Escolar Documentos

Profissional Documentos

Cultura Documentos

Combustion Gas Turbine (Api 616-4Th) Data Sheet S I Units: Applicable To

Enviado por

tutuionutDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Combustion Gas Turbine (Api 616-4Th) Data Sheet S I Units: Applicable To

Enviado por

tutuionutDireitos autorais:

Formatos disponíveis

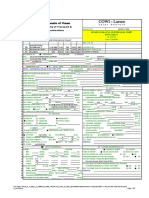

JOB NO.

ITEM NO.

PURCHASE ORDER NO.

SPECIFICATION NO.

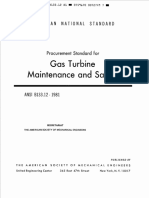

COMBUSTION GAS TURBINE (API 616-4TH)

DATA SHEET

S I UNITS

1 APPLICABLE TO:

2 FOR

PROPOSAL

REVISION NO.

PAGE

PURCHASE

OF

10

BY

AS BUILT

UNIT

3 SITE

SERIAL NUMBER

4 SERVICE

5

NUMBER REQUIRED

CONTINUOUS

INTERMITTENT

6 MANUFACTURER

STANDBY

9 CYCLE:

DRIVEN EQUIPMENT

MODEL

ISO RATING (3.17)

7 NOTE: INFORMATION TO BE COMPLETED:

8

REGEN

BY PURCHASER

EXHAUST HEAT RECOVERY TYPE:

@

11 OUTPUT SHAFT SPEED RANGE (4.1.5)

MIN

kW @

ATTENDED

MULTI SHAFT

RATED SHAFT kW

POTENTIAL MAXIMUM POWER (3.33)

kW

PERFORMANCE

LOCATION (4.1.19)

15 GAS TURBINE INCLUDING ALL LOSSES

INDOOR

OUTDOOR

GRADE

16

SITE

NORMAL

SITE

SITE

HEATED

UNDER ROOF

17

RATED

DUTY

MAX

MIN

UNHEATED

PARTIAL SIDES

18

(3.45)

(3.26)

TEMP

TEMP

DRY BULB TEMP, C

20

RELATIVE HUMIDITY %

APPLICABLE CODE:

21

BAROMETER, kPa

CLASS:

22

OUTPUT,kW (1)

AREA CLASSIFICATION

23

HEAT RATE,LHV,

NON-HAZARDOUS

HAZARDOUS

NEC 500

GROUP:

MJ/kW-HR

IEC

DIVISION

ZONE

WINTERIZATION REQD

OUTPUT SHAFT SPEED, RPM

26

AIR FLOW kg/SEC

27

EXHAUST FLOW kg/SEC (1)

28

FIRING TEMPERATURE, C

29

GAS GEN. EXHAUST TEMP., C

30

PT EXHAUST TEMP., C

31

CERTIFIED POINT (3.26)

32 (1) INCLUDING

TROPICALIZATION REQD (5.4.6.6)

UNUSUAL CONDITIONS:

EMISSION CONTROL

STEAM FLOW, kg/HR

35

WATER FLOW, m /HR

DUST

FUMES

CORROSIVE AGENTS (4.10.1.1)

OTHER (5.5.3.4)

NOISE SPECIFICATIONS: (4.1.10)

STEAM

34

APPLICABLE TO MACHINE: (5.7.4.1)

WATER EFFECTS FOR

SEE SPECIFICATION

AUGMENTATION (4.1.9)

APPLICABLE TO NEIGHBORHOOD: (5.7.4.2)

SEE SPECIFICATION

36

PAINTING:

37 APPLICABLE SPECIFICATIONS:

MANUFACTURER'S STANDARD

38

API 616 GAS TURBINES FOR THE PETROLEUM, CHEMICAL,

OTHER

39

& GAS INDUSTRY SERVICES

40

GOVERNING SPECIFICATION (IF DIFFERENT)

NOTE:

VENDOR HAVING UNIT RESPONSIBILITY (4.1.2)

REMARKS:

41

42

NEC 505

TEMPERATURE CODE:

THIRD PARTY CERTIFICATION REQUIRED

25

33

MEZZANINE

ELECTRICAL AREA CLASSIFICATION(4.1.14)

19

24

RPM

RPM

UNATTENDED

14

RPM

BY MFR IF NOT BY PURCHASER

SINGLE SHAFT

RPM

MAX

DESIRED MINIMUM SITE POWER

13 OPERATION

kW @

BY MANUFACTURER

GENERAL

SIMPLE

10 DRIVEN EQUIPMENT: NORMAL SHAFT, kW

12

DATE

All Data Sheets References to GG=Gas Generator,

SS = Single Shaft, and PT = Power Turbine

43

44 SHIPMENT: (6.4)

45

DOMESTIC

46

OUTDOOR STORAGE MORE THAN 6 MONTHS (6.4.1)

EXPORT

EXPORT BOXING REQUIRED

47 SPARE ROTOR ASSEMBLY PACKAGED FOR (6.4.3.10)

48

DOMESTIC

EXPORT

SHIPMENT

49 COMMENTS:

50

319678788.xlsx, API616_1

Page 1 of 10, Date Printed: 05/30/2016

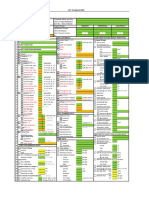

JOB NO.

COMBUSTION GAS TURBINE (API 616-4TH)

DATA SHEET

S I UNITS

PAGE

DATE

2

OF

10

BY

FUEL SYSTEM (5.8)

1

2 TYPE

GAS (5.8.2)

LIQUID (5.8.3)

DUAL (5.8.1.5.1)

3 DUAL SYSTEM REQMTS (5.8.1.5.1)

4

ITEM NO.

REVISION

GAS/GAS

COMPLETE FUEL RECEIVING SYSTEM (5.8.1.1)

GAS/LIQUID

LIQUID/LIQUID

MAXIMUM TIME ALLOWED TO COMPLETE TRANSFER

SECONDS

5

6

GAS FUELS (5.8.2)

LIQUID FUELS (5.8.3)

FUEL GRADE (5.8.3.3)

8

9

ASTM D1655

FUEL ANALYSIS - MOL % (5.8.2.1)

10 COMPOSITION:

M.W.

JET

NORMAL

STARTING

ALT

A-1

ASTM

0GT

1GT

D2880

2GT

3GT

11 AIR

29

LIQUID FUEL TREATMENT REQUIRED

YES

12 OXYGEN

32

TREATMENT SYSTEM BY

VENDOR

13 NITROGEN

38

FUEL TRANSFER EQUIP REQUIRED (5.8.1.4.5)

14 WATER VAPOR

18

HEATER REQUIRED (5.8.1.4.4)

15 CARBON MONOXIDE

28

16 CARBON DIOXIDE

44

17 HYDROGEN

NO

OTHER

YES

YES

NO

ASTM

METHOD

FUEL ANALYSIS DATA (5.8.3.3)

PROPERTY

18 METHANE

16

VISCOSITY, SSU @ 38C

D-445

19 ETHYLENE

26

DISTILLATION DATA

D-86

20 ETHANE

30

21 PROPYLENE

42

22 PROPANE

44

23 I-BUTANE

58

BOMB METHOD

D-129

24 A-BUTANE

58

LAMP METHOD

D-1266

25 I-PENTANE

72

HIGH-TEMP METHOD

D-1552

26 A-PENTANE

72

END POINT, C MAX

SULFUR CONTENT %WEIGHT, MAX. (SELECT APPL. METHOD)

CARBON RESIDUE (ON 10%

BOTTOMS)

28

CONRADSON

D-189

29 TOTAL

RAMSBOTTOM

D-524

30 AVG. MOL. WT.

% WT. MAX.

COPPER STRIP CORROSION PLATE

32 CONTMNTS (5.8.2.2.1)

PPM

D-130

3 HOURS AT 100C MAXIMUM

AROMATIC CONTENT

D-1319

33 LHV MJ/m3/HR (5.8.2.4)

ASH CONTENT

D-482

34 FUEL PRESS.MAX/MIN, kPag

SPECIFIC GRAVITY, 15C

D-1298

35 FUEL TEMPERATURE MAX/MIN, C

FLASH POINT, C

D-56

36

FUEL PRESSURE REQUIRED

POUR POINT, C

D-97

37

MAXIMUM/MINIMUM, kPag

WATER

D-95

D-2276

38 COMPRESSION SYS REQD (5.8.1.2.2)

YES

NO

FILTERABLE DIRT, MG/100ML

39 HEATER REQD (5.8.2.1)

YES

NO

TRACE METALS (ATOMIC

40

MEASURED

VALUE

50% RECOVERY, C MAX

27 HEXANE PLUS

PPM

NO

LIQUID FUEL PRESS REQUIRED, MAX/MIN, kPag

31 CORS AGNTS (5.8.2.3)

4GT

OTHER, INDICATE ANALYSIS BELOW (5.8.3.3 c)

RATE OF CHANGE OF LHV (5.8.2.4)

ABSORPTION PREFERRED)

41

SODIUM

42 REMARKS:

POTASSIUM

43

VANADIUM

44

CALCIUM

45

LEAD

46

D-3605

OTHER METALS

47

48

48

LOWER HEATING VALUE, MJ/kg

FUEL SYSTEM PIPING

49

BY PASS AND VENT VALVE (3.7.1.3)

ISOLATION BLOCK VALVES

50

TWIN Y-TYPE STRAINER WITH CONTINUOUS FLOW

NACE MATERIAL STANDARDS (4.10.1.8)

51

52

TRANSFER VALVE (5.8.1.2.4)

319678788.xlsx, API616_1

D-2382

ANSI FLANGE RATING

Page 2 of 10, Date Printed: 05/30/2016

JOB NO.

COMBUSTION GAS TURBINE (API 616-4TH)

DATA SHEET

S I UNITS

1

ITEM NO.

REVISION

DATE

PAGE

SPEEDS:

MAX. CONT.

LATERAL CRITICAL SPEEDS (DAMPED)

FIRST CRITICAL

RPM

MODE

SECOND CRITICAL

RPM

MODE

THIRD CRITICAL

RPM

MODE

TURBINE

STAGE

FOURTH CRITICAL

RPM

MODE

PROTOTYPE OR MODIFIED ROTOR SUPPORT (4.7.3.5)

10

TRAIN LATERAL ANALYSIS REQUIRED (D.1.3)

11

TRAIN TORSIONAL ANALYSIS REQUIRED (2.7.4.5)

12

TORSIONAL CRITICAL SPEEDS:

13

FIRST CRITICAL

RPM

14

SECOND CRITICAL

RPM

15

THIRD CRITICAL

RPM

16

FOURTH CRITICAL

BY

MATERIALS OF CONSTRUCTION (4.10)

RPM

RPM TRIP

RPM

COMPRESSOR ROTOR BLADES

COMPRESSOR STATOR VANES

SHAFT

BLADE/VANE COATING

NOZZLES

WHEELS OR

DISCS

BLADES

COMBUSTORS

17 VIBRATION: (4.7.4.5) (7.2.3 o):

COMPRESSOR CASING

ALLOWABLE TEST LEVEL: SHAFT

19

20

10

CONSTRUCTION FEATURES (NOTE 1)

18

OF

CASE

ROTATION, VIEWED FROM DRIVE END

MICRONS P/P

COMBUSTOR CASING

mm/SEC

TURBINE CASING

CW

CCW

GAUGE BOARDS AND CONTROL PANELS

21 AIR COMPRESSOR:

22

STAGES

MAXIMUM TIP SPEED

23

TYPE

PRESSURE RATIO

24

CASING SPLIT (2.2.3)

25

ROTOR

m/SEC

GAUGE BOARDS

LOCATION

AXIAL

SOLID

RADIAL

CONTROL CONSOLES (5.4.5.1.1)

ON-SKID

BUILT UP

26 TURBINE:

WEATHER PROTECTION REQUIRED

27

STAGES

28

CASING SPLIT (4.2.3)

29

ROTOR

MAX. TIP SPEED

m/SEC

AXIAL

SOLID

OFF SKID LOCAL

OFF SKID REMOTE

RADIAL

YES

NO

SPECIFICATION

ANNUNCIATOR REQUIRED (5.4.4.8.5)

BUILT UP

VISUAL DISPLAY UNIT (VDU)

KEYBOARD

30 COMBUSTORS: (4.3.2)

31

SINGLE

MULTIPLE, NUMBER

32

GAS

LIQUID

33

MAXIMUM ALLOWABLE TEMP. VARIATION

34

APPLICABLE PLANE

35

FUEL NOZZLES PER COMBUSTOR

36

WOBBE INDEX NO REQD (4.3.7)

DUAL FUEL

C

CONTROL SYSTEMS

TYPE (5.4.1.5)

MECH

MAX

MIN

PNEU

HYDRA

ELECTRIC

MICROPROCESSOR BASED

37 MAINTENANCE INTERVALS, HOURS

SIGNAL SOURCE

38

HOT GAS PATH INSPECTIONS

SENSITIVITY

39

MAJOR OVERHAULS

TIME OF AC OUTAGE PROTECTION

40

OTHER

SHUT OFF VALVES FOR SHUT DOWN SENSORS (5.4.4.9)

41

GOVERNOR (5.4.3)

MFR'S STD.

OTHER

MANUAL

MAKE

MODEL

44

CONSTANT SPEED

VARIABLE SPEED

45

ISOCHRONOUS

DROOP

46 REMOTE SHUTDOWN SIGNAL

47

RANGE

TO

MIN (5.4.1.6)

STARTING SYSTEM (5.4.2.1)

42

43

ELECTRONIC

COMBINED

PNEUMATIC

48 MANUAL SPEED CHANGER, RPM

MINUTES

NOTE (1) FOR MULTIPLE SHAFT TURBINES, COMPLETE ALL APPLICABLE

PORTIONS FOR EACH SHAFT.

NONE

MAX.

49

MAINTAIN TURBINE SPEED UPON FAILURE OF CONTROL

50

SIGNAL OR ACTUATOR

319678788.xlsx, API616_1

AUTOMATIC

SEPARATE SHUTDOWN VALVE TEST DURING OPERATION

ELECTRIC

HYDRAULIC

SEMI AUTOMATIC

PURGE (5.4.2.2)

REMARKS:

MIN.

Page 3 of 10, Date Printed: 05/30/2016

JOB NO.

COMBUSTION GAS TURBINE (API 616-4TH)

DATA SHEET

S I UNITS

1

ITEM NO.

REVISION

PAGE

DATE

4

OF

10

BY

CONSTRUCTION FEATURES CONTINUED (NOTE 1)

BEARINGS AND BEARING HOUSINGS (4.8)

3 RADIAL (NOTES 2 AND 3)

INLET

EXHAUST

THRUST (NOTE 3)

ACTIVE

TYPE

TYPE

MANUFACTURER

MANUFACTURER

LENGTH, mm

UNIT LOAD (ULTIMATE), kPa

SHAFT DIAMETER, mm

UNIT LOAD (SITE RATED), kPa

UNIT LOAD (ACT/ALLOW), kPa

UNIT LOAD (MAX POTEN.), kPa

BASE MATERIAL

NO. OF PADS/AREA, (cm2)

10

BABBITT THICKNESS, mm

BASE MATERIAL

11

NO. PADS

BABBITT THICKNESS, mm

12

LOAD: BETWEEN/ON PAD

13

PIVOT: CENTER/OFFSET, %

LUBRICATION:

FLOODED

DIRECTED

14

DAMPER BEARING

THRUST COLLAR:

INTEGRAL

REPLACEABLE

PIVOT: CENTER/OFFSET, %

15

BEARING MATERIAL

16 BEARING TEMPERATURE DEVICES

17 (4.8.5.5)

18

SEE ATTACHED API-670

DATA SHEET

RADIAL VIBRATION DETECTORS:

TYPE

SELECTOR SWITCH & IND. BY:

PURCH

MFR

NO. AT EACH SHAFT BEARING

RESISTANCE MATERIAL

22

MODEL

MFR

RESISTANCE TEMPERATURE DETECTORS

21

SEE ATTACHED API-670

DATA SHEET

VIBRATION DETECTORS (4.8.5.3)

THERMOCOUPLES

19

20

OHMS

SELECTOR SWITCH & IND. BY:

PURCH

TOTAL NO.

OSCILLATOR-DEMODULATOR SUPPLIED BY

MFR

MFR

MODEL

23

LOCATION-JOURNAL BEARING

24

NUMBER

25

OTHER

MFR

26

LOCATION-THRUST BEARING

SCALE RGE

27

NO. (ACT)

28

OTHER

29

NO.(INACT)

30

OTHER

TYPE

MODEL

31

MONITOR SUPPLIED BY (5.4.7.5)

MFR

NO. REQUIRED

EA PD

EA PD

EA PD

LOCATION

33

MFR

34

SCALE RANGE

35

MONITOR SUPPLIED BY (5.4.7.8.2)

EVERY OTH PAD

PER BRG

EVERY OTH PAD

LOCATION

PER BRG

SHUTDOWN

ENCLOSURE

MODEL

ALARM SET @

SET @

MICRONS

MICRONS

TIME DLY

SEC

AXIAL POSITION DETECTOR (4.8.5.3):

32

36

INACTIVE

EVERY OTH PAD

PER BRG

SEE ATTACHED API-670 DATA SHEETS

ENCLOSURE

OSCILLATOR-DEMODULATOR SUPPLIED BY

MODEL

SHTDWN

SET @

REMARKS:

MFR

ALARM SET @

SEC

TIME DLY

MODEL

MONITOR SUPPLIED BY (3.4.7.8.2)

LOCATION

ENCLOSURE

MFR

37

SCALE RGE

38

SHTDWN

39

MODEL

ALARM SET @

SET @

MICRONS

MICRONS

TIME DLY

SEC

ACCELERATION TRANSDUCERS

40

SEE ATTACHED API-670 DATA SHEETS

41

MFR

MODEL

42

LOCATION

NUMBER

43

MONITOR SUPPLIED BY (3.4.7.8.4)

44

LOCATION

45

MFR

46

SCALE RGE

47

SHTDWN

ENCLOSURE

MODEL

SET @

48 NOTES:

(1)

FOR MULTIPLE SHAFT TURBINES, COMPLETE ALL APPLICABLE PORTIONS FOR EACH SHAFT.

49

(2)

FOR THREE BEARING SHAFTS, USE A SEPARATE SHEET FOR THE EXTRA BEARING.

50

(3)

FOR ROLLING ELEMENT BEARINGS, MODIFY ENTRIES AS REQUIRED. SHOW L-10 BEARING LIFE.

319678788.xlsx, API616_1

ALARM SET @

SEC

TIME DELAY

Page 4 of 10, Date Printed: 05/30/2016

JOB NO.

COMBUSTION GAS TURBINE (API 616-4TH)

DATA SHEET

S I UNITS

1

ITEM NO.

REVISION

PAGE

DATE

5

OF

10

BY

UTILITIES: CONNECTIONS

UTILITY CONDITIONS:

STEAM:

INLET MIN

TOTAL UTILITY CONSUMPTION:

AUXILIARY DRIVERS

HEATING

COOLING WATER

kPag

kPag

STEAM LEVEL

NORM

kPag

kPag

STEAM, NORMAL

MAX

kPag

kPag

STEAM, MAX

m3/HR

kPag

kPag

kPag

kg/HR

kg/HR

EXHST MIN.

kPag

kPag

INSTRUMENT AIR

NORM

kPag

kPag

MOTORS (AUXILIARIES)

kW

MAX

kPag

kPag

BATTERY CHARGERS

kW

HEATERS

PURGE (AIR OR N2)

10

11

STARTING

INLET MIN

INJECTION

kPag

kPag

Nm3/HR

kW

Nm3/HR

12

NORM

kPag

kPag

C TURBINE AIR EXTRACTION REQUIRED: (4.1.22)

13

MAX

kPag

kPag

NM3/HR

kPag

14

EXHST MIN.

kPag

MAXIMUM PRESSURE AVAILABLE AT MINIMUM SPEED:

kPag

15

NORM

kPag

MINIMUM SPEED:

RPM

16

MAX

kPag

DISCHARGE TEMPERATURE:

17

PILOT LIGHT INDICATORS

ELECTRICITY: (5.4.6.1)

18

MOTORS

HEATING

CONTROL

SHUTDOWN

19

VOLTAGE

20

HERTZ

21

PHASE

22

COOLING WATER:

23

INLET TEMPERATURE

24

DESIGN TEMPERATURE

25

NORM PRESS

kPag MIN RETURN

kPag

26

DESIGN PRESS

kPag MAX ALLOW P

kPa

27

WATER SOURCE

28

INSTRUMENT AIR PRESSURE DESIGN, kPag

29

MAX

COMPRESSOR EXTRACTION STAGE NUMBER:

MAX RETURN

REMARKS:

NORMAL

MIN

30 REMARKS:

31

32

33

34

35

36

37

38

PURCHASER CONNECTIONS

39

40

41

DESIGN

CONNECTION

APPROVAL

42

REQUIRED

43

(4.10.4.6.4)

FACING

SIZE

FLANGED

MATING FLG

GAS

and

POSITION

OR

& GASKET

VELOCITY

RATING

(4.4.1)

STUDDED

BY VENDOR

M/SEC

(4.4.1)

(4.4.5.4)

44 INLET

45 EXHAUST

46 FUEL SUPPLY

47 STEAM

48 WATER

49

50

51

52

319678788.xlsx, API616_1

Page 5 of 10, Date Printed: 05/30/2016

COMBUSTION GAS TURBINE (API 616-4TH)

DATA SHEET

S I UNITS

1

JOB NO.

ITEM NO.

REVISION

DATE

PAGE

OF

BY

INSTRUMENTS

TRANS-

CONTROL

MITTERS

ROOM

TYPE

LOCATION

FURNISHED

RECEIVERS

BY

FURN BY

VENDOR

ROOM

CONTROL

LOCAL PANEL

LOCAL

INDICATING

RECORDING

DESCRIPTION

5

6

.. 7

..8

..

9

10

OTHERS

INSTRUMENT

VENDOR

INSTRUMENT

OTHERS

11 GAS GENERATOR OR SINGLE SHAFT GAS TURBINE

12

TACHOMETER(S) (NO.

13

P AIR INLET SYSTEM

14

COMPRESSOR DISCHARGE PRESSURE

15

FUEL FILTER P

16

FUEL SUPPLY PRESSURE

17

STARTING GAS SUPPLY PRESSURE

18

STARTING GAS EXHAUST PRESSURE

19

TEMP COMBUSTOR MEASUREMENT (6 PTS MIN) (4.3.2)

20

TEMP GAS TURB CONTROL PLANE (6 PTS MIN)

21

INLET AIR TEMPERATURE

22

TEMPERATURE, GG COMPRESSOR DISCHARGE

23

TEMPERATURE, THRUST BEARING OIL DRAIN

24

TEMPERATURE, EACH BEARING SUMP (ROLLING ELEMENT TYPE)

25

TEMPERATURE, FUEL MANIFOLD

26

TEMPERATURE, LUBE OIL RESERVOIR

27

FIRED HOUR METER

28

29

A) NUMBER STARTS COUNTER

B) START SEQUENCE TIMER

30

LUBE OIL RESERVOIR LEVEL

31

LUBE OIL PUMP PRESSURE INDICATORS (NO

32

LUBE OIL COOLER OIL INLET TEMPERATURE

33

LUBE OIL COOLER OIL OUTLET TEMPERATURE

34

LUBE OIL COOLER COOLANT INLET TEMPERATURE

35

LUBE OIL COOLER COOLANT OUTLET TEMPERATURE

36

LUBE OIL FILTER P

37

LUBE OIL PRESSURE EACH LEVEL

(NO.

38

CONTROL OIL PRESSURE

39

SITE FLOW INDICATOR EACH DRAIN (NO.

40

INLET GUIDE VANE POSITION INDICATOR

41

EXHAUST DUCT DIFFERENTIAL PRESSURE INDICATOR

42

ENCLOSURE COOLING AIR EXHAUST TEMPERATURE

43 POWER TURBINE

44

TACHOMETER(S)

45

EXHAUST TEMPRTATURE (2 PTS MIN)

46

JOURNAL BEARING TEMPERATURE

47

THRUST BEARING TEMPERATURE

48

BEARING DRAIN TEMPERATURE

49

SITE FLOW INDICATOR EACH DRAIN (NO.

50

LUBE OIL INLET PRESSURE

51

LUBE OIL INLET TEMPERATURE

319678788.xlsx

(NO.

Page 6 of 10, Date Printed: 05/30/2016

JOB NO.

COMBUSTION GAS TURBINE (API 616-4TH)

DATA SHEET

S I UNITS

1

ITEM NO.

REVISION

DATE

PAGE

OF

BY

ALARMS AND SHUTDOWNS (5.4.4)

TO:

..

4

(5.4.4.8.5)

ANNUNCIATOR POINT IN

VENDOR FURNISHED

CONTROL PANEL

SENSING DEVICES

TO BE FURNISHED

BY

DESCRIPTION

5

6

SINGLE

SEP

7

8

SHAFT

OR G.G.

PWR

TURB.

9 RADIAL SHAFT VIBRATION (NO.

(1)

ALARM

SHUTDOWN

VENDOR

OTHERS

(2)

10 AXIAL THRUST POSITION (NO.

11 OVERSPEED (1) (NO.

LIGHT ONLY

APPLIES

3

INDICATING

)

)

12 CASING VIBRATION (NO.

13 HIGH THRUST BEARING TEMPERATURE

14 HIGH RADIAL BEARING TEMPERATURE

15 LOW FUEL SUPPLY PRESSURE

16 HIGH FUEL FILTER P

17 GAS TURBINE TEMPERATURE SPREAD HIGH

18 EXHAUST OVER TEMPERATURE

19 FAILURE OF OVER-TEMPERATURE SHUTDOWN DEVICE

20 HIGH INLET AIR P EACH FILTER

21 COMBUSTOR FLAME-OUT (1)

22 CHIP DETECTOR, ANTI FRICTION BEARING

23 FAILURE STARTING CLUTCH TO ENGAGE OR DISENGAGE

24 LOW OIL PRESSURE (NO.

25 HIGH LUBE OIL TEMPERATURE

26 LOW LUBE OIL RESERVOIR LEVEL

27 HIGH LUBE OIL RESERVOIR LEVEL

28 HIGH OIL FILTER P (NO.

29 LUBE OIL SPARE PUMP OPERATING

30 LOW CONTROL OIL PRESSURE

31 LOW STARTING GAS PRESSURE

32 ANTI-ICING SYSTEM - NOT OPERATING

33 LOW D.C. VOLTAGE

34 EMERGENCY D.C. PUMP OPERATING

35 RESERVOIR HEATER "ON"

36 IMPLOSION DOOR OPEN

37 EXTERNAL PERMISSIVE START SIGNAL

38 EXTERNAL SHUTDOWN SIGNAL

39 LOSS OF AUXILIARY COOLING AIR

40 LAMP TEST PUSH BUTTON

41 ENCLOSURE HIGH TEMPERATURE

42 CONTROL SIGNAL FAILURE

43 CONTROL SYSTEM ACTUATOR FAILURE

44 GOVERNOR FAILURE

45 ENCLOSURE VENT FAN FAILURE

46

47

48

49 NOTES:

(1) VENDOR TO ADVISE METHOD OF ANNUNCIATION

50

(2) VDU MAY USE MESSAGE INDICATOR

319678788.xlsx

Page 7 of 10, Date Printed: 05/30/2016

JOB NO.

COMBUSTION GAS TURBINE (API 616-4TH)

DATA SHEET

S I UNITS

1

DATE

PAGE

OF

BY

ACCESSORIES SUPPLIED BY GAS TURBINE MANUFACTURER

2

3

ITEM NO.

REVISION

STARTING AND HELPER DRIVERS (5.1)

STARTER ONLY (5.1.1.2)

4 TYPE (5.1.1.1)

GEARS: SEE SEPARATE API 613 GEAR DATA SHEETS (5.2.1.1)

STARTER/HELPER (5.1.1.3)

MOTOR

DRIVEN EQUIPMENT, SEE SEPARATE API DATA SHEETS

STEAM TURBINE

FIRE PROTECTION EQUIPMENT (5.7.3.1)

GAS EXPANDER

IC ENGINE

HYDRAULIC

TYPE

GAS TURBINE

STARTER IS CLUTCHED (5.1.1.7)

HALON 1301

HELPER RATING (5.1.2.2)

kW

ULTRA VIOLET

NUMBER

STARTER RATING (5.1.2.1)

kW

INFRA RED

NUMBER

SHAFT TURNING DEVICE REQUIRED (5.1.3.1)

NUMBER OF DETECTORS

ADDITIONAL LEVELS (5.7.3.2)

10

MOTOR:

11

TYPE

RATING

12

MFR

MODEL

13

STEAM TURBINE (REFERENCE API DATA SHEETS)

14

MFR

15

KW

16

TOTAL/START

17

GAS EXPANDER

kW

MOUNTING PLATES (5.3)

TYPE (5.3.1.1)

SOLEPLATE

BASEPLATE

SHIM PACK THICKNESS

mm (5.3.1.2.9)

MODEL

MAX. STEAM FLOW

kg/HR

BASEPLATE (5.3.2)

kg

FURNISHED BY

VENDOR

GAS TURBINE ONLY

18 APPLICABLE SPEC. (5.1.1.6)

MFR

MODEL

20

kW

21

TOTAL/START

22

GAS FOR EXPANSION TURBINE:

kg/HR

ENCLOSURE REQUIRED

REQUIREMENTS (5.7.5.1):

MIN

MAX

NORMAL

ACOUSTICAL

24

INLET PRESSURE, kPa

WEATHERPROOF

25

EXHAUST PRESS, kPa

SAFETY

26

GAS TEMPERATURE, C INLET

FIREPROTECTION

27

GAS TEMPERATURE, C EXHAUST

28

MOLECULAR WEIGHT

29 SPEED CONTROL

ADDITIONAL VENTILATION (5.7.5.6.3)

COUPLINGS AND GUARDS (5.2.2)

GOVERNOR

PRESSURE REGULATOR

30

YES

NO

SEE ATTACHED API-671 DATA SHEETS

MANUFACTURER

TYPE

31

INLET CONTROL VALVE FURNISHED

MODEL

32

STAINLESS STEEL PIPING MANIFOLD

MAXIMUM OUTSIDE DIAMETER

33

CARBON STEEL FLANGES

HUB WEIGHT

34

Y-STRAINER W/BREAKOUT FLANGES

SPACER LENGTH

35

LOW SPEED CAPABILITY

IDLING ADAPTER REQUIRED

36

(FOR COMPRESSOR CLEANING)

37

RELIEF VALVE PRESSURE SET POINT

38

CASING MATERIAL

39

SEAL TYPE

GUARD SUPPLIED BY

mm

kg

mm

SPACER WEIGHT

kg

SOLO PLATE REQUIRED

GUARD SUPPLIED BY

kPag

TYPE:

FULLY ENCLOSED

SEMI-OPEN

OTHER

LUBRICATING REQUIREMENTS:

NON-LUBE

40

QUANTITY PER HUB

INTERNAL COMBUSTION ENGINE

42 TYPE

LEVELING PADS (5.3.2.3)

ENCLOSURES (5.7.5)

KG

23

DRIP RIM

COLUMN MOUNTING (5.3.2.4) (3-POINT)

MAX. GAS FLOW

(5.3.2.1)

(5.3.2.1)

EXTENDED FOR

SUB-SOLEPLATES REQUIRED (5.3.2.7)

19

41

CO2

HALON 1211

TYPE OF SENSOR

SPARK IGNITED

GREASE

CONT. OIL LUBE

kg or m3/HR

REMARKS:

DIESEL

43 APPLICABLE SPECIFICATION (5.1.1.6)

44

MANUFACTURER

45

SPEED

MODEL

RPM

POWER

kW

46

47

COMBUSTION GAS TURBINE

48 APPLICABLE SPECIFICATION (5.1.1.6)

49

MANUFACTURER

50

SPEED

319678788.xlsx

MODEL

RPM

POWER

kW

Page 8 of 10, Date Printed: 05/30/2016

JOB NO.

COMBUSTION GAS TURBINE (API 616-4TH)

DATA SHEET

S I UNITS

1

ITEM NO.

REVISION

PAGE

DATE

OF

BY

ACCESSORIES SUPPLIED BY GAS TURBINE MANUFACTURER

INLET SYSTEM

EXHAUST SYSTEM

AIR FILTER (5.5.4.1)

EXTENT OF FURNISHED INSULATION (SEE SKETCH) (5.7.1.2)

INERTIAL TYPE SEPARATOR

MEDIA FILTERS

(RELIEF) (DIVERSION) VALVE (5.5.6.8)

PAD TYPE PREFILTERS

COMBINATION

EXHAUST HEAT RECOVERY SYSTEM (5.5.3.1)

SELF CLEANING (PULSE TYPE)

SINGLE STAGE WITH PROVISION FOR

FUTURE EXTRA STAGES

NORMAL DUST LOADING

10

WIND DESIGN VELOCITY

11

SNOW LOAD

12

SEISMIC ZONE

13 LOCATION:

EMISSION CONTROL SYSTEM (5.5.3.1)

EXHAUST SILENCER PLATE ELEMENT MATERIAL (5.5.5.2.3

YES

NO

kg/Nm3/HR

km/HR

EMISSIONS SAMPLING SYSTEM (5.5.6.10)

EXPANSION JOINT MFR

kg/m

TYPE

DUCTING GAUGE/MATERIAL

GROUND LEVEL

ELEVATED (5.5.4.6)

FILTRATION EFFICIENCY

15

MAINTENANCE INTERVAL

MONTHS

16

CLEANING FREQUENCY

DAYS

17

IMPLOSION DOOR (5.5.4.5)

18

EVAPORATIVE COOLER (5.6.1.1)

19

LIQUID TO AIR EXCHANGER (5.6.2.2)

TYPE

20

WALKWAY, LADDERS, HANDRAILS REQUIRED (5.6.1.5)

SYSTEM SITE RATED PRESSURE DROP

21

COMPRESSOR CLEANING SYSTEM, TYPE

22

SILENCER PLATE ELEMENT MAT'L (5.5.5.1.4)

23

FILTER MFR.

% (5.5.4.3)

ANTI-ICING (5.5.3.10)

COOLER MFR.

27

EXCHANGER MFR (5.6.2.3)

DUCTING GAUGE / MATERIAL

30

EXPANSION JOINT MFR

SILENCER MFR

MANOMETER MFR

kg/HR

MODEL

TEMP

RANGE

C

mm H2O

ATMOSPHERIC RELIEF DEVICE (5.5.6.8)

MFR

LOCATION

mm H2O

NOx REQUIREMENTS (5.5.3.1.1)

mm H2O

mm H2O

mm H2O

NOx EMITTED

EMISSIONS REDUCTION METHOD (IF REQUIRED)(5.8.4.2)

WATER INJECTION (5.8.4.4)

SCR

STEAM (5.8.4.4)

DRY COMBUSTOR

SOx REQUIREMENTS

TYPE

P

mm H2O

SULFUR CONTENT OF FUEL

SOx EMITTED (BASED ON STATED SULFUR CONTENT)

MODEL

mm H2O

RANGE

34

SYSTEM SITE RATED PRESSURE DROP

36

kPag

RATE

OTHER

33

35

PRESS

EMISSION SUPPRESSION SYSTEM REQUIRED (5.8.4.1)

ALARM

29

32

mm H2O

ATMOSPHERIC EMISSIONS

MODEL

MODEL

31

(5.5.3.9)

mm H2O

mm H2O

26

TYPE

MANOMETER MFR

@ 110% RATED AIR FLOW P

CLEAN

MFR

STEAM GEN:

MODEL

25

28

mm H2O

HEAT RECOVERY DEVICE

14

24

SILENCER MFR

@ 110% RATED AIR FLOW

mm H2O

CO REQUIREMENTS

CO EMITTED

REMARKS:

PARTICULATE REQUIREMENTS

37

PARTICULATE EMITTED

38

UNBURNED HC REQUIREMENTS

39

UNBURNED HC EMITTED

40

APPLICABLE EMISSION CODES OR REGULATIONS

41

EPA - TITLE 40 - CFR

OTHERS

42

43

44

SPECIALIZED INSTRUMENTS

45 TACHOMETERS: (5.4.7.2.2)

SWITCHES: (5.4.4.8.2)

46 TYPE

ELECTRICAL

ELECTRONIC

47

ANALOG

DIGITAL

48

MANUFACTURER

49

OIL FILLED PRESSURE GAUGES (5.4.7.6)

50

319678788.xlsx

CIRCUIT SHALL

ENERGIZE

DEENERGIZE

TO ALARM

ENERGIZE

DEENERGIZE

TO SHUTDOWN

ENCLOSURES

EXPLOSION PROOF

WEATHER PROOF

Page 9 of 10, Date Printed: 05/30/2016

JOB NO.

COMBUSTION GAS TURBINE (API 616-4TH)

DATA SHEET

S I UNITS

1

ITEM NO.

REVISION

DATE

PAGE

OF

BY

INSPECTION AND TESTING; LUBRICATION, WEIGHTS

2 SHOP INSPECTION AND TESTS: (6.1.1)

REQ

WITOBSERNESSED

VED

4 SHOP INSPECTION (6.1.2)

LUBRICATION SYSTEMS (4.9)

SEE API 614 DATA SHEETS

LUBE OIL VISCOSITY (4.9.8) ISO GRADE

5 CLEANLINESS (6.2.3.3)

COMMON TO

GAS GENERATOR/SINGLE SHAFT TURBINE

6 HYDROSTATIC (6.3.2)

FREE POWER TURBINE

LOAD GEAR

7 MECHANICAL RUN (6.3.3)

DRIVEN EQUIPMENT

AUXILIARIES

8

9

10

11

CONTRACT

COUPLING

IDLING

ADAPTOR(S)

CONTRACT

PROBES

SHOP

PROBES

(COMBINED) (SEPARATE) LUBE/SEAL SYSTEM (4.9.5)

SYSTEM DESIGNED FOR SYNTHETIC LUBRICANT (4.9.2)

LUBE SPECIFICATION

COMMON TO

12 VIBRATION PLOTS(6.3.3.3.4)

LOAD GEAR

13 TAPE RECORD VIB DATA (6.3.3.3.6)

AUXILIARIES

GAS GENERATOR

POWER TURBINE

DRIVEN EQUIPMENT

14 PERFORMANCE TEST (6.3.4.1)

15 COMPLETE UNIT TEST (6.3.4.2)

16 PACKAGE TEST(6.3.4.2.1)

OIL REQUIREMENTS

17 LOAD GEAR TEST (6.3.4.3)

GG OR SS TURBINE

18 SOUND LEVEL TEST (6.3.4.4)

DRIVEN EQUIPMENT

19 AUXILIARY EQUIPMENT (6.3.4.5)

GEAR

20 POST TEST INSPECTION (6.3.4.6)

COUPLINGS

21 HYDRAULIC COUPLING INSP (6.3.4.7)

POWER TURBINE

22 GOVERNOR RESPONSE TEST (6.3.4.8)

FLOW

m3/HR

PRESSURE

kPag

HEAT LOAD

MJ/HR

TOTAL

23 SPARE PARTS (6.3.4.9)

24 FIRE PROTECTION (6.3.4.10)

25 OTHER (6.3.4.11)

MOUNTING ARRANGEMENT

CONSOLE

COLUMN

BASEPLATE

26

27 MATERIALS INSPECTION REQUIREMENTS (6.2.1.3)

28

WEIGHTS

SPECIAL CHARPY TESTING (4.10.5.3)

29

RADIOGRAPHY REQUIRED FOR

30

MAGNETIC PARTICLE REQUIRED FOR

GG OR SS TURBINE

31

LIQUID PENETRANT REQUIRED FOR

SS TURB. ROTOR

32

ULTRASONIC REQUIRED FOR

POWER TURBINE

33

WELD INSPECTION (4.10.4.6.1)

P.T. ROTOR

34

WELDING HARDNESS TESTING (6.2.3.4)

LUBE SYSTEM

35

DRY

INSTALLED

SHIPPING

WT. (kg)

WT. (kg)

DIMEN

LxWxH (m)

DRIVEN EQUIPMENT

36 MISCELLANEOUS:

FILTER

37

VENDOR'S REVIEW & COMMENTS ON PURCHASER'S

INLET SILENCER

38

PIPING & FOUNDATION (4.1.18)

EXHAUST SILENCER

39

FINAL ASSEMBLY CLEARANCES (6.2.1.1 e)

DUCTING

40

COORDINATION MEETING SITE (7.1.3)

41

SPEED-TORQUE CURVE (7.2.4-a)

42

INCREASE POWER FOR STEAM/WATER (7.2.4 b)

43

EFFECTS OF AMB. COND. ON EXHAUST FLOW (7.2.4 c)

44

RUN DOWN CURVES (7.2.4 d)

45

PURCHASER REVIEW OF CAMP./GOODMAN DIAG. (4.5.3.3)

46

VENDOR WITNESS ALIGNMENT (4.1.18)

47

TECHNICAL DATA MANUAL (7.3.6.4)

48

NUMBER OF PROPOSAL COPIES (7.2.1)

MAX ERECTION

WEIGHT (kg)

ITEM

MAX MAINTENANCE

WEIGHT (kg)

ITEM

REMARKS:

49

50

319678788.xlsx

Page 10 of 10, Date Printed: 05/30/2016

Você também pode gostar

- API STD 2000-7th Ed-March 2014 Venting Atmospheric and Low-Pressure Storage TanksDocumento3 páginasAPI STD 2000-7th Ed-March 2014 Venting Atmospheric and Low-Pressure Storage TanksOscar J MirandaAinda não há avaliações

- API 611, General-Purpose Steam TurbinesDocumento6 páginasAPI 611, General-Purpose Steam TurbinesMReza100% (1)

- Api 618 4th Ed Si DatasheetsDocumento17 páginasApi 618 4th Ed Si Datasheetshmshawki100% (5)

- Tpe 331Documento424 páginasTpe 331Lucio Menga75% (12)

- API 674 Pump Data SheetDocumento5 páginasAPI 674 Pump Data SheetEason Ng100% (2)

- API 692 Seal Gas Filters & SeparatorsDocumento4 páginasAPI 692 Seal Gas Filters & SeparatorsTasawwur Tahir100% (1)

- Rotary Compressor API 619Documento26 páginasRotary Compressor API 619EDUARDO25% (4)

- SCR Mean - Metal - Temps For Heat Exchanger TubeDocumento2 páginasSCR Mean - Metal - Temps For Heat Exchanger TubescranderiAinda não há avaliações

- D6M Test Hydraulic SystemDocumento21 páginasD6M Test Hydraulic SystemTeresa Marina Peralta100% (4)

- Error Codes XMDocumento14 páginasError Codes XMnilomell100% (1)

- API 675 Data Sheet SIDocumento2 páginasAPI 675 Data Sheet SIhappale2002100% (3)

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Documento17 páginasReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutAinda não há avaliações

- API 541 DatasheetDocumento7 páginasAPI 541 Datasheetjavier716730% (1)

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Documento9 páginasCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)tutuionutAinda não há avaliações

- Heat Exchanger Data SheetDocumento21 páginasHeat Exchanger Data SheetSajad Abdul100% (2)

- Pump Data SheetDocumento6 páginasPump Data Sheeta_s_a_dAinda não há avaliações

- Boiler Data SheetDocumento10 páginasBoiler Data Sheetameya natu100% (2)

- A.3 Sequence of Operation Fuel SystemDocumento9 páginasA.3 Sequence of Operation Fuel SystemPLC Swa100% (2)

- API 673 3rd Ed Data SheetsDocumento27 páginasAPI 673 3rd Ed Data Sheetsjuan ninaAinda não há avaliações

- Asme PTC 10 (1997)Documento191 páginasAsme PTC 10 (1997)Luigi RondonAinda não há avaliações

- Air Eliminator Datasheet PDFDocumento2 páginasAir Eliminator Datasheet PDFbecpavanAinda não há avaliações

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Documento3 páginasData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisAinda não há avaliações

- Api 619 SiDocumento9 páginasApi 619 SitutuionutAinda não há avaliações

- Api 673 SiDocumento11 páginasApi 673 Situtuionut100% (1)

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Documento9 páginasCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)tutuionutAinda não há avaliações

- TA30T3 A8941011 To A8941753Documento528 páginasTA30T3 A8941011 To A8941753Khaled Naseem Abu-Sabha100% (5)

- U140eand U241Documento25 páginasU140eand U241yosergey80% (5)

- Whirlpool Awm 6080Documento17 páginasWhirlpool Awm 6080pansatuilieAinda não há avaliações

- Reciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitsDocumento17 páginasReciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitstutuionutAinda não há avaliações

- Data SheetDocumento6 páginasData Sheetmkfe2005Ainda não há avaliações

- API 610 11th Ed DatasheetDocumento13 páginasAPI 610 11th Ed DatasheetHatem ShawkiAinda não há avaliações

- Native Data Sheet Asme b73.1Documento4 páginasNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- Pages From 05-01269 Regeneration API-617-datasheet-rev11 PDFDocumento1 páginaPages From 05-01269 Regeneration API-617-datasheet-rev11 PDFalikajbafAinda não há avaliações

- Nioec SP 00 89 (R0) (Ed1)Documento8 páginasNioec SP 00 89 (R0) (Ed1)aminAinda não há avaliações

- SA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02Documento5 páginasSA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02altipatlarAinda não há avaliações

- (API 674-2nd) Reciprocating PumpDocumento6 páginas(API 674-2nd) Reciprocating PumpadistiAinda não há avaliações

- Api 526-2009Documento1 páginaApi 526-2009고희숙Ainda não há avaliações

- Condensate Tank - For 250Documento3 páginasCondensate Tank - For 250Sakthi VelAinda não há avaliações

- Boiler Design Step 2Documento2 páginasBoiler Design Step 2Amad TaupiqAinda não há avaliações

- Data Sheet Multiphase Pump BornermanDocumento5 páginasData Sheet Multiphase Pump BornermanUmar Ijaz KhanAinda não há avaliações

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocumento2 páginasDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658Ainda não há avaliações

- Appendix 41Documento5 páginasAppendix 41Rafael_YevgenyAinda não há avaliações

- Air Blower Haya Water VerfDocumento9 páginasAir Blower Haya Water Verfgharsallah mounaAinda não há avaliações

- Asme B133.12-1981Documento10 páginasAsme B133.12-1981vijay pawarAinda não há avaliações

- Api 677Documento8 páginasApi 677ecsuperal0% (1)

- DHG PVE DD 3 ME SPC 007 - Spec For Gas Engine Screw Compressor PackageDocumento61 páginasDHG PVE DD 3 ME SPC 007 - Spec For Gas Engine Screw Compressor PackageThanh Tin NguyenAinda não há avaliações

- API 682 4th Ed DatasheetDocumento2 páginasAPI 682 4th Ed DatasheetMuhammad Ghufran KhanAinda não há avaliações

- Vent Silencer Spec SheetDocumento2 páginasVent Silencer Spec SheetAqeel Bisma100% (1)

- NFPA 68 2012 Revised 20130122 1Documento95 páginasNFPA 68 2012 Revised 20130122 1xjaf01Ainda não há avaliações

- API 610 Data Sheet 1 PDFDocumento6 páginasAPI 610 Data Sheet 1 PDFSuresh Kumar MittapalliAinda não há avaliações

- HSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterDocumento2 páginasHSD-A-TS-M-DS-0010 - Rev-A01 Mechanical Datasheet For Closed Drain Vessel Immersion HeaterThanh Phuc Nguyen100% (1)

- Air Blowe DatasheetDocumento1 páginaAir Blowe DatasheetMoein PAinda não há avaliações

- Drainage & Sump Pumps Specs PDFDocumento25 páginasDrainage & Sump Pumps Specs PDFWalid El Ghonamy100% (1)

- Basics of Gas Turbine (PGT25)Documento74 páginasBasics of Gas Turbine (PGT25)PDAinda não há avaliações

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Documento5 páginasSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarAinda não há avaliações

- Air Consumption Rev 1Documento1 páginaAir Consumption Rev 1Cahyadi YadiAinda não há avaliações

- Technical Comparison Format - Process Gas Reciprocating CompressorDocumento11 páginasTechnical Comparison Format - Process Gas Reciprocating CompressorAlvin Smith100% (1)

- 1.tbe1 Fire PumpDocumento11 páginas1.tbe1 Fire Pumpvinoj chandranAinda não há avaliações

- Final Acoustic Enclosure PresentationDocumento48 páginasFinal Acoustic Enclosure PresentationsartajyadAinda não há avaliações

- API 619 (97) PD CompressorsDocumento118 páginasAPI 619 (97) PD CompressorsMuhammadAwais100% (1)

- API Datasheet Heat ExchangerDocumento4 páginasAPI Datasheet Heat ExchangerSoraya ZahraAinda não há avaliações

- For Information: GE OfficialDocumento6 páginasFor Information: GE OfficialMaulik Dave50% (2)

- API 650 Datasheet 1Documento16 páginasAPI 650 Datasheet 1alwacsAinda não há avaliações

- Asme PTC ListDocumento2 páginasAsme PTC ListDeepikaAinda não há avaliações

- Ds Screw ConveyorDocumento2 páginasDs Screw ConveyorGuntur NugrohoAinda não há avaliações

- Silencer PDFDocumento4 páginasSilencer PDFvkumaranAinda não há avaliações

- (GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Documento3 páginas(GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Said ArjonaAinda não há avaliações

- Rotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsDocumento9 páginasRotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsghostamirAinda não há avaliações

- Fuel Gas Superheater 195-E-301 A/B: Mechanical - Data SheetDocumento3 páginasFuel Gas Superheater 195-E-301 A/B: Mechanical - Data SheetZulfikar N JoelAinda não há avaliações

- New Steel Plate LNGDocumento7 páginasNew Steel Plate LNGtutuionutAinda não há avaliações

- Technical Insulation - Cryolene PDFDocumento8 páginasTechnical Insulation - Cryolene PDFtutuionutAinda não há avaliações

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocumento1 páginaRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutAinda não há avaliações

- Speed Sensor Data Sheet: Customer Profile Speed SensorsDocumento2 páginasSpeed Sensor Data Sheet: Customer Profile Speed SensorstutuionutAinda não há avaliações

- AZOBEDocumento4 páginasAZOBEtutuionutAinda não há avaliações

- API 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)Documento10 páginasAPI 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)tutuionutAinda não há avaliações

- Turboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP CompDocumento6 páginasTurboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP ComptutuionutAinda não há avaliações

- API 614-Chapter 3 DATA SHEET General Purpose Oil System Si UnitsDocumento8 páginasAPI 614-Chapter 3 DATA SHEET General Purpose Oil System Si UnitstutuionutAinda não há avaliações

- API 614-Chapter 2 DATA SHEET Special Purpose Oil System Si UnitsDocumento7 páginasAPI 614-Chapter 2 DATA SHEET Special Purpose Oil System Si UnitstutuionutAinda não há avaliações

- Required System Performance - Purchaser: Elevated Flare Data Sheet No. 1 SI UnitsDocumento20 páginasRequired System Performance - Purchaser: Elevated Flare Data Sheet No. 1 SI UnitstutuionutAinda não há avaliações

- Special Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitsDocumento4 páginasSpecial Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitstutuionutAinda não há avaliações

- Bfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingDocumento25 páginasBfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingtutuionutAinda não há avaliações

- API 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentsDocumento3 páginasAPI 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentstutuionutAinda não há avaliações

- Tank 305Documento74 páginasTank 305tutuionutAinda não há avaliações

- Storage Tank Normal Venting Capacity CalculationsDocumento1 páginaStorage Tank Normal Venting Capacity CalculationstutuionutAinda não há avaliações

- Service Training DM Valves EN Compatibility Mode PDFDocumento170 páginasService Training DM Valves EN Compatibility Mode PDFAob AprilAinda não há avaliações

- Final Year ProjectDocumento52 páginasFinal Year ProjectMohamed A. HusseinAinda não há avaliações

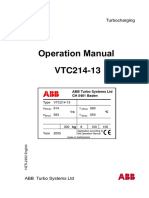

- BBC VTC214Documento201 páginasBBC VTC214engkos koswaraAinda não há avaliações

- Engine Engine KTA38 G2A Engine ScribdDocumento1 páginaEngine Engine KTA38 G2A Engine Scribddmc constructionAinda não há avaliações

- Presentation 1Documento22 páginasPresentation 1Divyansh SinghAinda não há avaliações

- E90 Dynamic Driving SystDocumento55 páginasE90 Dynamic Driving SystArturo Martinez SerranoAinda não há avaliações

- Motorized Valve With Actuator Bernard (WAFN3 - MSEENR)Documento3 páginasMotorized Valve With Actuator Bernard (WAFN3 - MSEENR)hvacvn1984Ainda não há avaliações

- Catalogue VECV Range of Products - J P Products, ChennaiDocumento2 páginasCatalogue VECV Range of Products - J P Products, ChennaiS KumarAinda não há avaliações

- 90 Degree Turning Motorized Steering MechanismDocumento62 páginas90 Degree Turning Motorized Steering MechanismMani Kandan100% (1)

- Mil P 17639FDocumento60 páginasMil P 17639FcarlosloucaoAinda não há avaliações

- 补正全套胶合板设备(日惹)Documento3 páginas补正全套胶合板设备(日惹)khoirulhimawan96Ainda não há avaliações

- Musso A1 F2Documento50 páginasMusso A1 F2Paulo De CastroAinda não há avaliações

- Procedure For Crankshafts That Will Not Rotate After Installation During A Rebuild (1000, 1202)Documento10 páginasProcedure For Crankshafts That Will Not Rotate After Installation During A Rebuild (1000, 1202)TASHKEELAinda não há avaliações

- Oil Pressure Is LowDocumento3 páginasOil Pressure Is Lownay hlaing SoeAinda não há avaliações

- ACM Composites Hydropower Presentation 19.07.17Documento50 páginasACM Composites Hydropower Presentation 19.07.17Osvaldo Luiz HiramaAinda não há avaliações

- MDLM Benelli TRK 502 - Manual de Taller-DesbloqueadoDocumento408 páginasMDLM Benelli TRK 502 - Manual de Taller-DesbloqueadoGaston Figueroa100% (1)

- Cyl Head Install 3054Documento5 páginasCyl Head Install 3054steven manuputtyAinda não há avaliações

- 12V Cummins Torque Specs PDFDocumento8 páginas12V Cummins Torque Specs PDF180976Ainda não há avaliações

- New Product Catalog 2022Documento92 páginasNew Product Catalog 2022Paulo César BritoAinda não há avaliações

- Speed Control of Hydraulic CylinderDocumento3 páginasSpeed Control of Hydraulic CylinderSriram SastryAinda não há avaliações

- Diagnostic Trouble Codes (DTC) : DTC P2724 Pressure Control Solenoid 1 (PCS1) Stuck OnDocumento1 páginaDiagnostic Trouble Codes (DTC) : DTC P2724 Pressure Control Solenoid 1 (PCS1) Stuck OnViktor ReneAinda não há avaliações

- 2017 NEC Table of ContentsDocumento124 páginas2017 NEC Table of ContentsFaheem PP13Ainda não há avaliações

- NSK Bearing Replacement GuideDocumento28 páginasNSK Bearing Replacement GuideAvila Dhanu KAinda não há avaliações

- KR MV5 Tropical PDFDocumento2 páginasKR MV5 Tropical PDFDjamal MohammediAinda não há avaliações