Escolar Documentos

Profissional Documentos

Cultura Documentos

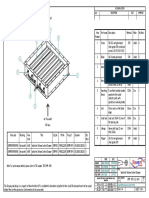

Drawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PM

Enviado por

jonodo89Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Drawing No. ATD: 000-000-000-4000 - 2.dgn 2011/10/31 01:08:29 PM

Enviado por

jonodo89Direitos autorais:

Formatos disponíveis

0 0 0 0 0

0 0 0

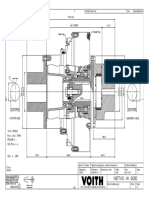

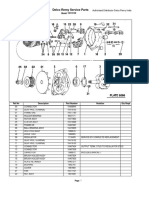

WEAR

DRIVEN

W0

SHAFT ENDS

W2

BELT

ANG.(TAPER

T3

T4

0.8

W2

OVER LOCKING

D4

H8

D2

h8

D1

h8

0.8

R-L

ELEMENT LENGTH

D3

D4

0.8

R-L

H8

D2

h8

D1

h8

D5

D6

R-M

0.8

S3

OVER LOCKING

AS PER

CLIENT

ORDER

D5

0.8

ELEMENT LENGTH

D3

LOCKING

ELEMENT

T4

S3

R-N

AS PER

CLIENT

ORDER

R-M

0.8

IN DEG.)

T3

R-N

LOCKING

ELEMENT

4 0 0 0

1.6

MAX

W2

BELT

W1

T2

SHAFT ENDS

MAX

NON-DRIVEN

+5

T1-0

DRIVEN

SHAFT ENDS

MIN.AFTER

MACHINING

WEAR

W1

W0

ATD

1.6

+5

-0

T1

SHAFT ENDS

T2

NON-DRIVEN

MIN.AFTER

MACHINING

DRAWING No.

1.6

BEARING

R-N

DETAIL

>

S2

HOUSING(1)

HOUSING(1)

TYPICAL WELD DETAIL.

WELD PROCEDURE TO BE

DETAIL C

BEARING

HOUSING(1)

>

>

S2

DETAIL

BEARING

BEARING

DETAIL A

>

HOUSING(1)

APPROVED BY CLIENT

S1

S1

TYPICAL WELD DETAIL.

WELD PROCEDURE TO BE

STANDARD END DISCS

COMPACT END DISCS

T2

1.6

WEAR

W1

DRIVEN

SHAFT ENDS

W0

W2

MAX

+5

-0

T1

SHAFT ENDS

T-BOTTOM TYPE/C

1.6

NON-DRIVEN

MIN.AFTER

MACHINING

APPROVED BY CLIENT

TURBINE TYPE/S

W2

BELT

R-N

LOCKING

ELEMENT

AS PER

CLIENT

ORDER

R-M

0.8

0.8

OVER LOCKING

BEARING

1.6

GENERAL NOTES:

TABLE OF SIZES AND RATED LOADS:- SEE DGN 4001

ALL SIZES IN mm, TAPER ANGLE IN DEGREES.

BELT TENSIONS F1 & F2 IN kN

DETAIL

>

>

S2

T3

R-N

BEARING

DETAIL B

HOUSING(1)

D4

H8

D2

h8

R-N

HOUSING(1)

D1

h8

D5

D6

IN DEG.)

0.8

R-L

ELEMENT LENGTH

D3

ANG.(TAPER

T4

S3

SHAFT TORQUE Q IN Nm

SHAFTS DESIGNED FOR 2,5 TIMES RATED TORQUE TO ALLOW FOR HIGHER STARTUP TENSIONS AND TORQUES

SHAFTS DESIGNED FOR 2,5 TIMES RATED TORQUE DRIVEN FROM A SINGLE END

S1

BEARING LIFE OF 100 000 HRS, BASED ON BELT SPEED OF 10 m/s

NOTES, GENERAL:

TYPICAL WELD DETAIL.

BEARING CENTRES ARE TO THE CENTRE OF THE BEARING HOLDING DOWN BOLT GROUP.

WELD PROCEDURE TO BE

BEARINGS ARE NOT ALWAYS LOCATED AT THE CENTRE OF THE BEARING HOUSING (1).

APPROVED BY CLIENT

T-BOTTOM TYPE/S

NOTES FOR MANUFACTURER:

BREAK ALL SHARP EDGES

DRIVE PULLEYS: FIXED BEARING TO BE MOUNTED ON THE DRIVE END OF THE SHAFT

STANDARD END DISCS

DRUM LONGITUDINAL WELD: WELD PROCEDURE TO BE APPROVED BY THE CLIENT.THE WELD

MUST BE DONE COMPLETELY IN THE FLAT POSITION AS PART OF THE WELD PROCEDURE.

THE INTERNAL WELD BEAD MUST BE GROUND FLUSH.

END DISC TO DRUM CIRCUMFERENTIAL WELD FOR T-BOTTOM PULLEY:IF DESIRED THE WELD CAN BE

MOVED FURTHER ALONG THE DRUM BY USING A THICKER END PLATE TO START WITH. THIS WILL

PROVIDE BETTER ACCESS TO PERFORM THE INNER ROOT WELD. OTHER END DISC DETAILS REMAIN UNCHANGED.

NOTES FOR CLIENT: OPTIONAL DECISION BY CLIENT / PROJECT ENGINEER:

SHAFT STEP LOCATED TO ALLOW FITTING OF TACONITE SEALS IF REQUIRED (WIDER THAN LABYRINTH SEALS SPECIFIED AS STANDARD IN THIS TABLE).

TO MINIMISE NUMBER OF BEARING SIZES, A LARGER BEARING SIZE THAN TABLED CAN BE SPECIFIED. BUT CHECK DIM S2 AND SUFFICIENT LENGTH FOR BEARIN

NOTES FOR CLIENT:

DRIVE SHAFT COUPLINGS:

IF BIKON FLANGE COUPLINGS ARE USED THE SHAFT DIAMETER (DIMENSION D1) CAN BE REDUCED BY UP TO 10 mm OUTSIDE OF THE BEARINGS.

IF KEYED COUPLINGS ARE USED THE KEYWAY STRESSES MUST BE EVALUATED. IT MAY BE NECESSARY TO USE TWO KEYS. IN THIS CASE TANGENTIAL TAPER KEY

BELT TENSION RATINGS:

BELT TENSION RATED LOADS F1 & F2 ARE FOR THE RUNNING CONDITION. NO ALLOWANCE HAS BEEN BUILT IN FOR OVERLOADING.

IF THE CLIENT IS CONCERNED THAT ACTUAL RUNNING BELT TENSIONS MAY BE HIGHER, THEN A LARGER PULLEY MUST BE SELECTED.

MATERIALS:

SHAFT:

080M40 Cond N (EN8)

THIS DRAWING MUST BE READ INCONJUCTION WITH

Min Izod 20 J at room temp (all sizes)

DRAWING NUMBER 00000-000-4001

SHELL:

S355JR TO EN 10025:24

END DISC:

CONVEYOR DATA SHEET

4001

DATA SHEET ADDED

18/04/2006

SW

DRAWING & DATA SHEET UPDATED

20/07/2006

SW

ISSUED FOR MANUFACTURE

1.0

COMPACT END DISC ADDED,TOLERANCE AND

2.0

A. LILL DRAWN

A. LILL

CHECKED

A. LILL

31/07/2006

SW

12/09/2011

GTS A. LILL DESIGNED

S355JR TO EN 10025:24

COPYRIGHT

S.WRENCH

S.WRENCH

COMPANY

ANGLO AMERICAN

A.D.LILL

A.LILL

PROJECT

STANDARD DRAWINGS

AREA

CONVEYORS

SCALE:

LOCATION

GENERAL NOTES EDITED TO SUIT THE CLIENT.

DES.ENG.

A.D.LILL

A.LILL

ANGLO TECHNICAL DIVISION

PROJ.ENG

ORIGINAL

JOB

A1

TITLE

DRG. SIZE

CONVEYOR PULLEY DETAILS

SHEET

TITLE

DRG No

REFERENCES

000-000-000-4000_2.dgn 2011/10/31 01:08:29 PM

TITLE

DRG No

DETAIL

MARK

REVISIONS

DATE

INIT APPVD

COPYRIGHT

NAME

DATE

DRG No.

SIGNATURE

PROJ.

50

100

150

-0

0

BUS. UNIT

-4

SEQ. No.

REV.

2.0

Você também pode gostar

- Robots User Manual (CE) - EnglishDocumento170 páginasRobots User Manual (CE) - EnglishVlad-Andrei Cucuteanu100% (3)

- ENG ECI ELC SPC 004 Electrical InstallationDocumento68 páginasENG ECI ELC SPC 004 Electrical Installationjonodo89Ainda não há avaliações

- Surface Preparation and Paint SpecificationDocumento63 páginasSurface Preparation and Paint Specificationjonodo89Ainda não há avaliações

- UK National Annex To Eurocode 3: Design of Steel Structures: BSI Standards PublicationDocumento16 páginasUK National Annex To Eurocode 3: Design of Steel Structures: BSI Standards PublicationTuan Pn100% (2)

- Manual Da Deslintadeira-200 SerrasDocumento56 páginasManual Da Deslintadeira-200 SerrasAilson Silva AlvesAinda não há avaliações

- Co2 Damper6Documento4 páginasCo2 Damper6sabir hussainAinda não há avaliações

- Fire Protection Standard For Vehicles and Moving MachineryDocumento39 páginasFire Protection Standard For Vehicles and Moving Machineryjonodo89100% (1)

- EXX-EME-STD-0008 - Wear Liners For Plate Work and ChutesDocumento22 páginasEXX-EME-STD-0008 - Wear Liners For Plate Work and Chutesjonodo89100% (1)

- AATC000859 - AATC Design Criteria and Guidelines For Surface Infrastructure - Mechanical & StructuralDocumento68 páginasAATC000859 - AATC Design Criteria and Guidelines For Surface Infrastructure - Mechanical & Structuraljonodo89Ainda não há avaliações

- Designing A Keyphasor TriggerDocumento8 páginasDesigning A Keyphasor TriggerMahesh JadhavAinda não há avaliações

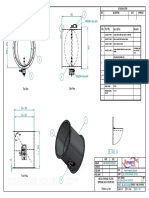

- Notes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512Documento2 páginasNotes: Unless Otherwise Specified: Idd, Tau Camera, 9mm-f1.4, 17um 640x512antoine131Ainda não há avaliações

- m0043 016 2 PDFDocumento1 páginam0043 016 2 PDFajarekarga ajarekarAinda não há avaliações

- Part 1 - Trolley WheelDocumento1 páginaPart 1 - Trolley WheellexatrinAinda não há avaliações

- 50 Cu Yd (Heaped) Aggregate Bin 225 BBL (MAX) Cement I Bin: Rear ViewDocumento1 página50 Cu Yd (Heaped) Aggregate Bin 225 BBL (MAX) Cement I Bin: Rear ViewDavid SarccoAinda não há avaliações

- 11-2756-b Elevator Boot Assy 28SIDocumento1 página11-2756-b Elevator Boot Assy 28SIBoanerges BritoAinda não há avaliações

- A554 y 730 HV DWG Hva 300Documento1 páginaA554 y 730 HV DWG Hva 300josephAinda não há avaliações

- 185-170-5-300-M44-0055 RevBDocumento1 página185-170-5-300-M44-0055 RevBVashish RamrechaAinda não há avaliações

- Peract Pi Q23 DW 0004 PDFDocumento5 páginasPeract Pi Q23 DW 0004 PDFGAinda não há avaliações

- Test Fixture Optical MountDocumento1 páginaTest Fixture Optical Mounti50229Ainda não há avaliações

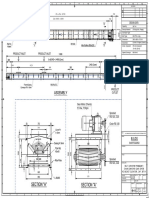

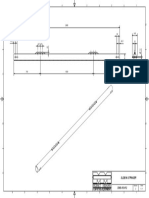

- Belt Conveyor 600x12000 (k2) - Belt Conveyor TataDocumento1 páginaBelt Conveyor 600x12000 (k2) - Belt Conveyor TataAde SAinda não há avaliações

- 0740 19a PDFDocumento1 página0740 19a PDFDavid SarccoAinda não há avaliações

- Power Powders: The inDocumento6 páginasPower Powders: The insalkan_rahmanovic810Ainda não há avaliações

- Weld Map Control RoomDocumento12 páginasWeld Map Control RoomAry Cipta KusumaAinda não há avaliações

- Sae Insert S1yt3232 DWG 0Documento1 páginaSae Insert S1yt3232 DWG 0kaliya12Ainda não há avaliações

- Sliding Elastomeric Bearing - 301 MTDocumento1 páginaSliding Elastomeric Bearing - 301 MTAnusha KishoreAinda não há avaliações

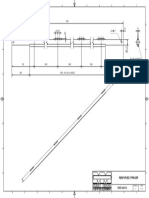

- Plan Elevation: Job No. ClientDocumento1 páginaPlan Elevation: Job No. Clientriz2010Ainda não há avaliações

- Sheet 1 of 1: All Dimensions Are in MMDocumento1 páginaSheet 1 of 1: All Dimensions Are in MMPRASHANTHAinda não há avaliações

- North: East Elevation View SCALE 1/100Documento16 páginasNorth: East Elevation View SCALE 1/100Potential SupportAinda não há avaliações

- Machine Afzar Shams: Bearing HousingDocumento8 páginasMachine Afzar Shams: Bearing HousingmasoodkamaliAinda não há avaliações

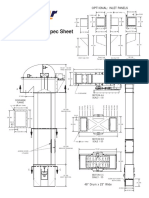

- Be 4800 Spec Sheet 2Documento1 páginaBe 4800 Spec Sheet 2Nhero DulatreAinda não há avaliações

- SEMA AH Hook Block Assly. Sheet 2 3Documento1 páginaSEMA AH Hook Block Assly. Sheet 2 3Ade Y SaputraAinda não há avaliações

- Detail H Scale 1: 3: Section E-E SCALE 1: 10Documento2 páginasDetail H Scale 1: 3: Section E-E SCALE 1: 10Brahamadandi Achyuth KumarAinda não há avaliações

- Preliminar Não Fabricar: Plan View From Above Showing Foundation Hole DrillingDocumento1 páginaPreliminar Não Fabricar: Plan View From Above Showing Foundation Hole DrillingbarrosojmsAinda não há avaliações

- GA-150027-1 (003) Ffetbigbore1750 PDFDocumento1 páginaGA-150027-1 (003) Ffetbigbore1750 PDFriinAinda não há avaliações

- Rti, Mois, Mec, Ga, GaDocumento3 páginasRti, Mois, Mec, Ga, GaLuis PurisAinda não há avaliações

- Sprocket PT Petrodrill Manufacture IndonesiaDocumento1 páginaSprocket PT Petrodrill Manufacture Indonesiaer_winwibowoAinda não há avaliações

- Assembly: Section "A"Documento2 páginasAssembly: Section "A"mrmp bbiAinda não há avaliações

- Note 1: Design Code: Pd5500 Cat Ii 2015Documento1 páginaNote 1: Design Code: Pd5500 Cat Ii 2015Edo FaiZal CandraWinataAinda não há avaliações

- Approval Required: Material ListDocumento2 páginasApproval Required: Material ListJorge VarelaAinda não há avaliações

- Kennedy Valve: 3"-12" Oil Cushion Check Valve AssemblyDocumento1 páginaKennedy Valve: 3"-12" Oil Cushion Check Valve AssemblySamuel Lopez BenitesAinda não há avaliações

- Wip Rev-E 25-Jun-19Documento2 páginasWip Rev-E 25-Jun-19QuyetAinda não há avaliações

- DWG 415-019 REV 0Documento7 páginasDWG 415-019 REV 0jonodo89Ainda não há avaliações

- Equations For The Design of Standard Sprocket TeethDocumento4 páginasEquations For The Design of Standard Sprocket TeethvanjaurkeAinda não há avaliações

- Nozzle Table: K-K Foundation Detail TypDocumento1 páginaNozzle Table: K-K Foundation Detail TypVishal KandAinda não há avaliações

- 050 0160 A (Main Frame Assembly)Documento3 páginas050 0160 A (Main Frame Assembly)Miltongrimi GrimilAinda não há avaliações

- Donaldson UK Manual TDS PDFDocumento19 páginasDonaldson UK Manual TDS PDFPatricio TamayoAinda não há avaliações

- Ls Bearing Positioning Ls Bearing Positioning: Section View Reducer Jumborex Jc62Documento1 páginaLs Bearing Positioning Ls Bearing Positioning: Section View Reducer Jumborex Jc62Luu Thanh CongAinda não há avaliações

- S.No. Part No. Description Remarks: 11.5 MM Dia #12 Equal Distance Both Side 550 6 M5X40#4 Allen BoltDocumento1 páginaS.No. Part No. Description Remarks: 11.5 MM Dia #12 Equal Distance Both Side 550 6 M5X40#4 Allen Boltsabir hussainAinda não há avaliações

- CombineddrawingsDocumento20 páginasCombineddrawingsapi-429073519Ainda não há avaliações

- DFZC 7985 1 91 en - GB 1211Documento4 páginasDFZC 7985 1 91 en - GB 1211RogerioAinda não há avaliações

- 3147 Hoist r3Documento1 página3147 Hoist r3Ade Y SaputraAinda não há avaliações

- Chipper Knives For The Wood IndustryDocumento5 páginasChipper Knives For The Wood IndustryX800XLAinda não há avaliações

- 5 HP 18 CFM 3 Cylinder Compressor - Geometric Exploded ViewDocumento4 páginas5 HP 18 CFM 3 Cylinder Compressor - Geometric Exploded ViewEaton CompressorAinda não há avaliações

- App1002413340030-03 Piping Drawing Miscellaneous Piping Ass Rev.ADocumento11 páginasApp1002413340030-03 Piping Drawing Miscellaneous Piping Ass Rev.AAswindana Ibnu SenaAinda não há avaliações

- Ротациона глава - Обновен каталогDocumento3 páginasРотациона глава - Обновен каталогGoran BogdanoskiAinda não há avaliações

- AGMA Fatores de ServiçoDocumento4 páginasAGMA Fatores de Serviçochu42Ainda não há avaliações

- Intercambiador de Calor PDFDocumento10 páginasIntercambiador de Calor PDFShalber Jhoel Garcia SaraviaAinda não há avaliações

- V-8120 DWG CommentsDocumento1 páginaV-8120 DWG CommentsSulist N WahyudieAinda não há avaliações

- Sample Seal Pot DWGDocumento1 páginaSample Seal Pot DWGsandesh sadvilkarAinda não há avaliações

- Offer For 1000 TPD Prepressing PDFDocumento14 páginasOffer For 1000 TPD Prepressing PDFrajee7Ainda não há avaliações

- Ball - Screw - Calculations - As Per THK and PmiDocumento5 páginasBall - Screw - Calculations - As Per THK and PmiDharmeshPatelAinda não há avaliações

- Chain Appron Conveyor R1a01-BushingDocumento1 páginaChain Appron Conveyor R1a01-Bushinger_winwibowoAinda não há avaliações

- Vie Pc01 STN DWG ZML Sub 1152 (r5) Grid 1 To 9Documento1 páginaVie Pc01 STN DWG ZML Sub 1152 (r5) Grid 1 To 9Ashish BhartiAinda não há avaliações

- Acrobat Document PDFDocumento1 páginaAcrobat Document PDFKhepa BabaAinda não há avaliações

- 01) 5333-107-B - General Arrangement Drawing CN8202 ElevatorDocumento1 página01) 5333-107-B - General Arrangement Drawing CN8202 ElevatorRicardo Diaz AristaAinda não há avaliações

- 1714010223-Vent Ext Fima - RDocumento1 página1714010223-Vent Ext Fima - RMilton IngaAinda não há avaliações

- Discrete Element Method to Model 3D Continuous MaterialsNo EverandDiscrete Element Method to Model 3D Continuous MaterialsAinda não há avaliações

- 36-68-07 Machined End Tolerances For Drum Nozzles& Nipples, Header, Pipe, FittingsDocumento4 páginas36-68-07 Machined End Tolerances For Drum Nozzles& Nipples, Header, Pipe, FittingsJKKAinda não há avaliações

- Fire Protection Standard For Electrical Equipment and InstallationsDocumento27 páginasFire Protection Standard For Electrical Equipment and Installationsjonodo89100% (1)

- Sole PlatesDocumento12 páginasSole Platesjonodo89Ainda não há avaliações

- Fire Protection Standard For Use of Plastic PipesDocumento6 páginasFire Protection Standard For Use of Plastic Pipesjonodo89Ainda não há avaliações

- Static Shaft Pulleys With Internal BearingsDocumento14 páginasStatic Shaft Pulleys With Internal Bearingsjonodo89100% (1)

- Screw Take UpsDocumento7 páginasScrew Take Upsjonodo89Ainda não há avaliações

- Mechanical StandardsDocumento10 páginasMechanical Standardsjonodo890% (1)

- v487tvvs - Ha - Sx260Documento1 páginav487tvvs - Ha - Sx260jonodo89Ainda não há avaliações

- Generic Geared ReducersDocumento12 páginasGeneric Geared Reducersjonodo89Ainda não há avaliações

- K0001 A430 M SPC 0011 Rev02 Metallic Wear LiningDocumento15 páginasK0001 A430 M SPC 0011 Rev02 Metallic Wear Liningjonodo89Ainda não há avaliações

- M&T Risk & AssuranceDocumento39 páginasM&T Risk & Assurancejonodo89Ainda não há avaliações

- Belt Conveyor Idlers and RollsDocumento14 páginasBelt Conveyor Idlers and Rollsjonodo89Ainda não há avaliações

- Aa Spec 114005Documento45 páginasAa Spec 114005jonodo8950% (2)

- New Doc 2018-04-24Documento6 páginasNew Doc 2018-04-24jonodo89Ainda não há avaliações

- 2RVRETURNS25Documento1 página2RVRETURNS25jonodo89Ainda não há avaliações

- New Doc 2018-04-24Documento6 páginasNew Doc 2018-04-24jonodo89Ainda não há avaliações

- BB Design ReportDocumento79 páginasBB Design Reportjonodo89Ainda não há avaliações

- SolidwovendatasheetDocumento1 páginaSolidwovendatasheetjonodo89Ainda não há avaliações

- DWG 415-006 REV 0Documento1 páginaDWG 415-006 REV 0jonodo89Ainda não há avaliações

- G - 1 - A1 General Arrangment DrawingDocumento1 páginaG - 1 - A1 General Arrangment Drawingjonodo89Ainda não há avaliações

- Macsteel VRN - Wear Abrasion Steels - Creusabro 8000Documento4 páginasMacsteel VRN - Wear Abrasion Steels - Creusabro 8000jonodo89Ainda não há avaliações

- DWG 415-008 REV 0Documento1 páginaDWG 415-008 REV 0jonodo89Ainda não há avaliações

- DWG 424-012 REV 1Documento1 páginaDWG 424-012 REV 1jonodo89Ainda não há avaliações

- DWG 415-009 REV 0Documento1 páginaDWG 415-009 REV 0jonodo89Ainda não há avaliações

- DWG 415-007 REV 0Documento1 páginaDWG 415-007 REV 0jonodo89Ainda não há avaliações

- DWG 415-012 REV 2Documento1 páginaDWG 415-012 REV 2jonodo89Ainda não há avaliações

- Gearbox Overhaul and Repair ProcedureDocumento3 páginasGearbox Overhaul and Repair ProcedureHugho0% (1)

- 160 Kva MangrolDocumento6 páginas160 Kva MangrolrajendranrajendranAinda não há avaliações

- Atlas Copco Portable Air Compressors: 43 To 69 L/s (70 To 147 Cu - Ft/min) - 7 Bar (102 Psig)Documento6 páginasAtlas Copco Portable Air Compressors: 43 To 69 L/s (70 To 147 Cu - Ft/min) - 7 Bar (102 Psig)Thierry Nolla100% (1)

- Factors Affecting Comfort Air Conditioning:: A) Fan: B) Air Condition: C) Filters: D) Supply Duct and OutletDocumento4 páginasFactors Affecting Comfort Air Conditioning:: A) Fan: B) Air Condition: C) Filters: D) Supply Duct and Outletbibekananda sahooAinda não há avaliações

- Delco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaDocumento2 páginasDelco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaWilson AcostaAinda não há avaliações

- Managed Pressure Drilling MPD BrochureDocumento5 páginasManaged Pressure Drilling MPD Brochureswaala4realAinda não há avaliações

- Chapter 7 (Part 1)Documento96 páginasChapter 7 (Part 1)orangesweetsauceAinda não há avaliações

- IMI CCI Product DRAG-Control-Valves AW LRESDocumento4 páginasIMI CCI Product DRAG-Control-Valves AW LRESOscarGomezMecanicoAinda não há avaliações

- H. K. Moffatt and Tadashi Tokieda - Celt Reversals: A Prototype of Chiral DynamicsDocumento8 páginasH. K. Moffatt and Tadashi Tokieda - Celt Reversals: A Prototype of Chiral DynamicsVortices3443Ainda não há avaliações

- Service Parts List: M18™ 1/4" Hex Impact Driver - Single SpeedDocumento2 páginasService Parts List: M18™ 1/4" Hex Impact Driver - Single SpeedhiramfgarciaAinda não há avaliações

- Outline Design Specification of Phase IV (March 2019) 01042019 PDFDocumento164 páginasOutline Design Specification of Phase IV (March 2019) 01042019 PDFBilal A BarbhuiyaAinda não há avaliações

- Demin Tank ReportDocumento69 páginasDemin Tank Reportshahroze mustafaAinda não há avaliações

- Clio Brakes ABS TN.3588A - XBXX-2 PDFDocumento1 páginaClio Brakes ABS TN.3588A - XBXX-2 PDFdario024Ainda não há avaliações

- 5.3 Code, Standard and RegulationDocumento7 páginas5.3 Code, Standard and Regulationandrieysyah2525Ainda não há avaliações

- Science Unit-Wheels and LeversDocumento11 páginasScience Unit-Wheels and Leversapi-535552931Ainda não há avaliações

- JC2 Physics H2 2018 RafflesDocumento88 páginasJC2 Physics H2 2018 RafflesVarshLokAinda não há avaliações

- Biddle - VRVDocumento31 páginasBiddle - VRVutzu_yooAinda não há avaliações

- Öhlins Ka049 Zxr750r 91-94Documento2 páginasÖhlins Ka049 Zxr750r 91-94sasaAinda não há avaliações

- Vent Master Cam C InjeccionDocumento2 páginasVent Master Cam C InjeccionFreddy VeraAinda não há avaliações

- GCSE Physics P2Documento6 páginasGCSE Physics P2AdamAinda não há avaliações

- ch5 Limit Switches PDFDocumento208 páginasch5 Limit Switches PDFkhaled tahaAinda não há avaliações

- Rr410801 Transport PhenomenaDocumento8 páginasRr410801 Transport PhenomenaSrinivasa Rao GAinda não há avaliações

- XX X XXXX XX XXXX - Tank Foundation 45m Dia X 25m High On Earthen Bund FoundationDocumento30 páginasXX X XXXX XX XXXX - Tank Foundation 45m Dia X 25m High On Earthen Bund FoundationKhairul JaggerAinda não há avaliações

- Laboratory Study On Pore Pressure Generation and Liquefaction of Low-Plasticity Silty Sandy Soils During The 2012 Earthquake in ItalyDocumento10 páginasLaboratory Study On Pore Pressure Generation and Liquefaction of Low-Plasticity Silty Sandy Soils During The 2012 Earthquake in ItalyPinak RayAinda não há avaliações

- Spc s4s 403 0 s4s Dt 中国sslDocumento20 páginasSpc s4s 403 0 s4s Dt 中国sslnksiavashAinda não há avaliações

- Fluid and Thermodynamics - Volume 1 - Basic Fluid MechanicsDocumento652 páginasFluid and Thermodynamics - Volume 1 - Basic Fluid Mechanicslig100% (1)

- Miniature Flowmeters For Analytical Process DK 700: Installation and Operating InstructionsDocumento2 páginasMiniature Flowmeters For Analytical Process DK 700: Installation and Operating InstructionsMateusz SynowieckiAinda não há avaliações