Escolar Documentos

Profissional Documentos

Cultura Documentos

HTTP WWW - Cncroutersource.com Homemade-Cnc-Router

Enviado por

premakoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

HTTP WWW - Cncroutersource.com Homemade-Cnc-Router

Enviado por

premakoDireitos autorais:

Formatos disponíveis

Homemade CNC Router The Builders Guide (FREE!

The Builder's Guide

"Your homemade CNC router project begins

here"

Introduction

So you've decided to

build a homemade CNC

router or maybe you’re

just considering it, but

where do you start?

There are many

advantages to owning a

CNC router. Homemade

CNC routers can cut and

carve almost anything.

For any hobbyist or

DIY’er, this opens many

doors. The fact that you

could own one for a

fraction of the retail cost

is even more enticing.

Yes, you can build a CNC router that is just about as good as any other for

a fraction of the retail price, and it’s not that difficult! This is not a sales

pitch, this guide is FREE its all below.

There is also a great deal of flexibility when you design and build your own

machine. You will be able to customize your machine to fit you needs best.

Not to big, not to small, just right.

There are many reasons people want to build their own homemade CNC

router. It’s usually because we simply can’t afford to buy one off the shelf

and that’s as good of a reason as any other. Or you may be like me and

enjoy working with your hand and creating something unique. You might

simply be in it for the learning experience. For me personally, I think it

was a little of both.

My Experience

When I first started to design and build my first homemade CNC router, I

had it all figured out in about a day. I had my design ready to go. Then as

I started to buy the parts, I did a little research. I found bits and pieces of

information here and there, but it just lead to more questions.

http://www.cncroutersource.com/homemade-cnc-router.html (1 of 5) [8/6/2008 12:52:12 AM]

Homemade CNC Router The Builders Guide (FREE!)

“Do I really need ball screws or will ACME screws work fine?”

“What kind of linear bearing is the best, and can I afford it?”

“How big of a motor do I need, and should I use steppers or servos?”

“Will this material flex too much over that span?”

Etc.

Luckily, some of my questions I could answer with my mechanical

engineering background. However, many of the problems I would

encounter could not be “calculated”. I just needed someone with

experience and information on the subject.

So I researched the internet. The information available is scattered and

hard to come by, and how do I know if it’s valid. Most of the answers to

my questions came through reading hundreds and hundreds of threads like

CNCzone.com. Which is a rood resource. I would post my questions and

wait for people who already have built a homemade CNC router to

hopefully give me a good answer.

Of course I would get many answers to my questions from different

people, many of which contradicted each other. Then I’d have to read

though a thread where people were bickering back and forth. Of course

then I would have to research further to find out which answers were

worth while and which ones were garbage.

Every time I had a question that I didn’t know, I would have to go through

the same process. A lot of this was due to the fact I was on a budget and

wanted the best design my money could buy. Which is the same situation

many people building a homemade CNC router are in?

CNC router kits and plans

Yes, there are homemade CNC router kits available, but I have yet to see

one that gives any explanation as to what you are actually doing. It just

says “do these things” and you are supposed to follow directions. But what

if you do not have the parts available? Or you want your design to vary

slightly. Then you are left to fend for your self.

Maybe you don’t want to design your own, but still want to build your own.

That’s where the kits and plans help you most, like the CNC router kits at

www.solsylva.com . Plans are good for what they are, they are

instructions.

There are a lot of them out there and how do you know which one is the

right one. No matter how good the instructions are, if it’s a bad design it

WILL be a bad machine.

That is why you need to be educated as to what you are building and what

each part does!

This Guide

This is where this guide will help you. After designing and building several

of my own homemade CNC routers, I would like to share the knowledge

from my experiences, good and bad. I think it’s sad that this information

isn’t out there, and I DON”T think it should cost you anything.

This guide aims to keep you for making some of the same mistakes that I

http://www.cncroutersource.com/homemade-cnc-router.html (2 of 5) [8/6/2008 12:52:12 AM]

Homemade CNC Router The Builders Guide (FREE!)

made costing me precious time, money, and frustration.

We will walk through ever component down to the bolts, looking at

advantages and disadvantages of every type of each component. I will

discuss every aspect of designing and building your own homemade CNC

router. It will take you through the mechanics to software and everything

in between. If you still want to use a homemade CNC router plan or kit,

you can find CNC router plans here. Keep in mind, homemade CNC Router

plans offer little in the way of explaining concepts. This often leads to a

"sloppy" design or unsatisfactory machine performance. That is why I

suggest I you read through this guide first.

By the end, you should be talking CNC like a pro! This will give you a

real heads up when you go to build and design your homemade CNC

router. Regardless if you are using your plans or someone else's.

LET’S GET STARTED

Step 1: Key Design Decisions

This section covers the following:

Identifying the right design for you

Required cutting area

Space availability

Materials

Tolerances

Constructing Methods

Available tools

Budget

Step 2: The Base and X-axis Frame

This section covers the following:

Designing and Building the main base or x-axis base

A breakdown of different designs

Fully Supported Frames

Partially Supported Frames

etc.

STEP 3: The Y- Axis Gantry Design

This section covers the following:

Designing and Building the Y-axis Gantry

A breakdown of different designs

Forces and Moments on the Gantry

Do's and Don't

etc.

STEP 4: The Z- Axis Assembly Design

This section covers the following:

Designing and Building the Z-axis Assembly

Forces and Moments on the Z-axis Assembly

Linear rail/rods and bearing spacing

The Plunge arm Design

etc.

http://www.cncroutersource.com/homemade-cnc-router.html (3 of 5) [8/6/2008 12:52:12 AM]

Homemade CNC Router The Builders Guide (FREE!)

STEP 5: The Liniear Motion System

This section covers the following:

Detailed Overview of linear motion systems

Choosing the right system for your machine

Designing and building your own

Linear Shaft and bushings

Linear Rails and Guide Blocks

etc.

STEP 6: Mechanical Drive Components

This section covers the following topics:

Detailed overview of the drive components

Choosing the right components for your design

Stepper and Servo motors

Lead screws and ball screws

Drive nuts

Radial and thrust Bearings

Motor coupling and mounting

Direct drive vs. Geared

Rack and Pinions

Lead screw motor sizing

etc.

STEP 7: The Cutting Table design

This section covers the following:

The Cutting table designs overview

T-slot Table

Vacuum Table

Perforated cutting bed

The Cutaway bed

Designing and Building your own

etc.

STEP 8: The Spindle Options

This section covers the following:

CNC Spindles overview

Types and features

Pricing and costs

Mounting and cooling options

Coolant systems

Building your own

How to calculate chip load and cutting force

How to find optimal feed rates

etc.

http://www.cncroutersource.com/homemade-cnc-router.html (4 of 5) [8/6/2008 12:52:12 AM]

Homemade CNC Router The Builders Guide (FREE!)

STEP 9: The Electronics

This section covers the following:

CNC Electronics overview

The Control panel

Wiring and Fusing

Buttons and switches

MPG's and Jog wheels

Power Supplies

etc.

STEP 10: The CNC Controller options

This section covers the following:

The CNC Controller overview

Controller selection

Options available

Closed loop vs. Open loop systems

Best priced controllers

Building your own from scratch

etc.

STEP 11: Selecting the Software

This section covers the following:

The CNC related Software overview

What software will I need

CAM software

CAD software

NC Controller Software

Best choices

Free ware

etc.

Go to Homepage from the Homemade CNC router guide

http://www.cncroutersource.com/homemade-cnc-router.html (5 of 5) [8/6/2008 12:52:12 AM]

CNC Plans ~Solsylva Home Page~

. CNC Router Plans

Plans Home Page

Plans for low cost

CNC machines

The tables were

designed to be:

● Inexpensive

to build

● Simple to

assemble

● Accurate

for the cost

Table parts

Primarily off-the- Rack and Pinion or Leadscrew

shelf from home 24 x 48 Inch Cutting Area

centers and department stores.

Part descriptions and sources for the other components

are provided in the plans.

This site gives a list of software, stepper and drive

suppliers.

Manuals There are two plan books.

One manual is for the single table shown above. This

manual covers a variety of options including rack and

pinion and/or leadscrews for the X and Y axes.

http://www.solsylva.com/ (1 of 4) [8/6/2008 12:53:15 AM]

CNC Plans ~Solsylva Home Page~

Dual Leadscrew Table

25 x 37 Inch ( 640 x 950 mm) Cutting Area

The other manual includes plans for the 5 machines

shown below.

Both plan sets include hundreds of images and

dimensioned CAD drawings, with step by step written

instructions.

All machines were designed around the drive, stepper

and power supply packages sold by Xylotex and

HobbyCNC.

These cost $250 to $600 depending on the desired

features.

Tables' cost (Not

including the

above drive

packages)

Fixed gantry table:

Less than $100

Smaller blue

tables: Less than

$250

Belt drive, and

rack and pinion

tables: Less than

$600 and up Belt Drive Table

27.5 x 64 Inch Cutting Area

depending on the

components used.

Cutting areas

Belt Drive Table X 64" Y 27.5" Z 7"

Rack/Leadscrew Table X 48" Y 24" Z 8"

Dual Leadscrew Table X 37.5" Y 25.5" Z 6.5"

http://www.solsylva.com/ (2 of 4) [8/6/2008 12:53:15 AM]

CNC Plans ~Solsylva Home Page~

Small Blue Tables X 20" Y 17.5" Z 4"

Fixed Gantry Table X 13" Y 13" Z 5"

Footprint Size

Belt Drive Table 3'

x 6'

Rack and Pinion

Table 3' x 5'

Dual Leadscrew

Table 36" x 49"

Small Blue Tables

31" x 33.5"

Fixed Gantry

Table: 18" x 25"

Fixed Gantry Table

13 x 13 Inch Cutting Area Accuracy Very

good for the cost. Pictures are worth thousands of

words.

Stepper Size 200 oz.in. for the 13" x 13" and 17 x 20

inch prototypes.

. . . 269 to 425 oz.in. for the 25 x 37 inch prototype,

the Belt Drive table and the Rack/Leadscrew table.

Speed 35+ inches per minute rapid, 30 ipm cuts on

the small tables, and up to 300+ ipm rapids on the

rack and belt drive tables.

The machines were all designed to use the

stepper and drive systems from Xylotex and

HobbyCNC. The recommended software is

Mach3 or TurboCNC.

These suppliers work with the Do It Yourself

market, and supply documentation and help

forums for their products.

http://www.solsylva.com/ (3 of 4) [8/6/2008 12:53:15 AM]

CNC Plans ~Solsylva Home Page~

These are

all real

machines

that have

been built

and tested

in this shop.

Small Dual Leadscrew Table

All of the 17 x 20 Cutting Area

machines were designed around standard sizes of

lumber and hardware store components. This keeps

construction simple and prices low.

Suppliers for the other parts, such as belts and pulleys,

are listed in the manuals.

Though the

machines are

similar, each

was designed to

meet specific

goals. The

smaller

machines use a

Small Overhead Leadscrew Table

minimum of

17 x 20 Cutting Area components,

are

inexpensive, and are simple to build.

The large machines were designed to move quickly

with a larger cutting area.

The Rack and Pinion/Leadscrew machine is designed

to carry a full sized router.

It can use racks or leadscrews on the X and Y axes;

the plans address the multiple versions.

Back to the top

http://www.solsylva.com/ (4 of 4) [8/6/2008 12:53:15 AM]

CNC Router Plans: Download free CNC router plans

CNC Router Plans

CNC router plans are a great

starting point for anyone wanting to

build a CNC router. They give

valuable insight on how these

machines work. Many of us are

very visual people and it helps to

see examples of these machines

laid out on paper. Some plans are

thorough enough to act as a

complete blueprint from start to

finish while others only offer bits of

information.

You may prefer to design and build

your own machine. However, CNC router plans can still be a valuable

resource. Plans can give you great ideas. You may like the linear motion

system on one design but prefer the cutting bed design on another. They

may also uncover aspects of your design that may or may not work.

This is why we want to provide you with as many free plans and blueprints

as possible. There several companies devoted to providing plans you can

buy. Some are worth while, and others are not. At the moment, we are

working on several free plans complete with pictures, 3D and 2D

downloads, and even videos.

Even if you decide to use plans, we strongly suggest you read through the

Builder’s Guide There you will find in depth information regarding all the

components and their function.

For now, feel free to check out the plans below. These designs have been

tested and built by many CNC router enthusiasts.

CNC Router Plans Download Center

“JGRO’s” Design

This design is very popular among the DIY

CNC router community. This set of plans is

very detailed and contains dimensions on all

parts. This is a mobile gantry type designed

around a wood or MDF construction utilizing

skate bearings for the linear motion system.

http://www.cncroutersource.com/cnc-router-plans.html (1 of 2) [8/6/2008 12:54:06 AM]

CNC Router Plans: Download free CNC router plans

This build can be very sturdy if built correctly. The set of plans also

contains a complete BOM (bill of materials).

Download JGRO’s Design in PDF format

Download JGRO’s Design in DXF format

Please note, that by downloading this plan, you are under the

agreement that they are not to be resold or used for commercial

purpose. Personal use ONLY!

“Joe’s 2006 R-1” Design

This is another very popular design. This

design is also a mobile gantry CNC router,

designed around a wood or MDF structure.

The linear motion system is also design

around skate bearings. However, the x-

axis employs dual rods and each side

instead of one. This design is very

ergonomic looking and employs anti-

torsion framing and slanted gantry side

arms to account for CG location.

This set of plans are in a 3D format which can be viewed, rotated, and

dimensioned using a free E-drawing viewer that you may download here.

Download JOE’s 2006 design in EASM format

Download the free EASM viewer here

Please note, that by downloading this plan, you are under the

agreement that they are not to be resold or used for commercial

purpose. Personal use ONLY!

MORE PLANS ARE COMING VERY SOON!!!!

If you have any question or would like to submit a set of your own CNC

router plans to be reviewed and posted, feel free to contact us.

Return to Homepage from CNC Router Plans

http://www.cncroutersource.com/cnc-router-plans.html (2 of 2) [8/6/2008 12:54:06 AM]

The Hobby CNC Router: Builders Guide Step 1

Building a Hobby CNC Router

Step 1

As we discussed earlier,

there are numerous

advantages to designing

and building a hobby

CNC router. Designing

and building any machine

has the potential of being

a good or bad

experience. This is also

the case wen designing

and building a CNC

router.

The concepts of CNC

routers are fairly straight

forward, but you can quickly become overwhelmed in the process. Don’t

let this stand in the way.

That’s why this guide is here; to keep you from making mistakes that

might cost you time, money, and performance.

Although this guide is primarily focusing on hobby CNC routers, the

concepts may be applies to most any CNC linear motion system. For

example, you could use these same concepts to build a CNC plasma cutter.

If you are thinking of building your own machine, there is a good chance

you already have a design in mind. This is to be expected. After all, it’s

your machine. This guide does not aim to subtract from any of your ideas

but rather supplement your project with valuable information. I wish that I

had known a lot of this stuff before my first machine. It would have saved

me many headaches and money.

One last comment before we jump in head first. I am assuming you know

some very CNC basics, such as what CNC means etc. If you do not, then

you may wish to start at the CNC router Basics.

Let’s Get Started:

http://www.cncroutersource.com/hobby-cnc-router.html (1 of 6) [8/6/2008 12:54:41 AM]

The Hobby CNC Router: Builders Guide Step 1

1) Choosing your design

There are two primary styles of the hobby CNC router. This may seem

contradictory as every design is unique. However, there are two overall

designs types that you will encounter.

1) Stationary Gantry, Mobile bed

2) Mobile Gantry, stationary bed

Here you can see an example of each.

Let’s take a look at these two designs in detail.

The Mobile bed

This type of design is less prominent in the hobby CNC router community

than the mobile gantry design. However, there are reasons for choosing

the mobile bed design type. The mobile bed design is typically found on

smaller CNC machines such as a PCB or engraving machines. For this size

machine, the mobile bed design works well.

http://www.cncroutersource.com/hobby-cnc-router.html (2 of 6) [8/6/2008 12:54:41 AM]

The Hobby CNC Router: Builders Guide Step 1

Another advantage of this design is that creating a sturdy gantry that will

not flex under load is much easier. This is because the gantry is stationary

and does not have to be light or conform to a certain size to fit your linear

bearings. With a mobile gantry, you must take into consideration the

weight of the gantry itself and the size, in regards to the linear bearings on

the x axis. With the mobile bed design, the gantry itself does not move,

therefore you have more breathing room in regards to the weight, size,

and structural design.

There are disadvantages with this type of design as well. As the length of

the x-axis increases the mobile bed design become less efficient.

If you are unfamiliar with the x, y, and z, axis notation, take a look at the

picture below labeling each. As we discuss the hobby CNC router, the x, y,

and z axis will always be this configuration.

With the mobile bed design, as you increase the x axis length your design

become less efficient due to the size of the bed. When you see a mobile

bed design employed on a hobby CNC router, the total x axis travel is

usually between 12-36 inches. I have seen larger, however the design

becomes increasingly complicated. If you made an extended x axis with a

mobile bed, the actual size of the object you could cut would still be

relatively small because the bed itself is still relatively small.

As a side note, the y and z axis usually changes very little between the

mobile bed and mobile gantry designs.

In conclusion, the mobile bed design is for you if you want a smaller

machine that is compact and relatively easy to build, offering rigid a gantry

but limiting on the overall size. Now let’s look at the mobile gantry.

The Mobile Gantry

The mobile gantry design accounts for probably 95% of the hobby CNC

routers. This design type is similar to the mobile bed except the whole

gantry moves along the x axis. This is advantageous because the overall

size virtually limitless.

It can be tricky to design a gantry that is light enough for your design and

still offer little flex under load. Not to mention, you must design it to be

mobile and fit some sort of linear bearing assembly.

The mobile gantry design is very versatile. If you are building anything

other than a small machine, I suggest this be your design choice. Of

course, we will go into greater detail on both designs later.

http://www.cncroutersource.com/hobby-cnc-router.html (3 of 6) [8/6/2008 12:54:41 AM]

The Hobby CNC Router: Builders Guide Step 1

For now, you need to decide which design will fit your needs best. Now lets

move on to some other considerations.

2) The Cutting Area

The cutting area is the total distance the machine can cut along each axis.

Keep in mind, this is one of those decisions that is likely to change as you

search for parts. The linear bearings will probably be you primary

restrictions. After all, most of us want as big of a machine as we can get

away with. We will look at sizing in more depth later when we look at the

structural considerations.

Right now it’s a good idea to have an idea of the size of piece you want to

be able to cut. Later you may find that you are limited to a certain size due

to materials and parts. For example, some linear systems and materials

may flex excessively over a certain span, which could also limit the cutting

area.

The cutting area is also called the machine travel for each axis. The travel

is not the overall machine size, which brings us to our next consideration.

3) The Machine Size

Most of us want as big of a machine as we can get, however, you may be

limited due to shop space or some other factor. So if you have a machine

footprint limitation, keep this in mind as you design your machine. You do

not want to have wasted space in your hobby CNC router design. For

example, if your limitation is 36”x24”, then your ideal travel for that

machine is 36”x24”. Although, it is unlikely you will achieve the maximum

travel for your machine size, working towards getting as much travel as

possible is worth the effort.

4) The Machine Tolerance

One of the most important considerations when designing or building a

hobby CNC router is the accuracy and precision of the machine. Don’t get

accuracy and precision confused. Take a look at the illustration below.

You want to design and build your machine to hold a certain accuracy and

precision. For example, you machine may be able to cut a piece that is

within .0001 of an inch but the repeatability may be .1 inch.

Many people design and build a hobby CNC router and live with the results,

or keep adjusting to get the results they want. However, there are ways to

design machine to hold a certain tolerance. For example, if you know you

only need a tolerance of .01 inch and you know that all you will ever need,

http://www.cncroutersource.com/hobby-cnc-router.html (4 of 6) [8/6/2008 12:54:41 AM]

The Hobby CNC Router: Builders Guide Step 1

you can save a lot of money by designing for that requirement.

On the other hand, if you want a machine to hold a tolerance of .0001 inch

repeatable, then there are some design requirements that must be met to

get the required performance.

Typical hobby CNC routers hold a tolerance of .001 to .0001 inch.

However, this is up to you. At this point all you need to do is have an idea

as to what kind of tolerance you require. Keep in mind the larger the

machine, the more costly it is to hold tight tolerances.

5) Materials and Tools

The tools and materials can define your design almost as much as any

other factor. Hobby CNC routers are constructed from all types of

materials. I have seen machines made out of plastic, wood, MDF,

aluminum, steel, and others.

The material from which you construct your machine should be based on 3

criteria, budget, tools you have to work with, and materials available. It is

hard to say which material is best as it varies with the design. I have seen

machines made from MDF that hold better tolerances than those

constructed of solid metal.

That is why it is crucial to choose your materials ahead of time. Of course,

your hobby CNC router will probably integrate many materials. However,

you will have a certain material that will make up the bulk of your

machine. The right design for a wood machine is not the right design for

an aluminum or steel machine.

The tools you have may also define the type of material you must use. If

you do not have access to a milling machine or heavy metalworking

equipment, then it may be hard to build your design correctly out of metal.

This will eventually lead to a poor overall machine.

On a piece of paper right down all the tools you have to work with, and

then think of the material you can use. Keep in mind, I have seen

machines built with as little as a drill motor and a hand saw. So there is no

need to think that because you have limited tools you can not create a

hobby CNC router. A popular method is to build a basic CNC router and

then use that to build a nicer one. This method works well if you have

limited tools. Do not take on a job that you do not have the tools for.

We will look at properties of material later. There we will cover how to

calculate deflection and other mathematical models with relative ease. This

will help you design your machine to the load ratings you specify.

6) Budget

Last but not least is the

budget. For most of us, this

is the one factor that will

determine many of our

decisions. After all, if we had

the money, we would just

buy one. Well maybe we

would just buy really nice

parts and bolt them

http://www.cncroutersource.com/hobby-cnc-router.html (5 of 6) [8/6/2008 12:54:41 AM]

The Hobby CNC Router: Builders Guide Step 1

together. I suggest you have

an overall budget in mind

and keep track of how much

you spend. Below you will find an excel spreadsheet that you may

download.

It breaks down all the components of a hobby CNC router and parts you

will need. This will help you stay organized and see where you should

spend the bulk of your money. I also included information on what you

should expect to pay. As a warning, the bulk of your budget should go

towards the linear motions system and the drive system. We will cover this

in greater detail in later steps.

Summary of Step 1

So by now you should have the following decisions made or understand

them at least.

1) Mobile bed or mobile gantry

2) Required cutting area

3) Machine size requirements

4) Tolerance requirements

5) Materials and Tools

6) Budget

Now that we have the major decisions worked out, let con Building a

hobby CNC router Step 2

View and Download a Sample Expense sheet

Back to the Builders Guide Index

Homepage

http://www.cncroutersource.com/hobby-cnc-router.html (6 of 6) [8/6/2008 12:54:41 AM]

Build your own CNC router Step 2: The frame

Build your own CNC router Step 2

The Frame and Base

When you design and build your

own CNC router, one of the first

considerations is the base and

frame. Although another practice

is to actually design from the top

down, but well start at the bottom

and work our way up.

The Base and Frame Overview

The base and frame of a CNC

router is the main structural

element of your machine.The base

and frame is what holds

everything together. This is what

will determine your motor

placement and lead screw

placement along with everything else.

The frame and base design will be determined partially by the materials and

supplies that you have, the number of lead screws lead screws , and motors your

budget allow etc. However, we need to become familiar with different designs so

that you may buy parts that fit your design.

If you can not find or can’t afford the parts for the design you would like. Then it’s

back to the drawing board to optimize the design for the materials you do have.

This will likely happen a lot when you build your own CNC router.

When you look at other homemade CNC router designs, you may notice that

almost ever unit is different. Although this is true, you can break down these

designs into categories.

The X-Axis Base and Frame

When you build your own CNC router, the X-axis frame should also act as the base

for the machine as the X-axis should be the axis closest to the ground. This

portion of the machine will perform 3 primary tasks.

1) Act as the base for the machine

2) Support the X axis linear motion system

3) Support the cutting table

http://www.cncroutersource.com/build-your-own-cnc-router.html (1 of 7) [8/6/2008 12:55:24 AM]

Build your own CNC router Step 2: The frame

Lets look at the most common designs for the base.

Fully Supported Frame

The fully supported base is one of the best designs and is the design used on most

industrial or professional routers.

The image above shows only the base and does not show the gantry. Pay no

attention to the type of linear bearings.

The fully supported design means that both the Y and X axis may rest on the floor

or some other structure. There is nothing connecting the gantry across the Y-axis.

This allows for a very sturdy design and is not susceptible to the cutting table or

the structure itself flexing under its own or external weight.

In order for this system to flex or deform, the material itself would need to

compress.

Keep in mind we are not talking about massive amounts of flex. This all ties back

in to the Step 1 on how to build your own CNC router. Where you should already

have some idea as to the desired precisions and accuracy you want your machine

to hold. A deformation of 0.001” is acceptable if you only expect 0.010” accuracy

from your machine.

There are drawbacks with this design, the cost. You will need and extra lead

screw, lead nut, and motor. You may employ a fully supported frame design with

one motor using a pulley and belt system, but you will need to make sure you

motor is up to the task. We will cover how to calculate that in the CNC drive

system section. With this design you can get away with a lighter material as it will

be supported against the ground or some other structure. Now let’s look at

another design.

http://www.cncroutersource.com/build-your-own-cnc-router.html (2 of 7) [8/6/2008 12:55:24 AM]

Build your own CNC router Step 2: The frame

Fully Supported Frame vs. Fully Supported Bearing Rods/Rails

When we say “fully supported” in this section, we mean that there is nothing

obstructing sweeping across that axis during operation.

Later we will discuss fully and end supported linear bearing systems, but that is

not the focus in this section. We are focusing on the frame itself.

It is possible to have a fully supported linear bearing system and not have a fully

supported frame. You can see this in the Solsyva design below.

Partially Supported X-axis Fully Supported Y-axis Frame

The more common design with most hobby CNC routers out there is the partially

supported X or Y-axis.

The

image above illustrates a supported Y-axis and a end supported X-axis frame. This

is the most common design.

The gantry would have an undercarriage that would connect the gantry to the lead

screw. With this setup you could have a “fully supported” linear rails or rods

http://www.cncroutersource.com/build-your-own-cnc-router.html (3 of 7) [8/6/2008 12:55:24 AM]

Build your own CNC router Step 2: The frame

setup. . However, the rods or rails would still be able to flex with the frame itself.

You may only support the frame on the ends since there must be clearance

between the ground and the frame to allow the gantry undercarriage to move

along the X-axis. In the image above, the Y-axis would be considered supported

since you could have a frame that would not interfere with the gantry movement.

The frame across the Y-axis would prevent flexing for that axis. This would mean

the cutting bed would be very rigid in the Y-axis but could flex or deform along the

X-axis.

With the design above, even if the frame were made of solid aluminum measuring

1-1/2’’ by 4-1/2’’ and the X-axis span were 60 inches, the frame would “sag” .01

inches in the center, just under its own weight. That does not include the weight

of the gantry or anything else.

You can understand that this would be an issue if I’m trying to design a machine

to hole a tolerance of 0.001’’ in the Z-axis. It is true that the machine would flex

as a whole and could be compensated. However, the machine could vibrate and

bounce when cutting creating lines in the work. If your machine has a relatively

small X-axis span, this design works well and is probably the easiest to setup.

There are other solutions.

Partially Supported Y- axis Fully Supported X-axis

Let’s say I have only one motor and lead screw for the X-axis and still wish to

maintain a high tolerance on my machine. I could move the Y-axis gantry

assembly inside the frame which would allow me to fully support the X-axis

because the gantry would not cut under the X-axis frame. However in that

situation, the Y-axis frame would not be fully supported.

http://www.cncroutersource.com/build-your-own-cnc-router.html (4 of 7) [8/6/2008 12:55:24 AM]

Build your own CNC router Step 2: The frame

As you can see in this design, the longer X-axis is fully supported (on the ground),

however the gantry would cut through any frame in the Y-axis inside the cutting

area.

This means that no matter how much weight I put on the gantry or cutting table

(not pictured), the X-axis frame would only deform if the material itself deformed.

With this design, the cutting bed would need to have its own frame and could

“sag” in the center. However, he machine itself would be constant and once the

cutting bed is installed, you could true the cutting table surface by plain the

surface with the machine.

The cutting bed would then be true to the machine.

When you design or build your own CNC router, you need to decide which is more

important. Have the machine remain constant or have the cutting bed and the

machine flex together. We will cover this more when we discuss the cutting bed.

Alternatives

There are other alternatives when you build or design your own CNC router. One

way to obtain a fully supported router is to do away with the gantry undercarriage

and have the lead screw connect at the top of the gantry or have 2 lead screws

high on each side. You may see this application in the Solsyva designs. They offer

these blueprints on how to build your own CNC router.

However, with a single lead screw up high above the gantry, it makes access to

the cutting bed somewhat difficult. This design works well for smaller machines

that you wish to be mobile. For instance, a CNC router designed to carve shapes

on wood flooring.

http://www.cncroutersource.com/build-your-own-cnc-router.html (5 of 7) [8/6/2008 12:55:24 AM]

Build your own CNC router Step 2: The frame

The Mobile bed design

The mobile

bed or

movable bed

design

approaches the CNC router frame differently. With a mobile bed CNC router, like

the one pictured above, you may have a fully supported frame and bearing system

for the X-axis without compromising any structural framing.

With this design you also only require one motor and lead screw for the X-axis.

Because the lead screw attaches to the bed itself and there is no undercarriage for

the gantry, the bearings and frame would not be in the way. This is advantageous

because if you want design and build your own CNC router, the chances are you

want to save as much money as possible.

The bed must also only support its weight and the weight of the material you will

be cutting. It does not hold the weight of the gantry itself. However, this design

may be inefficient for larger designs as we discussed in step one.

Other Considerations

When you design and build your own CNC router, the material you use to

construct the frame will play a big role in the design of the frame.

Different materials will deform differently. Keep the material consideration in mind

as you choose a frame design. Most popular materials are:

1) MDF

2) Plywood

3) Aluminum Stock

4) 80/20 Structural aluminum.

http://www.cncroutersource.com/build-your-own-cnc-router.html (6 of 7) [8/6/2008 12:55:24 AM]

Build your own CNC router Step 2: The frame

5) Steel

Keep the materials in mind as you think of how to build your CNC router.

In later sections of this guide we will discuss bearing placement, lead screw and

motor placement, and other design features. All of which should be considered

when you build your own CNC router.

For now just review and consider your options for the base and X-axis. When you

design or build your own CNC router, you may decide to employ some elements

from each design.

If you try to rush the process and forget to consider these design issues when you

build your own CNC router, then you may be setting yourself back.

Before you set anything in stone, let’s take a look at the Y-axis gantry and the Z-

axis frame assemblies.

Go back to Step 1: How to build a CNC router

Step 3: Designing and Building the Y-axis and Z-axis Frame

Homepage from how to build your own CNC router

We add and edit this information on how to design and build your own CNC router.

Stay up to date with our RSS feed.

http://www.cncroutersource.com/build-your-own-cnc-router.html (7 of 7) [8/6/2008 12:55:24 AM]

Do it yourself CNC router: Design Considerations, the Gantry

The "Do It Yourself CNC router"

The Gantry Design Considerations

Now that we have looked at the X-axis frame

designs and considerations in a do it yourself

CNC router design, let’s look at the Y-axis

gantry assembly.

The gantry design is the most popular design in

the do it yourself CNC router community. It is

popular for a reason, it works. When you build

a CNC router, it is important to keep the design

trade offs in mind. No matter your budget, the

parts you have, or the material you use, there

is a design that is best for you.

The gantry design is a proven design for "do it yourself CNC routers." However, there

are still many things that you should be aware of.

From a design standpoint, you want your gantry to be stable and balanced. Design the

CNC gantry to meet the forces that it will encounter. This will prevent excess stress and

strain on you bearings, lead screw, motor, etc.

In order for you to be able to design and build your gantry to meet the required forces,

you first need to identify and understand the forces involved.

Let’s take a look at the forces evolved with a do it yourself CNC router gantry.

http://www.cncroutersource.com/do-it-yourself-CNC-router.html (1 of 5) [8/6/2008 12:56:07 AM]

Do it yourself CNC router: Design Considerations, the Gantry

The above image illustrates a side view of a typical do it youself CNC router gantry.

Take a minute to look over the image, there is a lot there. Now let’s discuss what is

happening. It may seem confusing at first but it’s rather simple once you understand

what is taking place. We will discuss.

Center of gravity/mass

Forces

Moment

Let quickly identify the labels above:

D1 = the distance between the cutting tool (the router bit) and the center between the

http://www.cncroutersource.com/do-it-yourself-CNC-router.html (2 of 5) [8/6/2008 12:56:07 AM]

Do it yourself CNC router: Design Considerations, the Gantry

two Y-axis linear bearing rods/rails (D3).

D2 = distance between lead screw/ linear bearings and the bottom Y-axis linear

bearing rail/rod.

D3 = distance between the lower and upper Y-axis linear bearing rods/rails.

D4= distance between the 2 linear bearings that sit on the X-axis linear bearing rods/

rails.

Now we will look at the forces evolved.

The Technical Explanation: CNC Router Forces

(scroll down for the short Version)

The image above illustrates a gantry that is moving from left to right as you look at the

screen. It is being pulled or pushed by the CNC drive system at the bottom. Now, the

router spindle at the bottom. Now, the router spindle is lowered and it starts cutting.

The cutting action apposes the movement of the gantry resulting in a cutting force. The

cutting force varies according to the gantry acceleration, spindle RPM, and the chip

load. The chip load depends on the bit you use, the RPM, and the material. We will get

into these details when we discuss the CNC router spindle. For now just know you have

a cutting force apposing the movement of the gantry.

Just so you know, a force is equal to mass of multiplied by its acceleration. The units of

force are lb-f (pounds of force) in the English system or the Newton in the SI system.

The cutting force results in a moment, which is moment A in the figure above. A

moment results when you have a force applied at a distance. A moment has units of lbf-

in or N-m, we usually call a moment force torque.

Moment A, in the image above, is the result of the cutting force being applied at the

distance D1.

Moment A = D1 x Cutting force

Example:

If the distance D1= 12 inches and the cutting force is 5 lb of force. Then the Moment A

would be 5lb x 1ft = 5 ft lb of force. ( I converted 12 inches to 1 foot) You can see that

even if the cutting force remains the same, the longer the distance of D1 the larger the

moment will be.

Moving on, the Moment A results in 2 forces on the Y-axis linear bearing rods/rails.

These resulting forces are forces A and B in the figure above. Force A and Force B are

equal to each other Force A = Force B.

Force A = Moment A divided by 2 divided by ½ of D3 this equals to

Force A = Force B = Moment A / D3

You can see that as the vertical distance between the two linear rods/rails (for the Y-

axis linear bearings) grows, the resulting forces A and B shrink which is good. Why is

this good? It reduces the amount of centralized torque that is on the gantry itself.

http://www.cncroutersource.com/do-it-yourself-CNC-router.html (3 of 5) [8/6/2008 12:56:07 AM]

Do it yourself CNC router: Design Considerations, the Gantry

Moment B will decrees as force A decreases.

Moment B = D2 x Force A

Moment B is what causes the whole gantry to rock or want to rotate due to the cutting

force. This is not a good thing. You want to decrease Moment B as much as possible.

Why?

You want to make have equal amounts of force on your set of linear bearings as

possible. This will reduce deformation and chatter in your machine.

There are two ways to reduce Moment B.

1) Reduce Force A

2) Reduce the D3

A well designed machine keeps force C and force D to be as equal as possible. And that

is the goal.

Force C and D are the sum of the weight of the machine and resulting forces that occur

do to moment B.

We also need to consider the weight of the gantry and try and calculate or guess where

the center of gravity will be and keep that directly in the center between the two

separated bearings (½ D4). The center of gravity is the point at which the machine

would balance.

That is why you often see the gantry upright side arms slanted backwards an a do it

yourself CNC router. This compensated for the weight of the spindle which hangs our

over the Y-axis linear bearings. When you build a do it yourself CNC router, you want

the center of gravity of the whole gantry assembly to be directly between the two

linear bearings. Or if you have a stationary gantry and a mobile bed, you want center

of gravity to be in the center of the bottom of you gantry side arms.

This assures that your machine is balanced and could stand own its own. This applies

equal load on your bearings.

The short answer (summary)

When you design or build a do it yourself CNC router, keep the following in mind:

Try and keep the distance between the X-axis lead screw and linear bearings, as close

as possible to the bottom Y-axis linear bearing rods/rails. Or as close to the center

distance between the top and bottom Y-axis linear rods/rails. (Minimize D2)

Keep the spindle plunge arm on the Z-axis assembly as short as possible and make

that arm out of rigid material to prevent flexing. A normal Z-axis arm travel is

anywhere from 3 to 6 inches. (Minimize D1)

Calculate or estimate where the center of gravity of the gantry will be located, including

the spindle. Design your gantry side arms to compensate and place the center of

gravity (CG) between the front and back X-axis linear bearings per arm. (CG should be

located at ½ D4 and as close to X-axis lead screw as possible)

Maximize the distance between the upper and lower Y-axis linear bearing rods/rails but

http://www.cncroutersource.com/do-it-yourself-CNC-router.html (4 of 5) [8/6/2008 12:56:07 AM]

Do it yourself CNC router: Design Considerations, the Gantry

still allow for clearance under the bottom rod/rail for your max Z travel. (Maximize D3)

Other considerations

A good gantry design is one of the most crucial factors for a quality do it yourself CNC

router. As with all DIY CNC routers, budget is a concern which means material are also

a concern. Try and visualize and estimate the forces evolved and make your do it

yourself CNC router design work with the materials you have.

If you would like a more thorough analysis you may consult us. We offer free

engineering design analysis of your machine. We can help you find:

Specific CG location

Material stress and strain analysis

Dynamic simulation of your machine

Material selection

And more

Remember, we will discuss more on the gantry design in later section. Topics such as

lead screw placement, motor placement, linear bearing attachments, etc. Which are all

important consideration with a do it yourself CNC router project.

Now let’s take a look at Step 4: the Z-axis assembly design for the do it yourself

CNC router.

Go to Homepage from do it yourself CNC router gantry design

http://www.cncroutersource.com/do-it-yourself-CNC-router.html (5 of 5) [8/6/2008 12:56:07 AM]

Building a CNC Router Step 4: The Z-axis assembly

Building a CNC Router

Step 4: The Z-axis assembly

So far we have looked at the first three steps in building a CNC router

Step 1: Key Design Decisions Step 2: The Base and X-axis Frame

Step 3: The Y-axis Gantry Assembly

Now let’s look at the 4th step,

The Z-axis assembly

Below you can see two examples of Z-axis assemblies with the Y-Axis CNC Router Gantry in the

background.

http://www.cncroutersource.com/building-a-cnc-router.html (1 of 8) [8/6/2008 12:56:26 AM]

Building a CNC Router Step 4: The Z-axis assembly

As with the previous discussions, when designing or building a CNC router it is important to consider the

forces that are evolved. That way, you can adjust your design and verify that it will meet your design

requirements . However, in order to design and build your machine to meet your requirements, you first

need to understand the forces evolved.

Forces on the Z- Axis Assembly

http://www.cncroutersource.com/building-a-cnc-router.html (2 of 8) [8/6/2008 12:56:26 AM]

Building a CNC Router Step 4: The Z-axis assembly

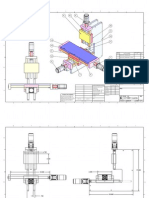

Let’s interpret the above image.

The following explains the dimensions:

D1 = the vertical distance between the upper and lower Y-axis linear bearing rods/rails.

http://www.cncroutersource.com/building-a-cnc-router.html (3 of 8) [8/6/2008 12:56:26 AM]

Building a CNC Router Step 4: The Z-axis assembly

D2 = the vertical distance between the upper and lower sets of Z-axis linear bearings.

D3 = the length of the spindle attachment plunge arm.

D4 = the width of the Z-axis assembly.

D5 = the horizontal distance between the Z-axis linear bearing rods/rails.

D6 = the thickness of the plunge arm

D7 = the distance between the cutting force (approx, tip of the cutting tool) and 1/2 D2.

Now that we understand what the dimensions are, let’s analyze the forces and moments.

Forces and Moments on the Z-Axis Assembly

Building a CNC router can be easy or hard. Some people over analyze and some people just build it and

see if it works. I think the best approach is a mix of the two methods. So let’s first try and understand

what is happening.

The above image illustrates an example of a Z-axis assembly shown in a front view and a side view. Look

at the front view and notice that the Z-axis assembly is moving to the right while it rides on the Y-axis

linear bearing rails/rods.

The plunge arm is at max Z travel and is cutting into a material as it moves from left to right. This

cutting action produces a cutting force that apposes the movement of the Z-axis assembly.

The cutting force is a variable of spindle RPMs, the number of flutes on the cutting tool, the feed rate,

and the material that is being cut. You can learn more on how to calculate cutting force here . When

building a CNC router an important decision to make is what types of material you would like to be able

to cut, which was covered in step 1.

For now, just understand that there is a force in the opposite direction than the Z-axis assembly is

moving. Now let’s see what happens because of this cutting force.

The cutting force creates a moment, which is illustrated in the image above as Moment A.

A moment is just a force that is applied at a distance. We covered moments in greater details in Step 3.

Moment A = D6 x Cutting Force.

http://www.cncroutersource.com/building-a-cnc-router.html (4 of 8) [8/6/2008 12:56:26 AM]

Building a CNC Router Step 4: The Z-axis assembly

Moment A torques the plunge arm in the opposing direction of the cutting force, which torques the whole

Z-axis assembly.

br> This moment results in resultant forces that are applied to

the Z-axis linear bearing rails/rods and the Z-axis linear

bearings themselves. (Yellow arrows)

As D5 and D2 increase in length, the resulting forces decrease. You can see that when you are designing

or building a CNC router, it is important to maximize the horizontal distance between the Z-axis linear

rails rails (D5), and the vertical distance between the Z- axis linear bearing blocks.

The Plunge Arm

D2 also has an effect while cutting along the X-axis. Take a look at the image to the bellow.

The cutting force causes another moment; Moment B.

http://www.cncroutersource.com/building-a-cnc-router.html (5 of 8) [8/6/2008 12:56:26 AM]

Building a CNC Router Step 4: The Z-axis assembly

Moment B is the result of the cutting force being multiplied by the distance between the cutting force and

½ D2.

This moment will apply resulting forces on the Z-axis bearings. As the distance between these bearings

(D2) increase, these forces will decrease. That is why it is best to maximize D2.

As a rule of thumb when building a CNC router, D2 should never be any less that half the length of the

plunge arm. Also, you want the thickness if the plunge arm (D6) to be thick enough to not flex under

your maximum cutting force.

The flex will depend on the maximum cutting force you are designing your machine around, the thickness

of the material (d6), plunge arm length (D3), and the material it is made of.

If you need help calculating your desired cutting force or the amount of deformation a certain material

and size will have, you may contact us We offer free design consultation and other engineering services.

http://www.cncroutersource.com/building-a-cnc-router.html (6 of 8) [8/6/2008 12:56:26 AM]

Building a CNC Router Step 4: The Z-axis assembly

Summary

Keep the following in mind when you design or build a CNC router:

Maximize D1, reduces the forces due to torque caused by the cutting force in the X-axis.

Maximize D2 reduces the forces due to torque caused by the cutting force in the X-axis.

Minimize D3, but still allow for your desired Z-axis travel.

Maximize D4, reduces the forces due to torque caused by the cutting force in the Y-axis.

Other Considerations

In later sections of the building a CNC router guide , we will discuss other features such as lead screws,

motor placement, linear bearings etc.

Don’t forget that you may contact us with any questions regarding CNC machines in general or your

design. We will try and help any way possible.

The motor mount that is used in the above image may be bought pre-fabricated from K2CNC.com for a

variety of router spindles.

Conclusion

So far we have looked at the first 4 steps when building a CNC router,

Step 1: Key Design Decisions

Step 2: The Base and X-axis Frame

Step 3: The Y-axis Gantry Assembly

Step 4: The Z-axis Assembly

Now let’s continue to one of the most important features when designing or building a CNC router

system, the linear motion system.

Building a CNC router Step 5: The linear Motion System

http://www.cncroutersource.com/building-a-cnc-router.html (7 of 8) [8/6/2008 12:56:26 AM]

Building a CNC Router Step 4: The Z-axis assembly

Homepage

http://www.cncroutersource.com/building-a-cnc-router.html (8 of 8) [8/6/2008 12:56:26 AM]

CNC Linear motion: Everything you need to know

CNC Linear Motion Systems

The linear motion system plays a

vital role in any linear CNC

machine, and CNC routers are no

exception. Without these systems

coupled with a drive system, a CNC

router would be of little use.

The LM system is responsible for

three primary tasks.

1) Support Machine Components

2) Guide the machine in a precise

linear motion with minimal friction

3) Support secondary loads

(Torque, Lateral Loads, etc)

A LM system is composed of some type of linear bearing and the linear

bearing guides. There are a number of types of bearings and guides, each

with advantages and disadvantages. Because of the importance of this

system, it is vital for a buyer a builder to be knowledgeable about the LM

components.

For the Buyer

The linear motion system can make or break a machine. For people buying

new CNC routers today, there should be little concerns regarding these

components. The quality and performance of linear motion slides have

drastically improved over the last few years. Almost all of the new CNC

router machines are using quality linear bearing systems.

This holds true for mid-range to high-end models. . If you are buying

hobby CNC routers or low end machines, it is still important for you to be

able to identify quality systems. Some manufacturers do not specify what

types of components are installed and you should know how to identify

faulty systems.For those interested in buying a used system, you need to

know what types of linear system are installed and be able to identify

faults or at least know the right questions ask.

It can cost $10,000 or more to replace a full set of linear bearings

http://www.cncroutersource.com/linear-motion.html (1 of 3) [8/6/2008 12:56:40 AM]

CNC Linear motion: Everything you need to know

(depending on the system). If the system is older, the companies may no

longer sell the parts. If you must replace a part you could be dead in the

water. So it is important to be able to identify the components, know what

faults to look for, and know whether or not the replacements are still in

production.

For the Builder

The LM system can be one of the most expensive and difficult features of a

machine. That is why it is imperative to get it right the first time. If you

are here following the step 3 in the builder's guide then I suggest your

read through all the sections and not just the section on building your own.

This guide will go through the many options you have for linear systems. It

will discuss advantages and disadvantages of each and also show you how

to build your own if you so choose. It will also include information on how

to mount rails, linear shafts, and much more, including money saving tips

and tricks. If you have any questions regarding LM systems, don’t hesitate

to contact us.

Sections

Linear Motion Systems Overview

This Section covers:

Categories of LM systems

Rating and Terminology

How LM systems work

Etc.

Rails and Guide Blocks

This Section covers:

How rails and guide blocks work

Terminology

Types and features

Manufacturers

Where to Buy and Buying Tips

Etc.

Rods and Bushings

This Section covers:

How rods and bushings work

Supported and Unsupported shaft

Shaft types and features

Plain and ball bearing bushings

Manufacturers

Where to Buy and Buying Tips

Etc.

V-Groove Wheels and Track Rollers

This Section covers:

How V-groove wheels and track rollers work

Types and features

Manufacturers

Where to Buy and Buying Tips

http://www.cncroutersource.com/linear-motion.html (2 of 3) [8/6/2008 12:56:40 AM]

CNC Linear motion: Everything you need to know

Etc.

Homemade Linear Motion Systems

This Section covers:

Homemade LM systems overview

“Skate bearing” systems

Plain Bearing systems

Linear Surfaces

Mounting Linear bearing rails

Linear Rods

Other Linear Bearing Systems

Etc.

The Builder's Guide Step 6

Homepage

http://www.cncroutersource.com/linear-motion.html (3 of 3) [8/6/2008 12:56:40 AM]

CNC Drive Components: Stepper Motors, Servo Motors, Leadscrews Etc.

Your Guide to

CNC Drive Components

So what are CNC drive

components?

The drive components are the

mechanical components that "drive"

the CNC machine along its axis. The

most common components

associated with a drive system, are

the motor and lead or ball screw.

The whole idea of a drive system is

to convert controlled rotary motion

to controlled linear motion with the

help of a CNC Controller .

The idea of a CNC drive system is a

fairly simple one. However, the

actual mechanics evolved can be

complicated. This is where many

"DIY CNC'ers" get lost. The drive system is a direct correlation to the

machines capabilities.

By understanding the CNC drive system you have a much better

understanding of a CNC machine. Just by changing a few components you

can control the machines cutting speed, cutting force, precisions, and

accuracy; which should be taken into consideration.

If you are buying a CNC machine, it is best to know what type of drive

components are installed. For example, if someone quotes a precision

of .0001 inch and then informs you they have standard ACME screws and

no anti-backlash nut installed, then they are probably over stating the

machines capabilities.

Again, this is especially true if you are buying a used machine. You need to

know what kind of components are installed, how much wear they have,

and could you buy replacement parts if needed.

What will this guide do?

This guide offers detailed information on every component that makes up a

CNC drive system. If you are building a CNC router, we will discuss money

http://www.cncroutersource.com/cnc-drive.html (1 of 3) [8/6/2008 12:56:55 AM]

CNC Drive Components: Stepper Motors, Servo Motors, Leadscrews Etc.

saving tips and options as well as assembly. If you are interested in Buying

CNC drive parts , then visit our store or take a look at our links page.

There you will find a list of recommended places to buy each part.

1. Stepper Motors and Servo Motors

A CNC machine wouldn't be a CNC machine without some sort of motor.

Stepper motors or Servo motors both perform the same task, which is take

in electrical power and convert it to rotational motion. Think of the motors

as the workhorse for the machine, however, they need to be told what to

do, which is the job of the CNC controller. This section will take you though

the ins and outs of CNC motors.

2. Leadscrews and Ballscrews

The first step to converting the rotational motion supplies by the motors to

linear motion, is the lead screw or ball screw. With the help of a CNC drive

nut, you can have a great amount of linear force with little torque. Just like

the jack on your car. Try to lift your 2000 lb vehicle without the aid or your

jack and see how far you get. However, there are many different types of

leads crews and ball screws. This guide will walk you through the pros and

cons of each type and also discuss alternative solutions for CNC machines

on a budget.

3. CNC Drive Nuts

The drive nut is the one link between the lead or ballscrew and the actual

machine. Therefore it is often discussed in direct relation with the

leadscrews. However, you may have the nicest system money can buy and

less than par drive nuts, and not be able to hold a tolerance of .01 inch.

That is why I am devoting a full section to drive nuts. This one component

will make or break your machine. We will discuss the types of drive nut,

backlash and much more. If you are building a CNC router, you MUST read

this section. The CNC drive system is a vital part of your machine. I will

discuss how to obtain some very nice anti-backlash nuts for very cheap.

4. Rack and pinion

Rack and pinions are less pronoun than their leadscrew counterparts.

However, there are some applications where it is the only solution so that

close tolerances can still be held. Many hobby CNC'ers completely overlook

this option, primarily because of cost. However, there are ways to come

out even cheaper than alternative solutions.

4. Radial, Thrust bearing and Couplers

This section covers some of the minor components in a CNC drive system.

Things such as radial and thrust bearings for leadscrews and and shaft

couplers. Although, these are "minor" pieces in the whole system, they still

play a vital role. After all, a machine is only as good as it weakest link. If

you are buying a CNC router then you have nothing to worry about as

these parts are usually all the same. However, if you are building a CNC

machine, this section will cover vital information that will save major

headaches down the path.

5.Direct drive vs. Geared or Pulley Systems

There are two main ways of coupling your electric motor to the other CNC

http://www.cncroutersource.com/cnc-drive.html (2 of 3) [8/6/2008 12:56:55 AM]

CNC Drive Components: Stepper Motors, Servo Motors, Leadscrews Etc.

drive components. The first being direct drive via use of a anti-backlash

shaft coupler discussed above, and secondly, the use of either pulleys or

gears. We will cover the reasons for having each and also the pros and

cons as usual. This is another one of those things that people often

overlook.

Continue to The Builders Guide STEP 5: The X, Y, and Z axis

Homepage

http://www.cncroutersource.com/cnc-drive.html (3 of 3) [8/6/2008 12:56:55 AM]

The CNC Router Table Top, Where the magic happens

The CNC Router Table Top

The CNC router table

top is where the

cutting magic

happens. The table

top, also called the

cutting bed, can make

the life of a CNC

router operator

enjoyable or a

nightmare.

Many times when

buying a CNC router,

the type of table top is often overlooked or the significance

underestimated. I assure you there is a design that will fit your needs best.

For example, if you are in the prototyping business, you will probably be

working with all kinds of materials and shapes. This would probably push

you towards a T-slot style, which offers numerous clamping options. On

the other hand, you might produce the same type of product on a daily

basis which would push you towards a different style.

On higher end CNC router router tables now days, you may find a

combination of different types of cutting table tops. However, it is best to

be knowledgeable about what kind of CNC router table will be best for you.

If you are building your own CNC router , your options are limited unless

your budget allows. However, there is still a lot of material to be covered

regarding the cutting board. This information should be very helpful to

your design.

The T-Slot table top

The T-slot table is often seen on traditional CNC milling machines.

However, these are usually made of tooling steel and are extremely heavy.

The T-slot tables found on CNC routers are usually made of extruded

aluminum. There are many advantages to the T-slot type table. However

this style can be very...

The Vacuum table top

http://www.cncroutersource.com/cnc-router-table-top.html (1 of 2) [8/6/2008 12:57:11 AM]

The CNC Router Table Top, Where the magic happens

The vacuum style CNC router table top is often found on higher end

models. They can be very useful for many applications. However, there are

drawbacks. For example the...

The Perforated table top

Similar to the vacuum table in appearance, the perforated table top is

simple yet affective. Much cheaper than a T-slot style bed, yet offers

similar performance. The perforated table offers a lot as far as...

The "Disposable" table top

The "The "Disposable" table top is actually one of my favorites. Especially

if you are new to operating a CNC router. This table style, usually

composed of one or two sheets of high density MDF board, are very useful

even if you have some other table top installed. I can't tell you how awful

it makes you feel when you cut into your brand new t-slot or vacuum

table. Yes I know there are limit switches, touch off pad and sensors to

prevent that type of mistake. However, you would be surprised at how

often we "bypass" those features. The disposable bed can also...

Building your own CNC router table top

The CNC router table top on a homemade machine is a very important

considerations. The budget usually pushes towards the MDF style cutaway

table top, which I actually think is best because of its versatility. However,

design of the table support and structure should NOT be overlooked.

Continue this section for step 6 of the builders guide.

Continue to The builders guide: Step 7 Spindle Selection

Homepage

http://www.cncroutersource.com/cnc-router-table-top.html (2 of 2) [8/6/2008 12:57:11 AM]

The CNC Router Spindle: Your ultimate resource

The Router Spindle

So what is the router spindle? Don't be confused by

the "fancy" terminology. The spindle is simple the

actual motor doing the cutting, with the help of a

cutting tool of course. In other words it’s the actual

router of CNC router.

Like most everything else involving CNC routers,

there are a variety of spindle types out there. Some

made for wood, some made for metal, etc. As usual

there are many factors involved when choosing a

spindle for either your pre-build machine, or your

homemade CNC machine.

If you are buying an industrial CNC router , then

you should be well informed as to the capabilities of

the spindle before you buy. Most companies who sell CNC routers do a

pretty good job of displaying the spindle capabilities. The reason being,

this information is easily understood and appeals well to the reader. For

example, “our machine offers a 7 HP router.”

Most people readily understand these figures much more than linear

bearings and lead screw information and make a direct link to the

machines capabilities, which is somewhat true.

There are, however, many other important considerations. Such as, RPM,

load ratings, power requirements, and the collet type and size to say the

least.

If you are building a CNC machine, then you also need to make important

decision regarding the router spindle. Again, I realize a lot of hobbyists are

bound by budget which I respect. After all, that’s part of the challenge.

However, there are many choices to choose from within the same price

bracket.

One of the most important decisions for the hobbyists , I believe, is the

noise level. If you are anywhere near neighbors or your own house, then

this is a huge consideration. You don’t want to be running an extremely

load machine for hours at a time, unless you want angry neighbors.

This section will go into detail regarding all aspects of spindles of all types.

Well look at types and features, price ranges , mounting issues, and much

more.

http://www.cncroutersource.com/router-spindle.html (1 of 2) [8/6/2008 12:57:30 AM]

The CNC Router Spindle: Your ultimate resource

The Router Spindle: Types and Features

There are as many tpes of spindles as there are types of CNC routers out

there. We'll take a look at all types, from...

Spindle Prices and Costs

We'll look at general pricing of different types of spindles. This assures you

aren't getting ripped off by...

Mounting and Cooling Options

There are many ways to mount a spindle head, but there are very few

ways to do it right. Cooling the spindle and the cutting tool is a major issue

for some applications. The one way to make a bad...

Building your own

For the mechanically minded enthusiasts out there, there are ways to

make your won spindle that is specific to your needs. Although I view this

as an extra project and not a necessity as it would be hard to make

something cheaper than what is available commercially. Alternatively,

there are ways to crop parts from other machines to build a rather robust

router spindle that is…

Calculating Cutting Force

While designing, building, or operating a CNC router, you will probably run

across terms such as cutting force or chip load. This section will describe

how to calculate relative cutting force, chip load, optimal feed rates and

spindles speeds...

Continue to: The Builders Guide Step 8

Homepage

http://www.cncroutersource.com/router-spindle.html (2 of 2) [8/6/2008 12:57:30 AM]

CNC Electronics: MPG's, Buttons, Switches, Controle Panel

CNC Electronics

CNC electronics are a vital part of

any CNC machine. Aside from the

motors and CNC controllers , there

are many electronic components

that assist in the machine operation.

In this section we will cover all the

electronics involved with a CNC

router. Many people feel more

threatened by the electrical

components than the mechanics of

a machine. This doesn’t have to be the case. Whether you are building or

buying a CNC router , this section will help inform you on the electronic

systems found on a CNC router and help you understand how they come

together with other components to create a fully working machine.

For the buyer

If you are purchasing a CNC router , you will probably know right from the

start if something is wrong with the electronics. This should be checked

before ever committing to buying a CNC router. Of course for a new

machine, this should be of little concern. If you are buying a new machine,

everything should be in tip top shape and if not, send it back or have them

fix it.

However, if you are buying a used machine, it would be highly

recommended to check all the systems before hand. The control panel

buttons, limit switches, wiring, etc. For high end CNC routers, in any case

you should always have a professional inspect the machine if you find

something to be faulty. The chances of you shorting out other systems are

not worth the risk of trying to fix it yourself or having the “Maytag repair

man” look it over. For lower end models and hobby CNC routers , the

electronics are usually very straightforward but if you don’t feel

comfortable, have someone else do it.

For the Builder

There are many electronic aspects of a CNC router that are vital to its

function. Things such as limit and proximity switches, motor wiring, correct

cable sizing and selection etc. These features are, in my opinion, vital to

building a reliable machine. Yet many people neglect these feature

http://www.cncroutersource.com/cnc-electronics.html (1 of 3) [8/6/2008 12:57:48 AM]

CNC Electronics: MPG's, Buttons, Switches, Controle Panel

because of lack of “know how” or budget . Many of these “add-ons” cost

only pennies to install and could save either your machine or the piece you

are working on. For the most part, adding these components is by no

means difficult.

There are also some CNC electronic features that are not often required.

Such as manual pulse generators, home and e-stop buttons, touch-off tool

sensors etc. These things may or may not be essential to the machine,

depending on the user, but do increase user friendliness. Not to mention,

increasing the overall look and feel of the machine.

With a few CNC electronic add-ons and a well constructed user panel, you

can make you homemade CNC routers seem like one off the shelf.