Escolar Documentos

Profissional Documentos

Cultura Documentos

Distillation Column Operation Guide

Enviado por

Raffi RichardDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Distillation Column Operation Guide

Enviado por

Raffi RichardDireitos autorais:

Formatos disponíveis

Distillation column

The studies on distillation column suggest the following objectives:

1. Product quality control to maintain either the overhead or bottom composition at a

specified value

2. Material balances control to maintain its column hold-up and overhead and bottom

inventories between maximum and minimum limits.

3. Constraints. The column should not flood. Pressure should be high enough to maintain

effective column operation and the temperature difference in the reboiler should not

exceeded critical temperature difference.

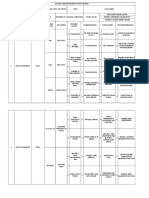

HAZOP Studies on Distillation Column

Guide

word

NO

Deviation

No flow

Possible

causes

Pipe blockage

Control valve shut

Valves fail

Tube leakage and

blocking

Pump failure

Consequences

Column dry out

Possible

dangerous

concentration

No operation

LESS

Less Flow

MORE

More flow

Pipe blockage

Control valve shut

Valves fail

Tube leakage and

blocking

Pump failure

Control valve is

fully opened

Increase pumping

capacity

Control valves

failure

Column dry out

Changes in

product quality

Flooding in the

column

Changes in

product quality

Temperature

decrease

Rise in bottom

Action

required

Install low level

alarm

Check

maintenance

procedure and

schedule

Make bypass

Emergency plant

shut down

Install low level

alarm

Check

maintenance

procedure

Make bypass

Emergency plant

shut down

Install high level

alarm

Check

maintenance

procedure and

schedule

Install control

liquid level

HIGH

High

pressure

High

Temperature

LOW

Low

pressure

Vapor pressure high

Pressure indicator

controller fail

Instrumentation

failure

More steam flow

Exchanger tube

failure

High steam pressure

Cooling water in

condenser failure.

Reboiler control

failure

Heating medium

leak into process

Vapour line leakage

Low

temperature

Instrumentation

failure

Less steam flow

Loss of heating

(steam leakage)

Low steam pressure

and temperature

Ineffective isolation

Low efficiency

of separation

Rupture of

column or other

related

equipment

Product loss

Separation

cannot be done

Changes in

product quality

Column

flooding

Film boiling in

column and

reboiler

Phase effect

Pressure

changes

Low efficiency

of separation

Loss of

products

Pressure change

Product loss

Changes in

product quality

Ineffective

separating

process

Phase effect

valves

Install flow

indicator

Make bypass

Install high

pressure alarm

Install pressure

relief valve

Install temperature

indicator

controller

Instruct operator

on procedure

Attention to heat

input and output

control

Install pressure

indicator

Install temperature

indicator

Instruct operator

on procedure

Upgrade isolation

Attention to heat

input and out

control

Você também pode gostar

- Distillation Column HAZOPDocumento6 páginasDistillation Column HAZOPAhmer SohailAinda não há avaliações

- Chapter 7 HazopDocumento11 páginasChapter 7 HazopMohd Azman Suwandi50% (2)

- HAZOP Study of Methanol, Ethanol, and Water Distillation ColumnDocumento7 páginasHAZOP Study of Methanol, Ethanol, and Water Distillation ColumnEng MohammedAinda não há avaliações

- Hazop Study On Distillation ColumnDocumento6 páginasHazop Study On Distillation ColumnEngineer Zaid100% (2)

- HAZOP Workbook-Distillation Column 101-102Documento4 páginasHAZOP Workbook-Distillation Column 101-102Ibrahim Nick DibalAinda não há avaliações

- C-102 Distillation Column Process Parameters and DeviationsDocumento5 páginasC-102 Distillation Column Process Parameters and DeviationsPutri SaidatinaAinda não há avaliações

- HAZOP On Distillation ColumnDocumento1 páginaHAZOP On Distillation Columnmuhammad arslan100% (1)

- HAZOP AnalysisDocumento35 páginasHAZOP AnalysisGopi Krish100% (3)

- Hazop For CSTRDocumento3 páginasHazop For CSTRRomel Leo100% (1)

- HAZOP for R-101 Reactor Process ParametersDocumento2 páginasHAZOP for R-101 Reactor Process ParametersHudaAinda não há avaliações

- Plant Design CP5062 HAZOP Example For Hui BeeDocumento22 páginasPlant Design CP5062 HAZOP Example For Hui BeeNoel Kristian0% (1)

- Distillation Column ReportDocumento81 páginasDistillation Column ReportJaspreet Singh67% (9)

- HAZOP ReactorDocumento9 páginasHAZOP ReactorChadGayle100% (9)

- Senior HazopDocumento113 páginasSenior HazopKongWeiHern100% (7)

- HAZOP Write UpDocumento3 páginasHAZOP Write UpGlacier RamkissoonAinda não há avaliações

- Hazop.1092475 Appendix 30.hazopDocumento67 páginasHazop.1092475 Appendix 30.hazopAudrey Patrick Kalla50% (2)

- HAZOP Flash DrumDocumento3 páginasHAZOP Flash DrumNurshahirahSapian75% (4)

- Hazop EvaporatorDocumento2 páginasHazop Evaporatorchemeng22033% (3)

- Final Design - Assignment IIIDocumento67 páginasFinal Design - Assignment IIIAmilcarwalter67% (3)

- HAZOPDocumento11 páginasHAZOPNathan Naelz Sandy100% (1)

- HAZOP Neautralization ReactorDocumento4 páginasHAZOP Neautralization ReactorIssyahira Ernie100% (1)

- HAZOP FinalDocumento2 páginasHAZOP Finalchiang95100% (3)

- Distillation Column Report PDFDocumento81 páginasDistillation Column Report PDFpavan kumarAinda não há avaliações

- HAZOP Centrifuge and DryerDocumento82 páginasHAZOP Centrifuge and Dryercharmerds0% (1)

- Distillation Column DesignDocumento130 páginasDistillation Column DesignKhushboo Khanna100% (5)

- Pump HazopDocumento3 páginasPump HazopNick100% (1)

- Hazard and Operability Study (Hazop) : Dr. M. Azam SaeedDocumento39 páginasHazard and Operability Study (Hazop) : Dr. M. Azam SaeedMuhammad Bilal100% (1)

- HAZOPDocumento32 páginasHAZOPMaximiano Ferraz71% (14)

- Distillation Column - HeuristicsDocumento25 páginasDistillation Column - HeuristicsTrinityRVx100% (1)

- Mass Transfer Tutorial: Distillation Example Problem 2: Mccabe-Thiele MethodDocumento11 páginasMass Transfer Tutorial: Distillation Example Problem 2: Mccabe-Thiele MethodTapiwa KapondaAinda não há avaliações

- Hazop of FurnaceDocumento2 páginasHazop of FurnaceTouhidBinAnwarAinda não há avaliações

- Hazard and Operability Study (HAZOP) Safety Assessment On: University of Nottingham Malaysia Campus H82PLD Coursework 2Documento127 páginasHazard and Operability Study (HAZOP) Safety Assessment On: University of Nottingham Malaysia Campus H82PLD Coursework 2KongWeiHern100% (2)

- Ethylbenzene ProductionDocumento30 páginasEthylbenzene ProductionNurul Ain Ibrahim75% (4)

- Batch Distillation ExperimentsDocumento29 páginasBatch Distillation Experimentsytconstance50% (4)

- Lab Report CSTR in SeriesDocumento13 páginasLab Report CSTR in SeriesNisha Sharif100% (1)

- HAZOPDocumento18 páginasHAZOPMark GuevarraAinda não há avaliações

- No-Flow Process Deviations GuideDocumento5 páginasNo-Flow Process Deviations GuideAnonymous QqE5tcEa100% (5)

- Chapter 8Documento50 páginasChapter 8Amirul Izan100% (1)

- Effect of air velocity on wet bulb approach and pressure dropDocumento9 páginasEffect of air velocity on wet bulb approach and pressure dropDinesh Kumar Vijeyan100% (6)

- Energy Balance On Distillation ColumnDocumento4 páginasEnergy Balance On Distillation ColumnCecilia Tan67% (9)

- Exp 3-Vapor-Liquid Equilibrium UnitDocumento18 páginasExp 3-Vapor-Liquid Equilibrium UnitKhairulAzwanizam100% (2)

- Thermocouple and RTD Measurement Calibration ExperimentDocumento6 páginasThermocouple and RTD Measurement Calibration Experimenthellothere50% (6)

- Introduction to Acrylic Acid: Properties, Production, and UsesDocumento262 páginasIntroduction to Acrylic Acid: Properties, Production, and Useslucas100% (6)

- V-103 HAZOP Study Nodes and ParametersDocumento15 páginasV-103 HAZOP Study Nodes and ParametersEdna TanAinda não há avaliações

- Distillation Column EfficiencyDocumento33 páginasDistillation Column EfficiencyAldi StefanusAinda não há avaliações

- CPE533 Gas Absorption Full Lab ReportDocumento30 páginasCPE533 Gas Absorption Full Lab ReportFazsroul82% (11)

- Stimulation Production of Acrylic Acid Using Aspen Plus - CASESTUDYDocumento7 páginasStimulation Production of Acrylic Acid Using Aspen Plus - CASESTUDYkhairulAinda não há avaliações

- Design of A Continuous Distillation Column For A Multi Component MixtureDocumento45 páginasDesign of A Continuous Distillation Column For A Multi Component MixtureSerkan73% (11)

- Separator Drum HAZOP ExerciseDocumento1 páginaSeparator Drum HAZOP Exercisevijaymoorthy140% (1)

- Heterogeneous Azeotropic Distillation Column DesignDocumento67 páginasHeterogeneous Azeotropic Distillation Column Designvenkatesh801100% (1)

- Distillation Control PhilosophyDocumento18 páginasDistillation Control PhilosophyArjun Shantaram ZopeAinda não há avaliações

- Ethylene Glycol Full ReportDocumento559 páginasEthylene Glycol Full ReportAbdullah Znd100% (2)

- Lab Report Aspen Hysis UiTMDocumento12 páginasLab Report Aspen Hysis UiTMAhmad SiddiqAinda não há avaliações

- Chapter 3 - Batch ProcessesDocumento54 páginasChapter 3 - Batch ProcessesMuhamad Hazim Zaaba100% (1)

- Formaldehyde Production From MethanolDocumento40 páginasFormaldehyde Production From MethanolGreg Voloshenko83% (24)

- Chemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsNo EverandChemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsNota: 2 de 5 estrelas2/5 (1)

- Control Valve Sourcebook - Chemical Unit Operations: Distillation ColumnDocumento6 páginasControl Valve Sourcebook - Chemical Unit Operations: Distillation Columnkumar_chemicalAinda não há avaliações

- 12.0 RecommendationsDocumento9 páginas12.0 RecommendationsNurtasha AtikahAinda não há avaliações

- HAZOP Study GuideDocumento30 páginasHAZOP Study Guidegandalalake2002Ainda não há avaliações

- Hazop Work SheetDocumento15 páginasHazop Work SheetPablo Castro100% (1)

- Tell Me About YourselfDocumento8 páginasTell Me About YourselfRaffi RichardAinda não há avaliações

- 22 Appendix C Sizing CostingDocumento33 páginas22 Appendix C Sizing CostingRaffi Richard100% (1)

- Plant Design Final PDFDocumento150 páginasPlant Design Final PDFRaffi Richard89% (9)

- Yus Bianco ReportDocumento13 páginasYus Bianco ReportRaffi RichardAinda não há avaliações

- Basis 100 KG of Feed Solution Cool To 17 /100 KG H MW of Feed Solution 130.6 Kg/kmol MW of S Solution 108.6 Kg/kmolDocumento2 páginasBasis 100 KG of Feed Solution Cool To 17 /100 KG H MW of Feed Solution 130.6 Kg/kmol MW of S Solution 108.6 Kg/kmolRaffi RichardAinda não há avaliações

- Cycle EfficiencyDocumento17 páginasCycle Efficiencyrashm006ranjanAinda não há avaliações

- Property Manager Water Flush Checklist FINALDocumento3 páginasProperty Manager Water Flush Checklist FINALannieone23Ainda não há avaliações

- TOTFLEX Catalog PDFDocumento38 páginasTOTFLEX Catalog PDFSuhail EhtishamAinda não há avaliações

- Hydraulically Operated 4/2 and 4/3 Directional Control Valve Technical SpecsDocumento2 páginasHydraulically Operated 4/2 and 4/3 Directional Control Valve Technical SpecsVito LaudicinaAinda não há avaliações

- Minor LossDocumento2 páginasMinor LossYe Thiha MinAinda não há avaliações

- Ultra-Frac High Performance TraysDocumento4 páginasUltra-Frac High Performance Traysnatee8632Ainda não há avaliações

- Chapter 05 COMPRESSIBLE FLUID FLOWDocumento88 páginasChapter 05 COMPRESSIBLE FLUID FLOWnurfara39Ainda não há avaliações

- G06 Aryclic ProductionDocumento300 páginasG06 Aryclic ProductionJacky100% (1)

- 232B, 242B, 252B & 262B Skid Steer Loaders Hydraulic System Dual Self Level - Raise & LowerDocumento2 páginas232B, 242B, 252B & 262B Skid Steer Loaders Hydraulic System Dual Self Level - Raise & LowerPablo PorrasAinda não há avaliações

- Lir - Cv.truba Jaya EngDocumento7 páginasLir - Cv.truba Jaya EngbegateamAinda não há avaliações

- Cooling Tower - SPX Catalog PDFDocumento64 páginasCooling Tower - SPX Catalog PDFBruno de RossoAinda não há avaliações

- Anaerobic Treatment of Tequila Vinasses in A CSTR-typeDocumento7 páginasAnaerobic Treatment of Tequila Vinasses in A CSTR-typeProyectos Plantas De Tratamiento De AguaAinda não há avaliações

- A Check Valve in The Chiller BypassDocumento5 páginasA Check Valve in The Chiller BypassGaye KanalAinda não há avaliações

- GRP Products for Industrial ApplicationsDocumento16 páginasGRP Products for Industrial ApplicationsRaghAinda não há avaliações

- Methven Nefa Pressure Reducing Valves ReferenceDocumento36 páginasMethven Nefa Pressure Reducing Valves ReferenceLen Salisbury100% (1)

- Uniform Channel Flow - Basic Concepts: Hydromechanics VVR090Documento34 páginasUniform Channel Flow - Basic Concepts: Hydromechanics VVR090intern kncesbAinda não há avaliações

- Cbe 555: Chemical Engineeringconnections: Impact of Chemical Engineering On The Outside WorldDocumento22 páginasCbe 555: Chemical Engineeringconnections: Impact of Chemical Engineering On The Outside WorldsereptAinda não há avaliações

- Flow Assurance Nov6Documento5 páginasFlow Assurance Nov6Vinh PhamthanhAinda não há avaliações

- FM200 ItDocumento10 páginasFM200 ItNguyễn Bửu ThắngAinda não há avaliações

- CRP Sampling LiteratureDocumento24 páginasCRP Sampling LiteratureSDP02Ainda não há avaliações

- The Calculation of Fixed Tubesheet Exchangers According To ASME Section VIII Division1Documento15 páginasThe Calculation of Fixed Tubesheet Exchangers According To ASME Section VIII Division1AKSHAY BHATKAR100% (1)

- Federation of European Heating, Ventilation and Air-Conditioning AssociationsDocumento41 páginasFederation of European Heating, Ventilation and Air-Conditioning Associationsslymerdak100% (1)

- Gate Solved Paper - Me: Heat TransferDocumento38 páginasGate Solved Paper - Me: Heat Transferrudresh JmAinda não há avaliações

- INQU 4010 - Chapter 7 - Dimensional Analysis and Similitude - CAVDocumento30 páginasINQU 4010 - Chapter 7 - Dimensional Analysis and Similitude - CAVCoral Del MarAinda não há avaliações

- Indicating Valves Butterfly or Ball Type 1Documento1 páginaIndicating Valves Butterfly or Ball Type 1Omar ElamirAinda não há avaliações

- HT3eChap11 103Documento31 páginasHT3eChap11 103msdhiman2003Ainda não há avaliações

- Packed Bed AbsorptionDocumento4 páginasPacked Bed AbsorptionSenthilNathanAinda não há avaliações

- Goulds Jet Pump InstallationDocumento12 páginasGoulds Jet Pump InstallationArnold DelinaAinda não há avaliações

- Assignment 1Documento3 páginasAssignment 1Anubhab SahuAinda não há avaliações

- List of Indian Standards For Fire Fighting: Revision)Documento2 páginasList of Indian Standards For Fire Fighting: Revision)Nanu PatelAinda não há avaliações