

elastic sections modulus is

20 103 Nm

=

118 103 mm3

170 106 Nm2

(d) The most appropriate standard SI Wide-Flange beam section that should be used from

the table given is the one that have the least value of elastic section modulus that is

greater that min , which is the shape W150 18 . This choice often guarantees the

selection of the least expansive beam in the table, once their price generally increases

with greater section modulus. The chosen beams dimensions are shown above:

7.11 mm

102 mm

153 mm

2

5.84 mm

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 13/25

MSE 3380

UWO

Sample Problems (v3)

(e) We define the maximum shear stress distribution by

max =

max

However, if we assume an uniform shear stress on the beams section, we can define

the maximum shear stress by

max =

max

where is the section area of the web, i.e. = 2 , so that

max =

(10 kN)

12 MPa

(0.00584 m)(0.153 m 2 0.00711 m)

Thus, once

max < all = 100 MPa

the beam chosen will endure the loads without any failing on the web.

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 14/25

MSE 3380

UWO

Sample Problems (v3)

(f) Now that we have information about the section, we can calculate the real maximum

shear stress at the outermost surface of the flange by

a =

max max

where the second moment of area can be checked within a table or calculated as

0

1 12 )

= 1 + 2 + 3 = (1 +

+ (2 +

1

= { (0.102 m)(0.00711 m)3

12

2 22 )

+ (3 + 3 32 )

1

2

(0.102 m)(0.00711 m) {[0.153

(0.153 m)2} }

+

m (0.00711 m)2]

1

(0.00584 m)(0.153 m 2 0.00711 m)3

12

2

1

+ { (0.102 m)(0.00711 m)3

12

3

2

+ (0.102

m)(0.00711 m) [(0.00711

m)2 (0.153

m)2] }

9.0 10

which does not match exactly with the value 9.20 106 m4 of the table from

Appendix C of [1]. Using the both values, we have

1

(20 103 Nm) [(0.153 m)2]

(9.0 106 m4 )

2 =

170 MPa

(20 103 Nm) [(0.153 m)2]

(9.20 106 m4 )

166 MPa

Once 2 < 1 all = 170 MPa , the chosen beam will (almost) not fail.

Bonus: At the web-flange junction, we have a different = max

= max 0.00711 m

= (0.153 m)2 (0.00711 m) = 0.06939 m, so that

max1

(20 103 Nm) (0.06939 m)

(7.8 106 m4 )

max 2 =

75 MPa

(20 103 Nm) (0.06939 m)

(9.20 106 m4 )

77 MPa

Once max 2 < max1 < all = 170 MPa , the chosen beam will not fail.

[1] F. P. Beer, E. R. Johnston, Jr., J. T. DeWolf, and D. F. Mazurek, Mechanics of Materials, 7th ed.

New York, NY: McGraw-Hill, 2015.

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 15/25

MSE 3380

UWO

Sample Problems (v3)

3. [Stress analysis in shafts] A torque = 100 Nm is applied to the shaft , which is

running at constant speed and contains gear . Gear transmits torque to shaft

through gear , which drives the chain sprocket at , transmitting a force as shown.

Sprocket , gear , and gear have pitch diameters of = 150 mm, = 250 mm, and

= 125 mm, respectively. The contact force between the gears is transmitted through the

pressure angle = 20. Assuming no frictional losses and considering the bearings at

, , , and to be simple supports, locate the point on shaft that contains the

maximum normal and maximum shear stresses. Combine these stresses and determine the

maximum principal normal and shear stresses in the shaft.

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 16/25

MSE 3380

UWO

Sample Problems (v3)

SOLUTION

Analysing the first gear, , we have the following free body diagram

1

62.5 mm

= 100 Nm

Gear

Thus, equalling the sum of all the bending moments to zero, we have the following

reaction force

= 0

+ = 0

2

=

2

=

100 Nm

62.5 103 m

= 1.6 kN

and using the geometry of the force , we can calculate its norm by

=

=

cos

1.6 kN

cos 20

1.7 kN

and the norm of the normal force

= tan

= (1.6 kN) tan 20

0.58 kN

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 17/25

MSE 3380

UWO

Sample Problems (v3)

Using the law of conservation of energy with no frictional losses, the reaction force

calculated in the gear is the same reaction force in the gear with opposite orientation

125 mm

Gear

such that the norms are the same

= 1.7 kN

= = 1.6 kN

= 0.58 kN

and the static give the torque by

= 0

+ = 0

2

=

= (1.6 kN) (125 103 m)

= 200 Nm

This value could also be calculated by using the following relationship between the

diameter (or radius) of both gears

=

=

= (100 Nm) (

250 mm

)

125 mm

= 200 Nm

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 18/25

MSE 3380

UWO

Sample Problems (v3)

Assuming that this torque is transmitted without losses to the sprocket , we have

equal magnitude and opposite orientation

=

such that we have the following diagram

=

200 Nm

=

200 Nm

0 15 mm

75 mm

125 mm

Determining the force , we have

=

200 Nm

=

0.075 m

= 2. 6 kN

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 19/25

MSE 3380

UWO

Sample Problems (v3)

Thus, analysing the beam forces in the plane

0.58 kN

= 2. 6 kN

= 75 mm

= 250 mm

= 125 mm

we have the reaction forces given by the equilibrium of the bending moments in

= 0

( + ) + ( + + ) = 0

=

+ ( + )

++

(2. 6 kN) (0.075 m) + (0.58 kN) (0.325 m)

(0.450 m)

0.87 kN

and the equilibrium in the -axis

= 0

+ = 0

= +

2. 6 kN + 0.58 kN 0.87 kN

2.4 kN

This gives us the following shear force distribution in the -plane

2.4 kN,

() = { 0.28 kN,

0.87 kN,

Fernando Freitas Alves

ffreitas@uwo.ca

0 mm < 75 mm

75 mm < 325 mm

325 mm 450 mm

Jan 21, 2015 20/25

MSE 3380

UWO

Sample Problems (v3)

and the following bending moments distribution in the same plane

()

2.4 [kNm],

0 mm < 75 mm

= { ( 0.075) 0.28 + 0.20 [kNm],

( 0.075) ( 0.325) 0.87 + 0.39 [kNm],

75 mm < 325 mm

325 mm 450 mm

Thus, the maximum shear force max and the maximum bending moment max are

max 2.4 kN from to and max 180 Nm at

Analysing the state of stress at in the plane ,

max

max

Shaft

using the maximum bending moment max , we can calculate the maximum principal

normal stress in the shaft

max =

max ( 2) max ( 2) 2max

=

=

4 4

3

=

2 (180 Nm)

(0.015 m)3

34 MPa

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 21/25

MSE 3380

UWO

Sample Problems (v3)

and the maximum shear stress

max = max (

max ( 2)

max (2 3 3) ( 2)

= max (

)

( 4 4)

( 4 2)

= max (

8max 3

)

3 3

8 (2.4 103 N) (0.015 m) + 3 (200 Nm)

3 (0.015 m)3

28 MPa

Otherwise, analysing the beam forces in the plane

= 1.6 kN

= 2. 6 kN

= 75 mm

= 250 mm

= 125 mm

we have the reaction forces given by the equilibrium of the bending moments in

= 0

+ ( + ) ( + + ) = 0

=

+ ( + )

++

=

(2. 6 kN) (0.075 mm) + (1.6 kN) (0.325 m)

(0.450 m)

= 0.71 kN

and the equilibrium in the -axis

= 0

+ = 0

= +

= 2. 6 kN 1.6 kN + 0.71 kN

= 1. 7 kN

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 22/25

MSE 3380

UWO

Sample Problems (v3)

This gives us the following shear force distribution in the -plane

= 1. 7 kN,

() = { = 0. 8 kN,

+ = 0.71 kN,

0 mm < 75 mm

75 mm < 325 mm

325 mm 450 mm

and the following bending moments distribution in the same axis

()

= 1. 7 [kNm],

0 mm < 75 mm

= { ( 0.075) = 0. 8 + 0.20 [kNm],

( 0.075) + ( 0.325) = 0.71 0.32 [kNm],

75 mm < 325 mm

325 mm 450 mm

Thus, the maximum shear force max and the maximum bending moment max are

max = 1. 7 kN from to and max = 133. 3 Nm at

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 23/25

MSE 3380

UWO

Sample Problems (v3)

Analysing the state of stress at in the plane ,

max

max

Shaft

using the maximum bending moment max , we can calculate the maximum principal

normal stress in the shaft

max =

max ( 2) max ( 2) 2max

=

=

4 4

3

=

2 (133. 3 Nm)

(0.015 m)3

25 MPa

and the maximum shear stress

max = max (

max ( 2)

max (2 3 3) ( 2)

= max (

)

( 4 4)

( 4 2)

= max (

8max 3

)

3 3

8 (1. 7 103 N) (0.015 m) + 3 (200 Nm)

3 (0.015 m)3

26 MPa

Fernando Freitas Alves

ffreitas@uwo.ca

Jan 21, 2015 24/25

MSE 3380

UWO

Sample Problems (v3)

Plotting in a 3D view, we got the following state of stress at

max 34 MPa

max 28 MPa

max 28 MPa

max 25 MPa

max 26 MPa

Fernando Freitas Alves

ffreitas@uwo.ca

max 26 MPa

Jan 21, 2015 25/25

Você também pode gostar

- SAHARAN, L. Et Al. - Design of A 3D Printed Lightweight Orthotic Device Based On Twisted and Coiled Polymer Muscle, IGrab Hand Orthosis (SPIE, 2017)Documento10 páginasSAHARAN, L. Et Al. - Design of A 3D Printed Lightweight Orthotic Device Based On Twisted and Coiled Polymer Muscle, IGrab Hand Orthosis (SPIE, 2017)Fernando Freitas AlvesAinda não há avaliações

- Ashby How To Write A PaperDocumento47 páginasAshby How To Write A PaperGauri RanadiveAinda não há avaliações

- Lista 03 (Aula 04) (Entregar) (English) PDFDocumento1 páginaLista 03 (Aula 04) (Entregar) (English) PDFFernando Freitas AlvesAinda não há avaliações

- Mechatronics - Pneumatic and Hydraulic Actuation SystemsDocumento8 páginasMechatronics - Pneumatic and Hydraulic Actuation SystemsFernando Freitas AlvesAinda não há avaliações

- SAE Steel Grades (Wikipedia)Documento9 páginasSAE Steel Grades (Wikipedia)Fernando Freitas AlvesAinda não há avaliações

- CULLITY, B. STORCK, S. Elements of X-Ray Diffraction. 3. Ed. - Ap. 13. Crystal Structure Data (P. 488-491) PDFDocumento4 páginasCULLITY, B. STORCK, S. Elements of X-Ray Diffraction. 3. Ed. - Ap. 13. Crystal Structure Data (P. 488-491) PDFFernando Freitas AlvesAinda não há avaliações

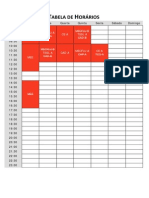

- Class Schedule and Timetable for the WeekDocumento1 páginaClass Schedule and Timetable for the WeekFernando Freitas AlvesAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Structure and Function of Complex NetworksDocumento58 páginasStructure and Function of Complex NetworksCelso GonçalvesAinda não há avaliações

- Física ITA 2010 (Resolvido)Documento31 páginasFísica ITA 2010 (Resolvido)Fernando Freitas AlvesAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Piping Work Method For Fuel Oil Pipe Fabrication Installation and TestingDocumento7 páginasPiping Work Method For Fuel Oil Pipe Fabrication Installation and Testingsamsul maarif100% (1)

- 2002 Yamaha FZS1000 Service Repair Manual PDFDocumento30 páginas2002 Yamaha FZS1000 Service Repair Manual PDFjhjnsemmemAinda não há avaliações

- Structural Analysis of Mast of Special Rotary Drilling Rig For Transmission LineDocumento5 páginasStructural Analysis of Mast of Special Rotary Drilling Rig For Transmission LineBruno SantosAinda não há avaliações

- Daenyx LOGODocumento6 páginasDaenyx LOGOamarAinda não há avaliações

- Remover e Instalar Camisas de CilindrosDocumento4 páginasRemover e Instalar Camisas de CilindrosAlejandro ValenzuelaAinda não há avaliações

- Connection HCS PDFDocumento25 páginasConnection HCS PDFPranay UpadhyayAinda não há avaliações

- YHZS75 Mobile Concrete Mixing Plant - (220V-60HZ)Documento5 páginasYHZS75 Mobile Concrete Mixing Plant - (220V-60HZ)DelioAinda não há avaliações

- 1 - NDT Basics Ut, MT.,PT, RiDocumento20 páginas1 - NDT Basics Ut, MT.,PT, RiGMAinda não há avaliações

- Cadenas de Tiempo Pontiac G5Documento17 páginasCadenas de Tiempo Pontiac G5Jorge Antonio GuillenAinda não há avaliações

- Crane FS Project Valves Cover LoresDocumento75 páginasCrane FS Project Valves Cover LoresErwin MaldoAinda não há avaliações

- Hoop StressDocumento3 páginasHoop Stresskarthikraja21Ainda não há avaliações

- CPS Refrigerant Leak Detector LS790BDocumento20 páginasCPS Refrigerant Leak Detector LS790BRichard WeimerAinda não há avaliações

- 4.2 Continuous Load Path: 4.3 Overall FormDocumento10 páginas4.2 Continuous Load Path: 4.3 Overall FormSirajMalikAinda não há avaliações

- Ies 1997 - II ScanDocumento21 páginasIes 1997 - II ScanK.v.SinghAinda não há avaliações

- TN54E DatasheetDocumento2 páginasTN54E DatasheetGreggs ShopukAinda não há avaliações

- Hydraulic Calculation of Box Culvert: Wlu HC Hu C HLB Blu BLC WLCDocumento1 páginaHydraulic Calculation of Box Culvert: Wlu HC Hu C HLB Blu BLC WLCIwanTiaraMotorAinda não há avaliações

- CraneDocumento16 páginasCraneAdrian Franco MolinaAinda não há avaliações

- TM 9 2320 363 24PDocumento1.164 páginasTM 9 2320 363 24PAdvocateAinda não há avaliações

- Davey Dewatering AEMDocumento2 páginasDavey Dewatering AEMJohan TanAinda não há avaliações

- Man P2862 Le ProjectDocumento406 páginasMan P2862 Le ProjectMuhammad Subhan IrfandyAinda não há avaliações

- ORC Guide: Technology and ApplicationsDocumento26 páginasORC Guide: Technology and ApplicationsdolphinAinda não há avaliações

- Gas Turb 10Documento224 páginasGas Turb 10Mohammad Ali AkhtardaneshAinda não há avaliações

- Thermodynamics Basics and First LawDocumento22 páginasThermodynamics Basics and First LawDamo Daran GAinda não há avaliações

- ASTM A106 GR.B Steel Tube PDFDocumento2 páginasASTM A106 GR.B Steel Tube PDFKader KaderAinda não há avaliações

- Howden Axial Fans HC Centrifugal Fans PDFDocumento116 páginasHowden Axial Fans HC Centrifugal Fans PDFSurya Kiran KAinda não há avaliações

- Indian Railways: 1 I:, 1 SP C. No. RDSO/Z015/CG 03Documento14 páginasIndian Railways: 1 I:, 1 SP C. No. RDSO/Z015/CG 03nikunjsingh04Ainda não há avaliações

- ONIXline BJ Series Dimensions GuideDocumento5 páginasONIXline BJ Series Dimensions Guidemarcusa85Ainda não há avaliações

- Steam System Properties and Energy SavingsDocumento34 páginasSteam System Properties and Energy SavingsArnav KothiyalAinda não há avaliações

- Automation and Robotics LabDocumento38 páginasAutomation and Robotics LabRanjit KumarAinda não há avaliações

- Root Cause of Sub-Synchronous Vibration in Multi-stage Centrifugal CompressorDocumento20 páginasRoot Cause of Sub-Synchronous Vibration in Multi-stage Centrifugal CompressorAUTVPDPPC1022 Muhammad Safuan Bin Md SallehAinda não há avaliações