Escolar Documentos

Profissional Documentos

Cultura Documentos

Project Execution Plan

Enviado por

Eka SatriaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Project Execution Plan

Enviado por

Eka SatriaDireitos autorais:

Formatos disponíveis

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

PERTAMINA EP CEPU

ONSITE UNDERGROUND PIPING WORK

JAMBARAN TIUNG BIRU PROJECT

DOCUMENT TITLE

DOCUMENT NO

THIS DOCUMENT CONSISTS OF TOTAL :

24

: PROJECT EXECUTION PLAN

: 9677-JTB-TS-PLA-16-001

UNAUTHORIZED

NAUTHORIZED COPYING OF THIS

DOCUMENT IS NOT PERMITTED

PAGES

REV

DATE

PURPOSE

ORIGINATOR

CHECKER

12 FEB 2016

IFR

IND

AR

-1-

CONTRACTOR

COMPANY

DATE

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

RECORD OF REVISIONS

THE REVISIONS LISTED BELOW HAVE BEEN INCORPORATED IN THIS COPY OF THE DOCUMENT

DO

REV.

No.

SECTION

PAGE

NO.

DESCRIPTION OF

CHANGES by

-2-

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

DOCUMENT REVIEW COMMENT SHEET

ITEM

NO

SECTION

COMMENTS

(REVIEWER)

1

2

-3-

BY

ACTION

UNDERTAKEN

(ORIGINATOR)

NATOR)

CLOSED

OUT

(O/C)

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

TABLE OF CONTENTS

1.0 INTRODUCTION................................

................................................................................................

..................................................... 6

1.1 Project General Description ................................................................

......................................................... 6

1.2 Project Overview ................................................................................................

................................

........................................... 6

1.3 Abbreviations................................................................................................

................................

................................................. 6

2.0 SCOPE OF WORK ................................................................................................

................................

................................................. 7

3.0 PROJECT MANAGEMENT PLAN

P

................................................................

.......................................................... 9

3.4

3.5

3.6

3.7

Project Objectives ................................................................................................

................................

......................................... 9

Health, Safety and Environmental ................................................................

.............................................. 10

Quality ................................................................................................

................................

.......................................................... 10

Budget ................................................................................................

................................

.......................................................... 10

4.0 PROJECT EXECUTION PROCESS

PR

................................................................

..................................................... 10

5.0 PROJECT SCHEDULE / PLANNING

LANNING ................................................................

................................................... 12

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

Overall Coordination ................................................................................................

................................... 12

Review and Analysis ................................................................................................

................................... 12

Progress Measurement ...............................................................................................

............................... 13

Reporting ................................................................................................

................................

..................................................... 13

Detail Scheduling and Planning ................................................................

................................................. 13

Progress Monitoring ................................................................................................

................................... 14

Non-Conforming

Conforming Item Control ................................................................

.................................................... 14

Documentation ................................................................................................

................................

............................................ 14

6.0 CONSTRUCTION ENGINEERING................................................................

ENGINEE

........................................................ 14

6.9 General ................................................................................................

................................

......................................................... 14

6.10 List of Engineering Documents and Software ........................................................

................................

15

6.11 Key Engineers ................................................................................................

................................

........................................... 16

7.0 PROCUREMENT PROCESS ................................................................................................

................................ 16

8.0 MATERIAL CONTROL ................................................................................................

................................

......................................... 17

9.0 QA/QC ................................................................................................................................

................................

.................................. 19

10.0 HEALTH, SAFETY AND ENVIRONMENTAL

NVIRONMENTAL ................................................................

....................................... 19

10.1 Procedures ................................................................................................

................................

................................................ 19

10.2 HSE Plan During Project Execution

Executio ................................................................

........................................ 20

11.0 DOCUMENTATION ................................................................................................

................................

.............................................. 21

11.1

11.2

11.3

11.4

Introduction................................................................................................

................................

............................................... 21

Objective Of The Document Control ................................................................

....................................... 21

Document ................................................................................................

................................

.................................................. 22

Detailed Design Package ................................................................

......................................................... 22

12.0 PROJECT CONTROLS ................................................................................................

................................

........................................ 22

12.1 Project Control Introduction ................................................................

.................................................... 22

12.2 CONTRACTOR Cost

Cos Control Plan ................................................................

........................................... 23

-4-

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

13.0 PROJECT CLOSE-OUT ................................................................................................

................................

....................................... 23

-5-

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

1.0 INTRODUCTION

1.1

Project General Description

PT. Pertamina EP Cepu act as Contractor of SKKMIGAS Oil and Gas Operator on

behalf of the other contractors by the PSC plans to develop and produce gas

reserves for Jambaran-Tiung

Jambaran

Biru in Bojonegoro, East Java.

JTB Unitization Gas Project is the development of Cepu Contract Area, and located

on the island of java, the Cepu and Bojonegoro. PT.Pertamina EP Cepu will develop

a gas field Jambaran Tiung Biru in an integrated manner with a capacity of

330MMSCFD

1.2

Project Overview

Tripatra-Saipem

Saipem JO is a national company in Engineering Procurement

Construction

ruction (EPC), is as Contractor in the cooperation contract with PT.

Pertamina EP Cepu to work on Development projects Jambaran Tiung Biru Gas

Development Project mentioned above

The

e Contractor Tripatra Saipem JO intend invited subcontractor to execution

Onsite Underground Piping Work

The Project Jambaran Tiung Biru (JTB) is located 150 Km from Surabaya and

55M above Sea Level (MSL) in Kabupaten Bojonegoro, East Java Province.

1.3

Abbreviations

COMPANY

PERTAMINA EP CEPU

CONTRACTOR

TRIPATRA SAIPEM JO

SUBCONTRACTOR JO URAWA AND ABACUS

JTB

Jambaran Tiung Biru

EPC

Engineering Procurement Construction

FEED

Front End Engineering Design

AFC

Aprroval for Construction

HSE

Health Safety Environment

-6-

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

SUBCONTRACTOR Refers to Other Parties engaged by the CONTRACTOR

CSR

Company Site Representative

HAZID

Hazard and Identification

HAZOP

Hazard and Operability Study

LTI

Loss Time Injury

2.0 SCOPE OF WORK

The purpose of this scope of work is to describe to construction work to be

performed by Subcontractor and than Subcontractor shall be responsible to perform

Piping Onsite Shop Fabrication and process Installation Piping at Site in accordance

acco

with the requirements and conditions as stipulated in This Scope of work and Split of

Work.

1.

2.

3.

Engineering CONTRACTOR

NTRACTOR has provided all document for this works

included Drawings and Procedure, Subcontractor shall provide

shop drawing and all documents

document s should be Approved For

Construction (AFC) by COMPANY.

Procurement CO

ONTRACTOR to provide all permanent material for this

work and Subcontractor shall supply all temporary material for support

fabrication and installation.

installation. Furnish all the construction equipment

eq

and

tools necessary for performing the work, included all the consumable

material such as grease and fuel. The equipment have to be in good

conditions and complete with the Standard Operation Procedure

necessary certificate (MIGAS, DEPNAKER, etc) and safety manual

instruction manual provided by Subcontractor which shall be subject to

Contractor Approval.

Fabrication / Installat

ation

Subcontractor to provide all labor, supervision, construcction, and

installation, equipment,

equ

tools and consumables for this work

3.2 The table of Split of Works Contractor with Subcontractor

3.1

-7-

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

ONSITE UNDERGROUND PIPING WORK

(PEKERJAAN PIPA BAWAH TANAH

DILAPANGAN)

DESCRIPTION

CONTRACT SUBCONTRAC

OR

TOR

No.

I.

1

(Deskripsi)

GENERAL

(UMUM)

SHOP

MANAGEMENT,

CONTROL

SUPERVISION

(MANAGEMEN

SUPERVISI)

II.

BENGKEL,

KONTROL

REMARKS

(Tambahan)

AND

&

PERMITS

(PERIJINAN)

Permits from local government, and Related

a. Department such

as DLLAJR, Police Department

(Ijin dari Pemda serta Departemen yang terkait

seperti

DLLAJR dan Kepolisian)

b Insurances which including: Comprehensive

. General Liability

Insurance (Body Injury and Property Damage),

Workmanship

Compensation Insurance, Employe's Liability

Insurance,

Comprehensive Automobile Liability

Insurance for

Subcontractor's automobil, Subcontractor All

Risk Equipment

Insurance and Watercraf Hull Insurace, All

Risk Marine Cargo

Insurace for Materiall and Equipment

supplied by the

Subcontractor, Other Insurance for

Subcontractor (if

necessary).

(Asuransi-asuransi

asuransi yang meliputi: Asuransi

Umum (Luka

Badan dan Kerusakan Properti), Asuransi

untuk Upah

Pekerja, Asuransi Kewajiban terhadap

Pekerja, Asuransi

Automobil, Asuransi untuk Kendaraan Laut,

Asuransi untuk

Angkutan Laut yang disuplai oleh

Subkontraktor, dan

Asuransi lain jika ada)

c. Other Local Permits

(Ijin lokal lainnya)

d

. Taxes

(Pajak-pajak )

MANPOWER MOBILIZATION &

DEMOBILIZATION

(MOBILISASI/DEMOBILISASI)

a

. Sub-Contractor's Manpower

(Tenaga Kerja Subkontraktor)

b. CONTRACTOR's Manpower

(Tenaga Kerja KONTRAKTOR)

TEMPORARY FACILITIES

(FASILITAS SEMENTARA)

-8-

X

X

X

X

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

GENERAL

(UMUM)

a

. Area/Space for Temporary Facility

(Area untuk Fasilitas Sementara)

b

. Housing for Subcontractor's Staff & Labor

Lab

(Housing for Subcontractor's Staff & Labor)

c. Subcontractor's Office

(Kantor Subkontraktor)

(UTILITAS)

a

. Water

(Air)

b

. Electricity

(Listrik)

c. etc.

(Lainnya)

GENERAL EXPENSES & SUPPLY

(PENGADAAN & PENGELUARAN UMUM)

a Home and office for Sub-Contractor's

Contractor's

. operation

(Tempat tinggal & Kantor untuk operasional

Subkontraktor)

REV. A

X

X

X

CONTRACTOR provide area office

(KONTRAKTOR menyediakan area office)

X

X

X

b

. Daily consumables for Sub-Contractor

Contractor

(Barang Habis Pakai harian untuk

Subkontraktor)

Safety health environment control and medical

c. services

(Kontrol SHE dan Layanan Medis)

d Daily Transportation for Sub-Contractor's

Contractor's labor

. to/from site

(Transportasi untuk tenaga kerja

Subkontraktor dari dan ke

lapangan)

e Sub-Contractor's

Contractor's office equipment and office

. supply

(Perlengkapan dan kebutuhan Kantor

Subkontraktor)

X

X

f. Safety Protection goods

(Alat Pelindung Diri Lengkap)

g

. Identification Card/ Badge

(Tanda pengenal di Site)

h. Fire Extinguisher

As per CONTRACTOR

ONTRACTOR and Client

requlation

(Mengacu pada aturan KONTRAKTOR

dan Klien)

As per CONTRACTOR and Client

regulation

(Mengacu pada aturan KONTRAKTOR )

3.0 PROJECT MANAGEMENT PLAN

P

3.4

Project Objectives

The key objectives are to execute the Project:

To the Quality as specified in the Contract

To the agreed Schedule

To within or below the specified Budget

To meet the above objectives, the Project Management Team shall emphasize on the

following principles during the Project Execution Phase:

-9-

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

3.5

3.6

REV. A

Health, Safety and Environmental

Ensure that HSE risks

sks are managed during fabrication/

fabrication/ installation phase

Monitor and maintain HSE legal compliance

complia

requirements

Achieve excellent project safety performance

Zero incidents

Zero LTI or long term debilitating illnesses for either Contractor, Sub-Contractor

Sub

or Company s personnel

Quality

3.7

9677-JTB-TS-PLA-16-001

Install the facilities so they meet the intent of the Contract requirements /

specifications or approved deviations and quality expectations

Budget

Complete the Project Scope of Work to within the allocated budget

SCHEDULE

Turnover the facilities on or before the agreed scheduled completion date

BUSINESS DEVELOPMENT

Fully exhibit CONTRACTORs execution capability in meeting Companys

expectations and such that HSE becomes the COMPANYs Company of choice.

4.0 PROJECT EXECUTION PROCESS

PR

The contract will be executed as Lump Sum Project for the Contractor.

Contractor For the proper

project execution Subcontractor has divided the overall SOW as follows:

Project Management and Procurement team are stationed in Jakarta &

Surabaya and supported by other departmental and personnel of Urawa site ,

Lamongan Shore base and Cepu.

- 10 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

CONTRACTORss execution plan is based around clear and

and unfettered access to

Pertamina EP Cepu facilities in line with the

he agreed Project Schedule.

COMPANYs and CONTRACTOR will be responsible

ible for liaison with their area

Operations and Governments to ensure that the required

equired access is provided.

And Subcontractor shall follow as

The Project Engineer will check and follow up the engineering works. He will be the link

between the Engineering team and the Project Management Team.

The resources, procedures,

procedures, and methods employed for the work will be developed to

allow an overall coordinated effort of engineering. Within 30 days after the

commencement date.

Immediately after project award, the engineering team will initiate engineering work with

the following

ng activities;

Up date Engineering schedule and staff requirements

Prepare all basic engineering documents

Establish engineering requirements for site visits/surveys and site coordination;

interface points and other queries.

Develop schedules, manpower requirements,

requirements, for each individual engineering

discipline

Technical capabilities for the various engineering disciplines are summarized in the

following paragraphs.

Prepare and conduct an internal kick off meeting to introduce project personnel,

define the scope

cope of work and initiate information flow CONTRACTOR.

CONTRACTOR

Develop thereafter the engineering works in accordance with the scope of work, the

list of documents to be provided, and the project schedule.

The Project Engineer will maintain a clear definition of

of the project scope as per Project

Manager Instructions and advice the Engineering team of approved changes. He will

direct the preparation of the Engineering Procedure and establish work plans and

manpower requirements. He will organize and staff the engineering

engineering team and assure

compliance with CONTRACTORs requirements.

The Project Engineer will ensure

ens

that all MTOs and material lists are issued in timely

manner. He will be in charge of preparing the requisitions.

More generally the

he Project Engineer willl identify and request the Project manager or

other relevant people to provide the information necessary for the completion of

engineering works.

ineering group will prepare shop drawings and MTO as per AFC Drawings by

Piping Engineering

CONTRACTOR. And Piping Engineering

Eng

Team will issue isometric drawings for pipe pre

- 11 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

fabrication. They will also design heat-tracing

heat tracing systems and design all supports and other

items within Battery Limit Facilities.

They will work closely with the Project Engineer to detail the tie in requirements to

facilitate timely installation during the construction.

5.0 PROJECT SCHEDULE / PLANNING

LANNING

5.1

Overall Coordination

Project schedule will be generated in accordance with the contract scope of work

and key milestone dates. WBS and work activities

activities for the Installation Project shall

be linked across all phases and the Project Critical Path shall be identified. The

Planning and Project Control Package shall be submitted to CONTRACTOR for

approval. The approved Plan shall be frozen once approved by Company and form

the baseline for actual progress monitoring.

This Baseline plan will form the basis for the monitoring and controlling of the

project execution and utilized for generating the Project Progress Report. All

outputs will be derived/ referenced

referenced from this Baseline Plan (e.g. bar chart update, SS

curves, manpower histogram and activities listing etc.).

All activities identified on the critical path shall be monitored diligently to ensure

there is no slippage and do not threaten the Overall Project

Project Schedule. If the need

arises, the baseline plan shall be revised upon mutual agreement between

CONTRACTOR and COMPANYs

5.2

Review and Analysis

Periodic review of the scheduled activities on this overall Baseline schedule will be

performed by the Planning Coordinator

Coordinator once a month at every cut-off

cut

date.

The schedule performance will be discussed in weekly/monthly project meetings

with the relevant departments and parties, where the status of the current on-going

on

activities will be reviewed. During this meeting

meeting the target plan activities due for the

next week/month will also be discussed. Scheduled variance / delays and problems

being faced currently and anticipated will be analysed. Ways to overcome these

difficulties will be determined and if necessary the schedule

schedule updated to reflect these

changes upon COMPANYs

COMPANY approval.

Monthly and weekly reports will be prepared and submitted to COMPANY. The

reports will include all the necessary planning and progress information.

- 12 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

5.3

9677-JTB-TS-PLA-16-001

REV. A

Progress Measurement

Weighted Values

Weighted

ted assigned to each activity reflects the contribution for that particular activity

to the overall completion of the project. The weighted value may be calculated

based on the estimated man hours required to complete the activity or based on the

estimated cost. In general, the higher the weighted, the longer will be the duration to

complete the activity.

Progress Calculating Procedure

Measurement of the physical progress for all current and on-going

on going activities shall be

done on weekly basis. The PMT will be

be responsible to monitor the progress for each

activity as well as the actual overall progress. In the event that the actual progress

is less than the planned progress, the information shall be communicated to the

responsible party either through the weekly

weekly progress meeting or via official memo

via the Planning Coordinator. The Project Manager or his assigned deputy has the

overall responsibility of the Progress.

5.4

Reporting

In compliance with CONRACTOR

NRACTOR requirements, SUBCONTRACTOR

CONTRACTOR will issue a daily,

weekly and monthly report. This report will be prepared by the Project Control Engineer

and will be distributed after review and approval by the PMT.

SUBCONTRACTOR

CONTRACTOR will be submited

subm

the daily report to CONTRACTOR

NTRACTOR day by day during

this project

5.5

Detail Scheduling and Planning

Planning and Scheduling Department will be managed by Project Service Manager. His

responsibility is to maintain the planning and scheduling system for the overall project by

producing and maintaining engineering, procurement, and overall project

pro

schedules and

coordinate planning and scheduling with Construction Planner within construction, and

Planning and Scheduling Department will be use Project Master Schedule, detail Schedule

level-3,

3, and Manpower Histogram as Controlling tools.

schedule level-1

1 already provide and to be sumitted in Technical Document

- 13 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

5.6

9677-JTB-TS-PLA-16-001

REV. A

Progress Monitoring

Regular progress meeting will be held between CONTRACTOR and the Sub-contractors.

Sub

In

this meeting, the review of the work progress will be made while the concern and problem

pr

areas will be highlighted and possible corrective actions are discussed and concluded.

5.7

Non-Conforming

Conforming Item Control

Non-conforming

conforming work control shall be carried out in accordance with the non-conforming

non

control procedure agreed by CONTRACTOR and the Sub-contractor.

S

5.8

Documentation

Final documentation shall be submitted to Company after review by CONTRACTORs

personnel for their relevant works.

The documentation includes the following, but not limited to:

Preservation/maintenance reports.

Final inspection documents/release notes

The approved outstanding list.

Spare-part lists.

6.0 CONSTRUCTION ENGINEERING

ENGINEE

6.9

General

CONTRACTORs will provide engineering team to prepare shop drawings and installation

drawings and procedures. which the CONTRACTOR engineering will

will coordination and

consultant with COMPANY engineers before starting construction activities related to

Drawings and Procedures Approval for Construction (AFC)

- 14 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

6.10

9677-JTB-TS-PLA-16-001

List of Engineering Documents and Software

List Of Engineering Deliverable :

NO.

DOCUMENT TITLE

PMT

1.1 Pre-Cons truction Survey Report

1.2 Project Mas ter Schedule

1.3 Progres s Meas urement

ENGINEERING

2.1 Shop Drawing

2.2 As -Buit Drawing

CONSTRUCTION

3.1 Construction Plan

3.2 Mobilization Plan

3.3 Scaffolding Plan

3.4 Scaffolding Ins tallation Procedure

3.5 Lifting Plan

3.6 Fabrication and Ins tallation Procedure

3.7 Diving Procedure

Work Packages Procedure

3.8 - Work Packages for Structure

QA / QC

4.1 Project Quality Plan

4.2 ITP for Structure Fabrication

4.3 Surface Preparation and Painting Procedure

Non Destructive Testing Procedure (NDT)

4.4 NDT Procedure (Structure Fabrication)

4.4.1 MPI Procedure

4.4.2 UT Procedure

4.4.3 Radiography procedure

4.4.4. MIGAS Approved WPS

4.4.5 MIGAS Approved Welder Matrix, WQT Cert

HSSE

5.1 Project HSE Plan

5.2 Enviromental Management

5.3 Emergency Res pon Plan

5.4 Level Two Risk Ass ess ment

List Of Software for Engineering :

Auto Cad 2D&3D

Navis Works

PDMS

Primavera P6

- 15 -

REV. A

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

6.11

9677-JTB-TS-PLA-16-001

REV. A

Key Engineers

The CONTRACTORs engineer allready mention in Project Management Team Organization

Chart included their CVs

7.0 PROCUREMENT PROCESS

After the

e decision has been made to purchase goods or outsource services, the procurement

team develops a plan that includes the following:

Selecting the appropriate relationships and contract approaches for each type of

purchased goods or outsourced service

Preparing

aring RFQs and RFPs and evaluating partnership opportunities

Evaluating RFQs, RFPs, and partnerships

Awarding and signing contracts

SO/PO process to Awarding

Managing quality, timely performance

Managing contract changes

Closing contracts

Depending on the complexity level of the project, each of these steps can take either hours or

sometimes weeks of work to complete. Each of these steps is also included in the project

master schedule. The time involved in the procurement cycle can influence the scheduling of

critical activities, including the decision to self-perform

self perform the work or contract the work to

others. The equipment and materials delivery dates and completion of contracted work dates

are placed on the project schedule and any procurement activities that

that create a project delay

or fall on the project critical path may require special attention.

- 16 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

Procurement Plan Flow Chart

PROCU RE M EN T P LA N FLOW CH ART

VE NDOR

SE LE CT ION

R F Q / R FP

R F Q / R FP

AW AR D /

C ON TR ACT

SO / P O

CLO SIN G

C ON TR CT

M ANAG E

C ON TR CT

M ANAGE

Q UALITY

8.0 MATERIAL CONTROL

Organization

Jobsite material control

ontrol is carried out by the Subcontractors

s Material Controller

C

who

monitors the status of all materials from requisition through receipt at the jobsite.

Coordination with receiving, inspection and document preparation of activities all

materials and equipment will be kept.

Monitoring of material delivery status and immediate reporting of any delivery slippages

or changes will be made in order to allow maximum time for re scheduling and

planning.

Site Material Control

Receiving Materials and Equipment

The equipments and materials (the Goods) will be delivered

delivered to the fabrication or and to

project site. The Goods will be unloaded and stored in a place in the station, pending

custom clearance.

Subcontractor will then perform immediately a preliminary visual inspection in the

contractual delivery point, to determine if any damage occurred during shipping and

- 17 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

handling. This inspection at this stage will be limited to the identification of any visual

damage or missing item, as compared to the Bill of Lading and packing list. In principle

the bags and/or packs will not be

be open in the station, even if damaged. This inspection

will be performed to disclose any physical damage to the containers or packs due to

rough handling, fire, and excessive exposure to weather, tie down failure, shocks,

accidents or other reasons. Damages

Damages to some bulk items such as pipes can be

identified at this stage.

An Subcontractors site representative acting as Material Controller will attend that

operation and countersign copy of the inspection report, subject agreement, and

an will

report immediately

ediately to CONTRACTOR.. It will be important to identify whether any

damage occurred before unloading the Goods (it will be PALs insurance responsibility)

or upon unloading (it will be Buyers responsibility).

Other containers, packs and bulk items will be checked.

Receiving documents

nts will include:

Materials receiving report and register

Record of the documentation attached

Overage, shortage and damage report and register

Shipping damage inspection tag (countersigned by the parties)

Returned material report and register (countersigned

(countersigned by the parties)

Equipment rental receipt / release record

Returnable containers record (if any )

The Material Controller will record the delivery on the Material Receiving Report (MRR),

register and input delivery information into the Materials Management

Manage

system.

Discrepancies noted before, during and after unloading will be listed on both the MRR

and the delivering carrier documentation, a copy of which will be retained in the file.

A Shipping Damage Inspection Tag will be attached to damaged shipment

shipmen until damage

is corrected, or items are returned to the suppliers, or scrapped and recorded.

Storage of Materials

aterials and Equipment on Site

The Storage on shop is sub-contractor responsibility; however Subcontractors

Subcontractor Material

Controller shall make sure good

good and safe procedures are applied, in line with following

guide lines, in order to avoid or minimize problems with missing or defective Goods

during the construction and installation.

Permanent materials will be stored in accordance with

with applicable project

specification, vendors requirements.

The storage areas/levels will be planned and provided as follow:

Items requiring indoor storage will be stored in a fire resistant, weather tight and

well-ventilated

ventilated building.

Items requiring temperature

emperature and humidity control as required by manufacturers

instructions will be stored in a building provided with heat / temperature control in

- 18 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

order to prevent condensation and corrosion.

Items that may be stored outdoors will be stored in areas marked

mark and designated for

the outdoor storage, and properly fenced or protected.

In general, storage areas will be maintained in a clean condition and provided with

fire protection as required. Methods of storing equipment and materials will comply

with the vendors

ndors / manufacturer requirements, and engineering specifications.

The Material Controller shall be responsible for the receipt, storage, protection and

preservation of all Company supplied items until they are incorporated into the

completed and tested.

.

9.0 QA/QC

The Quality Manual shall provide the frame-work

frame work for the overall Quality Management

System

ystem (QMS) and provide procedures, standards, controls and consistency to maintain a

system throughout Subcontractor.

Subcontractor. This Quality Manual includes policy and objectives aims

to enhance customer/client satisfaction through effective professionalism working

organization

ion including management responsibility, process for continual improvement of the

system, the assurance of conformity to customer, applicable statutory and regulatory

requirements. As the second tier documentation of the Quality Manual, there shall be

Quality

ity Control Procedures which address and support the sections of the Quality Manual

providing details for implementing and maintaining the Quality Manual requirements.

And Quality Manual and QA/QC Procedure will be submit to Contractor before Construction

start included ITP, WPS, NDE Procedure

Procedu and Others Procedure

10.0HEALTH,

EALTH, SAFETY AND ENVIRONMENTAL

EN

10.1

Procedures

Subcontractor has a Health, Safety and Environment commitment, which is reflected in

the form of Health and Safety Policy, Health Safety & Environment (HSE) Manual, Safety

Management Plan, Environment Management Plan, Emergency Response Plan, Waste

Management Plan, Accident / Incident Investigation Reporting Procedure, and other

related safety activities. In executing a project, Safety and Lost Control is always

developed based

sed upon these documents as well as a COMPANY safety policy and

requirement. Previous project safety documents including safety dossiers are available

upon request.

For executing the project, Subcontractor has used Contractors CSMS developing Safety

& Lost Control

ntrol procedures to achieve the HSE requirement. Some elements are

incorporated into this proposal as Contractor standard document and as proposed

document.

- 19 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

Implementation of CONTRACTOR HSE Regulation as related to COMPANY HSE

requirements for this specific project will be achieved via HSE Management Plan, Safety

dossiers will also be generated during the execution of the project.

10.2

HSE Plan During Project Execution

The proposed of the HSE Plan is to make sure that the job are done in accordance with

HSE regulations to prevent any accident or incident that may occurs due to personnel

negligence or the nature of the job. It is also to make sure that tools and equipment used

are of the right type, size and as intended.

HSE procedures will be generated to control the HSE implementation during yard

fabrication and site works execution. The procedure will contain specific safety plan for

each specific job to be performed. The procedure will have

have general format with the

elements as specified

ed on COMPANYs

CSMS Requirement. The following item shall be

described in HSE Plan :

HSE Responsibilities

HSE Policies

Evaluating and Monitoring the HSE Plan

Contractor and Company HSE Responsibilities

Incident Reporting

HSE Training & Education

Safety Meetings

Subcontractors HSE Control

Risk Assessment (Hazards Control Process)

Medical Services and First Aid

Emergency Drills

Emergency Response Plan

Telecommunication Operation

Personnel Protective Equipment

Equipment and Tools Safety

Electrical Safety

Working with near hazardous substances

Grit blasting, Painting and Coating

Cranes, Rigging and Heavy Construction Equipment

Ionizing Radiation

Civil Works

Housekeeping

Drugs, alcohol and firearms

Employees involvement

vement in Safety Matters

Permit to Work Procedure

HSE Reports and records

Audit and Inspection Plan

- 20 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

Detail description of the above sections plan is described in Project HSE Plan

11.0DOCUMENTATION

11.1

Introduction

Document Control will be set up in CONTRACTORs office in Jakarta

Jakar as the central

focal point for receiving, distributing and referencing all the project documents and

this location will control the flow of the documents and records between the

respective parties involved in the project.

During final stages of completion,

completi

the As-built

built dossier will be prepared by

CONTRACTOR with some assistance from its Survey Sub-contractor.

Sub contractor.

Control and distribution of all documents shall be executed by means of transmittals

or by the distribution matrix.

11.2

Objective Of The Document Control

Co

The objective of the Document Control shall be but not limited to:

To keep strict control of all relevant documents for the project and to ensure that

CONTRACTOR and COMPANY will receive a complete and updated set of final

documentation for this project.

proj

To centralize all documentation and filing systems to ensure the upkeep and

confidentiality of the documents.

To reduce duplication of filing systems between all Managers/Engineers.

To ensure all parties have the latest revisions of drawings specification

specifica

and

necessary information.

To simplify co-ordination

ordination of work between various departments and other

organization units.

To assist with the easy reference for all departments and organization units

involved.

To co-ordinate

ordinate all the various completed documents

documents for final hand over to

CONTRACTOR.

- 21 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

11.3

9677-JTB-TS-PLA-16-001

REV. A

Document

Document Control Will maintain and ensure all about document COMPANY and

CONTRACTOR submitted and receive by electronic mail first and after that will be

summitted by hard copy

Basically for this project, DC will co-ordinate

ordinate two (2) groups of documents as

follows:

i) COMPANYs Documents

11.4

Detailed Design Package

DEPs

Specifications

Procedures

Contract Documents

ii) CONTRACTOR Documents

Project Specific Procedures / Plans

Sub-contractors

contractors Procedures / Plans

As installed information for installation work

Acceptance Certificate

12.0PROJECT CONTROLS

12.1

Project Control Introduction

The purpose of the Project Control is to review, analyze, calculate and provide data to

Project Management Team (PMT) to evaluate the status

status work program and to take

immediate action to improve in case of any concern. After award, CONTRACTOR will

develop a project control procedure which will define the method of coordination, reporting

and list of periodic submission to Company Project Team. Throughout the project, the

dedicated PMT shall review and provide a comprehensive control system which will

comprise of:

Work progress status (schedule, progress and productivity)

Area of concern, remedial measured

Evaluate the project on regular basis, the quantity of work completed compared with

- 22 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

the planned activities.

12.2

Adapt the level of resources for accelerating the performance of each activity, as

required.

Assess the duration of on-going

on going activities and remaining activities.

Implement corrective action

action options to recover the schedule, where necessary.

CONTRACTOR Cost Control Plan

Followings are the key objectives for the Cost Control function:

Contract price breakdown / cost breakdown

Commitment Control

Expenditure

Variance and changes

Forecast / Estimate

timate to complete

Control and monitor all the above

Monthly Cost Report shall be prepared with the following information to be included

in the report:

A narrative summary of the project's current financial situation with details of any

disputes and intended

ded actions by either party.

A variation status with values of variations issued, agreed, disagreed, proposed,

withdrawn, completed with the current status of variations.

A contract status advising current forecast of final contract value containing lump

sums,

ums, measured works and variations as noted previously.

Variance between forecast final account and approved contract value.

13.0PROJECT CLOSE-OUT

The CONTRACTOR will provide as a minimum the following documentation:

A. Master Document Index

B. Design Report including

luding design documentation (AFC issue of design reports and

drawings), back-up

up calculations, all engineering analyses with explanation of the

theories and assumptions used in computer programs, specifications, bills of material,

updating of COMPANY drawings, etc.

- 23 -

ONSITE UNDERGROUND PIPING

WORK

DOCUMENT

NO.

9677-JTB-TS-PLA-16-001

REV. A

All documents to be provided by CONTRACTOR in the Final Documentation shall be

original where available.

CONTRACTOR shall submit the documentation in the form of PDF format and electronic

source file for hand-over

over purpose.

Electronic data shall be presented on CD-ROM

CD ROM (2 copies) with complete electronic index or

register.

Final Documentation shall be presented in the form of manual or dossiers in accordance

with COMPANY specification. CONTRACTOR shall provide one (1) original and one (1)

hardcopy of manuals or dossiers.

Dossiers and manual required by COMPANY shall include but not be limited to the

following:

Engineering Dossiers such as drawings, procedures, etc.

Construction and Installation Manual

Operating Dossier

Maintenance Dossier

As-Built Drawings

Supplier Vendor Documents

Close Out Report

- 24 -

Você também pode gostar

- Project Cost Estimating Manual PDFDocumento196 páginasProject Cost Estimating Manual PDFHasan Hamdan90% (20)

- ProjectExecutionPlan PDFDocumento69 páginasProjectExecutionPlan PDFrmagan100% (5)

- Project Execution PlanDocumento7 páginasProject Execution PlanJOHNK100% (12)

- Project Execution Plan for Quest CCSDocumento96 páginasProject Execution Plan for Quest CCSChijioke Obi86% (7)

- KPMG Learning Academy CatalogueDocumento20 páginasKPMG Learning Academy CatalogueSabyasachi KarAinda não há avaliações

- Construction Execution Plan1Documento28 páginasConstruction Execution Plan1Idaba100% (7)

- Project Execution Plan PDFDocumento21 páginasProject Execution Plan PDFBhavanishankar shetty80% (5)

- Progress Measurement ProcedureDocumento15 páginasProgress Measurement ProcedureSendhil_Kumar_2023100% (2)

- Day 3 - Project Management Methodology With PMP Exam Preparation Ver 1Documento169 páginasDay 3 - Project Management Methodology With PMP Exam Preparation Ver 1Zubair Khan100% (1)

- Shell Petroleum Construction Execution PlanDocumento40 páginasShell Petroleum Construction Execution PlanDaniel Dambo100% (26)

- Quest CCS Project Execution PlanDocumento69 páginasQuest CCS Project Execution PlanGraco Calle100% (6)

- Execution PlanDocumento50 páginasExecution Planmuhamedz100% (5)

- Estate Services Project Execution PlanDocumento30 páginasEstate Services Project Execution PlanHashim Habeed100% (5)

- Project Execution PlanDocumento25 páginasProject Execution Planvnarveka90% (21)

- Project Execution Plan PDFDocumento24 páginasProject Execution Plan PDFDindima100% (1)

- 1.6 Project Control PlanDocumento11 páginas1.6 Project Control Planaswar100% (1)

- A Project Manager Has Just Assigned To A Project. He Is Involved in Creating A Document ThatDocumento17 páginasA Project Manager Has Just Assigned To A Project. He Is Involved in Creating A Document ThatPrashant GuptaAinda não há avaliações

- 5A-QA-PL-02Rev00 - Project Execution and Quality PlanDocumento34 páginas5A-QA-PL-02Rev00 - Project Execution and Quality Planirzaldy100% (8)

- MIP17 - HSE - PP - 001 Environment Management Plan (EMP) 2021 REV 3Documento40 páginasMIP17 - HSE - PP - 001 Environment Management Plan (EMP) 2021 REV 3AmeerHamzaWarraichAinda não há avaliações

- TechnipFMC Project MobilizationDocumento9 páginasTechnipFMC Project MobilizationJobJob100% (8)

- Measure Progress with WBSDocumento7 páginasMeasure Progress with WBSF88% (8)

- Progress Reporting Procedure DraftDocumento9 páginasProgress Reporting Procedure DraftOhomina Josh100% (2)

- Project Execution Plan For Offshore Maintenance Coating OperationDocumento13 páginasProject Execution Plan For Offshore Maintenance Coating OperationMitchellgrany100% (3)

- Environmental Restoration Project Execution PlanDocumento49 páginasEnvironmental Restoration Project Execution PlanSunday Paul100% (1)

- Ssg-Ng01012401-Gen-Aa-5760-00001 - R04 - Project Execution PlanDocumento114 páginasSsg-Ng01012401-Gen-Aa-5760-00001 - R04 - Project Execution PlanStroom Limited100% (7)

- Project Execution Plan (Brief)Documento13 páginasProject Execution Plan (Brief)Dilip Kumar0% (1)

- Draft Plan For Construction and Pre-CommissioningDocumento77 páginasDraft Plan For Construction and Pre-Commissioningwangrui50% (2)

- A1G5F1 - OW-310690-201-MT - Excavation and Backfilling Rev C1Documento20 páginasA1G5F1 - OW-310690-201-MT - Excavation and Backfilling Rev C1khabiranAinda não há avaliações

- Appendix 4 - Method Statement (Project Execution Plan) For Building WorksDocumento13 páginasAppendix 4 - Method Statement (Project Execution Plan) For Building WorksFresly Patria100% (1)

- 202 Procedure 0-Project Execution PlanDocumento8 páginas202 Procedure 0-Project Execution PlanagaricusAinda não há avaliações

- Risk Management Plan for XXX Software DevelopmentDocumento8 páginasRisk Management Plan for XXX Software DevelopmentRysta YulandariAinda não há avaliações

- Project Execution Plan for 55MW Geothermal Power PlantDocumento26 páginasProject Execution Plan for 55MW Geothermal Power PlantMarzuqi Aqila100% (8)

- Project Execution Plan PDFDocumento84 páginasProject Execution Plan PDF1410200193% (27)

- WNS00 PP PC 0001Documento11 páginasWNS00 PP PC 0001Subramanian Saravanan100% (1)

- Project Control ProcedureDocumento21 páginasProject Control ProcedureSlamat Parulian Simamora100% (5)

- SOFTWARE DEVELOPMENT METHODOLOGIES COMPARED (39Documento29 páginasSOFTWARE DEVELOPMENT METHODOLOGIES COMPARED (39AhmadChoirulAinda não há avaliações

- Project Execution Plan - KLEDocumento63 páginasProject Execution Plan - KLEDebashish Das80% (5)

- PT BORNEO MITRA SINERGI – PROJECT EXECUTION PLAN FOR PIPELINE CONSTRUCTION SERVICESDocumento10 páginasPT BORNEO MITRA SINERGI – PROJECT EXECUTION PLAN FOR PIPELINE CONSTRUCTION SERVICESaswar100% (5)

- Construction Execution PlanDocumento31 páginasConstruction Execution Planmohammad kassar50% (2)

- Project Execution PlanDocumento52 páginasProject Execution PlanDr.Shahzada Irshad Mohammed100% (2)

- Execution PlanDocumento9 páginasExecution PlanM SiddiqueAinda não há avaliações

- Land Preparation Plan for 12 Ha Revetment ProjectDocumento12 páginasLand Preparation Plan for 12 Ha Revetment ProjectBerry UmpolaAinda não há avaliações

- J08937A-A-RT-00045 Rev A1 Basis of ScheduleDocumento15 páginasJ08937A-A-RT-00045 Rev A1 Basis of ScheduleMathias OnosemuodeAinda não há avaliações

- Engineering Progress MonitoringDocumento11 páginasEngineering Progress MonitoringSyed Faraz Raza100% (2)

- Resume of A Project CoordinatorDocumento3 páginasResume of A Project CoordinatorASHIL PRABHAKARAinda não há avaliações

- Work Method of Statement Site SurveyDocumento10 páginasWork Method of Statement Site Surveyahmed08839494Ainda não há avaliações

- Project Execution PlanDocumento10 páginasProject Execution PlanLuis M.Ainda não há avaliações

- 04 Mobilization PlanDocumento9 páginas04 Mobilization PlanMohd Khaidir100% (1)

- 4S08 Project ControlsDocumento14 páginas4S08 Project Controlssaleem_b89% (9)

- RFQ For Pressure TransmitterDocumento21 páginasRFQ For Pressure Transmittersugeng wahyudiAinda não há avaliações

- Project Execution Plan - TemplateDocumento12 páginasProject Execution Plan - TemplateTAHER AMMAR100% (2)

- Construction Execution Plan - ShellDocumento41 páginasConstruction Execution Plan - Shellrohit12389100% (3)

- PT Borneo Mitra Sinergi Project Control PlanDocumento11 páginasPT Borneo Mitra Sinergi Project Control Planaswar100% (3)

- 1.9 Engineering PlanDocumento9 páginas1.9 Engineering PlanaswarAinda não há avaliações

- Projects Controls PlanDocumento19 páginasProjects Controls PlanBGI Energy Services100% (3)

- Subcontracting PlanDocumento9 páginasSubcontracting PlanFayez Abdul Salam100% (2)

- CIMA Practical Experience PERDocumento14 páginasCIMA Practical Experience PERhmbogirriAinda não há avaliações

- Stephen Shumila CV Final SMSDocumento4 páginasStephen Shumila CV Final SMSAnonymous lRBvGgGW100% (1)

- MJPN PGAS 3514 GA PR 012 - Construction and As Build Survey Procedure - E - RevADocumento19 páginasMJPN PGAS 3514 GA PR 012 - Construction and As Build Survey Procedure - E - RevABayu Setiawan100% (1)

- SIBP Project Execution PlanDocumento11 páginasSIBP Project Execution PlanEnrique Pomales0% (1)

- Project Execution Plan - Tank Foundation WorksDocumento13 páginasProject Execution Plan - Tank Foundation WorksFresly Patria100% (1)

- PDOC 596 PEP 01 Project Execution Plan Rev 3Documento90 páginasPDOC 596 PEP 01 Project Execution Plan Rev 3Showki Wani80% (5)

- Agile ScrumDocumento32 páginasAgile ScrumPulkit AroraAinda não há avaliações

- Project Execution PlanDocumento13 páginasProject Execution Plansmshaidr100% (1)

- Water Bore Well at Hazira Onshore Facility Project Execution PlanDocumento6 páginasWater Bore Well at Hazira Onshore Facility Project Execution PlanSoumya KumarAinda não há avaliações

- DLR DatedDocumento4 páginasDLR Datedaneeshp_4Ainda não há avaliações

- MIP17-HSE-JSA-JUB-39 JSA For Piping Works (Flanged Installation, - Gasket Installation Welding & Bolt Tightening) - 2023 Rev 0Documento13 páginasMIP17-HSE-JSA-JUB-39 JSA For Piping Works (Flanged Installation, - Gasket Installation Welding & Bolt Tightening) - 2023 Rev 0AmeerHamzaWarraichAinda não há avaliações

- NBC - COLD PIPE BENDING PROCEDUREpdfDocumento16 páginasNBC - COLD PIPE BENDING PROCEDUREpdfVarghese MathewAinda não há avaliações

- Approval of BBS PDFDocumento2 páginasApproval of BBS PDFSanjeev Kr. ThakurAinda não há avaliações

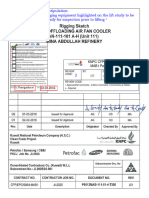

- P6012MAB-111-51-4-T300 - O2 - (Rigging SketchFOR OFFLOADING AIR FAN COOLER F.FAN-111-101 A-H (Unit 111) )Documento21 páginasP6012MAB-111-51-4-T300 - O2 - (Rigging SketchFOR OFFLOADING AIR FAN COOLER F.FAN-111-101 A-H (Unit 111) )Vasilica BArbarasaAinda não há avaliações

- Jadual PG Sept13Documento2 páginasJadual PG Sept13Ibrahim ShareefAinda não há avaliações

- Makerere University Makerere University Business School: TaskDocumento7 páginasMakerere University Makerere University Business School: TaskAnita KinyiiAinda não há avaliações

- Risk Identification and Common Risks in ConstructionDocumento13 páginasRisk Identification and Common Risks in ConstructionArya DdpAinda não há avaliações

- 70% + 50-69% 40-49% Weighting (Should Add Up To 100)Documento2 páginas70% + 50-69% 40-49% Weighting (Should Add Up To 100)Su Ba SaAinda não há avaliações

- 70 Free Questions & WebsitesDocumento53 páginas70 Free Questions & Websitesmy.nafi.pmp5283Ainda não há avaliações

- 1 s2.0 S2090447922001265 MainDocumento14 páginas1 s2.0 S2090447922001265 MainMahadeoAinda não há avaliações

- EDC SyllabusDocumento11 páginasEDC SyllabusDrew LevorsenAinda não há avaliações

- Project Failure As A Reoccurring Issue in Developing Countries PDFDocumento20 páginasProject Failure As A Reoccurring Issue in Developing Countries PDFKALKIDAN KASSAHUNAinda não há avaliações

- 3rd Sem SyllabusDocumento6 páginas3rd Sem SyllabusanjaliAinda não há avaliações

- Birdair CapabilitiesDocumento13 páginasBirdair CapabilitiesAnonymous heobCWOAinda não há avaliações

- Opmc Katalog enDocumento32 páginasOpmc Katalog envenki_2k2inAinda não há avaliações

- How PMBOK and MS Project Align To Help You Manage ProjectsDocumento1 páginaHow PMBOK and MS Project Align To Help You Manage ProjectsMohamed Arbi Ben YounesAinda não há avaliações

- Ultimate PMP Exam Prep CourseDocumento4 páginasUltimate PMP Exam Prep CoursesaromaAinda não há avaliações

- SQMDocumento9 páginasSQManuragAinda não há avaliações

- System Dev Unit One Questions - Multiple Choice and WrittenDocumento6 páginasSystem Dev Unit One Questions - Multiple Choice and WrittenMichaelAinda não há avaliações

- Everything You Need To Know About Agile Project ManagementDocumento5 páginasEverything You Need To Know About Agile Project ManagementAndreiAinda não há avaliações

- INFO3220 2019 Semester 1 StudentDocumento5 páginasINFO3220 2019 Semester 1 StudentDarius ZhuAinda não há avaliações

- Activity 1 Topic SynthesisDocumento5 páginasActivity 1 Topic SynthesisAlona SicsicAinda não há avaliações

- Sr. Unix Administrator - Job DescriptionDocumento4 páginasSr. Unix Administrator - Job DescriptionNikolaDerekAinda não há avaliações

- Hi-Tech ISTDocumento360 páginasHi-Tech ISTDharineeshAinda não há avaliações