Escolar Documentos

Profissional Documentos

Cultura Documentos

AWS Groove Weld Test Prameters 1

Enviado por

Danem HalasDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

AWS Groove Weld Test Prameters 1

Enviado por

Danem HalasDireitos autorais:

Formatos disponíveis

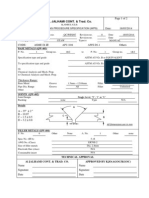

WELDING PROCEDURE SPECIFICATION (WPS)

AWS A5.17 Groove Weld Test Parameters

Company Name: Titus Steel

Authorized By: Steve Usatis

Welding Process(es): SAW Single Electrodes

Types: Mechanized

Date : May 8, 2008

Revision No. 1

Date: May 21, 2008

Butt

V- groove

Single

Steel-1/2 thick x 2 wide

A36

No

N/A

Joint Design Used:

Weld Type:

Single or Double Weld

Backing:

Backing Material:

Back Gouging:

Method:

Position:

None

Heat Treatment:

Position of Groove _____

Weld Progression ______

Other ________________

Flat (1G)

N/A

Temperature _______________

Time______________________

Other

Base Metal:

Material Spec. ASTM

Type or Grade A36

Thickness:

1.0

Diameter (Pipe): N/A

WPS No. SAW-1G-01

Supporting PQR No. N/A

Preheat: See General Notes

to

to

Preheat Temperature _________

Interpass Temperature ________

Other _____________________

Material Spec. ASTM

Type or Grade A36

Shielding Gas

Filler Metals:

AWS Specification ________

AWS Classification _______

Size of Filler Metal _______

Wire Brand

Flux Brand

Gas

Shielding: None

Backing: None

A5.17

F7A2-EM12K

5/32

Lincoln L61

Lincoln 761

Electrical Characteristics:

Current Type___________________________

Mode of Metal Transfer (GMAW)__________

Polarity_______________________________

Tungsten Electrode Size and Type__________

DC

N/A

Positive

None

% Comp.

(Mixture)

70F (ambient)

275 F -300 F

Flow Rate

WPS No. SAW-1G-01 contd

Technique:

String or Weave Bead_________________

Oscillation__________________________

Multi-pass or Single Pass (per side)______

Single or Multiple Electrodes___________

Gas Cup Size________________________

Interpass Cleaning ____________

Peening____________________________

Push or Drag Angle___________________

Transverse electrode angle _____________

Contact tube to work distance___________

Electrode Spacing____________________

String

None

Multi-pass

Single electrodes

N/A

Chipping hammer and/or wire brush

None

0-5 push

90

1-1/4

N/A

Electrode Skew______________________

N/A

Welding Data:

Weld

Size

S

1

Side

Layer

Pass

1

1

1

1

1

1

1

1

1

2

3

4

5

6

7

8

1-2

3-4

5-6

7-8

9-10

11-12

13-14

15-17

Filler

Metal

Class

EM12K

EM12K

EM12K

EM12K

EM12K

EM12K

EM12K

EM12K

Filler

Metal

5/32

5/32

5/32

5/32

5/32

5/32

5/32

5/32

Wire Feed

Speed

(ipm)

40

42

42

42

42

42

42

42

Amps.

Volts

(at feeder)

450-500

500-525

500-525

500-525

500-525

500-525

500-525

500-525

27-28

27-28

27-28

27-28

27-28

27-28

27-28

27-28

Travel

Speed

(ipm)

16

16

16

16

16

16

16

16

Max. Heat

Input

(kj/in)

52.5

55.1

55.1

55.1

55.1

55.1

55.1

55.1

General Notes:

1) The point of temperature measurement shall be at the mid-length of the test assembly, 1 from

the weld centerline as shown below.

2) Welding shall start with the material at room temperature. Welding shall continue, bead by

bead, until a temperature within the interpass temperature range is reached. Thereafter,

production of subsequent beads may only begin when the assembly is within the interpass

temperature range of 275 F -300 F.

3) Bead sequence

Você também pode gostar

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideNo Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideNota: 3.5 de 5 estrelas3.5/5 (7)

- Applied Welding Engineering: Processes, Codes, and StandardsNo EverandApplied Welding Engineering: Processes, Codes, and StandardsAinda não há avaliações

- Weld Like a Pro: Beginning to Advanced TechniquesNo EverandWeld Like a Pro: Beginning to Advanced TechniquesNota: 4.5 de 5 estrelas4.5/5 (6)

- WPS FormatDocumento2 páginasWPS FormatAmit SarkarAinda não há avaliações

- Welding Procedure SpecificationDocumento5 páginasWelding Procedure SpecificationFranklin londono0% (1)

- Welding FormDocumento4 páginasWelding FormAnand SomanAinda não há avaliações

- WPS FormatDocumento1 páginaWPS FormatAbdullah AnsariAinda não há avaliações

- WPS - PQR As Per IsDocumento3 páginasWPS - PQR As Per IsNiladri Sekhar Maiti50% (4)

- Welding Procedure Specification-1Documento8 páginasWelding Procedure Specification-1Suresh Rathod100% (1)

- Weld Joint 1Documento81 páginasWeld Joint 1rajibali27100% (1)

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesAinda não há avaliações

- The Essentials of Material Science and Technology for EngineersNo EverandThe Essentials of Material Science and Technology for EngineersNota: 5 de 5 estrelas5/5 (1)

- Welding Procedure Specification SampleDocumento2 páginasWelding Procedure Specification Sampleezdi2083% (23)

- Brittle Fracture in Steel StructuresNo EverandBrittle Fracture in Steel StructuresG.M. BoydAinda não há avaliações

- Ut Proceduregeneral 141118232235 Conversion Gate02Documento24 páginasUt Proceduregeneral 141118232235 Conversion Gate02Danem HalasAinda não há avaliações

- All-in-One Manual of Industrial Piping Practice and MaintenanceNo EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceNota: 5 de 5 estrelas5/5 (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsNo EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsAinda não há avaliações

- WPS 316 LDocumento4 páginasWPS 316 Llaz_k100% (2)

- PQR Group V-Asme (WI74)Documento7 páginasPQR Group V-Asme (WI74)Gusrizam DanelAinda não há avaliações

- Cajon-001 WPSDocumento2 páginasCajon-001 WPSDanem HalasAinda não há avaliações

- Which Process?: A Guide to the Selection of Welding and Related ProcessesNo EverandWhich Process?: A Guide to the Selection of Welding and Related ProcessesAinda não há avaliações

- Wps A53 Gtaw R00Documento2 páginasWps A53 Gtaw R00Richard PeriyanayagamAinda não há avaliações

- Wps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Documento5 páginasWps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Oscar Iván Duque DíazAinda não há avaliações

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsNo EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsNota: 4 de 5 estrelas4/5 (6)

- PQR Run SheetDocumento1 páginaPQR Run SheetsahadAinda não há avaliações

- WPS 204 NewDocumento6 páginasWPS 204 Newarockiyathass100% (1)

- P 91 - Welding WPSDocumento2 páginasP 91 - Welding WPSSuhailshah123475% (4)

- PWPS For Piping-API 1104Documento6 páginasPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- Office: Printout Sample - ASME WPSDocumento2 páginasOffice: Printout Sample - ASME WPSDanem HalasAinda não há avaliações

- Office: Printout Sample - ASME WPSDocumento2 páginasOffice: Printout Sample - ASME WPSDanem HalasAinda não há avaliações

- WPS - 007Documento11 páginasWPS - 007MAT-LIONAinda não há avaliações

- Ami-003 WPSDocumento2 páginasAmi-003 WPSBenjamin BrownAinda não há avaliações

- Wps Magi Tig ExempleDocumento6 páginasWps Magi Tig ExempleDanem HalasAinda não há avaliações

- Wps Magi Tig ExempleDocumento6 páginasWps Magi Tig ExempleDanem HalasAinda não há avaliações

- A 6 - A 6m - 02 QtytmdiDocumento63 páginasA 6 - A 6m - 02 QtytmdiDanem HalasAinda não há avaliações

- Design of Steel Structures: Materials, Connections, and ComponentsNo EverandDesign of Steel Structures: Materials, Connections, and ComponentsAinda não há avaliações

- 5092 P8 P1 SM 01Documento5 páginas5092 P8 P1 SM 01Danem HalasAinda não há avaliações

- WpsDocumento6 páginasWpsabhishek198327Ainda não há avaliações

- PQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0Documento12 páginasPQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0rodwellbAinda não há avaliações

- Wps Electrode WeldingDocumento2 páginasWps Electrode Weldingmysterious_westAinda não há avaliações

- AWS Groove Weld Test Prameters 1 PDFDocumento2 páginasAWS Groove Weld Test Prameters 1 PDFHoque AnamulAinda não há avaliações

- WPS-021, 09.07.07, Page-1Documento2 páginasWPS-021, 09.07.07, Page-1nidhinchandranvsAinda não há avaliações

- Presentasi Welding Prosedur Specification (WPS) Pre QualifiedDocumento8 páginasPresentasi Welding Prosedur Specification (WPS) Pre QualifiedDeri Agung WicaksonoAinda não há avaliações

- XXXXXXXXXXX XXXXXXXXXXX XXXXXXXXXXX Welding Procedure Specification WpsDocumento3 páginasXXXXXXXXXXX XXXXXXXXXXX XXXXXXXXXXX Welding Procedure Specification WpsManivannanMudhaliarAinda não há avaliações

- WPSDocumento3 páginasWPSDhanush NairAinda não há avaliações

- Form Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)Documento1 páginaForm Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)durandm10Ainda não há avaliações

- Codo Fierro Negro 90° 150LBS Mech 90 Certf. Ul-FmDocumento2 páginasCodo Fierro Negro 90° 150LBS Mech 90 Certf. Ul-FmEdgar YauriAinda não há avaliações

- Welding Procedure Specification TemplateDocumento2 páginasWelding Procedure Specification TemplateEngr AbdurRahmanAinda não há avaliações

- AWS WPQR WPS FormularioDocumento1 páginaAWS WPQR WPS FormularioAntonio RuscittoAinda não há avaliações

- Sample Forms AWS, ASME and APIDocumento14 páginasSample Forms AWS, ASME and APIaamirtec301Ainda não há avaliações

- 1035 03Documento2 páginas1035 03Anuj ShahiAinda não há avaliações

- Saep 1102Documento6 páginasSaep 1102Francis ReyesAinda não há avaliações

- A276A 276M.17 Norma Aceros Inoxidables Composicion PDFDocumento8 páginasA276A 276M.17 Norma Aceros Inoxidables Composicion PDFalucard375Ainda não há avaliações

- Wpsa-55-Sm-01 Rev.2 Job 4272Documento4 páginasWpsa-55-Sm-01 Rev.2 Job 4272ariestaAinda não há avaliações

- How to prepare Welding Procedures for Oil & Gas PipelinesNo EverandHow to prepare Welding Procedures for Oil & Gas PipelinesNota: 5 de 5 estrelas5/5 (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingNo EverandSpot Welding Interview Success: An Introduction to Spot WeldingAinda não há avaliações

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationAinda não há avaliações

- TWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDocumento26 páginasTWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDanem HalasAinda não há avaliações

- Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocumento3 páginasCarbon Steel Girder Rails of Plain, Grooved, and Guard TypesDanem HalasAinda não há avaliações

- CV Ait KoufiDocumento3 páginasCV Ait KoufiDanem HalasAinda não há avaliações

- Part2 Notice 1Documento21 páginasPart2 Notice 1Danem Halas100% (1)

- 8a Codes and Q & CDocumento35 páginas8a Codes and Q & CDanem HalasAinda não há avaliações

- WLD 290 Submerged Arc WeldingDocumento52 páginasWLD 290 Submerged Arc WeldingDanem HalasAinda não há avaliações

- 5000 XXXX HY80 HSLA100D1.1Documento2 páginas5000 XXXX HY80 HSLA100D1.1Danem HalasAinda não há avaliações

- 154614Documento108 páginas154614Danem HalasAinda não há avaliações

- 03 23814 MvolaDocumento13 páginas03 23814 MvolaDanem HalasAinda não há avaliações