Escolar Documentos

Profissional Documentos

Cultura Documentos

Desain Pci Girder

Enviado por

Fajrin HernataDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Desain Pci Girder

Enviado por

Fajrin HernataDireitos autorais:

Formatos disponíveis

PTWIJAYAKARYABETON

TECHNICALCALCULATION

PCIGIRDERMONOLITHFORHIGHWAYBRIDGES

Project

Product

Jobno

Rev.No.

:

:

:

:

TOLLSURABAYAGRESIK

PCIGirderMonolithH125cm;L20.15m;CTC160cm;fc'40MPa

13014A

04

DesignReff.

- SNIT122004

PerencanaanStrukturBetonUntukJembatan

- RSNIT022005

StandarPembebananUntukJembatan

- PCI:BridgeDesignManual

GedungJW,1 st & 2nd floor

Jl.Jatiwaringinno.54,PondokGedeBekasi

Ph:+622184973363fax:+622184973391

www.wikabeton.co.id

PTWIJAYAKARYABETON

TECHNICALCALCULATIONAPPROVAL

PCIGIRDERMONOLITHFORHIGHWAYBRIDGES

TOLLSURABAYAGRESIK

PCIGirderMonolithH125cm;L20.15m;CTC160cm;fc'40MPa

Jobno.: 13014A

Rev.: 04

Approvedby:

Consultan/Owner

Approvedby:

18Juni2013

Checkedby

18Juni2013

Designby:

18Juni2013

Ir.AchmadArifin

TechnicalManager

IgnatiusHarryS.,S.T.

ChiefofTechnical

Suko

TechnicalStaff

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

RESUME OF PCI GIRDER MONOLITH TECHNICALLY CALCULATION

1. BEAM SPECIFICATION

Span

Beam Height ( H )

Distance ctc of beam ( s )

Slab thickness

Beam Compressive strength

Slab Compressive strength

Bridge life time

Segment Arrangement

Beam Segment

1

Length (m)

6.275

Additional length at the end of beam

Total length of the beam

Total beam weight

2. STRESSING

Nos of PC Strand

=

Strand configuration

24

=

=

=

=

=

=

=

19.55

1250

1600

200

40

28

50

m (beam length

mm

mm

mm

MPa

MPa

years

4

0.00

5

0.00

20.15 m)

2

7.000

=

=

=

3

6.275

0.30

20.15

16.90

6

0.00

7

0.00

m

m

ton

strand

12.7

mm (PC Strand 270 grade, low relaxation)

No.

number

Tendon

strand

H strand bottom (mm)

edge

mid

Jacking Force

75%

UTS

1860.00

MPa

=

=

16.59%

UTS of Strand

Total Losses

fc initial

at middle

fc'

12

600

200

12

300

100

total

24

450.00

150.00

3. LOADING

1. Dead Load

a. Precast Beam

=

7.77

kN/m

b. Slab

=

7.86

kN/m

Slab thickness =

200

c. Deck Slab

=

2.31

kN/m

Deck slab thickness =

70

d. Asphalt

=

1.73

kN/m

Asphalt thickness =

50

e. Diaphragm

=

6.92

kN

for 1 diaphragm

No. Diaphragm

4

pcs

equivalent load =

0.94

2. Live Load

Taken from "Pembebanan Untuk Jembatan RSNI T-02-2005"

Moment force cause by D Loading is bigger than Truck Loading

a. Dynamic Load Allowance

(DLA)

=

1.40 for span length <= 50m

b. Knife Edge Load (KEL)

=

49.00 kN/m

c. Distribution Factor (DF)

=

1.00

d. Distribution Load

q=

9.00 kN/m2

9.00 kN/m2

9.00 x(0,5+15/span)kN/m2

e. Live Load

Distribution load :

q' = DF x q x s

=

14.40

Line Load

:

p' = DF x DLA x KEL x s

=

109.76

CALCULATION RESUME

80.0%

mm

mm

mm

kN/m

For Span <= 30m

For Span > 30m

kN/m

kN

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

4. BEAM SUPPORT REACTION

Ultimate total = 1,2*(Beam+Diaphragm+Deck Slab)+1,3*Slab+2*Asphaltic+1,8*(LL+I)

Beam support reaction :

a. Dead Load

b. Additional Dead Load

c. Live Load

=

=

=

75.90

125.48

250.52

kN

kN

kN

Ultimate support reaction =

713.78

kN

5. CONTROL OF BEAM STRESSES

1. Initial Condition

Middle span position

top stress

bottom stress

2. Service Condition

Middle span position

top stress

bottom stress

=

=

-0.57 MPa

17.34 MPa

required

required

>

<

-1.41 MPa

19.20 MPa

=

=

9.81 MPa

1.58 MPa

required

required

<

>

18.00 MPa

-3.16 MPa

6. CONTROL OF BEAM DEFLECTION

Deflection at the middle of beam span

1. Chamber due stressing

initial

erection

2. Deflection at composite DL

3. Deflection due live load

4. Total deflection at service

=

=

=

=

=

-17.68

28.08

-28

08

-8.25

7.48

-0.78

mm

mm

mm

mm,required <L/800

mm

7. MOMENT AND CRACKING CAPACITY OF BEAM

Moment Capacity requirement :

Mult = 1,2*(Beam+Diaphragm+Deck Slab)+1,3*Slab+2*Asphaltic+1,8*(LL+I)

Mn

Ratio, Mn / Mu (>1)

Cracking Capacity requirement :

Mcrack

=

3328.03 kN.m

Mn / Mcr

=

1.36

CALCULATION RESUME

=

=

=

= 24.44 mm

3488.59 kN.m

4523.79 kN.m

1.30

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

TECHNICAL CALCULATION OF PCI MONOLITH BEAM FOR HIGHWAY BRIDGES

19.55

M

SPAN

L =

I. DATA

0.3

L=

Beam length

Beam spacing (s)

Concrete Slab thickness (CIP)

Asphalt thickness

Deck slab thickness

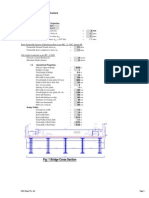

Cross Section

H

=

A

=

B

=

tweb =

19.55 M

20.15

1600

200

50

70

=

=

=

=

=

0.3

m

mm

mm

mm

mm

( edge anchor to edge anchor :

19.85

m)

1250

350

650

170

mm

mm

mm

mm

tfl-1

tfl-2

tfl-3

tfl-4

=

=

=

=

75

75

100

125

mm

mm

mm

mm

tfl-1

tfl-2

tweb

tfl-3

tfl-4

II. MATERIAL

B

2.1 Concrete

Beam

Slab

28.0

Compressive strength

[N/mm2]

at service

fc' =

40.0

at initial

80% fc'

Allowable stress

Allowable stress at initial (SNI T-12-2004 )

fc'i =

32.0

[N/mm2]

0.6 * fc'i =

19.2

[N/mm2]

0.25 * Sqrt(fc'i) =

Tensile

Allowable stress at service . (SNI T-12-2004 )

1.4

[N/mm2]

0.45 * fc' =

18.0

12.6

[N/mm2]

0.5 * Sqrt(fc') =

3.2

2.6

[N/mm2]

wc =

2500.0

2500.0

[kg/m3]

Ec = wc *0.043*sqrt(fc') =

33994.5

28441.8

[N/mm2]

Compressive

Compressive

Tensile

Modulus of elasticity

Concrete unit weight

1.5

1.5

Eci = wc *0.043*sqrt(fci') =

30405.6

[N/mm2]

4.4

[N/mm2]

Concrete flexural tension strength (fr)

f r = 0.7*sqrt(fc') =

2.2 Prestressing Cable

[Uncoated stress relieve seven wires strand]

( ASTM A 416 Grade 270 Low Relaxation or JIS G 3536 )

- Diameter strand

dia

:

12.7

[mm]

2

[mm ]

- Eff. Section area

Ast

- Modulus of elasticity

Es

: 1.93E+05

[N/mm2]

- Ultimate tensile strength

fu

[N/mm2]

2.3 Steel Reinforcement

- Diameter

98.78

1860

dia

13

[mm]

- Eff. Section area

Ast

132.73

[cm ]

- Modulus of elasticity

Es

: 2.10E+05

[N/mm2]

- Yield stress

fy

[N/mm2]

400

page 1 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

III. SECTION ANALYSIS

Remark :

2

Ep 1 =

33994

[N/mm ] [Girder]

Ep 2 =

28442

[N/mm ] [Slab]

5

4

n = Ep 2 / Ep 1

n=

0.84

1

2

Yb'

PRECAST BEAM

3.1 Precast Beam

[in mm ]

6

5

4

3

2

1

Total

Yb

Base Line

Zone

Ya'

Ya

Section

Width

Area

2

Level

Yb

Height

Bottom

Upper

mm

mm

mm

0.0

75.0

75.0

875.0

100.0

125.0

1250.0

150.0

350.0

170.0

170.0

650.0

650.0

150.0

350.0

350.0

170.0

170.0

650.0

0

26250

19500

148750

41000

81250

316750

1250

1175

1100

225

125

0

1250.0

1212.5

1141.8

662.5

165.2

62.5

519.3

Area

COMPOSITE BEAM

Area*Yb

3

mm

Io

Area*d

4

mm

Ix

mm4

mm

31828125

12304688

12613184758

12625489445

22265625

8775541

7556605867

7565381408

98546875

9490559896

3049566872

12540126768

6775000

30264228

5140086368

5170350595

5078125

105794271

16955415084

17061209355

164493750

9647698623

45314858949

54962557571

3.2 Composite Beam

[in mm ]

Zone

2

1

Total

Height

Width

Level

Yb

Area*Yb

Io

Area*d

Section

Bottom

Upper

mm

mm

mm

mm

mm4

mm4

mm4

200.0

70.0

1250.0

1520 0

1520.0

1338.7

167.3

650.0

1338.7

167.3

350.0

267731

11713

316750

596194

1320

1250

0

1420.0

1285.0

519.3

938 8

938.8

380178316

892437361.6

61987067626

62879504987

15051514

4782906.485

1403663073

1408445980

164493750

54962557571

55744385803

1.10707E+11

559723580

55859777839

1 19135E+11

1.19135E+11

1 74995E+11

1.74995E+11

Ya (mm)

Yb (mm)

Ix (mm4)

Wa (mm3)

Wb (mm3)

731

581

311

519.3

938.8

54962557571

75220826

105836180

174994894341

301106490

186397337

Ix

3.3 R e s u m e

[in mm ]

Area (mm2)

Description

Precast Beam

Composite Beam

[composite]

[precast]

316750

596194

562372124

IV. LOADING

4.1 Dead Load

a. Precast Beam

q1 = Ac precast girder x conc. Precast

b. Slab

q2 = Ac slab CIP x conc. slab

c. Deck slab

q3 = Ac deck slab x s

d. Asphaltic

q4 = Ac asphaltic x s

q1 =

q2 =

q3 =

q4 =

e. Diaphragm

0.317 x

0.334 x

0.098 x

0.080 x

2.50 =

2.40 =

2.40 =

2.20 =

0.792

[t/m'] =

7.77

[kN/m']

0.802

[t/m'] =

7.86

[kN/m']

0.235

[t/m'] =

2.31

[kN/m']

0.176

[t/m'] =

1.73

[kN/m']

6.92

[kN']

= Vol diaph with 0.20m thickness x diaph

0.294 x

2.40 =

0.706

note :

Number of diaph =

4

pcs

Diaph. placement

1

2

3

Location

0.00

6.52

13.03

Support Va

6.92

4.62

2.31

Mid Moment

0.00

22.56

22.56

Total Diaphragma Flexural Moment at Middle Span

eqivalen load q diaphragm

q5=

4

19.55

0.00

0.00

45.11

0.94

[ton'] =

from kg to N, multiply by 9.8060

kN.m

[kN/m']

page 2 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

4.2 Live Load

Taken from "Pembebanan Untuk Jembatan RSNI T-02-2005"

4.2.1."T"Loading(BebanTruk)

Unit

P1

Item

kN

225

Load

Impact

1.3

kN

292.5

LL+I

Distance

m

5.775

Va

kN

206.10

Va

kN

Mmax

kN-m

DF=S/3.4

MxDF

kN-m

P2

225

1.3

292.5

9.775

146.25

P3

50

1.3

65

14.775

15.88

M.maxdix= 9.775 m

DLA=

30%

Impact= 1+DLA=1.3

368.22

2429.38

0.47

1143.24

50kN

225kN

225kN

4.2.2."D"Loading(BebanLajur)

Taken from "Pembebanan Untuk Jembatan RSNI T-02-2005"

Load type :

Distribution Load Chart :

Dynamics Load Factored Chart :

Line Load (D load)

a. Dynamic Load Allowance [DLA]

DLA = 1 + 0,4

=

DLA = 1 + (0.0025*span+0.175)

DLA = 1 + 0,3

=

=

=

b. Knife Edge Load (KEL)

c. Distribution Factor (DF)

d. Distribution Load

2

q =

9.00 kN/m

q = 9 kN/m

2

q = 9 x(0,5+15/span)kN/m

which :

1.40

1.30

49.00

1.00

Span <= 50 m

50 < Span < 90 m

Span >= 90 m

[kN/m']

for

Span <= 30 m

Span > 30 m

e. Live load

Distribution load, qudl = DF x q x s

=

1.00

x

9.00

KEL, PKEL = DF x DLA x KEL x s

=

1.00

1.40

x

x

1.60

49.00

1.60

14.40

[kN/m']

109.76

[kN']

M.maxat0.5span=

9.775 m

Va=

195.64 kN

MLL=

1224.42 kN.m

RESUME: MomentforcecausebyDLoadingisbiggerthanTruckLoading

page 3 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

V. MOMENT ANALYSIS

[in kN-meter ]

Mid

Sec 1-1

Sec 2-2

Sec 3-3

Sec 4-4

span

0.00

6.28

13.28

19.55

DL

Precast beam

370.98

0.00

323.42

323.42

0.00

Subtotal

370.98

0.00

323.42

323.42

0.00

DL

Slab

375.54

0.00

327.39

327.39

0.00

ADL

Asphaltic Layer

82.45

0.00

71.88

71.88

0.00

SDL

Diaphragm+Deck Slab

155.30

0.00

135.39

135.39

0.00

Subtotal

613.29

0.00

534.66

534.66

0.00

LL

Distribution load

687.96

0.00

599.76

599.76

0.00

KEL

536.45

0.00

467.68

467.68

0.00

Subtotal

1224.42

0.00

1067.44

1067.44

0.00

Total (DL + LL)

2208.69

0.00

1925.52

1925.52

0.00

Ultimate total

3488.59

0.00

3041.34

3041.34

0.00

Ultimate total = 1,2*(Beam+Diaphragm+Deck Slab)+1,3*Slab+2*Asphaltic+1,8*(LL+I)

Type

Description

Sec 5-5

19.55

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

Sec 6-6

9.78

370.98

370.98

375.54

82.45

155.30

613.29

687.96

536.45

1224.42

2208.69

3488.59

Sec 5-5

19.55

-75.90

-75.90

-76.84

-16.87

-31.77

-125.48

-140.76

-109.76

-250.52

-451.91

-713.78

713 78

Sec 6-6

9.78

0.00

0.00

0.00

0.00

0.00

0.00

0.00

54.88

54.88

54.88

98 78

98.78

(m)

VI. SHEAR ANALYSIS

[in kN]

Mid

Sec 1-1

Sec 2-2

Sec 3-3

Sec 4-4

span

0.00

6.28

13.28

19.55

Precast beam

DL

0.00

75.90

27.18

-27.18

-75.90

Subtotal

0.00

75.90

27.18

-27.18

-75.90

Slab

DL

0.00

76.84

27.51

-27.51

-76.84

Asphaltic Layer

ADL

0.00

16.87

6.04

-6.04

-16.87

Diaphragm+Deck slab

SDL

0.00

31.77

11.38

-11.38

-31.77

Subtotal

0.00

125.48

44.93

-44.93

-125.48

Distribution load

0.00

140.76

50.40

-50.40

-140.76

LL

KEL

54.88

109.76

74.53

-74.53

-109.76

Subtotal

54.88

250.52

124.93

-124.93

-250.52

Total (DL + LL)

54.88

451.91

197.04

-197.04

-451.91

Ultimate total

98 78

98.78

713 78

713.78

318 99

318.99

-318.99

318 99

-713.78

713 78

Ultimate total = 1,2*(Beam+Diaphragm+Deck Slab)+1,3*Slab+2*Asphaltic+1,8*(LL+I)

Type

Description

(m)

VII. PRESTRESSING CABLE

7.1 Cable Profile

[in: mm ]

Tension

ten-

Nos

Total

JF

don

strand

Edge

Middle

left

right

tension

(kN)

0

0

0

0

1

2

0

0

0

0

12

12

24

0

0

0

0

600

300

450.00

0

0

0

0

200

100

150.00

0%

0%

0%

0%

75%

75%

75%

0%

0%

0%

0%

0%

0%

0%

0%

0%

0%

0%

75%

75%

75%

0

0

0

0

1654

1654

3307

total

Profile

Parabolic curve (Average of Strand's position vertically from the bottom of beam ( Value for Y axis ))

2

Y = A.x + B.x + C

where :

2

A = Constanta : ( (Ymiddle + Yedge)/(L/2) )

A=

0.003046

B = Constanta : ( L x A )

B = -0.060453

C = Average of strand's position when the parabolic curve reach the Y axis

Average of Strand's position vertically from the bottom of beam ( Value for Y axis )

2

+

-0.0604534

X +

0.450000

Y = 0.003046 X

Cable tendon angle :

o

tg =

0.006091 X

-0.0604534

eccentricity of tendon at middle section

Eccentricity [e]

=

Yb - Ys = 369.32 mm

Yb = Distance of Neutral Axis from the bottom of non composite beam ( Chapter 3.3 - Resume )

Ys = Distance of tendon from the bottom of the beam at the middle span ( Chapter 7.1, Cable Profile-middle)

page 4 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

Average of Strand's position vertically from the bottom of beam ( Value for Y axis )

0.80

0.60

0.40

0.20

0.00

0

10

15

20

25

7.2 Losses of Prestress

1. Losses of Prestress (Short Term)

a. Friction

When the jacking force is applied at the stressing end, the tendon will elongate. The elongation will be resisted by friction

between the strand and its sheating or duct. As the result of this friction, force will be decreased with distance from the jacking

end. The friction is comprised of two effects : curvature friction which is a function of the thendons profile, and wooble friction

which is the result of minor horizontal or vertical deviation form intended profile.

The equation for calculating the loss of prestress due to friction is :

-( + k.x)

Po.e

( AASHTO 1992, Chapt. 9.16.1 )

Px =

Where :

Px = Prestress force at section distance x from tensile point.

Po = Jacking force ( tensile force at anchor, initial)

= friction coefficient

= Change of cable angle from tensile point to x section

k = Wobble coefficient

x = Distance from tensile point to x section

80.0%

75.0%

70.0%

65.0%

60.0%

Friction and Wooble coeficient for grouting tendon in metal sheating

= 0.20

with Seven Wire Strand :

k = 0.003

0.00

10.00

20.00

30.00

Prestress tendon section

Prestresstendon

Table of calculation due to Friction

ten-

Nos

don

strand

Edge

Middle

from UTS

0

0

0

0

1

2

0

0

0

0

12

12

24

0

0

0

0

600

300

450.00

0

0

0

0

200

100

150.00

0%

0%

0%

0%

75%

75%

75%

total

Profile

% JF

(rad)

0.00000

0.00000

0.00000

0.00000

0.00406

0.00203

0.00305

0

0

0

0

-0.0806045

-0.0403023

-0.0604534

0.000

0.000

0.000

0.000

0.161

0.081

0.121

Prestress force (Px) = % UTS

9.925

19.85

0.00%

0.0%

0.00%

0.0%

0.00%

0.0%

0.00%

0.0%

70.49%

68.4%

71.64%

69.5%

0.00

0.0%

0.0%

0.0%

0.0%

75.0%

75.0%

75.0%

71.1%

69.0%

b. Anchor set

Tendons are typically anchored with two piece, conical wedges. When the tension applied by the jack is released, the strand

retracts pulling the wedges in to the anchorage device and locks the strand in place. The lost in elongation is small . It depend on

the wedges, the jack and the jacking procedure. This lost in elongation is resisted by friction just as the initial elongation is

resisted by friction.

Exact calculation is typical done as an iterative process as follows :

1. Calculated loss of prestress per length with assuming a linear variation in prestress at start to end of tendon

= Loss of prestress per length

= Fpu . (P at JF - P at end of tendon) / distance JF to end of tendon

2. Assuming drawn-in ().

3. The length, x, over which anchorage set is effective is determined as follows :

x = Sqrt ( Es . / )

effective anchorage set point position :

Cablechange

anglepoint

Cablechange

anglepoint

Anchorage

setarea

X(effective anchorageset)

Anchorage

setarea

X(effective anchorageset)

page 5 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

4. Check Assuming drawn-in (). The displacement of jacking end of tendon should be equal with assumption

= Anchorage set area x Ult. Tensile Stress / Modulus Elasticity of PC Strand

= Aset . Fpu / Es

= equal with assumption (trial)

Table of calculation due anchor set

draw in

tenNos

don

strand

0

0

0

0

1

2

0

0

0

0

12

12

24

total

From left side

From right side

after anchorage set = % UTS

9.925

19.85

0.00%

0.0%

0.00%

0.0%

0.00%

0.0%

0.00%

0.0%

68.03%

68.4%

68.49%

69.5%

Mpa/mm

0.00000

0.00000

0.00000

0.00000

0.00616

0.00512

mm

0.00

0.00

0.00

0.00

8.00

8.00

X (m)

0.00

0.00

0.00

0.00

15.83

17.36

Px (% UTS)

0.00%

0.00%

0.00%

0.00%

69.26%

70.06%

X (m)

0.00

0.00

0.00

0.00

0.00

0.00

Px (% UTS)

0.00%

0.00%

0.00%

0.00%

0.00%

0.00%

0.00

0.0%

0.0%

0.0%

0.0%

63.5%

65.1%

0.00564

8.00

16.60

69.66%

0.00

0.00%

64.33%

68.26%

68.98%

AVERAGELOSSESOFPRESTRESS

LOSSESOFPRESTRESS

DUETOANCHORAGESET

75.0%

80.0%

75.0%

70.0%

70.0%

68.26%

65.0%

65.0%

60.0%

55.0%

69.82%

69.50%

68.98%

64.33%

60.0%

0.00

10.00

20.00

30.00

0.00

Prestresstendon section

5.00

10.00

15.00

20.00

Prestresstendonsection

25.00

c. Elastic Shortening ( ES )

Elastic shortening refers to the shortening of the concrete as the postensioning force is applied.

As the concrete shorterns, the tendon length also shortens, resulting in a loss of prestress.

The following simplified equation to estimate the appropriate amount of prestress loss to attribute to elastic shortening

for member with bonded tendons :

ES = Kes . Es . fcir / Eci

where:

Kes =

0.50 for post-tensioned members when tendon are tensioned in sequential order to the same tension

ES = Elastic modulus of tendon material

Eci = Elastic modulus of the concrete at the time of prestress transfer

fcir = concrete stress at the centre of gravity of prestressing tendons due to prestressing force at transfer and the self weight of

the member at the section of maximum positive moment

2.37%

Assumption Losses due ES

Pi =

Total prestressing force at release

68.3% - 2.37% =

Pi =

65.89% UTS x nos x Aps =

2905.4202 kN

fcir = Pi / A + Pi. ec / I + Mg.ec/I

13.89 N/mm2

fcir =

so,

ES =

percent actual ES losses = Es/fpu

44.08 N/mm2,

2.37%

equal with losses assumption

2. Losses of Prestress ( Long Term )

d. Shrinkage ( SH )

SH = 8,2*e-6*Ksh*ES*(1-0,06*V/S)*(100-RH)

(ACI 318-95, Chapt. 18.6)

1.63%

SH =

30.33 N/mm2

percent actual SH losses = SH/fpu

Where :

The factor Ksh account for the shringkage that will have taken place before the prestressing applied.

for postensioning members, Ksh is taken from the following table :

Days

1

3

5

7

10

20

30

60

0.45

Ksh

0.92

0.85

0.8

0.77

0.73

0.64

0.58

"days" is the number of days between the end of moist curing and the application of prestress.In a structures

that are not moist cured, Ksh is typiclly based on when the concrete was cast

Ksh =

0.64

V/S =

RH =

0.08

70.00

Volume =

6.38 m

Surface =

78.67 m

page 6 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

e. Creep ( CR )

Over time, the compresive stress induced by postensioning causes a shortening of the concrete member. The increase in

strain due to a sustained stress is refered to as creep. Loss of prestress due to a creep is nominally propotional to the net

permanent compresive stressin the concrete. the net permanent compressive stress is the initial compressive stress in the

concrete due to the prestressing minus the tensile stress due to self weight and superimposed deadload moments

CR

= Kcr*(Es/Ec)*(fcir-fcds)

CR

90.40 N/mm

(ACI 318-95, Chapt. 18.6)

percent actual CR losses = CR/fpu

4.86%

Where :

Kcr =

1.60 (for postensioned member)

fcir = stress at center point prestress force, initial condition

2

fcir =

13.890 N/mm

Msd = Moment due to all superimposed permanent dead loads applied after prestressing

Msd =

613.29

kN.m

fcds = Stress in a concrete at the cgs of the tendon due to all superimposed dead load

fcds 1 = Msdl.e/I =

3.57 N/mm

component of fcd due to load on the plain beam

fcds 2 = Madl.e/Ic =

0.37 N/mm

component of fcd due to load on the composite beam

3.94 N/mm

fcds = fcds 1 + fcds 2 =

f. Steel Relaxation ( RE )

Relaxation is defined as a gradual decrease of stress in a material under constant strain. In the case of steel, relaxation is

the result of permanent alteration of the grain structure. The rate of relaxation at any point in time depends on the

stress level in the tendon at that time. Because of other prestress losses, there is a continual reduction of tendon strss;

this causes a reduction in the relaxation rate.

The equation for prestress loss due to relaxation of tendons is :

RE = [ Kre - J*(SH+CR+ES) ] *C

(ACI 318-95, Chapt. 18.6)

18.38 N/mm

RE =

percent actual RE losses = RE/fpu

0.99%

Where :

Kre =

J =

C =

5000.00 (for 270 grade, low relaxation strand)

0.04 (for 270 grade, low relaxation strand)

0 66

0.66

f fpi/fpu

for

f i/f =

0 683

0.683

RESUME DUE TO SHORT & LONG TERM LOSSES

I. Short Term Losses

Losses

Elastic

Section

Total

Friction Anchor set Shortening

Losses (%)

x (m)

(ES)

0.00

75.00%

64.33%

61.96%

13.04%

0.00

0.00

0.00

0.00

9.93

15.83

17.36

19.85

UTS

75.00%

75.00%

75.00%

75.00%

71.07%

69.82%

69.50%

68.98%

64.33%

64.33%

64.33%

64.33%

68.26%

69.82%

69.50%

68.98%

61.96%

61.96%

61.96%

61.96%

65.89%

67.45%

67.13%

66.61%

Shrinkage

(SH)

60.32%

60.32%

60.32%

60.32%

60.32%

64.26%

65.82%

65.50%

64.98%

13.04%

13.04%

13.04%

13.04%

5.18%

2.37%

2.37%

2.37%

Friction

LOSSESOFPRESTRESSDIAGRAM

Anchor set

Elastic Shortening (ES)

80.00%

Shrinkage (SH)

Creep (CR)

Steel Relaxation (SR)

75.00%

75.00%

71.07%

68.26%

65.00%

64.33%

64.33%

61.96%

60.32%

61.96%

60.32%

55.46%

54.48%

55.46%

54.48%

65.89%

64.26%

59.40%

58.41%

69.82%

69.50% 68.98%

67.45%

65.82%

67.13% 66.61%

65.50% 64.98%

60.96%

59.98%

60.64%

59.65% 60.12%

59.13%

50.00%

0.00

0.00

9.93

15.83

Prestresstendon section

17.36

19.85

II. Long Term Losses

Steel

Total Losses

Creep (CR) Relaxation

(%)

(SR)

55.46%

54.48%

20.52%

55.46%

54.48%

20.52%

55.46%

54.48%

20.52%

55.46%

54.48%

20.52%

55.46%

54.48%

20.52%

59.40%

58.41%

12.65%

60.96%

59.98%

9.85%

60.64%

59.65%

9.85%

60.12%

59.13%

9.85%

friction Losses equotion :

0 > x > 9.93

75.00% -+ 0.40% x

9.93 > x > 19.85

x - 9.925

71.07% + 0.07% x

Long term Losses equotion :

0 > x > 0.00

54.48% #DIV/0!

0 > x > 9.93

x-0

54.48% + 0.40% x

9.925 > x > 15.83

x - 9.925

58.41% + 0.26% x

15.83 > x > 17.36

59.98% -+ 0.21% x x - 15.8329534

17.36 > x > 19.85

x - 17.3636282

59.65% -+ 0.21% x

page 7 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

7.3 Effective Stress Force

Resume Prestressed Force at middle

Condition

short term

long term

Cable

% Losses of

prestress

%UTS

effective

prestress

[N/mm ]

[mm ]

[kN]

9.1%

16.6%

65.9%

58.4%

1226

1086

2370.72

2370.72

2905.42

2575.64

stress

2

Asp

VIII. STRESS AND DEFFLECTION ANALYSIS

1

2

Beam Segment

Length (m)

6.275

7.000

Additional length at the end of the beam =

6.275

0.30

0.00

0.00

0.00

0.00

Total Length =

0.00

20.15

8.1 Stress at initial

Description

Moment DL

Jacking Force

Losses due to friction

Pi

e (eccentricity)

Pi.e

Moment Net.

Middle

SEC 1-1

SEC 2-2

SEC 3-3

SEC 4-4

SEC 5-5

x - [m]

Span

0.00

6.28

13.28

19.55

19.55

9.78

[kN.m]

[kN]

%

[kN]

[m]

[kN.m]

[kN.m]

370.98

3307.15

4%

3136.29

0.369

-1158

-787

0.00

3307.15

0%

3307.15

0.078

-259

-259

323.42

3307.15

2%

3197.47

0.332

-1062

-738

323.42

3307.15

4%

3144.40

0.332

-1044

-721

0.00

3307.15

3%

3164.51

0.078

-248

-248

0.00

3307.15

3%

3164.51

0.078

-248

-248

370.98

3307.15

4%

3136.29

0.369

-1158

-787

2

[N/mm ]

9.90

10.44

10.09

9.93

9.99

9.99

9.90

[N/mm ]

-10.47

-3.44

-9.81

-9.58

-3.29

-3.29

-10.47

Allow.

2

[N/mm ]

7.44

2.45

6.97

6.81

2.34

2.34

7.44

stress

Initial Stresses

top ( T )

-0.57

7.00

0.28

0.35

6.70

6.70

-0.57

-1.4

[N/mm2]

bot ( B )

17.34

12.89

17.07

16.74

12.33

12.33

17.34

19.2

Pi / A

M / Wa

M / Wb

8.2 Stress at service

> Load of precast

precast, slab

slab, diaphragm and prestress by PC Beam

> Live load and asphalt by composite

Description

Moment DL

Losses due to friction

effective prestress P

P.e

Moment --- M1

Moment --- M2

x - [m]

[kN.m]

%

[kN]

[m]

[kN.m]

[kN.m]

Middle

Span

901.82

17%

2573.02

-950.26

-48.44

1306.87

SEC 1-1

0.00

0.00

21%

2402.15

-188.13

-188.13

0.00

( = M1 )

( = M2 )

SEC 2-2

6.28

786.20

18%

2511.84

-833.95

-47.75

1139.32

SEC 3-3

13.28

786.20

16%

2614.77

-868.13

-81.93

1139.32

SEC 4-4

19.55

0.00

16%

2610.22

-204.42

-204.42

0.00

SEC 5-5

19.55

0.00

16%

2610.22

-204.42

-204.42

0.00

SEC 6-6

9.78

901.82

17%

2573.02

-950.26

-48.44

1306.87

P/A

2

[N/mm ]

8.13

8.13

8.13

8.13

8.13

8.13

8.13

M 1 / Wa

2

[N/mm ]

-0.64

-2.50

-0.63

-1.09

-2.72

-2.72

-0.64

M 1 / Wb

[N/mm ]

0.46

1.78

0.45

0.77

1.93

1.93

0.46

M 2 / Wa'

2

[N/mm ]

2.32

0.00

2.03

2.03

0.00

0.00

2.32

Allow.

M 2 / Wb'

[N/mm2]

-7.01

0.00

-6.11

-6.11

0.00

0.00

-7.01

stress

slab ( S )

4.34

0.00

3.78

3.78

0.00

0.00

4.34

12.6

top ( T )

9.81

5.63

9.52

9.07

5.41

5.41

9.81

18.0

bot ( B )

1.58

9.91

2.47

2.79

10.06

10.06

1.58

-3.2

Stress at Service

2

[N/mm ]

Note :

SEC 6-6

Moment DL =

Moment Bal =

Moment Net =

Pi =

P=

M=

A=

Wa =

Wb =

Wa' =

Wb' =

Moment due to dead load ( Chapter V - Moment Analysis )

Moment due to uniform load in balance condition ( Chapter 7.4 - Effective Stress Force )

( Moment DL + Moment Bal )

Initial Prestress ( at transfer condition - chapt. 7.4. Effective Stress Force )

Prestress at service condition.. ( Chapter 7.4 -effective Stress Force )

Moment Net.

Total Area of Precast Beam ( Chapter 3.1 - Precast Beam)

Modulus Section for Top section of Precast condition

Modulus Section for Bottom section of Precast condition

Modulus Section for Top section of composite Condition. ( Chapter 3.3 - Resume )

Modulus section for bottom section of composite condition . ( Chapter 3.3 - Resume )

page 8 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

8.3 Stress diagram at center span :

8.3.1. STRESS DIAGRAM AT INITIAL

a. Stress at beam end section when Prestress is applied :

Pi/A = 10.44 MPa

top = 7.39 MPa

M/Wa = -3.05 MPa

Pi/A = 10.44 MPa

bottom = 12.61 MPa

M/Wb = 2.17 MPa

effective prestress =

Pi =

eccentricity (ei) =

Mdl = Mbeam =

75% UTS

3307.15 kN

69.32

mm

0 kN-m

M = Mdl - Pi.e =

-229.24 kN-m

19.20

MPa

-1.41

MPa

control allow stress = meet requirement

allow comp at initial =

allow tension initial =

b. Stress at beam middle section when Prestress is applied :

Pi/A = 9.89 MPa

top = -0.56 MPa

M/Wa = -10.45 MPa

Pi/A = 9.89 MPa

bottom = 17.32 MPa

M/Wb = 7.43 MPa

effective prestress =

Pi =

eccentricity (ei) =

Mdl = Mbeam =

71% UTS

3133.66 kN

369.32 mm

370.98 kN-m

M = Mdl - Pi.e =

-786.3 kN-m

19.20

MPa

-1.41

MPa

control allow stress = meet requirement

allow comp at initial =

allow tension initial =

8.3.2. STRESS DIAGRAM AT CONSTRUCTION

a. Stress at beam middle section when diaphragm, RC deck is install and finish fresh concreting composite slab

Pi/A = 9.17 MPa

top = 6.90 MPa

M/Wa = -2.28 MPa

Pi/A = 9.17 MPa

bottom = 10.79 MPa

M/Wb = 1.62 MPa

effective prestress =

Pi =

eccentricity (ei) =

Mdl = Mbeam + Madl =

66% UTS

2905.42 kN

369.32 mm

901.82

M = Mdl - Pi.e =

allow comp at initial =

allow tension initial =

kN-m

-171.20

19.20

-1.41

kN-m

MPa

MPa

control allow stress = meet requirement

b. Stress at composite beam middle section due to asphaltic layer:

P/A = 9.17 MPa

M2/Wa'= 0.15 MPa

M1/Wa = -2.28 MPa

P/A = 9.17 MPa

effective prestress =

Pi =

eccentricity (ei) =

Mdl = Mbeam + Madl =

66% UTS

2905.42

369.32

901.82

M2/Wb'= -0.44 MPa

M1/Wb = 1.62 MPa

kN

mm

kN-m

slab = 0.27 MPa

top = 7.04 MPa

bottom = 10.35 MPa

M1 = Mdl + Pi.e =

M2 = Masphalt =

allow comp at initial =

allow tension initial =

-171.20

82.45

19.20

kN-m

kN-m

MPa

-1.41

MPa

control allow stress = meet requirement

page 9 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

8.3.3. STRESS DIAGRAM AT SERVICE (at center of span)

Stress at composite beam middle section due to Live Load

P/A = 8.13 MPa

P/A = 8.13 MPa

Mdl = Mbeam + Madl =

bottom = 1.59 MPa

M2/Wb'= -7.01 MPa

M1/Wb = 0.47 MPa

effective prestress =

Pi =

eccentricity (ei) =

slab = 4.34 MPa

top = 9.80 MPa

M2/Wa'= 2.32 MPa

M1/Wa = -0.66 MPa

58% UTS

2575.64 kN

369.32

mm

901.82

kN-m

M1 = Mdl + Pi.e =

M2 = Masphalt + LL =

-49.41

1306.87

kN-m

kN-m

allow comp at service =

allow tension at service =

18.00

MPa

-3.16

MPa

control allow stress = meet requirement

8.4 Deflection

8.4.1 Chamber due to Prestress Load

Deflection on middle section :

l

P

ee

pi= [ee+(5/6)(ec-ee)] x (P. l2 /8 Ec Ix)

l/2

pi=

ec

where :

l/2

P=

Eci =

Ixi =

l=

ee =

-26.52 mm

Prestress force

Modulus Elasticity of Concrete

Section Inertia

length of anchor to anchor

Distance between c.g of strand and

c.g of concrete at end

ec = Distance between c.g of strand and

c.g of concrete at centre

8.4.2 Deflection at initial, erection and service condition (based : PCI handbook 4.6.5 Long-Time Chamber Deflection)

Deflection () on simple span structure :

where :

q = Uniform Load

q= (5/384)*q*L4/Ec Ix)

P = Point Load

l = Beam Span

p= P.l /48 Ec Ix

Deflection calculation table : Estimating long-time cambers and deflections

Loading

WORKING LOAD

Release (1)

q (kN/m)

P (kN)

-26.52

1. Due to Prestress force

8.84

2. Due to beam weight (DL)

7.77

-17.68

3.25

3. Due to ADL

4. Due to Composite Overtoping

7.86

5. Due to asphaltic (SDL)

1.73

6. Due to Live Load = UDL + KEL

14.40

Resume of deflection :

1. Deflection at service

2. Deflection due to Live Load

3. Total deflection with LL

=

=

=

Long time cambers and deflection

(2)

multipliers Erection

multipliers

1.80 x (1)

-47.74

2.20 x (1)

1.85 x (1)

16.35

2.40 x (1)

-31.39

3.31

3.00 x (2)

-28.08

8.00

2.30 x (2)

-20.08

109.76

-8.25 mm

7.48 mm < allow. deflection L/800 =

-0.78 mm, chamber upward

Service (3)

-58.35

21.21

-37.14

9.93

-27.21

18.40

-8.81

0.55

-8.25

7.48

-0.78

24.4375 mm OK

page 10 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

IX. FLEXURAL STRENGTH AND DUCTILITY

9.1 Steel Index Requirement (SNI Beton 03-2847-2002 pasal 20.8)

Effectif slab width, is minimum length from :

1. Girder web thickness + 16 Slab thickness

=3370 mm

2. Beam Ctc

=1600 mm . Control

3. Span length / 4

=4887.5 mm

Thus, Effectif slab width is :

28.00

0.85

MPa

=1600 mm

Partial Rebar:

fy =

400 MPa

Use

0 Dia.13 mm

As =

0.00 mm2

at tension area

b web =

170 mm

d=

1190.5 mm

Partial tension rebar ratio :

t =

As / (bweb x d )

t =

0.00000

t =

t =

0.000

t . fy / fc

Low Relaxation strand :

fpu =

1860

MPa

Strand stress ratio fpu / fpy =

dp =

for slab with fc' =

Value =

0.9

Aps =

1370.0 mm

Rebar in compresion area is neglected due calculation

c =

c =

value p = 0.28

2

2370.72 mm

Prestress ratio :

p =

Aps / (beff x dp )

beff =

1600 mm

p = 0.00108153

fpu {1 - p / (p.fpu/fc + d/dp (t-c)))

p fps/fc

1816.0 MPa

0.070

Resume of Steel Index Requirement (SNI Beton 03-2847-2002 pasal 20.8)

p + d/dp (t-c)

0.36

<

fps =

p =

0.070

fps =

p =

<

0.306

Under Reinf, Meet With Steel Index Requirement

9.2 Momen Capacity

b. eff

Z

Zone

4

Zone 3

C 4

Cc4

Cc3

Cc2

Zone 3

Zone 2

a

Tps = Aps . Fps

Tps = 4305180.91 N

Cc1

Zone 1

dp

strength reduction factor

= 0.8

Tps=Aps.fps

T = As.fy

COMPOSITE BEAM

Location of Depth of Concrete Compression Block (a) :

hi

wi

Aci=hi.wi

Conc. Strength fc'i

Zone

4

3

2

1

(mm)

113.06

0.00

0.00

0.00

(mm)

1600

335

350

170

(mm2)

180889.95

0

0

0

MPa

28.00

28.00

40.00

40.00

CIP Slab

CIP Slab

Beam

Beam

Cci=0.85 fc'i.Aci

N

4305181

0

0

0

Depth of Concrete Compression Block is located at zone 4

a = Tps / ( 0.85 x fc'' slab x beff )

Mn = (Tps (dp - comp. point) + As.fy (d-comp. point)

Mn = 4523.7873 kN.m

50 year,so Transient act factor = 1

Bridge life time design for

Mn / Mult =

1.297

Mult = 1x 3,489kN-m

Comp (i)

Compresion

Point (mm) Point (mm)

57

113

56.53

113

113

a=

Mn =

113.06 mm

5654.73 kN.m

>1, Moment capacity meet with requirement

9.3 Cracking Capacity

Stress at bottom girder section due to service load (bot at service) =

1.58 MPa

Concrete flexural tension strength fr =

4.4 MPa

Crack Moment, Mcr = (bot at service + fr ) Wb.comp + Momen

Mcr =

Mn / Mcr =

(DL+ADL+LL+I)

3328.03 kN.m

1.359

> 1.2 ---- Cracking Capacity requirement is achieve

page 11 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

X. SHEAR ANALYSIS

10.1 Shear calculation based on SNI 03-2847-2002

Alternatif solution to calculated shear on prestress element is use for structure element which have effective prestress above 40%

of ultimate tensile stress

40% Ultimate Tensile Strength

Effective Prestress

Section Properties :

Ix = 5.496E+10 mm4

Yb = 519.31728 mm

Ag =

MPa

MPa

= 744

= 1086

Ixcomp =

Ybcomp =

Effective Prestress > 40% fpu

1.75E+11 mm4

938.8 mm

316750 mm2

Load :

Effective prestress Pe =

Factored Load :

qult DL + ADL =

26.89

qult LL =

25.92

Pult LL = 197.57

2575.64 kN

kN/m

kN/m

kN

Unfactored Load :

q DL + ADL =

q sdl =

q DL + ADL =

18.88

1.73

20.60

kN/m

kN/m

kN/m

Concrete Shear resistance contribution (Vc)

Nominal shear strength provide by concrete

Vc = {0.05sqrt(fc') + 5 (Vu.dp/Mu)}bw.d

but nominal strength (Vc) should taken between : (1/6).sqrt(fc').bw.d < Vc < 0.4sqrt(fc').bw.d

and Vu.dp/Mu 1

where :

Mu = Maximum factored moment at section

Vu = Maximum factored shear force at section

d = distance from extreme compresion fiber to centroid of prestress tendon.

But d need not to take n less than 0.8 hcomposite

bw = width of shear section

RSNI T-12-2005 : Shear force on beam is hold a part by concrete and the rest of force is hold by shear steel. Concrete contribution

(vc), is define as shear force when diagonal cracking appear.

Vn = Vc + Vs

Vn = Vu /

where :

Vn = Nominal Shear force

Vc = Concrete shear contribution

Vs = Shear steel contribution

Zonafication for shear steel stirup calculation

Zone 1

Vn < 0.5 Vc

Zone 2

Vn < Vc+[0.35 or (75/1200) sqrt(fc')] bw d

Zone 3

Zone 4

Zone 5

Vn < Vc+0.33 sqrt(fc') bw d

Vn < Vc+0.67 sqrt(fc') bw d

Vn > Vc+0.67 sqrt(fc') bw d

Vu = Ultimate Shear force

= Shear reduction factor

= 0.75

No need to use stirup

Required stirup spacing with minimum spacing :

S 0.75 H

S (av.fy) / (0.35 bw)

S 600mm

S (av.fy/fpu) (80/Aps) d sqrt(bw/d)

Required stirup spacing with spacing :

S (av.fy.d) / ((Vu/)-Vc)

S 0.75 H

S 600mm

Required tight stirup spacing with spacing :

S (av.fy.d) / ((Vu/)-Vc)

S 0.375 H

S 300mm

Section to small, change beam section

page 12 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

Shear rebar steel

fy =

400 MPa

Use

2 leg Dia.13 mm

Av =

265.46 mm2

shear width :

bw = 170

mm

650

mm

bw-e =

Shear steel requirement calculation table :

ecomp

dist.

d=dp>0.8H

Vu

Mu

m

m

m

kN

kN-m

0.1

0.3875

0.775

1.7

2

3

4

5

6

7

8

9

9.775

kN

0.504

0.520

0.542

0.590

0.605

0.649

0.687

0.719

0.745

0.765

0.779

0.787

0.789

1.08

1.10

1.12

1.17

1.19

1.23

1.27

1.30

1.33

1.35

1.36

1.37

1.37

707.49

689.40

665.02

606.82

587.95

525.03

462.12

399.20

336.29

273.37

210.46

147.54

98.78

71.01

271.11

531.25

1107.91

1281.52

1812.74

2270.95

2656.13

2968.30

3207.44

3373.56

3466.66

3488.59

dp(Vu/Mu)

Vc

kN

Vn

kN

Vs

kN

Shear

Zonasi

1.00

1.00

1.00

0.64

0.54

0.36

0.26

0.20

0.15

0.11

0.08

0.06

0.04

980.51

995.59

1015.20

701.82

612.19

438.72

346.48

286.00

240.79

203.75

171.27

141.27

118.82

943.32

919.20

886.69

809.10

783.93

700.04

616.16

532.27

448.38

364.50

280.61

196.72

131.71

-37.19

-76.39

-128.51

107.27

171.74

261.32

269.68

246.27

207.59

160.75

109.34

55.45

12.89

2

2

2

3

3

3

3

3

3

3

3

2

2

Use Space

mm

600

600

600

600

600

500

499

561

600

600

600

600

600

use

mm

300

300

300

300

300

300

300

300

300

300

300

300

300

ShearSteelRequirementPosition

2000.0

1800.0

1600.0

1400.0

1200.0

1000.0

800.0

600.0

400.0

200.0

0.0

Zona1

Zona2

Zona3

Zona4

Vn=Vu/f

beam sectionpoint

x (m) from

range

nos shear

span edge

(m)

(row)

Shear spacing S - 75

0

0

0

Shear spacing S - 100

0

0

0

Shear spacing S - 125

0

0

0

Shear spacing S - 150

0

0

0

Shear spacing S - 200

0

0

0

Shear spacing S - 250

0

0

0

Shear spacing S - 300

9.775

9.775

33

total shear rebar per half span (row) =

33

total shear rebar per span (row) =

66

Shear Rebar configuration

page 13 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

10.2 Horisontal Shear

Width of contact surface area

Effective Height

= 0.75

fy =

400 MPa

Use

2 leg Dia.13 mm

bv =

d=

Area horisontal Shear Steel

Avh =

Horisontal Shear steel Spacing

s=

v =

Horisontal Shear steel ratio

Shear horisontal Nominal

Vnh = (1.8 Mpa + 0.6 v. fy) . bv .d

200 mm

1216 mm

265.46 mm2

300 mm

0.442%

Vnh =

696.00 KN

Requirement for shear horisontal steel :

Vult <Vnh < 350 bv.d

Vult = Ultimate shear due to superimposed DL + LL

Vult =

396.87 kN

Vnh =

522.00 kN

RESUME:

3.5 bv d =

851.20 kN

Shear horisontal : OK

Minimal Use :

bys =

200 mm

Spacing =

1540.04 mm or

4 tweb = 680 mm

Avh = 50 by.s / fy

Max. Spacing =

300.00 mm

Avh =

172.375 mm2/m

min no. Spacing =

66 @ 2D13 for shear horisontal / span

Resume = additional shear horizontal required

XI. END BLOCK DESIGN

Block Anchor dimension

type

b

a

dia hole

(mm)

(mm)

(mm)

165

215

265

165

215

265

51

63

84

7

12

19

Concrete Area

Block Area

2

2

2

A (mm ) A1 (mm ) A2 (mm ) sqrt(A2/A1)

25182.18

43107 75

43107.75

64683.23

27225

46225

70225

1625000

1950000

2275000

7.73

6 49

6.49

5.69

SNI 03-2847-2002 Pasal 11.3.2 (Anchorage Zone)

Maximum strand =

12

Anchor Block type =

12

Strand

Load factor =

1.2

Reduction factor () =

0.85

1. End Bearing

Ultimate Point Load

Pu = min (1.2 x nStrand x Astrand x %JF x fpu , nstrand x Astrand x 96% x fpu)

Pu =

1984.3

kN

Nominal concrete comp. :

End Bearing stress :

comp = Pu / A

fci =

32.00 Mpa

comp =

46.03

MPa

min(2, sqrt(A2/A1)) =

2.0

Nominal fci = x 0.7 x fci x min(2,sqrt (A2/A1))

> comp =

46.03 MPa

Nominal fci =

38.08

ten-

Nos

Anchor

don

strand

Height

sheath

hole

Ult. Point

Load

(Pu)

kN

Block

Area

(A)

mm2

63

63

1984.29

1984.29

43107.75

43107.75

( ai )

mm

0

0

0

0

1

2

0

0

0

0

12

12

215

215

End Bearing Nominal

comp. fci

Stress

(EBS=Pu/A)

Mpa

Mpa

46.03

46.03

38.08

38.08

Remark

EBS > Nominal compresion (not good)

EBS > Nominal compresion (not good)

page 14 / 15

PCI Monolith H-125cm ; L-20.15m ; CTC-160cm - RSNI (Rev.04)

2. Stirrup and Spalling Reinforcement

Load factor =

1.2

Reduction factor () =

0.85

fy =

400

MPa

Bursting Steel

Diameter closed stirup =

13 mm

Stirup Area =

132.7 mm2

tenNos

Anchor

sheath

Jacking

don

strand

Height

hole

Force

kN

Bursting

Area

(Abs)

mm2

End

Bearing

(EBS)

Mpa

1653.5772

1653.5772

43107.75

43107.75

38.36

38.36

( ai )

mm

0

0

0

0

1

2

total

EBS/0.7

(fcc'-fci)/4.1

fl / 0.5 fy

fcc'

Mpa

fl

Mpa

64.47

64.47

7.9

7.9

3.96%

3.96%

sp

(mm)

0

0

0

0

12

12

24

215

215

Anchor Zone Stirrup

JF Load =

Ult. JF =

63

63

3307.15 kN

a1 =

430.00 mm

3968.59 kN

H=

1250 mm

T bursting = 0.25 Ult.JF (1-a1/H)

T bursting = 650.84799 kN

Diameter closed stirup =

No. Leg of stirrup =

Stirup Area =

13 mm

4 leg

530.9 mm2

62.4

62.4

d bursting = 0.5(h-2e)

d bursting = 694.317285 mm

Anchor Stirup Rebar = T bursting / 0.5 fy

Anchor Stirup Rebar =

3254.2 mm2

use no of stirup =

7 pcs

Spalling Rebar

Spalling Force = 2% JF

p

g Force =

66.1 kN

Spalling

Diameter closed stirup =

Stirup Area =

use no of stirup =

13 mm

132.7 mm2

3 pcs

page 15 / 15

PTWIJAYAKARYABETON

TECHNICALCALCULATION

PCIGIRDERMONOLITHFORHIGHWAYBRIDGES

Project

Product

Jobno

Rev.No.

:

:

:

:

TOLLSURABAYAGRESIK

PCIGirderMonolithH125cm;L20.80m;CTC160cm;fc'50MPa

13014B

04

DesignReff.

- SNIT122004

PerencanaanStrukturBetonUntukJembatan

- RSNIT022005

StandarPembebananUntukJembatan

- PCI:BridgeDesignManual

GedungJW,1 st & 2nd floor

Jl.Jatiwaringinno.54,PondokGedeBekasi

Ph:+622184973363fax:+622184973391

www.wikabeton.co.id

PTWIJAYAKARYABETON

TECHNICALCALCULATIONAPPROVAL

PCIGIRDERMONOLITHFORHIGHWAYBRIDGES

TOLLSURABAYAGRESIK

PCIGirderMonolithH125cm;L20.80m;CTC160cm;fc'50MPa

Jobno.: 13014B

Rev.: 04

Approvedby:

Consultan/Owner

Approvedby:

18Juni2013

Checkedby

18Juni2013

Designby:

18Juni2013

Ir.AchmadArifin

TechnicalManager

IgnatiusHarryS.,S.T.

ChiefofTechnical

Suko

TechnicalStaff

PCI Monolith H-125cm ; L-20.80m ; CTC-160cm - RSNI (Rev.04)

RESUME OF PCI GIRDER MONOLITH TECHNICALLY CALCULATION

1. BEAM SPECIFICATION

Span

Beam Height ( H )

Distance ctc of beam ( s )

Slab thickness

Beam Compressive strength

Slab Compressive strength

Bridge life time

Segment Arrangement

Beam Segment

1

Length (m)

6.600

Additional length at the end of beam

Total length of the beam

Total beam weight

2. STRESSING

Nos of PC Strand

=

Strand configuration

28

=

=

=

=

=

=

=

20.20

1250

1600

200

50

28

50

m (beam length

mm

mm

mm

MPa

MPa

years

4

0.00

5

0.00

20.80 m)

2

7.000

=

=

=

3

6.600

0.30

20.80

17.41

6

0.00

7

0.00

m

m

ton

strand

12.7

mm (PC Strand 270 grade, low relaxation)

No.

number

Tendon

strand

H strand bottom (mm)

edge

mid

Jacking Force

75%

UTS

1860.00

MPa

=

=

16.89%

UTS of Strand

Total Losses

fc initial

at middle

fc'

900

300

12

600

200

12

300

100

total

28

514.29

171.43

3. LOADING

1. Dead Load

a. Precast Beam

=

7.77

kN/m

b. Slab

=

7.86

kN/m

Slab thickness =

200

c. Deck Slab

=

2.31

kN/m

Deck slab thickness =

70

d. Asphalt

=

1.73

kN/m

Asphalt thickness =

50

e. Diaphragm

=

6.92

kN

for 1 diaphragm

No. Diaphragm

4

pcs

equivalent load =

0.91

2. Live Load

Taken from "Pembebanan Untuk Jembatan RSNI T-02-2005"

Moment force cause by D Loading is bigger than Truck Loading

a. Dynamic Load Allowance

(DLA)

=

1.40 for span length <= 50m

b. Knife Edge Load (KEL)

=

49.00 kN/m

c. Distribution Factor (DF)

=

1.00

d. Distribution Load

q=

9.00 kN/m2

9.00 kN/m2

9.00 x(0,5+15/span)kN/m2

e. Live Load

Distribution load :

q' = DF x q x s

=

14.40

Line Load

:

p' = DF x DLA x KEL x s

=

109.76

CALCULATION RESUME

80.0%

mm

mm

mm

kN/m

For Span <= 30m

For Span > 30m

kN/m

kN

PCI Monolith H-125cm ; L-20.80m ; CTC-160cm - RSNI (Rev.04)

4. BEAM SUPPORT REACTION

Ultimate total = 1,2*(Beam+Diaphragm+Deck Slab)+1,3*Slab+2*Asphaltic+1,8*(LL+I)

Beam support reaction :

a. Dead Load

b. Additional Dead Load

c. Live Load

=

=

=

78.43

129.35

255.20

kN

kN

kN

Ultimate support reaction =

730.57

kN

5. CONTROL OF BEAM STRESSES

1. Initial Condition

Middle span position

top stress

bottom stress

2. Service Condition

Middle span position

top stress

bottom stress

=

=

-0.09 MPa

19.75 MPa

required

required

>

<

-1.58 MPa

24.00 MPa

=

=

11.16 MPa

2.67 MPa

required

required

<

>

22.50 MPa

-3.54 MPa

6. CONTROL OF BEAM DEFLECTION

Deflection at the middle of beam span

1. Chamber due stressing

initial

erection

2. Deflection at composite DL

3. Deflection due live load

4. Total deflection at service

=

=

=

=

=

-17.86

28.36

-28

36

-8.12

7.85

-0.28

mm

mm

mm

mm,required <L/800

mm

7. MOMENT AND CRACKING CAPACITY OF BEAM

Moment Capacity requirement :

Mult = 1,2*(Beam+Diaphragm+Deck Slab)+1,3*Slab+2*Asphaltic+1,8*(LL+I)

Mn

Ratio, Mn / Mu (>1)

Cracking Capacity requirement :

Mcrack

=

3737.99 kN.m

Mn / Mcr

=

1.37

CALCULATION RESUME

=

=

=

= 25.25 mm

3689.39 kN.m

5131.84 kN.m

1.39

PCI Monolith H-125cm ; L-20.80m ; CTC-160cm - RSNI (Rev.04)

TECHNICAL CALCULATION OF PCI MONOLITH BEAM FOR HIGHWAY BRIDGES

20.20

M

SPAN

L =

I. DATA

0.3

L=

Beam length

Beam spacing (s)

Concrete Slab thickness (CIP)

Asphalt thickness

Deck slab thickness

Cross Section

H

=

A

=

B

=

tweb =

20.20 M

20.80

1600

200

50

70

=

=

=

=

=

0.3

m

mm

mm

mm

mm

( edge anchor to edge anchor :

20.50

m)

1250

350

650

170

mm

mm

mm

mm

tfl-1

tfl-2

tfl-3

tfl-4

=

=

=

=

75

75

100

125

mm

mm

mm

mm

tfl-1

tfl-2

tweb

tfl-3

tfl-4

II. MATERIAL

B

2.1 Concrete

Beam

Slab

28.0

Compressive strength

[N/mm2]

at service

fc' =

50.0

at initial

80% fc'

Allowable stress

Allowable stress at initial (SNI T-12-2004 )

fc'i =

40.0

[N/mm2]

0.6 * fc'i =

24.0

[N/mm2]

0.25 * Sqrt(fc'i) =

Tensile

Allowable stress at service . (SNI T-12-2004 )

1.6

[N/mm2]

0.45 * fc' =

22.5

12.6

[N/mm2]

0.5 * Sqrt(fc') =

3.5

2.6

[N/mm2]

wc =

2500.0

2500.0

[kg/m3]

Ec = wc *0.043*sqrt(fc') =

38007.0

28441.8

[N/mm2]

Compressive

Compressive

Tensile

Modulus of elasticity

Concrete unit weight

1.5

1.5

Eci = wc *0.043*sqrt(fci') =

33994.5

[N/mm2]

4.9

[N/mm2]

Concrete flexural tension strength (fr)

f r = 0.7*sqrt(fc') =

2.2 Prestressing Cable

[Uncoated stress relieve seven wires strand]

( ASTM A 416 Grade 270 Low Relaxation or JIS G 3536 )

- Diameter strand

dia

:

12.7

[mm]

2

[mm ]

- Eff. Section area

Ast

- Modulus of elasticity

Es

: 1.93E+05

[N/mm2]

- Ultimate tensile strength

fu

[N/mm2]

2.3 Steel Reinforcement

- Diameter

98.78

1860

dia

13

[mm]

- Eff. Section area

Ast

132.73

[cm ]

- Modulus of elasticity

Es

: 2.10E+05

[N/mm2]

- Yield stress

fy

[N/mm2]

400

page 1 / 15

PCI Monolith H-125cm ; L-20.80m ; CTC-160cm - RSNI (Rev.04)

III. SECTION ANALYSIS

Remark :

2

Ep 1 =

38007

[N/mm ] [Girder]

Ep 2 =

28442

[N/mm ] [Slab]

5

4

n = Ep 2 / Ep 1

n=

0.75

1

2

Yb'

PRECAST BEAM

3.1 Precast Beam

[in mm ]

6

5

4

3

2

1

Total

Yb

Base Line

Zone

Ya'

Ya

Section

Width

Area

2

Level

Yb

Height

Bottom

Upper

mm

mm

mm

0.0

75.0

75.0

875.0

100.0

125.0

1250.0

150.0

350.0

170.0

170.0

650.0

650.0

150.0

350.0

350.0

170.0

170.0

650.0

0

26250

19500

148750

41000

81250

316750

1250

1175

1100

225

125

0

1250.0

1212.5

1141.8

662.5

165.2

62.5

519.3

Area

COMPOSITE BEAM

Area*Yb

3

mm

Io

Area*d

4

mm

Ix

mm4

mm

31828125

12304688

12613184758

12625489445

22265625

8775541

7556605867

7565381408

98546875

9490559896

3049566872

12540126768

6775000

30264228

5140086368

5170350595

5078125

105794271

16955415084

17061209355

164493750

9647698623

45314858949

54962557571

3.2 Composite Beam

[in mm ]

Zone

2

1

Total

Height

Width

Level

Yb

Area*Yb

Io

Area*d

Section

Bottom

Upper

mm

mm

mm

mm

mm4

mm4

mm4

200.0

70.0

1250.0

1520 0

1520.0

1197.3

149.7

650.0

1197.3

149.7

350.0

239466

10477

316750

566693

1320

1250

0

1420.0

1285.0

519.3

914 1

914.1

340041823

798220242.5

61294439175

62092659418

13462483

4277961.612

1441454078

1445732040

164493750

54962557571

49359610133

1.04322E+11

517998057

55765055775

1 12096E+11

1.12096E+11

1 67861E+11

1.67861E+11

Ya (mm)

Yb (mm)

Ix (mm4)

Wa (mm3)

Wb (mm3)

731

606

336

519.3

914.1

54962557571

75220826

105836180

167860559162

277030629

183640372

Ix

3.3 R e s u m e

[in mm ]

Area (mm2)

Description

Precast Beam

Composite Beam

[composite]

[precast]

316750

566693

499692375

IV. LOADING

4.1 Dead Load

a. Precast Beam

q1 = Ac precast girder x conc. Precast

b. Slab

q2 = Ac slab CIP x conc. slab

c. Deck slab

q3 = Ac deck slab x s

d. Asphaltic

q4 = Ac asphaltic x s

q1 =

q2 =

q3 =

q4 =

e. Diaphragm

0.317 x

0.334 x

0.098 x

0.080 x

2.50 =

2.40 =

2.40 =

2.20 =

0.792

[t/m'] =

7.77

[kN/m']

0.802

[t/m'] =

7.86

[kN/m']

0.235

[t/m'] =

2.31

[kN/m']

0.176

[t/m'] =

1.73

[kN/m']

6.92

[kN']

= Vol diaph with 0.20m thickness x diaph

0.294 x

2.40 =

0.706

note :

Number of diaph =

4

pcs

Diaph. placement

1

2

3

Location

0.00

6.73

13.47

Support Va

6.92

4.62

2.31

Mid Moment

0.00

23.31

23.31

Total Diaphragma Flexural Moment at Middle Span

eqivalen load q diaphragm

q5=

4

20.20

0.00

0.00

46.61

0.91

[ton'] =

from kg to N, multiply by 9.8060

kN.m

[kN/m']

page 2 / 15

PCI Monolith H-125cm ; L-20.80m ; CTC-160cm - RSNI (Rev.04)

4.2 Live Load

Taken from "Pembebanan Untuk Jembatan RSNI T-02-2005"

4.2.1."T"Loading(BebanTruk)

Unit

P1

Item

kN

225

Load

Impact

1.3

kN

292.5

LL+I

Distance

m

6.100

Va

kN

204.17

Va

kN

Mmax

kN-m

DF=S/3.4

MxDF

kN-m

P2

225

1.3

292.5

10.100

146.25

P3

50

1.3

65

15.100

16.41

M.maxdix= 10.100 m

DLA=

30%

Impact= 1+DLA=1.3

366.83

2535.00

0.47

1192.94

50kN

225kN

225kN

4.2.2."D"Loading(BebanLajur)

Taken from "Pembebanan Untuk Jembatan RSNI T-02-2005"

Load type :

Distribution Load Chart :

Dynamics Load Factored Chart :

Line Load (D load)

a. Dynamic Load Allowance [DLA]

DLA = 1 + 0,4

=

DLA = 1 + (0.0025*span+0.175)

DLA = 1 + 0,3

=

=

=

b. Knife Edge Load (KEL)

c. Distribution Factor (DF)

d. Distribution Load

2

q =

9.00 kN/m

q = 9 kN/m

2

q = 9 x(0,5+15/span)kN/m

which :

1.40

1.30

49.00

1.00

Span <= 50 m

50 < Span < 90 m

Span >= 90 m

[kN/m']

for

Span <= 30 m

Span > 30 m

e. Live load

Distribution load, qudl = DF x q x s

=

1.00

x

9.00

KEL, PKEL = DF x DLA x KEL x s

=

1.00

1.40

x

x

1.60

49.00

1.60

14.40

[kN/m']

109.76

[kN']

M.maxat0.5span=

10.100 m

Va=

200.32 kN

MLL=

1288.76 kN.m

RESUME: MomentforcecausebyDLoadingisbiggerthanTruckLoading

page 3 / 15

PCI Monolith H-125cm ; L-20.80m ; CTC-160cm - RSNI (Rev.04)

V. MOMENT ANALYSIS

[in kN-meter ]

Mid

Sec 1-1

Sec 2-2

Sec 3-3

Sec 4-4

span

0.00

6.60

13.60

20.20

DL

Precast beam

396.06

0.00

348.50

348.50

0.00

Subtotal

396.06

0.00

348.50

348.50

0.00

DL

Slab

400.92

0.00

352.78

352.78

0.00

ADL

Asphaltic Layer

88.03

0.00

77.46

77.46

0.00

SDL

Diaphragm+Deck Slab

164.25

0.00

144.52

144.52

0.00

Subtotal

653.20

0.00

574.76

574.76

0.00

LL

Distribution load

734.47

0.00

646.27

646.27

0.00

KEL

554.29

0.00

487.73

487.73

0.00

Subtotal

1288.76

0.00

1134.00

1134.00

0.00

Total (DL + LL)

2338.02

0.00

2057.26

2057.26

0.00

Ultimate total

3689.39

0.00

3246.35

3246.35

0.00

Ultimate total = 1,2*(Beam+Diaphragm+Deck Slab)+1,3*Slab+2*Asphaltic+1,8*(LL+I)

Type

Description

Sec 5-5

20.20

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

Sec 6-6

10.10

396.06

396.06

400.92

88.03

164.25

653.20

734.47

554.29

1288.76

2338.02

3689.39

Sec 5-5

20.20

-78.43

-78.43

-79.39

-17.43

-32.52

-129.35

-145.44

-109.76

-255.20

-462.97

-730.57

730 57

Sec 6-6

10.10

0.00

0.00

0.00

0.00

0.00

0.00

0.00

54.88

54.88

54.88

98 78

98.78

(m)

VI. SHEAR ANALYSIS

[in kN]

Mid

Sec 1-1

Sec 2-2

Sec 3-3

Sec 4-4

span

0.00

6.60

13.60

20.20

Precast beam

DL

0.00

78.43

27.18

-27.18

-78.43

Subtotal

0.00

78.43

27.18

-27.18

-78.43

Slab

DL

0.00

79.39

27.51

-27.51

-79.39

Asphaltic Layer

ADL

0.00

17.43

6.04

-6.04

-17.43

Diaphragm+Deck slab

SDL

0.00

32.52

11.27

-11.27

-32.52

Subtotal

0.00

129.35

44.82

-44.82

-129.35

Distribution load

0.00

145.44

50.40

-50.40

-145.44

LL

KEL

54.88

109.76

73.90

-73.90

-109.76

Subtotal

54.88

255.20

124.30

-124.30

-255.20

Total (DL + LL)

54.88

462.97

196.30

-196.30

-462.97

Ultimate total

98 78

98.78

730 57

730.57

317 72

317.72

-317.72

317 72

-730.57

730 57

Ultimate total = 1,2*(Beam+Diaphragm+Deck Slab)+1,3*Slab+2*Asphaltic+1,8*(LL+I)

Type

Description

(m)

VII. PRESTRESSING CABLE

7.1 Cable Profile

[in: mm ]

Tension

ten-

Nos

Total

JF

don

strand

Edge

Middle

left

right

tension

(kN)

0

0

0

1

2

3

0

0

0

4

12

12

28

0

0

0

900

600

300

514.29

0

0

0

300

200

100

171.43

0%

0%

0%

75%

75%

75%

75%

0%

0%

0%

0%

0%

0%

0%

0%

0%

0%

75%

75%

75%

75%

0

0

0

551

1654

1654

3858

total

Profile

Parabolic curve (Average of Strand's position vertically from the bottom of beam ( Value for Y axis ))

2

Y = A.x + B.x + C

where :

2

A = Constanta : ( (Ymiddle + Yedge)/(L/2) )

A=

0.003263

B = Constanta : ( L x A )

B = -0.066899

C = Average of strand's position when the parabolic curve reach the Y axis

Average of Strand's position vertically from the bottom of beam ( Value for Y axis )

2

+

-0.066899

X +

0.514286

Y = 0.003263 X

Cable tendon angle :

o

tg =

0.006527 X

-0.066899

eccentricity of tendon at middle section

Eccentricity [e]

=

Yb - Ys = 347.89 mm

Yb = Distance of Neutral Axis from the bottom of non composite beam ( Chapter 3.3 - Resume )

Ys = Distance of tendon from the bottom of the beam at the middle span ( Chapter 7.1, Cable Profile-middle)

page 4 / 15

PCI Monolith H-125cm ; L-20.80m ; CTC-160cm - RSNI (Rev.04)

Average of Strand's position vertically from the bottom of beam ( Value for Y axis )

1.20

1.00

0.80

0.60

0.40

0.20

0.00

0

10

15

20

25

7.2 Losses of Prestress

1. Losses of Prestress (Short Term)

a. Friction