Escolar Documentos

Profissional Documentos

Cultura Documentos

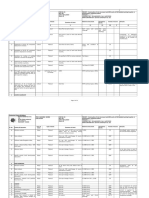

CIVIL CONSTRUCTION QA PLAN

Enviado por

Anonymous TjdHCuTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CIVIL CONSTRUCTION QA PLAN

Enviado por

Anonymous TjdHCuDireitos autorais:

Formatos disponíveis

QUALITY ASSURANCE PLAN

Client Name

ITEM : Civil Work

RITES Ltd

An ISO 9001-2000 Company

Sl. No

Name of work :Construction of Ancillary

Buildings like Gas Godown cum Tools

Store, Bogie Store, Canteen Building,

Toilet Block cum Parking, Compressor

Room and other works in connection with

Bogie & AC Container Manufacturing

Factory at Budge Budge of RCF at West

Bengal

Activity and Operation

Class of check

2

3

CONCRETING WORK

Coarse Aggregate for concrete and filters

1.0

1.1

1.2

Characteristics /

instruments

Project

Package -

QP NO. :

REV. NO.:

DATE:

PAGE:

Type of check

1 Contract No

Construction Agency

Quantum Of check

Reference

Documents

Acceptance Format of Remarks/ Precautions

Norms

Record

10

Physical

one test per 100 cum/

change of source

whichever is earlier

IS: 2386 Part-I, (for test

procedure), IS:383 (for

permissible value)/TS

SR/LB

Results should be as per

request of design mix subjected

to verification within the limits

specified in relevant IS code

Check by RITES.

Lab analysis &

Physical

To be done twice per

source. Once at the

starting, another in the

middle

IS: 2386 Part-II, (for test

procedure), IS:383 (for

permissible value)/TS

SR/LB/

Test

Report

Experts opinion regarding

suitability of the aggregates

shall be obtained from any

specialist institute, Results will

be reported nearest to 0.1% for

clay lumps

Check by RITES

Balance, Sieve

Determination of specific

B

gravity , water absorbtion, bulk (confirming to IS-460density and voids

1962) etc.

Physical

Once in twelve weeks/

500 cum or change of

source whichever is

earlier

IS: 2386 Part-III, (for test

procedure), IS:383 (for

permissible value)/TS

SR/LB/

Test

Report

These tests shall be carried out

while establishing design mix &

results be intimated.

RITES

1.1.4

Determination of Crushing

value, Determination of

impact value

Standard Apparatus A

for these test shall

be used

Physical

IS: 2386 Part-IV, (for test

procedure), IS:383 (for

permissible value)/TS

SR/LB/

Test

Report

1.1.5

Moisture content

Balance, Sieve(

B

confirming to IS-4601962) and Oven

etc.

Physical

To be done twice per

source. Once at the

starting, another in the

middle

Once for each stack of

100 Cu.M. or part there of

Except during monsoon

when this has to be done

every day before start of

concreting

IS:2386 Part-III

IS : 456

IS : 383/TS

SR/LB

These tests shall be carried out

while establishing design mix &

results be intimated.

RITES to check

Accordingly water content of the

concrete will be adjusted. These

tests shall be carried out while

establishing design mix &

results be intimated.

RITES to check

1.1.6

Soundness

Reagents (sodium B

Sulphate or

Magnesium

Sulphate)

Chemical/

Physical

IS: 2386 Part-V, (for test

procedure), IS:383 (for

permissible value)/TS

SR/LB/

Test

Report

1.1.1

Particle Size & Shape (Sieve

analysis, flakiness index,

elongation index including

visual inspection.

Sieves (confirming

to IS-460-1962) ,

balance, Oven,

Thickness gauge,

Length Gauge,

Metal Scoop etc

1.1.2

Deleterious materials &

organic impurities

B

Balance, Sieve

(confirming to IS-4601962) etc.

1.1.3

To be done twice per

source. Once at the

starting, another in the

middle.

Fine aggregate

250

These tests shall be carried out

while establishing design mix &

results be intimated.

RITES to check

QUALITY ASSURANCE PLAN

Client Name

Sl. No

Name of work :Construction of Ancillary

Buildings like Gas Godown cum Tools

Store, Bogie Store, Canteen Building,

Toilet Block cum Parking, Compressor

Room and other works in connection with

Bogie & AC Container Manufacturing

Factory at Budge Budge of RCF at West

Bengal

Activity and Operation

1.2.1

Characteristics /

instruments

2

3

Bulkage, bulk density, surface As per IS Code

moisture & water absorption

Class of check

4

B

Package -

QP NO. :

REV. NO.:

DATE:

PAGE:

ITEM : Civil Work

RITES Ltd

An ISO 9001-2000 Company

Project

1 Contract No

Construction Agency

Type of check

Quantum Of check

Reference

Documents

5

Physical

6

Bulkage & surface

moisture to be done

everyday before starting

the work.

Bulk density & water

absorption to be done

once in twelve weeks/

500 cum or change of

source whichever is

earlier

7

8

IS: 2386 (Part III), IS:383/ TS

LEGEND:

Acceptance Format of Remarks/ Precautions

Norms

Record

9

10

SR/LB/TR Volume of sand and weight of

water shall be adjusted as per

bulk and moisture content

RITES to check

DOC. NO.:

REV-

Legend to be used: Class # : A = Critical, B=Major, C=Minor; SR,TR,MfrTC

SR = Site Register , TR= Test Report , Mfr TC=Manufacturer's Test Certificate , duly correlated

Construction Agency

Stamp and Signature

1.2.2

This document shall be read in conjunction with RITES Tech. Specifications, BOQ &

Drawings.

B

Physical

1.2.3

B

Silt, Clay content and organic Balance, Sieve

(confirming to IS-460impurities and deleterious

1962) etc.

materials

Physical

1.2.4

Sieve Analysis, particle shape set of sieves

& size

Physical

1.2.5

Soundness

1.3

Mortar making properties

As per IS Code

REVIEWED BY

Once per source & one

for every change of

source

To be done twice per

source. Once at the

starting, another in the

middle

one test per 100 cum/

change of source

whichever is earlier

IS: 2386 (Part VI), IS:383/ TS

IS: 2386 Part-II, (for test

procedure), IS:383 (for

permissible value)/ TS

APPROVE

D BY

Approval Seal

SR/LB/TR should be as per requirement of

design mix

RITES to check

SR/LB/

should be as per requirement of

Test

design mix

Report

RITES to check

IS: 2386 (Part-I), IS:383/ TS

SR/LB/TR Should be as per requirement of

design mix subject to variation

specified in relevant IS codes.

RITES to check

These tests shall be carried out

while establishing design mix &

results be intimated.

RITES to check

Reagents (sodium B

Sulphate or

Magnesium

Sulphate)

Chemical/

Physical

To be done twice per

source. Once at the

starting, another in the

middle

IS: 2386 Part-V, (for test

procedure), IS:383 (for

permissible value)

SR/LB/

Test

Report

PH meter/ PH paper B

(to be recorded at

site)

Testing at lab

One per month for each

source

IS:3025, IS:456

SR/LB/TR do

Water

1.3.1

Tests for PH Value

251

QUALITY ASSURANCE PLAN

Client Name

Sl. No

Name of work :Construction of Ancillary

Buildings like Gas Godown cum Tools

Store, Bogie Store, Canteen Building,

Toilet Block cum Parking, Compressor

Room and other works in connection with

Bogie & AC Container Manufacturing

Factory at Budge Budge of RCF at West

Bengal

Activity and Operation

Characteristics /

instruments

Class of check

Package -

QP NO. :

REV. NO.:

DATE:

PAGE:

ITEM : Civil Work

RITES Ltd

An ISO 9001-2000 Company

Project

Type of check

1 Contract No

Construction Agency

Quantum Of check

Reference

Documents

Acceptance Format of Remarks/ Precautions

Norms

Record

2

3

4

5

6

7

CEMENT (review of manufacturers test certicate for each consignment brought at site with the information to RITES.

1.4

10

Visual

100% covered storage

Refer RITES tech

Spec

SR/LB

RITES site engineer to check.

Manufacturers test certificate to

be submitted by the contractor

As required

Physical

One per 200 MT

IS: 4031/

1489/269/455/TS

SR/LB

do

Initial & Final Setting time

Soundness

As required

As required

B

B

Physical

Physical

do

do

IS:4031/TS

IS:4031/TS

SR/LB

SR/LB

do

do

1.4.5

Specifiv Gravity

As required

Physical

do

IS:4031/TS

SR/LB

do

1.4.6

Compressive Strength

As required

Physical

do

IS:4031/TS

SR/LB

do

SR

proper care should be taken in

order to combat corrosion.

Proper care should be taken

while cleaning, moving and

stacking the scafolds. It should

be ensured that they are free

from warped, broken or

damaged edges or uneven

surface before putting them on

works.Cleaning and oiling is to

be done.to check for loose

connections if any

Check by RITES

1.4.1

a) Ensure that cement is

stored in weather tight

covered storage on raised

platform.

1.4.2

Fineness

1.4.3

1.4.4

STAGING, SHUTTERING AND FORMS

1.5

1.5.1

Materials and accessories

As required

Visual

100% IS 4014

1.5.2

Steel plate / Plywood for

concrete shuttering work

As required

Visual

100% IS 4990:1993,

IS 1734; ( Part 1 -11)/TS

1.5.3

Durability, Strength &

As required

Soundness of staging, joists,

shuttering and scaffolding

Connection between individual As required

scaffolding units and safe

slenderness ratio. Two

independent safety measures

against collapse

Visual

Once

Visual

Fortnightly

1.5.4

252

As per technical specification,

manufacturer's spec.and IS:

3696,4014, 4990

As per relevant IS Codes

SR

SR

Relevant documents &

recommended method of use &

loading etc. to be checked by

RITES

To be checked by RITES before

& after placement of concrete

RITES site engineer to check

QUALITY ASSURANCE PLAN

Client Name

ITEM : Civil Work

RITES Ltd

An ISO 9001-2000 Company

Sl. No

Name of work :Construction of Ancillary

Buildings like Gas Godown cum Tools

Store, Bogie Store, Canteen Building,

Toilet Block cum Parking, Compressor

Room and other works in connection with

Bogie & AC Container Manufacturing

Factory at Budge Budge of RCF at West

Bengal

5

Measurement

6

Each member & before

each lift of shuttering or

before next stage

7

8

As per approved drawings

9

SR/LB

10

length,breadth,depth,shape,

level, plumb line to be checked.

Diagonal bracings are to be

checked.

Check form's seam marks and As required

water tightness

Mix Design

As required

Physical

Random

As per approved drawings

SR/LB

RITES site engineer to check

Physical

Once for every change in IS: 516 & IS:456,

mix materials source.

IS:10262/RITES

Tech. Spec.

Mix Design Design mix is to be carried out

Report

at any approved lab.

1.6.2

Trial mix (Cubes compressive As required

strength)of the Mix Design

Physical

Min. 3 Trial Mixes with

admixtures (if any) and

Without admixtures

IS: 516 & IS:456,

IS:10262/ RITES

Tech. Spec.

SR/LB/

Test

Report

RITES will conduct the trial

mixes

Mixing shall be in RITES

approved batching plant/ weigh

batcher.

1.6.3

Crushing strength of trial mix

cubes

Physical

As per IS 456

IS: 516 & IS:456,

IS:10262/ RITES

Tech. Spec.

SR/LB

witness by RITES

Physical

To be calibrated at the

time of starting and as

desired by Engineer-in charge

Review of

calibration chart/

Certificate, IS 456/

TS

1.6 1.6.1

1.7

1.7.1

3

As required

Construction Agency

Reference

Documents

1.5.6

2

Alignment/Shape

As required for 7 &

28 days strength

test

Class of check

1 Contract No

Quantum Of check

1.5.5

Characteristics /

instruments

Package -

QP NO. :

REV. NO.:

DATE:

PAGE:

Type of check

Activity and Operation

Project

Concrete conveying, placing and Compaction

Mixing of concrete

mixing of concrete B

shall be done in a

approved mixer/

weigh batcher/

batching plant such

as to produce a

homogenous mix

1.7.2

Handling and Conveying

Buckets , Chutes,

belt conveyer etc

Physical

1.7.3

Placement of concrete

Visual

Physical

100% as per Tech.

Spcfn./constructio

n/erection

methodology/ IS

457

100% as per

construction/erecti

on methodology

as per tech.specs

253

Acceptance Format of Remarks/ Precautions

Norms

Record

time of mixing will be as given in

Technical specification / IS 456

Min. time of mixing should be 2

minutes for mixer capacity 2

cum or less

Min. time of mixing should be 3

minutes or as recommended by

by the mixer manufacturer for

mixer capacity above 2 cum

SR

Technical specification is to be

followed.

SR

no concrete shall be placed until

the place of deposite has been

thoroughly inspected and

accepted,

Check by RITES

QUALITY ASSURANCE PLAN

Client Name

Sl. No

Name of work :Construction of Ancillary

Buildings like Gas Godown cum Tools

Store, Bogie Store, Canteen Building,

Toilet Block cum Parking, Compressor

Room and other works in connection with

Bogie & AC Container Manufacturing

Factory at Budge Budge of RCF at West

Bengal

Activity and Operation

2

1.7.4

Compacting

1.7.5

Curing

1.8

Characteristics /

instruments

3

As required

As required

minimum 7 days

Class of check

Package -

QP NO. :

REV. NO.:

DATE:

PAGE:

ITEM : Civil Work

RITES Ltd

An ISO 9001-2000 Company

Project

Type of check

5

Physical

Physical

1 Contract No

Construction Agency

Quantum Of check

Reference

Documents

7

100% Check for

segregation as per

IS 456 & TS

100% Check for period

of curing as per IS

456 & TS

Acceptance Format of Remarks/ Precautions

Norms

Record

8

9

SR

SR

10

Bleeding or segregation etc. is

to be avoided as far as

possible. Accumulated water is

to be removed and shall not be

covered with concrete, or dry

concrete

Check by RITES

Exposed concrete surface shall

be protected against heating

and drying for atleast 72 hrs

after placement.

Check by RITES

Tests on Green Concrete

1.8.1

Workability :- Slump test

Standard apparatus B

for different method

used for measuring

workability, slump

cone

Physical

One sample every 2 hrs.

from every mixing plant/

IS 456

IS:456, IS 11991959 & RITES

Tech. Spec.

SR/LB/TR Slump test for medium & high

workability

RITES site engineer to check

1.8.2

Crushing strength (works

Tests cubes)

As required for 7 &

28 days

Physical

As per IS 456

IS:516, IS:456,

RITES Tech.

Spec.

SR/LB/

Test

Report

RITES site engineer to do the

test.

1.8.3

Water cement ratio( Cement

Content And Water Content)

As required

Physical

At random at the time of

batching.

As per IS:1199

and approved

design mix.

SR/LB

As per mix design

RITES site engineer to check

1.8.4

Check for cement content

Physical

At random at the time of

batching.

SR/LB

do

1.8.5

Admixtures for Concrete (if

any)

As per IS : 9103

Testing

As per IS:3026,

IS: 456, approved

design mix &

technical

specification.

100% IS:456, appd.

Design mix &

technical

specification

Test

Report

Admixture of appd. Brand and

tested quality shall be

used.Manufacturers TC

required.RITES site engineer to

check

1.8.6

Visual examination of

finished structure

As required

Visual

100% As per Tech.

Specification./App

d. Drg./IS-456

-do-

RITES to check

254

QUALITY ASSURANCE PLAN

Client Name

Sl. No

Name of work :Construction of Ancillary

Buildings like Gas Godown cum Tools

Store, Bogie Store, Canteen Building,

Toilet Block cum Parking, Compressor

Room and other works in connection with

Bogie & AC Container Manufacturing

Factory at Budge Budge of RCF at West

Bengal

Activity and Operation

Characteristics /

instruments

2

1.8.7

Dimensions

Class of check

3

do

4

B

Package -

QP NO. :

REV. NO.:

DATE:

PAGE:

ITEM : Civil Work

RITES Ltd

An ISO 9001-2000 Company

Project

Type of check

1 Contract No

Construction Agency

Quantum Of check

5

Measurement

Reference

Documents

7

100% As per Tech.

Specification./App

d. Drg./IS-456

Acceptance Format of Remarks/ Precautions

Norms

Record

8

9

do

10

RITES to check

TEST/CHECK ON RCC STRUCTURE IN HARDENED CONDITIONS:

1.9

100% IS: 13311 Part- I and Tech.

Specification/ IS 456

1.9.1

Ultrasonic Pulse Velocity Test for critical

foundations

NDT

1.9.2

Load Test , Core test &

Rebound Hammer

Test

As required by RITES

Engineer.

As required

As per Technical

specification and

IS:456-2000

Test

Report

Shall be performed by qualified

persons/institution with

calibrated equipments in

presence of RITES, if there is

any doubt in crushing stregth

and on specific instruction

Test

Report

The test shall be carried out

only in case of doubt regarding

grade & quality of concrete.

MTC

Approved brands are

SAIL/TATA TISCON/

RINL/IISCO

SR/LB

To be checked at site

Reinforcement Steel

2.0

2.1

Physical and Chemical

Properties as per relevant IS

codes

As required/ agreed B

Review of TCs

In 100 MT or part thereof IS 1786/ 456/ TS

2.2

Tolerance

As required/agreed

Physical

At random

IS:1786

2.3

Freedom from defects

As required/ agreed C

Visual

Random before and

during placement

As per technical specifications & SR

IS: 468

RITES to check

C

255

Any of the bars selected for use

shall be free from cracks,

surface flaws, laminations and

rough, jagged and imperfect

edges.Steel issued should be

free from excessive rust. To be

stored diameter wise in such a

place so as to permit easy

approach for inspection &

identification. It should be

cleaned of excessive rust

before use.R/f will be tied with

annealed wire. Water

accumulation & distortion of r/f

are to be avoided. To be

checked by RITES

QUALITY ASSURANCE PLAN

Client Name

Sl. No

Name of work :Construction of Ancillary

Buildings like Gas Godown cum Tools

Store, Bogie Store, Canteen Building,

Toilet Block cum Parking, Compressor

Room and other works in connection with

Bogie & AC Container Manufacturing

Factory at Budge Budge of RCF at West

Bengal

Activity and Operation

Characteristics /

instruments

Class of check

Package -

QP NO. :

REV. NO.:

DATE:

PAGE:

ITEM : Civil Work

RITES Ltd

An ISO 9001-2000 Company

Project

Type of check

Construction Agency

Quantum Of check

3

As required/ agreed B

2.5

Cutting tolerance

As required/ agreed B

Physical

Measurement

100%

Approved drawings & check list. SR

Tolerance as per specifications

3.1

Grout

Grouting Pressure

Calibrated Pressure B

Gauge

Physical

At random

Approved Drwaing

SR/LB

To be checked at site by RITES

3.2

Composition of Grout

NIL

Verification of

MTC

Each lot/Batch

As per Technical Specification

SR/LB

To be checked at site by RITES

3.3

Compressive strength (7 & 28 As required

days)

Physical

6 cubes for every grout at As per Technical specification

the time of each grouting

SR/LB

To be checked at site by RITES

As per Technical Specification

MTC

To be checked at site by RITES

IS: 1077, IS:

3495, IS:2691,

Tech.

Specification

SR/LB

To be checked at site by RITES

as per frequency stipulated in

specification & guideline.

4.1

5.0

5.1

5.1.1

Visual

7

8

9

10

100% As per approved drawings and SR/LB/

RITES Engineer to check as

approved Bar Bending schedule/ Pour card per Bar Bending Schedule

IS 456/ TS

(BBS) and as per relevant codal

provision

Expansion Joints (Test Certificate of Manufacturer & Inspection agency is to be reviewed before placement)

Check of type & location of

NIL

B

Visual

100%

installation and release for

concreting

Brick Masonry, Sheeting & allied works

Test on Bricks

Soundness

As required

C

Physical

As per relevant IS Code/

One Sample for 10,000

Nos. or part thereof

5.1.2

Colour

Visual

One for each stack

do

Deep cherry red copper colour

5.1.3

Compressive strength

As required

Physical

As per relevant IS Code/ IS: 1077, IS: 3495

One Sample for 10,000

(part I), IS:2891,

Tech.

Nos. or part thereof

Specification

do

To be checked at site by RITES

as per frequency stipulated in

specification & guideline.

5.1.4

Water Absorption

As required

Physical

do

do

5.1.5

Visual & Dimension

Visual &

Measurement tape

Straight edge &

scale

Visual &

Measurement

Measurement

As per relevant IS Code/ IS: 1077, IS: 3496

One Sample for 10,000

(part I), IS:2891,

Nos. or part thereof

Tech.

Specification

Random

IS: 1077 & tech.

do

do

do

do

5.1.6

5.2

Acceptance Format of Remarks/ Precautions

Norms

Record

Placement

4.0

Reference

Documents

2.4

3.0

1 Contract No

Warpage

Sand (masonary work & road works)

256

Per 10000 Nos.

do

Spcfn.

IS: 1077

QUALITY ASSURANCE PLAN

Client Name

ITEM : Civil Work

RITES Ltd

An ISO 9001-2000 Company

Sl. No

Name of work :Construction of Ancillary

Buildings like Gas Godown cum Tools

Store, Bogie Store, Canteen Building,

Toilet Block cum Parking, Compressor

Room and other works in connection with

Bogie & AC Container Manufacturing

Factory at Budge Budge of RCF at West

Bengal

Activity and Operation

Characteristics /

instruments

Class of check

Package -

QP NO. :

REV. NO.:

DATE:

PAGE:

1 Contract No

Construction Agency

Type of check

Quantum Of check

Reference

Documents

Acceptance Format of Remarks/ Precautions

Norms

Record

5.2.1

2

3

Silt, Clay content and organic As per IS Code

impurities

5

Physical

6

7

8

Once per source & for on IS: 2386 Part-II, IS:383 /TS

every change of source

5.2.2

Grading Of Sand

IS Sieves

Physical

once for 100 cum or part

thereof or change of

source whichever is

earlier.

IS 2116/ IS 383/ TS

5.2.3

Balance, Sieve

B

(confirming to IS-4601962) etc.

Physical

do

IS: 2386 Part-III, (for test

procedure), IS:383 (for

permissible value)

5.3.1

Determination of specific

gravity and water absorbtion,

& Bulk density

Masonry construction

Workmanship

---

Visual/ Physical All work

As per Spec And

IS 2212 for brick

works

RITES to check

5.3.2

Laying

Trovel, Square,

Plumb bob etc

Physical

All work

As per Spec And

Clause no 11.0 of

IS 2212 for brick

works

RITES to check

5.3.3

Physical

All work

IS 2212 and Tech

Spec

RITES to check

7.1.1

Verticality and Alignment of

Plumb bob

B

Plumb

BOUGHT OUT ITEMS - BOI

Bought out items to be

As required / agreed B

procured form the

manufacturers acceptable to

RITES

Paver Block etc.

RCC PIPES as per IS: 458 & T.S.

Tests at Manufacturer's Works (RITES approved)

Hydrostatic Test

As required / agreed B

Physical

As per IS 458

Testing Procedure as per IS 458 IR/TC

RITES to check

7.1.2

Absorption Test

As required / agreed B

Physical

As per IS 459

Testing Procedure as per IS 459 IR/TC

do

7.1.3

3 Edge Bearing Test

As required / agreed B

Physical

As per IS 460

Testing Procedure as per IS 460 IR/TC

do

7.1.4

Straightness Test

As required / agreed B

Physical

As per IS 461

Testing Procedure as per IS 461 IR/TC

do

7.1.5

Dimensional Check & Visual

Inspn.

As required / agreed B

Physical

As per IS 462

Testing Procedure as per IS 462 IR/TC

do

5.3

6.0

6.1

7.0

7.1

Project

Verification of

MTC / Testing/

review

257

9

10

SR/LB/TR RITES to check

RITES to check

SR/LB/

Test

Report

do

100% RITES tech spec. / BOQ. List of Relevant RITES to check

documents

all BOI to be submitted for

approval along with proposed

/ TC

vendors

QUALITY ASSURANCE PLAN

Client Name

Sl. No

Characteristics /

instruments

7.1.6

2

RCC wire check & spacing

3

As required / agreed B

7.2.1

Checks at site

Check for Laying and Jointing As required / agreed B

7.2

1.0

2.0

3.0

4.0

Name of work :Construction of Ancillary

Buildings like Gas Godown cum Tools

Store, Bogie Store, Canteen Building,

Toilet Block cum Parking, Compressor

Room and other works in connection with

Bogie & AC Container Manufacturing

Factory at Budge Budge of RCF at West

Bengal

Activity and Operation

General Points:

Quality Control Manpower

Quality Control Laboratory

Construction Equipments

Organisation Chart

Class of check

Package -

QP NO. :

REV. NO.:

DATE:

PAGE:

ITEM : Civil Work

RITES Ltd

An ISO 9001-2000 Company

Project

1 Contract No

Construction Agency

Type of check

Quantum Of check

5

Measurement

Random

Visual

As per IS 783

v) Swelling Index

A check

A check

A check

B check

As per T.S.

As per T.S.

As per T.S.

As per T.S./As per requirement /

direction of EIC

258

Reference

Documents

7

TS/IS 458

Acceptance Format of Remarks/ Precautions

Norms

Record

8

As per IS 783 & RITES Tech.

Spec

9

IR/TC

do

10

IR/TC

RITES to check

Você também pode gostar

- Methodology For Emb With Pond AshDocumento10 páginasMethodology For Emb With Pond Ashjitendra100% (4)

- Methodology-TG DECK-rev0 (4feb12)Documento11 páginasMethodology-TG DECK-rev0 (4feb12)beshnu garanaik100% (1)

- Quality Assurance Plan: Pre-Engineered Steel BuildingDocumento3 páginasQuality Assurance Plan: Pre-Engineered Steel BuildingsivakumarAinda não há avaliações

- QAP RoadDocumento54 páginasQAP RoadSachin PawarAinda não há avaliações

- MTC CEBEX 100 Batch No IN1MF00537868KDocumento1 páginaMTC CEBEX 100 Batch No IN1MF00537868KBeshnu Garanaik50% (2)

- Methodology For Filter MediaDocumento3 páginasMethodology For Filter MediaLaxminarayana Sastry100% (1)

- Methods Statement For Minor Bridges SUPER STRUCTUREDocumento5 páginasMethods Statement For Minor Bridges SUPER STRUCTUREPrasanna S KulkarniAinda não há avaliações

- Quality Assurance Plan for Name of ProjectDocumento23 páginasQuality Assurance Plan for Name of ProjectBhawesh Ashu100% (2)

- Is.14893.2001 Pile Integrity Test PDFDocumento14 páginasIs.14893.2001 Pile Integrity Test PDFParth Patel100% (1)

- Anti-Termite Treatment MethodDocumento4 páginasAnti-Termite Treatment Methodbeshnu garanaikAinda não há avaliações

- Pile Load Test MethodologyDocumento4 páginasPile Load Test MethodologyAkhilesh Dwivedi100% (1)

- CHECKLIST FOR WBM & ASPHALT ROAD CONSTRUCTIONDocumento2 páginasCHECKLIST FOR WBM & ASPHALT ROAD CONSTRUCTIONCheng Engi100% (2)

- Qap & Inspection Test Plan (Itp) - SimplexDocumento50 páginasQap & Inspection Test Plan (Itp) - SimplexN.Prabhu100% (1)

- Anchor Pile Load Test MethodologyDocumento11 páginasAnchor Pile Load Test MethodologyHegdeVenugopal50% (4)

- Cebex 100 491846aDocumento1 páginaCebex 100 491846aMahan Buildcon LLPAinda não há avaliações

- Checklist For RA Bills - R1Documento1 páginaChecklist For RA Bills - R1jaineranaAinda não há avaliações

- Marth 1800 PrestressingDocumento17 páginasMarth 1800 PrestressingRamesh100% (4)

- Amendment N - I MA Y 2002 IS 1200 (PART 8) : 1993 Methods Measurement of Building and Civil Engineering WorksDocumento8 páginasAmendment N - I MA Y 2002 IS 1200 (PART 8) : 1993 Methods Measurement of Building and Civil Engineering Worksraviteja036Ainda não há avaliações

- METHOD FOR CONSTRUCTION OF CAST-IN-SITU PILES USING TRIPOD STANDDocumento27 páginasMETHOD FOR CONSTRUCTION OF CAST-IN-SITU PILES USING TRIPOD STANDShakti SharmaAinda não há avaliações

- Auramix BCI Corrosion ProtectionDocumento2 páginasAuramix BCI Corrosion Protectionraviteja036Ainda não há avaliações

- Procedure For Rubble SolingDocumento6 páginasProcedure For Rubble SolingBhargav Bbvs100% (3)

- N' +HÑR Oaqøhv Ijh (K.K I FR K¡: HKKJRH EkudDocumento20 páginasN' +HÑR Oaqøhv Ijh (K.K I FR K¡: HKKJRH Ekudjitendra100% (2)

- Is:4926 RMCDocumento21 páginasIs:4926 RMCRamesh100% (7)

- Methodology For Pile Foundation 08-09Documento4 páginasMethodology For Pile Foundation 08-09Jeremy Jenkins86% (7)

- RMC Plant Calibration ReportDocumento5 páginasRMC Plant Calibration ReportSurendra kumar100% (1)

- PEB Checklist GL 1-2-20.9.16Documento4 páginasPEB Checklist GL 1-2-20.9.16Prem Kumar90% (10)

- Section 900 Quality Control For Road WorksDocumento24 páginasSection 900 Quality Control For Road WorksAmul Kotharkar73% (11)

- PSC Girder Before Concreting MIPL CL 32Documento2 páginasPSC Girder Before Concreting MIPL CL 32Rayudu VVS100% (1)

- Noida Metro Rail Project Cec-Sam-Jv.: Presentation On U-Girder Casting by L.K.PrasadDocumento116 páginasNoida Metro Rail Project Cec-Sam-Jv.: Presentation On U-Girder Casting by L.K.PrasadLOHITH N100% (1)

- Hume Pipe Laying DocumentsDocumento7 páginasHume Pipe Laying DocumentsamaravathiaspAinda não há avaliações

- Morth Section 900Documento256 páginasMorth Section 900VikasMauryaAinda não há avaliações

- Road Work For GSB, WMM & Bitumen Job QAPDocumento2 páginasRoad Work For GSB, WMM & Bitumen Job QAPSasanka SekharAinda não há avaliações

- Reasons For Cube FailureDocumento3 páginasReasons For Cube Failureharish chandra78% (9)

- Method Statement For Random Rubble Masonry WorkDocumento4 páginasMethod Statement For Random Rubble Masonry WorkarunaAinda não há avaliações

- Microtech Testing & Research Laboratory: Condition of Sample, When Received: SatisfactoryDocumento1 páginaMicrotech Testing & Research Laboratory: Condition of Sample, When Received: SatisfactoryKumar AbhishekAinda não há avaliações

- QAP - ITP - Steel Girder ApproachDocumento21 páginasQAP - ITP - Steel Girder ApproachPartha Gangopadhyay100% (1)

- Is 4990 2011 PDFDocumento20 páginasIs 4990 2011 PDFPratik DiyoraAinda não há avaliações

- Methodology For Water Tightness Test For Expansion JointDocumento1 páginaMethodology For Water Tightness Test For Expansion Jointvenkateswara rao PothinaAinda não há avaliações

- Is 2911 Part 4 2013Documento17 páginasIs 2911 Part 4 2013Manvendra Nigam60% (15)

- Is 269-2015 PDFDocumento13 páginasIs 269-2015 PDFSabari Nathan100% (1)

- Casting Method for RE Wall Fascia PanelsDocumento4 páginasCasting Method for RE Wall Fascia PanelsAkhilesh DwivediAinda não há avaliações

- Acceptance Criteria Indian Standard Cube StrengthDocumento8 páginasAcceptance Criteria Indian Standard Cube StrengthGaneshAinda não há avaliações

- Method Statement For Cuplock Shuttering WorkDocumento7 páginasMethod Statement For Cuplock Shuttering WorkAkash YadavAinda não há avaliações

- Check List of PQCDocumento2 páginasCheck List of PQCkrishna67% (3)

- Hilti Chemical Anchoring MethodologyDocumento3 páginasHilti Chemical Anchoring MethodologyEgg Pegg (Pegg)100% (1)

- Hardened Concrete - Methods of Test: Indian StandardDocumento16 páginasHardened Concrete - Methods of Test: Indian StandardjitendraAinda não há avaliações

- QAP For Road WorksDocumento25 páginasQAP For Road WorksBhawesh AshuAinda não há avaliações

- Method Statement: Granular Sub Base (GSB) Layer Compaction ProcessDocumento1 páginaMethod Statement: Granular Sub Base (GSB) Layer Compaction ProcessjitendraAinda não há avaliações

- REPORT ON VERTICAL PILE LOAD TESTDocumento8 páginasREPORT ON VERTICAL PILE LOAD TESTshaaz v s mAinda não há avaliações

- 3812 1 PDFDocumento14 páginas3812 1 PDFइंजि कौस्तुभ पवारAinda não há avaliações

- Is 458-1988Documento46 páginasIs 458-1988Rajashekhar Katta100% (2)

- QC Frequency Test Plan (5th Revision)Documento42 páginasQC Frequency Test Plan (5th Revision)Deven PatleAinda não há avaliações

- Pipe Fittings InspectionDocumento7 páginasPipe Fittings InspectionRamalingam PrabhakaranAinda não há avaliações

- AC7102.1D Nadcap Audit Criteria For BrazingDocumento11 páginasAC7102.1D Nadcap Audit Criteria For BrazingrsjfidderAinda não há avaliações

- Sample QAPDocumento3 páginasSample QAPsniperiAinda não há avaliações

- Fhwa-Office of Structures Checklist For Structural Steel Bolting Process Review of State Central OfficeDocumento19 páginasFhwa-Office of Structures Checklist For Structural Steel Bolting Process Review of State Central Officegalfar7Ainda não há avaliações

- Jawad+Ahsan + ResumeDocumento3 páginasJawad+Ahsan + ResumeAndiappan PillaiAinda não há avaliações

- Piping Engineer 2019Documento8 páginasPiping Engineer 2019Richard PeriyanayagamAinda não há avaliações

- 102-V-5 QipDocumento8 páginas102-V-5 QipSaleemSahabAinda não há avaliações

- Welding of Duplex Stainless SteelDocumento7 páginasWelding of Duplex Stainless SteelAnthony YUAinda não há avaliações

- Pressure Testing Outside The Trench:: Allowance For Expansion Under Test PressureDocumento1 páginaPressure Testing Outside The Trench:: Allowance For Expansion Under Test PressurembobterateraAinda não há avaliações

- Pump Affinity Laws GuideDocumento3 páginasPump Affinity Laws Guidesubramanyanvenkat6185Ainda não há avaliações

- ConstructivismDocumento23 páginasConstructivismAnonymous TjdHCu75% (4)

- Metals AbbreviationsDocumento3 páginasMetals AbbreviationsAnonymous TjdHCuAinda não há avaliações

- Waste Water PDFDocumento150 páginasWaste Water PDFAnonymous TjdHCu100% (1)

- BS 970-1-1991Documento62 páginasBS 970-1-1991raghav248100% (6)

- Pump Head CalculationsDocumento65 páginasPump Head CalculationsAnonymous TjdHCuAinda não há avaliações

- FLange Dimesions B16.5Documento2 páginasFLange Dimesions B16.5Anonymous TjdHCuAinda não há avaliações

- Doc: MTD 8 (4660) : (Fifth RevisionDocumento8 páginasDoc: MTD 8 (4660) : (Fifth RevisionAnonymous TjdHCuAinda não há avaliações

- 1874C 02RD MT 0640 0 PDFDocumento236 páginas1874C 02RD MT 0640 0 PDFShafi AshrafAinda não há avaliações

- Consultant: Punjab State Power Corporation LimitedDocumento9 páginasConsultant: Punjab State Power Corporation LimitedKoushik DeyAinda não há avaliações

- Uttar Pradesh Hand Sanitizer BidDocumento3 páginasUttar Pradesh Hand Sanitizer BidKetan The TendersAinda não há avaliações

- Nioec SP 00 89 (R0) (Ed1)Documento8 páginasNioec SP 00 89 (R0) (Ed1)aminAinda não há avaliações

- Fiberglass Coating SpecDocumento3 páginasFiberglass Coating Specponnivalavans_994423100% (1)

- Design+Commissioning Report July 6 2017 FINALDocumento108 páginasDesign+Commissioning Report July 6 2017 FINALComputer SoftwareAinda não há avaliações

- Inspection & Test Plan For Fabrication, Erection & Testing of Piping SystemDocumento4 páginasInspection & Test Plan For Fabrication, Erection & Testing of Piping SystemAbdullah Al Jubayer100% (4)

- D4228Documento3 páginasD4228masv792512100% (1)

- Roo Tanks Osp Ps Tec Com Eng Emc 16117 Rev ADocumento11 páginasRoo Tanks Osp Ps Tec Com Eng Emc 16117 Rev AAmr TarekAinda não há avaliações

- ORA-LAB.5.5 Equipment v02Documento19 páginasORA-LAB.5.5 Equipment v02Fredrick OtienoAinda não há avaliações

- TR Technical Drafting NCIIDocumento73 páginasTR Technical Drafting NCIIArtist tutorialsAinda não há avaliações

- Constructability (Value Engineering) GuidelinesDocumento60 páginasConstructability (Value Engineering) GuidelinesIgnacio Manzanera50% (2)

- 9110 PDFDocumento15 páginas9110 PDFPawan KumarAinda não há avaliações

- 附件2-Explanatory Notes for Industry on the Preparation of a Site Master File-PICS Sep. 2007Documento22 páginas附件2-Explanatory Notes for Industry on the Preparation of a Site Master File-PICS Sep. 2007jarodtuAinda não há avaliações

- Understanding ISO/IEC 17020:2012Documento47 páginasUnderstanding ISO/IEC 17020:2012Diego Torres ObregonAinda não há avaliações

- Basis of Design - Pipeline System GaslineDocumento10 páginasBasis of Design - Pipeline System GaslineAndreas Schlager100% (1)

- Tank DesignDocumento51 páginasTank Designtheerapolj86% (7)

- HVAC Technical SpecificationsDocumento132 páginasHVAC Technical SpecificationsFaquruddin Ali100% (1)

- Internal Marks Assessment Software Requirements SpecificationDocumento13 páginasInternal Marks Assessment Software Requirements SpecificationGaurav MittalAinda não há avaliações

- Bahrain Electricity Meter Cabinet Specification FinalDocumento9 páginasBahrain Electricity Meter Cabinet Specification FinalVignesh Subramani100% (1)

- Aircraft Polyurethane Coating SpecificationDocumento24 páginasAircraft Polyurethane Coating SpecificationAnes HalilovićAinda não há avaliações

- FQP GeneralDocumento21 páginasFQP GeneralgaladrialAinda não há avaliações

- VESSM001 (Specification For Small Pressure Vessel and Heat Ex Changer)Documento12 páginasVESSM001 (Specification For Small Pressure Vessel and Heat Ex Changer)dwpurna100% (1)

- BBB1776 VER3-RevDocumento13 páginasBBB1776 VER3-RevfesamuelAinda não há avaliações

- Att#20 - 7077T-000-PP-0000-108 - 00 List of Codes and StandardsDocumento62 páginasAtt#20 - 7077T-000-PP-0000-108 - 00 List of Codes and Standardsabdelmalek boudjemaaAinda não há avaliações

- 3.3 Piping Design Criteria Rev 2Documento15 páginas3.3 Piping Design Criteria Rev 2Maheswaran KurusamyAinda não há avaliações

- Railway USSORDocumento123 páginasRailway USSORPrincipal DPWTCAinda não há avaliações

- The Payments Data Revolution: How ISO 20022 Is Transforming The Language of PaymentsDocumento12 páginasThe Payments Data Revolution: How ISO 20022 Is Transforming The Language of PaymentsEller100% (1)

- KBOB Empfehlung BACnet e 2017 v1.1Documento91 páginasKBOB Empfehlung BACnet e 2017 v1.1testAinda não há avaliações

- SRS 2Documento46 páginasSRS 2AritroAinda não há avaliações