Escolar Documentos

Profissional Documentos

Cultura Documentos

Design of Lifting and Tailing Lugsnetsc001 PDF

Enviado por

Shirley Farrace0 notas0% acharam este documento útil (0 voto)

15 visualizações30 páginasTítulo original

design_of_lifting_and_tailing_lugsNetsc001.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

15 visualizações30 páginasDesign of Lifting and Tailing Lugsnetsc001 PDF

Enviado por

Shirley FarraceDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 30

P. DESIGN OF LIFTING AND TAILING LUGS

203

Ad, GH, J, K

B

c

D

D3

F

R

t

bab

N

S,P,E

8

t

t

v

w

Ww

Zz

:

a

oy

o

os

oO

%

ow

Ser Fea

LIST OF SYMBOLS

shackle dimension

width of lug plate

= centroidal distance

lug plate width at the pin.

bolt circle diameter

= lift load at each lug

= talling lug load

vessel wall stress factor

dimensions of lug plate

number of bolts for the nozzle

dimensions of trunnion

lug thickness

lug plate thickness

collar plate thickness

thickness of vessel shell

weld size

weight of vessel

section modulus

angle of vessel from horizontal

stress ratio, o,/o,

allowable bending stress

allowable bearing stress

allowable shear stress,

allowable tensile stress

vessel stress

allowable stress in the weld

bending stress in lug plate due to angle e

angle of lift cable from vert.

204

A. PURPOSE

This design guide describes methods of selecting and designing different types of lifting

and tailing devices for use in the erection of pressure vessels.

B.' CODES AND STANDARDS -

Since lifting or tailing lugs are non pressure retaining structural members, vesse! codes

or Standards are not applicable in the design of these lugs. Good engineering practice

and the recommended procedures given in the AISC Steel Construction Manual are all

that are needed.

C. TYPES OF LIFTING/TAILING LuGs

Besides slings and attachments improvised in the field, lifting lugs for towers, reactors and

other pressure vessels can be broadly classified into (1) the ear type, (2) trunnions, and

(3) the top nozzle blind type. See Fig. 1.

By far the most common are the ear type lifting lugs. These are usually installed at the

top of the vessel and can be used for most vessels, especially large towers. Because of

their location, interference with vessel appurtenances, such as platforms and ladders

below the top head is not very critical. See Section 1.

When a tower is unusually tall, so that lifting it will require a large crane and/or a long

boom, or will produce excessive bending stress in the vessel as a beam, the trunnion

type lifting lugs may be more suitable. ‘These are attached to the vessel shell some

distance down from the top head. In using this type of lugs, the interference of the lifting

cables with external ladders, platforms, nozzles, etc. attached to the vessel above the

lugs, from the tying down to the up-right position of the tower should be carefully checked

and avoided. See Section. 2.

Most heavy wall vessels have a large and strong nozzle located at the center of their top

head. With a special bolted attachment, this nozzle can be used for the erection of the

vessel. This type of lifting blind is especially attractive when there are several vessels

with the same size and rating top nozzles, so that one such lifting blind can be used on

all ofthem. Even if the top nozzles were of different size, a special lifting blind can usually

be designed to adapt it to more than one nozzle size. The advantages of the top nozzle

liting blind are economy, little interference with vessel appurtenances, and elimination of

welding to the vessel which can cause stress risers that are undesirable in some critical

vessels. See Section; 3.

In uprighting @ vessel from the horizontal to its vertical position, a pivot point, which is

also capable of sliding toward the vessel foundation, is needed. This point can be

provided simply and relatively inexpensively by a tailing lug. The design of tailing lugs is

described in Section © 4, .

2l0

1, _ EAR TYPE LIFTING LUGS. (FIG. 2)

1.1. In designing a lifting lug, the first thing to do is to determine the lift load. Normally

a vessel is lifted in the empty state, but in recent years, the trend has been to lift it fully

dressed. That means the vessel will have insulation, some piping and all non-interfering

ladders and platforms installed on it during lifting. Whatever the méthod of erection,

determine the lift weight, W, multiply it by an impact factor, and then divide it by two to

obtain the lift load, F, for each lug. The impact factor can vary from 1.25 to 2.0. The

commonly used value is 1.50. Thus:

1.50", a)

=0.75W

When the lift employs a tailing lug, the lift load is reduced in proportion to the relative

distances of the lifting and tailing points from the center of gravity of the vessel. However,

when the column is nearing its vertical position, the tailing device is going to be removed.

Then the lifting load will be as calculated in Eq. (1).

1.2._Iniifting, the field uses standard shackles with safe working load ratings determined

Yrom the minimum breaking loads with a safety factor of 5. Based on the lift load from

Eq. (1), choose a shackle size from Table 1.

_1.3. The dimensions of the shackle selected will determine the lug pin diameter, d, the

lug thickness, T, at the pin joint, and the lug projection, L, to provide clearance between

the shackle and the vessel. The lug pin diameter can also be determined based on its

shearing strength as in (21.6 below.

1.4. Although the lug pin may be conservatively sized so that it can take some bending

as well as shearing, it is best to keep the difference between the shackle dimension, G,

and the lug thickness, T, to a minimum, usually from 3/32" to 3/16",

4.5 The width of the lug plate, D, at the pin is set equal to 3d minimum.

“4.6 Lug Design (See Fig. 3 for different failure modes)

4. Determine lug pin diameter from either the commercial shackle size 1.3) or

@

21

2. Determine lug plate thickness t from

FE . Fr @

ae se? Faq7

3. Find lug thickness. T = t + 2t,, to suit the shackle 1.3) or from

(4)

F E é

Fe Re

P

4. “If collar plates are not used, t, = 0, then t = T, and the lug pin may have to be

checked for combined shearing and bending loads, especially where T< Bz,

tB?/é to, ©

1.8 The combined tensile and bending stress in the lug plate should be checked when

the vessel is lifted into a position where the axis is at an angle « from the horizontal.

(See Fig. 4). If excessive, B should be increased to reduce this stress

Fsine , 6Flcosa ©)

tbo," e5%0,

Ifo, is taken equal to A

th, 2% tbo,

Combined stress,

22

Coop §S @ maximum at a certain angle, ,, Such that

d F ~8 FL singe

Ge Com) “Fycosa-$ FE sinaso :

Thus

62 cine

cosa- (75) sina=0

‘Therefore, stan" (22)

If A= 10 chen a, = tan*(2)

= 6L

(7a)

If o,71.50, , 4=1.5, then a,stan*(—2)

4b

(7b)

1.9 In calculating the lift load, F, the eccentricity of the tailing load has to be

considered.

From Fig. 5

W(1,cosa+1,sina) ©

2pa—an200Se+h sing) _

T,c0sa+I,cosa+1,sina

Fux (Impact factor)

4.10 Stress in the weld for direct load, F, is

FE

0.7 (B+2L,) o, 5"

214

Centroidal distance, C, of the weld is

2

os

3E8

Moment about the weld centroid = F (L +L, -C)

Replacing the U shape weld conservatively with an approximate rectangular shape weld,

where L, = 2C,

then: Polar moment of inertia = 1.4 t, BC (C+'4B)

2.4t,ac(c+da)

VCrB*74

Polar section modulus =

Stress due to moment 10)

P(Ltly-O VEE TE we)

1. 4BC(C-B/2) b,

From the combination of stresses (8) & (10), the weld size t, can be determined.

If L, is made equal to B, the above expressions can be simpiiied:

B

Moment =F (L+8-2) =F(L+0.6678)

=1 2) (2s3) en 2

T=2.4(B) (2) (F+3) t-0.3898%t,

0.3895,

-647B7t,

VB°/S+B*/4

Lig

F 1 F(L+0.6678) _

0.7 (B+2B)C, 0.647B?t, Bt,

(1.5432+1.5072)

Using an allowable stress for the weld ,, = 13500 psi, we have:

: 7 (11)

tee (0.2242+0.112B) 10~

Table 2 shows weld size, t,, per 1000 Ib. of lift load, F, for various ratios of L/B.

TABLE 2 - WELD SIZE t, INCH PER 1000 LB. LIFT LOAD

ue as lie s 12" 15° 18" aig 24"

0.75__| 0.066_| 0.033 _| 0.022 | 0.016 | 0.013 | 0.011 | 0.009 | 0.008

1.0 0.075 _| 0.038 | 0.025 | 0.019 | 0.015 | 0.013 | 0.011 | 0.009

1.25 {0.085 | 0.042 | 0.028 | 0.021 | 0.017 | 0.014 [0.012 |-0.011

1.5 0.094 _| 0.047_|'0.031_| 0.024 | 0.019 [0.016 | 0.013 | 0.012

1.75__| 0.104 | 0.052 | 0.035 | 0.026 | 0.021 | 0.017 | 0.015

2.0 0.113 | 0.057_| 0.038 _| 0.028 | 0.023 | 0.019 | 0.016

2.25 | 0.123 | 0.061 | 0.041 | 0.031 | 0.025 | 0.020 | 0.018

25 0.132 _| 0,066 _| 0.044 | 0.033 | 0.026 | 0.022 | 0.019 | 0.017

2.75 0.142 | 0.071_| 0.047 | 0.035 | 0.028 | 0.024 | 0.020 | 0.018

3.0 0.151 _| 0.076 | 0.050 | 0.038 | 0.030 | 0.025 | 0.022 | 0.019

411 In order to keep the lifting cable vertical, 2 spreader bar is used. When the

‘spreader bar is not available or not to be used, then the cables will make an angle with

the axis of the vessel. This will produce out-of-plane bending of the lug plate. If the cable

angle is 8°, the corresponding bending stress in the lug plate is

6FisinO1

ee (12)

‘The maximum allowable angle to ensure og, < 0, is

1, Bt?a,

(ae 7 13)

ee ar) (43)

eS

ze

To reduce this bending stress, a bracing plate may be used tying the lug plate to the

vessel head at a distance L, from the lug pin. The reduced bending stress is now

00, () a9, (14)

The load on this bracing plate, F sine, is rather small for small angles, 8. Therefore its

thickness, t,, and the weld sizes usually are minimal. For very large angles of, this plate

should be properly designed.

2, TRUNNIONS (Fig. 6)

‘Trunnions are used to erect vessels that are too tall to be lifted by lugs located at the top

head. There are generally 3 different types of trunnions. The most common is the fixed

pipe, fixed plate type. Sometimes, for clearance purposes, the lug plate has to be made

very long. In order to prevent the high twisting moment at the pipe-vessel attachment,

the lug plate is allowed to turn over the lug pipe. When the lug pipe projection has to be

large, again for clearance purposes, the bending moment at the vessel attachment may

be very high. This will produce excessive stress and distortion in the shell, especially in

large diameter, thin wall vessels. In this case, a turning axle type trunnion can be used.

2.1 _As for the ear type lifting lug in Sectior_.1, determine the lift load, shackle size, pin

diameter and lug plate thickness.

2.2 For the tuming plate trunnion, the dimension, s, is determined by

(15)

F F i

Zst <7 or "Fro,

2.3. The trunnion pipe size is determined by either its bending strength:

(16)

or its torsional resistance:

(17)

FL

ge

or its shear resistance: P (18)

ae

where A, = cross-sectional area of the lug pipe

14

Ze

(19)

In addition: FLLP

az ast

2.4 For the rotating axle type trunnion, the pipe diameter, P, is determined from:

7 EF

Fa 20)

2.5 Weld size, t,, is determined from

FE 455705 @)

O.7xPt,” Pe, *°*

or from

0.91FE ., (22)

o.7e(n et) PPty

2

or from

1.82FE

Pe “TPE oY

x(2)(0.78,) ™

7

(23)

2.6 Except in the case of the turning axle trunnion, the lift load on the trunnion

produces local stresses in the vessel shell. These need to be evaluated using WRC

Bulletin 107 or other similar methods. A simplified way to check the vessel stresses is:

(Fig. 7 Solid Lines).

(24)

£,(42) <0,

In checking the stress of the vessel in the vertical position, when the load F represents

the entire vessel weight not reduced by any tailing load, use the stress factor given by the

dashed lines in Fig. 7.

When the vessel wall stress is excessive, use a reinforcing pad. The stress is dependent

on the combined vessel and pad thicknesses at the edge of the trunnion pipe and on the

vessel thickness at the edge of the pad.

27

2.7. After a vessel has been erected, the trunnion lifting lugs are usually cut off. In the

case of the tuming axle type, the lug is cut apart and the axle withdrawn. The openings

in the vessel are covered by welded plates or bolted flanges.

3. TOP LIFTING BLINDS

Heavy wall vessels have sturdy nozzles. if there is a large central nozzle in the top head,

it can usually be utilized to lift the vessel into place. A specially designed liting blind is

bolted to the top nozzle, and lug plates are welded to the biind for attachment of the lifting

shackle, When there are several vessels with the same size top nozzles, one lifting blind

can be made to lift all of them. Even if the top nozzles are of different size and/or rating,

the lifting blind can be designed with different sets of bolt holes to fit more than one size

of nozzles.

3.1. In lifting, usually not all the bolts for the top nozzle are used. if only half of the

nolts are used, the load on each bolt due to a moment is approximately 22% more than

if all the bolts are utilized. In checking the adequacy of the botis, the following concitions

have to be satisfied:

ML Bolt capacity in tension’ (25)

2F, -

+s Bolt capacity in shear (28)

2F, apa

Fs Bott capacity in tension (27)

Where —_F, = max. load on the lug when iting angle a = 0

(vessel in horizontal position)

lifting load when vessel is in the vertical position = W. impact factor.

E = distance from lug pin center line to biind flange back face. See Fig8.

4, = thickness of blind flange.

N. = total number of bolts for the nozzle.

3.2. Design of the lug plate, that is to be welded to the blind, follows the same

procedure as for the ear type lug.

3.3 A conservative way to determine the thickness of the blind is to design it for the

pressure equivalent to the max. moment acting on it at the initial lifting condition. This

moment equals F,(E+t) and the equivalent design pressure

16F, (E+ty)

RGp 5

where G, = gasket diameter of the flange.

and the blind thickness is:

e (232#)-< 4.8F, (E+)

° oS “ =Gpa,

By assuming an initial value of 2" for t, and using the bolt circle diameter D; as G,, we

have

(28)

ifthe calculated t, is much different from 2", another iteration may be done. In any case,

do not use t, less than the lug plate thickness determined in 3.3.2 above. The equivalent

Pressure due to the force F, on the lug is relatively insignificant.

3.4 Examples of one lifting biind fitting two sizes of nozzles are shown in Fig. 9.

4, TAILING LuGs

In iting a tall vessel, whether by lifting lugs attached near the top head, or by trunnions

located lower down the shell, a tailing lug is usually required to lift the entire column off

the ground in order to facilitate the uprighting of the vessel. Since most vertical vessels

have skirt supports, the tailing lug is usually attached to the bottom of the vessel to take

advantage of the stiffness of the base ring there, Unless the tailing load is unusually

large, only one lug is required. See Fig. 10.

4.1 Design of the lug plate again follows the same procedure as for the ear type.

4.2 Check stresses in the base ring-skirt section

Max. moment = .2887 FR

where F, = load on the tailing lug.

LG

Generally the skirt plate is welded approximately to the midgle of the base ring. It does

not therefore contribute much to the section modulus of the section. Thus the bending

stress in the base ring during the lift is

w44F, ,

one where t, and B, = thickness and width of the base ring.

2 (Bo, -

When this stress is too high, a strut can be welded diametrally between the tailing lug and

the other side of the skirt, The force on the strut is approximately haff the tailing load,

and the moment in the base ring section will be reduced to about a third of that without

the strut. See the derivation in Appendix A.

In the case when the skirt plate is not centrally located on the base ring, a portion of the

skirt plate will act to resist the bending moment in the ring section, will increase the

section modulus of the base ring appreciably, and should therefore be taken into

consideration. If a second ring also exists, then the section modulus will be further

substantially increased. The length of the skirt plate that can be included in the base ring

section, varies with the skirt diameter and its thickness, but for simplicity, use

conservatively a length equal to 12 times its thickness. If a second ring exists, then this

length shall be taken beyond the second ring.

D. MATERIALS

Lifting and tailing lugs are structural elements that are used only for a short time during

the erection of vessels. For this reason, the most common structural steel A-36 is

adequate. However, parts of the lugs that are welded directly to vessels which are

constructed of alloy metals, such es Cr.Mo. steel, stainless steel, no-ferrous metal, etc.,

should preferably be of the same type of material as the vessel.

-105 and A-53-B respectively, except as

Forgings and pipes will also be carbon steel:

noted above.

E, ALLOWABLE STRESSES

Unless otherwise specified, use the following allowable stresses

38 Tensile - 20,000 psi

A-105 Bearing - 30,000 psi

A-53 Shear- 13,500

Bending - 22,000 psi

C.S. Welds: Full penetration - 20,000 psi

Shear - 43,500 psi

Vessel Stress: Membrane - 1.28

Bending - 1.5S

where S = code allowable tensile design stress.

ZLo

F. RECOMMENDED PROCEDURE

1_ Determine from Construction, the type of lifting to be used: from the top of the

vessel or lower down the shell; whether the vessel will be bare or insulated with platforms

and ladders installed; whether a’spreader beam will be used; whether a large sturdy

nozzle will be available on the top head for lifting, etc. Then choose the appropriate lugs

to be designed.

2 Calculate the lift load at each lifting lug, and if tailing lug is going to be used,

calculate the lift and tailing loads. See paragraph “1.1.

3 Design the lugs per sections 2. Sor 4.

4 Forward the lug design to the fabricator of the vessel on which the lugs are to be

installed.

5 When design of the lifting and tailing lugs is the responsibility of the vessel

fabricator, use this Design Guide to check the latter's calculations.

6 _ After erection, remove the lugs from the vessel as necessary, and patch up the

openings where the rotating axle type trunnion has been used.

G. REFERENCES

Formulas for Stress and Strain by R. J. Roark

Local Stresses in Spherical and Cylindrical Shells due to External Loadings, WRC Bulletin

107, by K. R. Wichman, A. G. Hopper and J. L. Mershon

Zu

ANCHOR SHACK

OROP FORGED STEEL. WELOLESS.

BRIGHT. HEAT TREATED)

ss Tew os

TRUNNION

FIGURE _1——LIFTING LuGs.

FIGURE 2——EAR TYPE LIFTING LUG

ezd

FIGURE 3——LIFTING LUG DESIGN

LUG PIN SHEARING

LUG PLATE TENSILE

LUG PIN BEARING

LUG TENSILE

LUG SHEARING

aia)

ga: EG

sary * GF

F

ame

eGR)

+ ¢ Grey)

a

ara

oe

array

FE

marae EG)

Tevsaramy © o THeaHy

Zur

GUI EA eee ANG Ee Ohm el nul

REGULAR TAILING LUG TANGENTIAL, NO_TAILING LUG

(ly 1S POSITIVE) TAILING LUG (ly IS NEGATIVE)

(1y=0)

FIGURE 5——LOCATION OF TAILING LUG

226

FIGURE 6——TRUNNIONS|

227

1

fyF

vesset stress 45%

a

{ TE

4

STRESS FACTOR.

VESSEL WALL

+08

+06

+04

-02|

0.02.04 .06 -08 -10 -12.14 .16 18.20.22 .24 26.28.30

TRUNNION DIAMTER

VESSEL DIAMETER

FIGURE 7——VESSEL STRESS FACTOR

2Z2

LIFTING BLIND

FIGURE 8

229

(16) 1h" HOLES ON 39/478.C. FOR

30” 300% FLANGE

(12) 1%" HOLES ON 32°8.C. FOR

24* 3008 FLANGE

(16) 24" HOLES ON 40'4°8.C. FOR

30° 600% FLANGE

(12) 27HOLES ON 33°8.C. FOR

24° 600# FLANGE

FIGURE 9——LIFTING BLIND

BOLT PATTERNS

240

CHAIR OR RING

FIGURE 10——TAILING LUG

Z4al

Desivatian of 4ing Moment

(D Increase in diameter due ro lead Wi-Ws 15+

2 yf, 5 = o 3

Dy FEB [3183 (s00e)- Z] = 2 eel WIR

UL) Decrease in hhameter due 7 load We 1s:

Dy= = 0784 WR?

(Fa

(DB) Elongation of Stret due 10 load We is

=2HR

4f1-~6

20788 (We-Ws JR? O74 Ws RF = 24R

él ZI AE

20372 WiR* _ Ws , .07¢AWsR?

z =

The tirst term en the cight sie us small compared

%o the second term, and can be neglected.

2 M=2Ws or We=FmM

Zar

From Keoark ,

Mament in the ring due ty outward oad 13.

My =(Wi-WS)RU. 2387 cos x~.S 0X 44892 (Asin ¥4/-Cosx))

Moment due to inward /oad 1s:

Maz WSR L 2387 cos (0-4) -.5 sin (I-A) P1892 [STH

+/- Cos or-ay)

= WR (-.2387 cosX- Son b.iste fir-asing t/t ccs)

No Strut Strut |

Mi Ma Ma 2M | M=NMitM2

OC |t. 1/94 WAR |-.0398 WR |4.2388 WR |40796 WR

Ye__|+.0099 WR |-.0243 WR \9.0198 WR \-.0188 WR |

Ys \-0449 WR |4.0124 WHR |-0898 WR |-.0325 WR

Te__|-0ase wR |4.045¢W:R 0908 WR) 6

12% | -.0128 wR | 4.0449 Wik 0248 Wer! #0525 WR!

[°% _|7.0243 wir |-.0099 WR | 4.0886 WR|-.0184 WER

W_|4.0398 WR \-.1194 WiR | 4.0796 WR\|-.0796 WR

W

29?

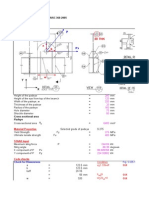

Sample Problem

Gwen: Clumn 60°08 1000 T/T ples 11 A shirt

We with trays, nsulaten and platforms

=F Aips

Center op gravity : 50% from base

Vessel phichness: Le top third , Fb miildle

third, and Ya" bette phird, Shirt 28.

LA poem (A) pear rhe Sop head.

(8) $5-60' fromm base.

Required: Lifting (ug design

Ya" we

0"

A) Ear Type Lifting Lug

Mex. tit load (vecrical, failing load =0)

FF Xs3sx1s = ot ead, 0 a Yens/ lug)

Horiz. htt load = Ca Fx/3$x/ Sx ZS = 45 Kips / hig

From Table 1, a size 3" anchor shackle /s reguueds

S* 344" (pin)

GOgrp)= 8). Use lug thick. 7 = 478

From on 8), ig plate thickness |

421 — ag.s2" Use 14" plate

eee SAG “373. 25420

24¢

Gller plate rhich. t= £0913 U4) 21.81". Use Veo

Assume dimension L =/2"

Thea xoom Eg.(5), a

Width of bug plote 8 2) GE = 10.9 Use 12°

Since Bis tihen rs be 22 ksi, ane! Op+ 204s)

A= Woz 7

- Max. combined stress rn the 1g plate occurs at

= typ Ab 2 4 NB2 .

m= ten BE = fan GF = 10.4

e . BS8D104 | & E412 cos od

<. Combined stress = Tiga tg SSS

= 0.54 416,09 = 16.6 ksi < 20 ksi we OX.

Assume a weld heagth £3714" and a weld

size Ly= fe"

trom Eg09), for vessel in the foriz pater,

shear stress in lug atachmen? weld

= *Yorii242:14)10.5) = 3.2 ksi

7

Ceatrerdal distance CIEE 4AT

oo Moment about weld centroid

¢ = 4S (12t/4-4.9)= 950 ink.”

2

, Blar mers. of mertia of weld

eet

= [OSE a o.50/4 (7-09) }tOS8/244.9°

2 :

+ 210.5014 xb*4 PFE2* = ye/Q jn,*

solo .

Polar sechen modulus * TE897 = 92:7 in?

1 Tonsvoral stress due to mement = 980/927 =/0.2 ke!

tas

Combned shear stress tor vessel in heriz. position

= F2Zt102 = 13.4 hs! OK.

Shear stress in weld tor vesse/ i vert pest Teele

= 0lffa7 20 28)xa5] = 72 ksi OK.

wey

i

fl A 3 & of

pa

B) Truanien Type lug (assume tied pipe) (55 tem base)

Max. lift load! (vertee!)= Jol k.

May. litt load Uhoriz.)= 00511521354 22 = 92

As in example (A), 3" shackle 13 reguired:

A344 t= Ble

Assume dimensions E and L fo meet Clearance

requirements: E=8° , L/S

From Ep. Ub), Z of trunnion PRS + 9248/02 * 33.5 in

0G), Z of frunmen pipe ~ INS (2313.5) “S11 sir?

From €.8), Xsechenal area of pype = 103.5 = 725 mae

TS ,— es

22

. : $2u/S 92 :

ee ———— SS =

This stress exceeds 2/35 hss -

be HEKS pipes 22715 m2, Azbh2 tn, Ceomb=18 kes

heck vesse/ stress using fiz. 7.

ihe True Diem 1h

Toes 976 | FRR Re aig

OAs 0.083

Vessel Stress « BPS gg ps;

& “sng 2 Lh" rhyck Pad » Ce2078 10.8252 1.375"

Stress around pipe =(O0s3r $28 1378°= 1S ksi

Stress around rhe pad (assume reasonchle size)

wll stl be excessive.

+. @ turning axle Frumnion /'s recommended.

Bearing svress at shell pening = HOE =VSksi OK.

Ff size of weld between 1g plate anil pype end

. = fol

(3 18, then weld shress =Wilinieg 6-6 ksi Ck

227

Você também pode gostar

- Guideline Lifting Lug DesignDocumento10 páginasGuideline Lifting Lug Designye-kyaw-aung80% (10)

- PADEYE-AISC-360-2005 CalculationDocumento6 páginasPADEYE-AISC-360-2005 CalculationsaswattAinda não há avaliações

- Design and Verification of Lifting LugsDocumento3 páginasDesign and Verification of Lifting LugsFabio Okamoto100% (1)

- Dupont Design of Trunnions 1979Documento26 páginasDupont Design of Trunnions 1979mjjanowski100% (1)

- Lifting LugDocumento7 páginasLifting LugSajal KulshresthaAinda não há avaliações

- Spreader Beam DesignDocumento5 páginasSpreader Beam DesigntndeshmukhAinda não há avaliações

- EJMA Example 06Documento5 páginasEJMA Example 06Mayank GodhaAinda não há avaliações

- Three Saddle Supports For Horizontal VesselDocumento7 páginasThree Saddle Supports For Horizontal VesselhuangjlAinda não há avaliações

- Lifting LugsDocumento2 páginasLifting LugsAdi Cahyoko82% (11)

- Sendai Project Lifting Lug DesignDocumento6 páginasSendai Project Lifting Lug DesignkalpanaadhiAinda não há avaliações

- Rectangular Tubesheet Design Guideline by HEIDocumento6 páginasRectangular Tubesheet Design Guideline by HEIm5416Ainda não há avaliações

- 0488a0vvgc001 06Documento73 páginas0488a0vvgc001 06AlienshowAinda não há avaliações

- 28 Roark Flat PlatesDocumento4 páginas28 Roark Flat PlatesJorge Silva100% (1)

- Load analysis and strength evaluation of vessel lifting lugDocumento3 páginasLoad analysis and strength evaluation of vessel lifting lugMudasir MughalAinda não há avaliações

- CAL-ST-070!17!01 Rev01 Shipping Saddles CalculationDocumento11 páginasCAL-ST-070!17!01 Rev01 Shipping Saddles CalculationgiubelloAinda não há avaliações

- Lifting Beam CalculationDocumento2 páginasLifting Beam CalculationAvish ShahAinda não há avaliações

- AISI - Anchor Chair DesignDocumento3 páginasAISI - Anchor Chair DesignJoséSebastián86% (7)

- Vertical Vessel Circular Pattern Anchor Bolt Design - ACI 318M-14Documento4 páginasVertical Vessel Circular Pattern Anchor Bolt Design - ACI 318M-14jesusAinda não há avaliações

- Lifitng Lug Design (BS5950)Documento2 páginasLifitng Lug Design (BS5950)Aya MontesAinda não há avaliações

- CMAA Specification 74-2004Documento37 páginasCMAA Specification 74-2004Dasniel Salinas50% (2)

- Trunnion Lifting LugDocumento3 páginasTrunnion Lifting LugUnyong JoAinda não há avaliações

- DNV Standards For Certification No 2.7-1 Offshore ContainersDocumento60 páginasDNV Standards For Certification No 2.7-1 Offshore ContainersMichael CovillAinda não há avaliações

- KDS 41 17 00 2019Documento75 páginasKDS 41 17 00 2019Suso IglesiasAinda não há avaliações

- SEISMIC ANALYSIS KazzincDocumento14 páginasSEISMIC ANALYSIS KazzincArees KhambattaAinda não há avaliações

- Anchor Bolt CalculationDocumento8 páginasAnchor Bolt CalculationRajput Pratiksingh100% (1)

- Lifting ClampDocumento10 páginasLifting ClampwallachiaAinda não há avaliações

- Design of Crane Runway GirdersDocumento22 páginasDesign of Crane Runway GirdersScooby DooAinda não há avaliações

- Mathcad - 06-Loads On StaircaseDocumento2 páginasMathcad - 06-Loads On Staircasedinu69inAinda não há avaliações

- AISC 13th Slip Critical Bolt Capacity ASDDocumento1 páginaAISC 13th Slip Critical Bolt Capacity ASDdantevariasAinda não há avaliações

- Main Plnat Wind LoadDocumento780 páginasMain Plnat Wind LoadArmie May RicoAinda não há avaliações

- Design of Tail LugDocumento34 páginasDesign of Tail LugPrajwal Shetty100% (1)

- Special and Different: The Autistic Traveler: Judgment, Redemption, & VictoryNo EverandSpecial and Different: The Autistic Traveler: Judgment, Redemption, & VictoryAinda não há avaliações

- Strangers' Voices In My Head: A Journey Through What Made Me Who I Am from My MindNo EverandStrangers' Voices In My Head: A Journey Through What Made Me Who I Am from My MindAinda não há avaliações

- Installation of Underground Petroleum Storage Systems - 4th Edition, 1987 (API 1615)Documento38 páginasInstallation of Underground Petroleum Storage Systems - 4th Edition, 1987 (API 1615)Tshilidzi Irene NetseloAinda não há avaliações

- PER 2012 - Pressure EquipmentDocumento35 páginasPER 2012 - Pressure EquipmentTshilidzi Irene Netselo100% (1)

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocumento10 páginasEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosAinda não há avaliações

- 409 Ferritic Stainless SteelsDocumento14 páginas409 Ferritic Stainless SteelsTshilidzi Irene NetseloAinda não há avaliações

- BP Pressure Vessels GS146-2Documento66 páginasBP Pressure Vessels GS146-2Tshilidzi Irene Netselo100% (3)

- Bs 2573 Crane DesignDocumento72 páginasBs 2573 Crane DesignAnonymous 1HFV185Sl480% (5)

- 2.10 Thermomechanically Treated SteelslDocumento9 páginas2.10 Thermomechanically Treated SteelslTshilidzi Irene NetseloAinda não há avaliações

- Application of WRC Bulletins 107, 297, 368Documento3 páginasApplication of WRC Bulletins 107, 297, 368shivabtowin3301100% (3)

- Bolted Flange Joints and Connections - KovesDocumento15 páginasBolted Flange Joints and Connections - KovesTshilidzi Irene NetseloAinda não há avaliações

- Bsi 6501 1 04Documento30 páginasBsi 6501 1 04Debayan PalAinda não há avaliações

- SANS 347:2012: Categorization and Conformity Assessment Criteria For All Pressure EquipmentDocumento51 páginasSANS 347:2012: Categorization and Conformity Assessment Criteria For All Pressure EquipmentTshilidzi Irene Netselo100% (3)

- Article - Screw Threads DesignDocumento7 páginasArticle - Screw Threads DesignjdfdfererAinda não há avaliações

- Weld Repair ProcedureDocumento6 páginasWeld Repair ProcedureTshilidzi Irene Netselo75% (4)

- Baron Münchhausen's Tall TalesDocumento8 páginasBaron Münchhausen's Tall TalesTshilidzi Irene NetseloAinda não há avaliações

- Adjudication of Disputes in The Construction IndustryDocumento2 páginasAdjudication of Disputes in The Construction IndustryTshilidzi Irene NetseloAinda não há avaliações