Escolar Documentos

Profissional Documentos

Cultura Documentos

Husky H-Line Levelling & Parallelism

Enviado por

gfplmsDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Husky H-Line Levelling & Parallelism

Enviado por

gfplmsDireitos autorais:

Formatos disponíveis

Assembly Manual Hylectric Machines

Chapter 1 Machine Leveling (Mono Base)

NOTE: All parts of the MACHINE must be installed onto the BASE reference

the Assembly Instructional Procedures.

Leveling Pads

NOTE: Check the area for cleanliness where

the leveling mounts are positioned.

Clean all oil, grease, and wax buildup.

2 Heavily coated areas should be

scraped or sanded back to bare

concrete.

1 1. Ensure that the LEVELING PADS are in the

proper orientation.

NOTE: Labels must face outwards and the

PADS are in the direction of the mold

stroke column movement.

3

2. Loosen off the locknuts.

3. Preload all of the LEVELING PADS.

NOTE: The mount pads should protrude

3mm (0.125 in) from the bottom of the

MOUNT HOUSING. However, due to

floor irregularities, this condition may

only be set at the highest floor level.

Printed Copies are Uncontrolled

Revision: 1 Date Released: 2003/04/09 Page 1 of 4 Machine Leveling (Mono Base)

Hylectric Machines

Moving Platen Position

1. Position the MOVING PLATEN to maximum

shut height.

2. The table below indicates the distance

between the STATIONARY PLATEN and the

MOVING PLATEN.

Maximum Shut Height Chart

Machine Max. Shut Machine Max. Shut

Sizes Height Sizes Height

H90 500mm HL90 700mm

H120 550mm HL120 750mm

H160 HL160

H225 660mm HL225 900mm

H300 750mm HL300 1000mm

H400 850mm HL400 1100mm

H500 950mm HL500 1200mm

H650 1100mm HL650 1400mm

H800 1200mm HL800 1500mm

H1000 1300mm HL1000 1600mm

Printed Copies are Uncontrolled

Machine Leveling (Mono Base) Page 2 of 4 Revision: 1 Date Released: 2003/04/09

Assembly Manual Hylectric Machines

Level Positioning

6

1. Position the V-blocks on the RAILS or the

BASE at the STATIONARY PLATEN end.

NOTE: The location of the “V-Blocks”

depends upon the space between the

STATIONARY PLATEN and the

RAILS.

2. Position the “Straight Edge” across the “V-

4 Blocks”.

3. Place the “Precision Level” across the BASE

on the “Straight Edge”.

4. Place the “Precision Level” length ways on the

4 RAILS or BASE.

5. Center the “Precision Level” between the

MOVING and the STATIONARY PLATENS.

1 Also between the MOVING and the CLAMP

PLATENS.

3

6. Place a “Precision Level” on the machined

pad on the INJECTION end.

Level Adjustment (Length

Ways)

1. Adjust one side of the BASE, along it’s length,

from the CLAMP end to the INJECTION end.

2. Adjust the level of the machine at the end

where the “Precision Level” indicates the

maximum deviation.

3. Turn the bolt of the PADS to raise and lower

the machine as needed.

NOTE: The use of a PANCAKE JACK may be

required for heavier machines.

4. Check the level of the machine and ensure

that the level is within tolerance 0.10mm /

meter (0.001in/ 10") at the CLAMP end and

0.8mm / meter (0.008 in/10") at the

INJECTION end.

5. Level the other side of the BASE then check

and readjust the first side.

3 NOTE: Make sure that both sides are level

first before continuing to level cross

ways.

Printed Copies are Uncontrolled

Revision: 1 Date Released: 2003/04/09 Page 3 of 4 Machine Leveling (Mono Base)

Hylectric Machines

Level Adjustment (Cross

Ways)

1. Check the level on the “Straight Edge” with the

“Precision Level”.

2. Adjust the level of the machine at the end

where the “Precision Level” indicates the

maximum deviation.

3. Adjust all PADS on one side evenly to achieve

the proper level within a tolerance of 0.10mm /

meter (0.001in / 10").

NOTE: The use of a PANCAKE JACK may be

required for heavier machines.

4. Recheck the level length ways and adjust as

required.

NOTE: Both length ways and cross ways

must be level before leveling is

achieved.

Level Achieved

NOTE: When Length ways and Cross ways are

within tolerance, level is achieved.

1. Once level is achieved, tighten all locknuts.

2. Check the “Precision Level” to determine the

1 level is still within tolerance.

3. Return all Precision Levels back to the

appropriate locations.

Printed Copies are Uncontrolled

Machine Leveling (Mono Base) Page 4 of 4 Revision: 1 Date Released: 2003/04/09

Assembly Manual Hylectric Machines

Chapter 2 Machine Leveling for Assembly (Split

Base)

NOTE: All parts of the MACHINE must be installed onto the BASE reference

the Assembly Instructional Procedures.

Leveling Pads

NOTE: Check the area for cleanliness where

the leveling mounts are positioned.

Clean all oil, grease, and wax buildup.

Heavily coated areas should be

scraped or sanded back to bare

concrete.

1. Make sure that the LEVELING PADS are in

the proper orientation.

NOTE: Labels must face outwards and the

PADS are in the direction of the mold

stroke column movement.

2. Loosen off the locknuts.

3. Preload all of the LEVELING PADS.

NOTE: The mount pads should protrude

3mm (0.125 in) from the bottom of the

MOUNT HOUSING. However, due to

floor irregularities, this condition may

only be set at the highest floor level.

Printed Copies are Uncontrolled

Revision: 1 Date Released: 2003/04/09 Page 1 of 4 Machine Leveling for Assembly (Split Base)

Hylectric Machines

Moving Platen Position

1. Position the MOVING PLATEN to maximum

shut height.

2. The table below indicates the distance

between the STATIONARY PLATEN and the

MOVING PLATEN.

Maximum Shut Height Chart

Size of Max. Shut Size of Max. Shut

Machines Height Machines Height

H90 500mm HL90 700mm

H120 HL120

550mm 750mm

H160 HL160

H225 660mm HL225 900mm

H300 750mm HL300 1000mm

H400 850mm HL400 1100mm

H500 950mm HL500 1200mm

H650 1100mm HL650 1400mm

H800 1200mm HL800 1500mm

H1000 1300mm HL1000 1600mm

Printed Copies are Uncontrolled

Machine Leveling for Assembly (Split Base) Page 2 of 4 Revision: 1 Date Released: 2003/04/09

Assembly Manual Hylectric Machines

Level Positioning (Clamp End)

4 1. Position the “V-Blocks” on the Rails or the

BASE at the STATIONARY PLATEN end.

2. Position the “Straight Edge” across the “V-

Blocks”.

3. Place the “Precision Level” across the BASE

on the “Straight Edge”.

4. Place the “Precision Level” length ways on the

RAILS or BASE.

4

5. Center the “Precision Level” between the

MOVING and the STATIONARY PLATENS.

Also between the MOVING and the CLAMP

PLATENS.

1 3

Level Adjustment (Length

Ways)

1. Adjust one side of the BASE, along it’s length,

from CLAMP end to the STATIONARY end.

2. Adjust the level of the machine at the end

where the “Precision Level” indicates the

maximum deviation.

3. Turn the bolt of the PADS to raise and lower

the machine as needed.

4. Check the level of the machine and make sure

that the level is within a tolerance of 0.10mm /

meter (0.001in/ 10").

3 5. Level the other side then check and readjust

the first side.

NOTE: Make sure that both sides are level

first before continuing to level cross

ways.

Printed Copies are Uncontrolled

Revision: 1 Date Released: 2003/04/09 Page 3 of 4 Machine Leveling for Assembly (Split Base)

Hylectric Machines

Level Adjustment (Cross

Ways)

1. Check the level on the “Straight Edge” with the

“Precision Level”.

2. Adjust the level of the machine at the end

where the “Precision Level” indicates the

maximum deviation.

NOTE: Adjust all PADS on one side evenly to

achieve the proper level within a

tolerance of 0.10mm / meter (0.001in /

10").

3. Recheck the level length ways and adjust as

required.

4. Both length ways and cross ways must be

level before leveling is achieved.

Printed Copies are Uncontrolled

Machine Leveling for Assembly (Split Base) Page 4 of 4 Revision: 1 Date Released: 2003/04/09

Assembly Manual Hylectric Machines

Chapter 3 Machine Leveling for Integration (Split

Base)

NOTE: Make sure that the Electrical cabinet and the Power pack are

disconnected from the Injection Base prior to leveling the BASE for

integration.

Integration Assembly

1. Loosen off the bolts that attach the

INJECTION BASE to the CLAMP BASE.

2. Measure the GAP between the INJECTION

6 BASE and the CLAMP BASE.

3. If the GAP is not equal proceed to the next

step. If they are equal proceed to LEVELING

PADS.

4. Torque the bolts and lift the CLAMP at the

STATIONARY PLATEN end slightly.

5. Lower the Machine and loosen the bolts.

6. Measure the GAP between the INJECTION

BASE and the CLAMP BASE.

7. Make sure that the GAPS are equal.

NOTE: The difference between both sides

should not be greater than 0.05 mm.

8. If the GAPS are not equal repeat steps 4 to 6.

Printed Copies are Uncontrolled

Revision: 1 Date Released: 2003/04/09 Page 1 of 8 Machine Leveling for Integration (Split Base)

Hylectric Machines

Leveling Pads

NOTE: Check the area for cleanliness where

the leveling mounts are positioned.

Clean all oil, grease, and wax buildup.

Heavily coated areas should be

scraped or sanded back to bare

concrete.

1. Make sure that the LEVELING PADS are in

the proper orientation.

NOTE: Labels must face outwards and the

PADS are in the direction of the mold

stroke column movement.

2. Loosen off the locknuts.

3. Preload all of the LEVELING PADS.

NOTE: The mount pads should protrude

3mm (0.125 in) from the bottom of the

MOUNT HOUSING. However, due to

floor irregularities, this condition may

only be set at the highest floor level.

Printed Copies are Uncontrolled

Machine Leveling for Integration (Split Base) Page 2 of 8 Revision: 1 Date Released: 2003/04/09

Assembly Manual Hylectric Machines

Moving Platen Position

1. Position the MOVING PLATEN to maximum

shut height.

2. The table below indicates the distance

between the STATIONARY PLATEN and the

MOVING PLATEN.

Maximum Shut Height Chart

Size of Max. Shut Size of Max. Shut

Machines Height Machines Height

H90 500mm HL90 700mm

H120 HL120

550mm 750mm

H160 HL160

H225 660mm HL225 900mm

H300 750mm HL300 1000mm

H400 850mm HL400 1100mm

H500 950mm HL500 1200mm

H650 1100mm HL650 1400mm

H800 1200mm HL800 1500mm

H1000 1300mm HL1000 1600mm

Printed Copies are Uncontrolled

Revision: 1 Date Released: 2003/04/09 Page 3 of 8 Machine Leveling for Integration (Split Base)

Hylectric Machines

Level Positioning (Clamp End)

4 1. Position the “V-Blocks” on the Rails or the

BASE at the STATIONARY PLATEN end.

2. Position the “Straight Edge” across the “V-

Blocks”.

3. Place the “Precision Level” across the BASE

on the “Straight Edge”.

4. Place the “Precision Level” length ways on the

RAILS or BASE.

4

5. Center the “Precision Level” between the

MOVING and the STATIONARY PLATENS.

Also between the MOVING and the CLAMP

PLATENS.

1 3

Level Adjustment (Length

Ways)

1. Adjust one side of the BASE, along it’s length,

from CLAMP end to the STATIONARY end.

2. Adjust the level of the machine at the end

where the “Precision Level” indicates the

maximum deviation.

3. Turn the bolt of the PADS to raise and lower

the machine as needed.

NOTE: The use of a PANCAKE JACK may be

required for heavier machines.

4. Check the level of the machine and make sure

that the level is within a tolerance of 0.10mm /

meter (0.001in/ 10").

5. Level the other side then check and readjust

the first side.

3 NOTE: Make sure that both sides are level

first before continuing to level cross

ways.

6. Check the interconnection bolts while levelling

to ensure that they are loose.

Printed Copies are Uncontrolled

Machine Leveling for Integration (Split Base) Page 4 of 8 Revision: 1 Date Released: 2003/04/09

Assembly Manual Hylectric Machines

Level Adjustment (Cross

Ways)

1. Check the level on the “Straight Edge” with the

“Precision Level”.

2. Adjust the level of the machine at the end

where the “Precision Level” indicates the

maximum deviation.

NOTE: Adjust all PADS on one side evenly to

achieve the proper level within a

tolerance of 0.10mm / meter (0.001in /

10").

3. Check the interconnection bolts from time to

time while levelling and ensure that they are

loose.

4. Recheck the level length ways and adjust as

required.

NOTE: Both length ways and cross ways

must be level before leveling is

achieved.

5. Make sure that the bolts that attach the

INJECTION BASE to the CLAMP BASE are

able to move freely.

Level Positioning (Injection

2

End)

1. Position the “Precision Level” on the RAILS.

2. Position the large “Precision Level” across the

RAILS.

1 NOTE: Make sure that the levels are

positioned at the end closest to the

STATIONARY PLATEN.

Printed Copies are Uncontrolled

Revision: 1 Date Released: 2003/04/09 Page 5 of 8 Machine Leveling for Integration (Split Base)

Hylectric Machines

Injection Leveling (Length

Wise)

1. Adjust one side of the BASE, along it’s length,

from GEAR BOX end to the STATIONARY

PLATEN end.

2. Adjust the level of the machine at the end

where the “Precision Level” indicates the

maximum deviation.

3. Turn the bolt of the PADS to raise and lower

the machine as needed.

NOTE: The use of a PANCAKE JACK may be

required for heavier machines.

4. Check the level of the machine and ensure

that the level is within a tolerance of 0.8mm /

meter (0.008in/ 10").

5. Check the interconnection bolts while levelling

to ensure that they are loose.

6. Level the other side then check and re-adjust

the first side if necessary.

NOTE: Make sure that both sides are leveled

before continuing to level cross ways.

Printed Copies are Uncontrolled

Machine Leveling for Integration (Split Base) Page 6 of 8 Revision: 1 Date Released: 2003/04/09

Assembly Manual Hylectric Machines

Injection Leveling (Across the

Rails)

1. Check the reading on the “Precision Level”

across the RAILS.

2. Adjust the level of the machine at the end

where the “Precision Level” indicates the

maximum deviation.

NOTE: Adjust all PADS on one side evenly to

achieve the proper level within a

tolerance of 0.8mm / meter (0.008in /

10").

3. Check the interconnection bolts while levelling

to ensure that they are loose.

4. Recheck the level length ways and adjust as

required.

5. Both length ways and cross ways must be

level before leveling is achieved.

6. Upon completion of leveling ensure that the

connection bolts are able to move freely.

7. Ensure that the positioning of the bolt that

joins the INJECTION BASE is as close to the

centre of the slot as possible.

Printed Copies are Uncontrolled

Revision: 1 Date Released: 2003/04/09 Page 7 of 8 Machine Leveling for Integration (Split Base)

Hylectric Machines

This page intentionally left blank

Assembly Manual Hylectric Machines

Chapter 4 Parallelism for Assembly

NOTE: Make sure that the Base is leveled as per Leveling procedures.

]-

Tie Bar Nuts

NOTE: The TIE BAR NUTS procedure must

be completed in Assembly.

1. Ensure that the correct GAP between TIE

BAR NUTS and the RETAINING PLATES are

set at the CLAMP end.

2. The table below indicates the GAP

dimensions.

Size of Machines Gap Dimensions

H/HL90 2mm

H/HL160 2mm

H/HL 225 2mm

H/HL 300 3mm

H/HL 400 3mm

H/HL 500 3mm

H/HL 650 5 mm

H/HL 800 5 mm

H/HL 1000 5 mm

3. Ensure that the TIE BAR NUTS are loosened

at the STATIONARY PLATEN end.

Printed Copies are Uncontrolled

Revision: 1 Date Released: 2003/04/09 Page 1 of 6 Parallelism for Assembly

Hylectric Machines

Moving Platen Position

1. Position the MOVING PLATEN to maximum

shut height.

2. The table below indicates the distance

between the STATIONARY PLATEN and the

MOVING PLATEN.

Maximum Shut Height Chart

Machines Max. Shut Machines Max. Shut

sizes Height sizes Height

H90 500mm HL90 700mm

H120 HL120

550mm 750mm

H160 HL160

H225 660mm HL225 900mm

H300 750mm HL300 1000mm

H400 850mm HL400 1100mm

H500 950mm HL500 1200mm

H650 1100mm HL650 1400mm

H800 1200mm HL800 1500mm

H1000 1300mm HL1000 1600mm

Printed Copies are Uncontrolled

Parallelism for Assembly Page 2 of 6 Revision: 1 Date Released: 2003/04/09

Assembly Manual Hylectric Machines

Stationary Platen

1. Place the “Box Level” onto the RAILS, close to

the PLATEN, to verify it’s accuracy.

2. Position the “Box Level” on the operator and

non-operator side of the STATIONARY

PLATEN.

3. Determine that the STATIONARY PLATEN is

perpendicular to the BASE on the operator

and non-operator sides.

NOTE: The tolerance, without TEST

BLOCKS or MOLDS, must be within

0.15 mm / m (0.0015 in / 10in) leaning

away from the MOVING PLATEN and

0.1mm / m (0.001in / 10 in) leaning

towards the MOVING PLATEN

relative to the “Precision Level” on the

BASE.

4. If unable to reach tolerance call Q.A.

Moving Platen

1. Place the “Box Level” onto the RAILS, close to

the PLATEN, to verify it’s accuracy.

2. Place the “Box Level” on the operator and

non-operator side of the MOVING PLATEN.

3. Determine that the MOVING PLATEN is

perpendicular to the BASE on the operator

and non-operator sides.

NOTE: The tolerance, without TEST

BLOCKS or MOLDS, must be within

0.15 mm / m (0.0015 in / 10") leaning

away from the STATIONARY PLATEN

and 0.1 mm / m (0.001in / 10 in)

leaning towards the STATIONARY

PLATEN relative to the “Precision

Level” on the BASE.

4. If unable to reach tolerance call Q.A.

Printed Copies are Uncontrolled

Revision: 1 Date Released: 2003/04/09 Page 3 of 6 Parallelism for Assembly

Hylectric Machines

Clamp Cylinder

1. Place the “Box Level” onto the RAILS, close to

the CYLINDER, to verify it’s accuracy.

2. Place the “Box Level” onto the CLAMP

CYLINDER.

3. Determine that the CLAMP CYLINDER is

perpendicular to the BASE.

NOTE: The tolerance is within +0.15 mm /

meter (0.0015 in / 10") relative to the

“Precision Level” on the BASE.

4. If unable to reach tolerance call Q.A.

Clamp Spacer Blocks

2

1. Remove the “Clamp locating pins” from the

CLAMP.

2. Insert the SPACER BLOCKS between the

CLAMP and the DOWEL PINS on both sides.

3. At the STATIONARY PLATEN adjust the

UPPER and LOWER TIE BAR NUTS equally,

Operator side or Non-Operator side, until both

sides reached the required measurement.

NOTE: Ensure that the Clamp spacer blocks

are able to move freely and a 0.1mm

(0.004") feeler gauge cannot be

inserted.

4. Loosen off the STATIONARY PLATEN TIE

BAR NUTS.

5. Turn all the TIE BAR NUTS until they contact

the STATIONARY PLATEN. Tighten the

RETAINING PLATES.

6. Torque the RETAINING PLATE bolts to the

required specification.

Printed Copies are Uncontrolled

Parallelism for Assembly Page 4 of 6 Revision: 1 Date Released: 2003/04/09

Assembly Manual Hylectric Machines

Parallelism Check

1. Take measurements from the four corners

between the STATIONARY and the MOVING

PLATENS MOLD FACES with an “Inside

Micrometer”.

NOTE: Take the measurements from just

above and below the TIE BARS.

2. Check that the measurements are within the

tolerances according to the Table 4-1

"Machine Parallelism Specifications".

3. If unable to obtain the tolerances from top to

bottom loosen the STATIONARY RETAINING

PLATES and verify the perpendicularity of the

PLATENS with a “Box Level”.

4. If unable to obtain the tolerances from side to

side loosen the RETAINING PLATES at the

STATIONARY PLATEN and the mounting bolts

that attach the MOVING PLATEN to the

LINEAR GUIDE RAILS.

5. Adjust the UPPER and LOWER TIE BAR

NUTS equally, Operator side or Non-Operator

side, until the tolerances are reached.

Table 4-1 Machine Parallelism Specifications 6. Loosen off all the STATIONARY PLATEN TIE

BAR NUTS. Turn all the TIE BAR NUTS until

Size of Machines Tolerances they contact the STATIONARY PLATEN.

7. Torque the MOVING PLATEN bolts that attach

H/HL 90 0.12 mm the PLATEN the LINEAR RAILS GUIDES to

the required specification and then torque the

H/HL 160 0.13 mm RETAINING PLATE bolts to the required

specification.

H/HL 225 0.15 mm

8. Retake the measurement with the “Inside

H/HL 300 0.17 mm Micrometer”.

NOTE: Make sure that the gap between the

H/HL 400 0.20 mm

SPACER BLOCKS and the DOWEL

H/HL 500 0.23 mm PINS are not greater than 0.1mm

(0.004 in.).

H/HL 650 0.25 mm 9. If unable to obtain the tolerances from side to

side repeat steps 4 to 8. If tolerances are

H/HL 800 0.28 mm

obtained witness mark the RETAINING

H/HL 1000 0.30 mm

PLATE BOLTS.

Printed Copies are Uncontrolled

Revision: 1 Date Released: 2003/04/09 Page 5 of 6 Parallelism for Assembly

Hylectric Machines

Transportation bolts

1. Ensure that the Transportation bolts can be

installed by hand.

2. If unable to insert the Transportation bolts

reposition the CLAMP CYLINDER and

preform the PARALLELISM FOR ASSEMBLY

procedure from the start.

Checking Column Guide

Bushings

1. Position the MOVING PLATEN to maximum

day light less the stroke required for access to

the CLAMP COLUMN BUSHINGS.

2. For machines H/HL 500 and smaller proceed

to step 3. For machines H/HL 650 and larger

proceed to step 4.

3. Use a 0.05 mm (0.002 in) feeler gauge to

check for a GAP between all the COLUMN

GUIDE BUSHINGS and the COLUMN.

4. Use a 0.05 mm (0.002 in) feeler gauge to

check for GAP between the VERY BOTTOM

COLUMN GUIDE BUSHING and the

COLUMN.

5. If unable to insert the feeler gauge repeat the

LEVELING & PARALLELISM procedure.

Printed Copies are Uncontrolled

Parallelism for Assembly Page 6 of 6 Revision: 1 Date Released: 2003/04/09

Você também pode gostar

- HAITIANMARS2MA GTech20150608Documento6 páginasHAITIANMARS2MA GTech20150608Hau TranAinda não há avaliações

- Modular Labelling System, Labeling Equipment - Tronics America Series S1000 Brochure, CatalogDocumento2 páginasModular Labelling System, Labeling Equipment - Tronics America Series S1000 Brochure, CatalogtronicsamericaAinda não há avaliações

- Blowing Wheel, Infeed/Discharge Starwheel: Contiform MaintenanceDocumento22 páginasBlowing Wheel, Infeed/Discharge Starwheel: Contiform Maintenancedavidwang8512Ainda não há avaliações

- Namco Limit SwitchDocumento4 páginasNamco Limit SwitchprabumunishAinda não há avaliações

- Klockner Moeller EASY 512 Programming InstructionsDocumento10 páginasKlockner Moeller EASY 512 Programming InstructionscdmcAinda não há avaliações

- DF6 Manual PDFDocumento184 páginasDF6 Manual PDFRicardo Garcia FuentesAinda não há avaliações

- Maintenance Manual Delta FWDocumento82 páginasMaintenance Manual Delta FWeudoAinda não há avaliações

- Manual de Operacion OGB-3 英文说明书Documento68 páginasManual de Operacion OGB-3 英文说明书Gabriel Cab PaatAinda não há avaliações

- Fundamentals of Electric CircuitsDocumento7 páginasFundamentals of Electric CircuitsHiếu DươngAinda não há avaliações

- HS SLSMAN 01 Rev.W - Pasteurizer 520 115V Operation ManualDocumento33 páginasHS SLSMAN 01 Rev.W - Pasteurizer 520 115V Operation ManualErick LoganAinda não há avaliações

- Ebp 650 - 2Documento52 páginasEbp 650 - 2Lau AlexAinda não há avaliações

- Plant Inspection Checklist: Faculty / Other Area (Foa) Information DateDocumento2 páginasPlant Inspection Checklist: Faculty / Other Area (Foa) Information Datemj santosAinda não há avaliações

- Vista Explodida - c550g - 1Documento73 páginasVista Explodida - c550g - 1DaveAinda não há avaliações

- Cy 600 800gii PDFDocumento92 páginasCy 600 800gii PDFArmando Rivera100% (1)

- 03 ASi-Bus SafetyDocumento43 páginas03 ASi-Bus SafetycelinAinda não há avaliações

- Pama - Product Pasteurization, Heating and Cooling Systems PDFDocumento9 páginasPama - Product Pasteurization, Heating and Cooling Systems PDFCar MiguelAinda não há avaliações

- Aldec 10+Documento2 páginasAldec 10+epebeAinda não há avaliações

- CF5763FF F0DA 498F BBF6 A7C0303913C4.Aurizon Generator TrainingDocumento28 páginasCF5763FF F0DA 498F BBF6 A7C0303913C4.Aurizon Generator TrainingAdriel RuelasAinda não há avaliações

- SK 0330 ProDocumento2 páginasSK 0330 ProAnonymous l1fc6gAinda não há avaliações

- RX Rotary Union: For Water, Air, and Thermal Oil ServiceDocumento24 páginasRX Rotary Union: For Water, Air, and Thermal Oil Servicexavicojm100% (2)

- Haitian Plastics Machinery Group CO., LTD.: Spare PartsDocumento529 páginasHaitian Plastics Machinery Group CO., LTD.: Spare PartshaisamnagyAinda não há avaliações

- ARCA Evolution160 240 enDocumento2 páginasARCA Evolution160 240 enadyturAinda não há avaliações

- Link 400 Splicer - Fosber USADocumento4 páginasLink 400 Splicer - Fosber USAAnh DucAinda não há avaliações

- MN StarterDocumento8 páginasMN StarterGanesh ChandrashekarAinda não há avaliações

- Sheet Refurbishment Command Shaft UPM UDocumento5 páginasSheet Refurbishment Command Shaft UPM UЛюбить ЕннеттAinda não há avaliações

- KRONES CELEROL FL 7301 LabellerDocumento2 páginasKRONES CELEROL FL 7301 LabellerChiranjeevi VijayaraghavanAinda não há avaliações

- Concept C-Series: Adhesive Melters The EconomicalsDocumento4 páginasConcept C-Series: Adhesive Melters The EconomicalsAhmed Awasha100% (1)

- CKG Manual 1910 MAY10 04iaDocumento26 páginasCKG Manual 1910 MAY10 04iaMatias Ulloa SaavedraAinda não há avaliações

- Innopack KistersDocumento2 páginasInnopack KistersDrdbuoiu Poiñhb Monihugy100% (2)

- Milk Harvest CIP Sanitation SystemsDocumento13 páginasMilk Harvest CIP Sanitation SystemsBouMaticAinda não há avaliações

- User's Manual For TL-30x Laser Engraving and Cutting Control SystemDocumento103 páginasUser's Manual For TL-30x Laser Engraving and Cutting Control SystemGPrado100% (1)

- Technical Description: 4XP1640.00-K01/K02 & 4XP0000.00-K01Documento30 páginasTechnical Description: 4XP1640.00-K01/K02 & 4XP0000.00-K01Justo Alberto Guerra Inca100% (1)

- PSS 3.2 - 520 - 5,5kW - DrawingDocumento1 páginaPSS 3.2 - 520 - 5,5kW - DrawingCentrifugal SeparatorAinda não há avaliações

- eSW-1200 eSW-1200s: Mechanical Edition For RobotDocumento44 páginaseSW-1200 eSW-1200s: Mechanical Edition For Robothung nguyenAinda não há avaliações

- Modelo Pequeño2Documento32 páginasModelo Pequeño2Robert Orosco B.Ainda não há avaliações

- Sigma Mixer Catalog NewDocumento4 páginasSigma Mixer Catalog NewHitesh B GandhiAinda não há avaliações

- Xerox Finishers PDFDocumento3 páginasXerox Finishers PDFXcopyAinda não há avaliações

- NM402 Norden Tube FillingDocumento8 páginasNM402 Norden Tube FillingSaka International LtdAinda não há avaliações

- Mav 2005 InstalationDocumento1 páginaMav 2005 InstalationCamilo Andrés Nope FajardoAinda não há avaliações

- Faults e NewDocumento73 páginasFaults e NewAlexandre Ferreira100% (1)

- Motor and Gear G500 S3100 5,5kW, 7,5kW - Parts List - 2020Documento1 páginaMotor and Gear G500 S3100 5,5kW, 7,5kW - Parts List - 2020Centrifugal SeparatorAinda não há avaliações

- Power Team Hydraulic JackDocumento9 páginasPower Team Hydraulic Jackslaeh75Ainda não há avaliações

- DE50AV Horizonal Auger Packer Brochure 2016 PDFDocumento18 páginasDE50AV Horizonal Auger Packer Brochure 2016 PDFJoão BaptistaAinda não há avaliações

- ProMinent UV InglesDocumento72 páginasProMinent UV InglesGilberto Prez RomeroAinda não há avaliações

- 28.GOMA Pump T-8000 CatalougeDocumento2 páginas28.GOMA Pump T-8000 Catalougeramesh babuAinda não há avaliações

- Tetra Plex C10-ECO: Plate Heat ExchangerDocumento2 páginasTetra Plex C10-ECO: Plate Heat ExchangerĐình KiênAinda não há avaliações

- SIDEL02Documento80 páginasSIDEL02Anthony JohanAinda não há avaliações

- Tai Mex by Tederic D SeriesDocumento13 páginasTai Mex by Tederic D SeriesPHYONEGRIPAinda não há avaliações

- TSTA User ManualDocumento218 páginasTSTA User ManualHieu NguyenAinda não há avaliações

- Piston VolumetricDocumento2 páginasPiston VolumetricBroyce GilbertAinda não há avaliações

- Volteq HY3030EX DC Power Supply CircuitDocumento2 páginasVolteq HY3030EX DC Power Supply CircuitEdward Maina100% (1)

- Multimac DDocumento40 páginasMultimac Dloko221Ainda não há avaliações

- Duplo DBM 100 Instruction ManualDocumento64 páginasDuplo DBM 100 Instruction ManualChris Createdc Burch100% (1)

- Electrical Panel Diagram - PT - BRDocumento1 páginaElectrical Panel Diagram - PT - BRCentrifugal SeparatorAinda não há avaliações

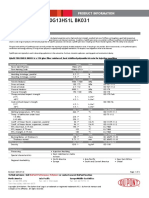

- Zytel 70 G13 HS1 LBK031Documento3 páginasZytel 70 G13 HS1 LBK031vikram goralAinda não há avaliações

- Fluiteco CatalogoDocumento84 páginasFluiteco CatalogoPablo FaldutiAinda não há avaliações

- Ricambi Hl10m 1 SerieDocumento10 páginasRicambi Hl10m 1 SerieLuca FroliAinda não há avaliações

- Produkte PowerStromteiler Datenbl EnglDocumento16 páginasProdukte PowerStromteiler Datenbl EnglCarlos Augusto100% (1)

- Tài liệu cảm biến bắt màu BANNER R58 Expert - R58ECRGB1Documento12 páginasTài liệu cảm biến bắt màu BANNER R58 Expert - R58ECRGB1Nguyễn Văn Dũng100% (4)

- 3 WB14B9Q1DW Ye PDFDocumento8 páginas3 WB14B9Q1DW Ye PDFsalvadorAinda não há avaliações

- Digital Stepper Drive CW250: DescriptionsDocumento7 páginasDigital Stepper Drive CW250: DescriptionsDavid MartinezAinda não há avaliações

- Basf ProteinsDocumento1 páginaBasf ProteinsJade LaceyAinda não há avaliações

- Qhy5 Mono/Color CMOS Camera ManualDocumento9 páginasQhy5 Mono/Color CMOS Camera ManualNeko TamAinda não há avaliações

- DragonflyDocumento37 páginasDragonflySiberians Amigurumis100% (7)

- EFT W3 Types of TourismDocumento19 páginasEFT W3 Types of TourismAndik GigihAinda não há avaliações

- Yoohoo Carry Out MenuDocumento2 páginasYoohoo Carry Out MenuYoohoo Chinese0% (1)

- Bestech LTDDocumento4 páginasBestech LTDBhavya ShahAinda não há avaliações

- CorelDRAW 12 UnleashedDocumento442 páginasCorelDRAW 12 UnleashedgabrielahrAinda não há avaliações

- Getting Started With: Create Your Own Games, Animations, Interactive Stories, and MoreDocumento15 páginasGetting Started With: Create Your Own Games, Animations, Interactive Stories, and MorezulfikarAinda não há avaliações

- No Slip Socks: Follow UsDocumento2 páginasNo Slip Socks: Follow UsrezgsfsfgAinda não há avaliações

- Videodeluxe enDocumento353 páginasVideodeluxe enMarcin StęplowskiAinda não há avaliações

- Pathfit 1 Module2-1Documento25 páginasPathfit 1 Module2-1Jim Roger Malabo LorenzoAinda não há avaliações

- A.AN - THE Karta PracyDocumento2 páginasA.AN - THE Karta PracyJeremi WasilewskiAinda não há avaliações

- Flicker Fade GoneDocumento3 páginasFlicker Fade GoneVanya Danyella Barachita100% (1)

- The Guru Granth SahibDocumento13 páginasThe Guru Granth SahibnirvaangAinda não há avaliações

- Rules With No NameDocumento27 páginasRules With No NameTudor IliescuAinda não há avaliações

- 8 Plus Maths Paper 2 PDFDocumento14 páginas8 Plus Maths Paper 2 PDFvishaaal69Ainda não há avaliações

- Chocolate and Gingerbread Marble CakeDocumento3 páginasChocolate and Gingerbread Marble CakeshabenzhuAinda não há avaliações

- Epic Sued Over Loot Boxes by A Minor in Potential Class-Action LawsuitDocumento36 páginasEpic Sued Over Loot Boxes by A Minor in Potential Class-Action LawsuitThe VergeAinda não há avaliações

- PDF - DobbleDocumento63 páginasPDF - DobbleAlpha BetaAinda não há avaliações

- Arnold Dumbbell Press: Exercise DataDocumento25 páginasArnold Dumbbell Press: Exercise Dataaries_02Ainda não há avaliações

- VGA Controller PDFDocumento6 páginasVGA Controller PDFAviPatelAinda não há avaliações

- YA3 TRM ListeningDocumento15 páginasYA3 TRM Listeningema_mirela88Ainda não há avaliações

- Full Body Home Workout (5 Days) - YBDocumento2 páginasFull Body Home Workout (5 Days) - YByugesh bhatiaAinda não há avaliações

- MenuDocumento10 páginasMenuRindelene A. CaipangAinda não há avaliações

- Vargr: Shared Legendary ActionsDocumento2 páginasVargr: Shared Legendary ActionsEduardo GuedesAinda não há avaliações

- Hanoi House BrunchDocumento2 páginasHanoi House BrunchJimmy LeAinda não há avaliações

- XAS 185 JDU7 FINAL - tcm795-2750265 PDFDocumento2 páginasXAS 185 JDU7 FINAL - tcm795-2750265 PDFRodrigo Andres Diaz BascuñanAinda não há avaliações

- PanelDocumento1 páginaPanelsr cAinda não há avaliações