Escolar Documentos

Profissional Documentos

Cultura Documentos

Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates

Enviado por

Can YörütenDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates

Enviado por

Can YörütenDireitos autorais:

Formatos disponíveis

Designation: D 2344/D 2344M – 00 (Reapproved 2006)

Standard Test Method for

Short-Beam Strength of Polymer Matrix Composite Materials

and Their Laminates1

This standard is issued under the fixed designation D 2344/D 2344M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 3171 Test Methods for Constituent Content of Composite

1.1 This test method determines the short-beam strength of Materials

high-modulus fiber-reinforced composite materials. The speci- D 3878 Terminology for Composite Materials

men is a short beam machined from a curved or a flat laminate D 5229/D 5229M Test Method for Moisture Absorption

up to 6.00 mm [0.25 in.] thick. The beam is loaded in Properties and Equilibrium Conditioning of Polymer Ma-

three-point bending. trix Composite Materials

1.2 Application of this test method is limited to continuous- D 5687/D 5687M Guide for Preparation of Flat Composite

or discontinuous-fiber-reinforced polymer matrix composites, Panels with Processing Guidelines for Specimen Prepara-

for which the elastic properties are balanced and symmetric tion

with respect to the longitudinal axis of the beam. E 4 Practices for Force Verification of Testing Machines

1.3 This standard does not purport to address all of the E 6 Terminology Relating to Methods of Mechanical Test-

safety concerns, if any, associated with its use. It is the ing

responsibility of the user of this standard to establish appro- E 18 Test Methods for Rockwell Hardness and Rockwell

priate safety and health practices and determine the applica- Superficial Hardness of Metallic Materials

bility of regulatory limitations prior to use. E 122 Practice for Calculating Sample Size to Estimate,

1.4 The values stated in either SI units or inch-pound units With a Specified Tolerable Error, the Average for a

are to be regarded separately as standard. The values stated in Characteristic of a Lot or Process

each system may not be exact equivalents; therefore, each E 177 Practice for Use of the Terms Precision and Bias in

system must be used independently of the other. Combining ASTM Test Methods

values from the two systems may result in nonconformance E 456 Terminology Relating to Quality and Statistics

with the standard. E 1309 Guide for Identification of Fiber-Reinforced

Polymer-Matrix Composite Materials in Databases

2. Referenced Documents E 1434 Guide for Recording Mechanical Test Data of Fiber-

2.1 ASTM Standards: 2 Reinforced Composite Materials in Databases

D 792 Test Methods for Density and Specific Gravity (Rela- E 1471 Guide for Identification of Fibers, Fillers, and Core

tive Density) of Plastics by Displacement Materials in Computerized Material Property Databases

D 883 Terminology Relating to Plastics

3. Terminology

D 2584 Test Method for Ignition Loss of Cured Reinforced

Resins 3.1 Definitions—Terminology D 3878 defines the terms re-

lating to high-modulus fibers and their composites. Terminol-

--`,``,,,,,,,,`,```,,`,,,``,,-`-`,,`,,`,`,,`---

D 2734 Test Methods for Void Content of Reinforced Plas-

tics ogy D 883 defines terms relating to plastics. Terminology E 6

defines terms relating to mechanical testing. Terminology

E 456 and Practice E 177 define terms relating to statistics. In

1

the event of a conflict between definitions, Terminology

This test method is under the jurisdiction of ASTM Committee D-30 on

Composite Materials and is the direct responsibility of Subcommittee D30.04 on D 3878 shall have precedence over the other documents.

Lamina and Laminate Test Methods.

NOTE 1—If the term represents a physical quantity, its analytical

Current edition approved Jan. 15, 2006. Published January 2006. Originally

approved in 1965. Last previous edition approved in 2000 as D 2344 – 00e1.

dimensions are stated immediately following the term (or letter symbol) in

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or fundamental dimension form, using the following ASTM standard sym-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM bology for fundamental dimensions, shown within square brackets: [M]

Standards volume information, refer to the standard’s Document Summary page on for mass, [L] for length, [T] for time, [Q] for thermodynamic temperature,

the ASTM website. and [nd] for nondimensional quantities. Use of these symbols is restricted

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Istanbul Teknik Universtesi/5956919001

No reproduction or networking permitted without license from IHS Not for Resale, 04/06/2011 08:00:28 MDT

Reproduction authorized per License Agreement with Monique Tyree (ASTMIHS Account); Mon Feb 6 14:08:00 EST 2006

D 2344/D 2344M – 00 (2006)

to analytical dimensions when used with square brackets, as the symbols

may have other definitions when used without the brackets.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 balanced laminate, n—a continuous fiber-reinforced

laminate in which each +u lamina, measured with respect to the

laminate reference axis, is balanced by a –u lamina of the same

material (for example, [0/+45/–45/+45/–45/0]).

3.2.2 short-beam strength, n—the shear stress as calculated

in Eq 1, developed at the specimen mid-plane at the failure

event specified in 11.6.

3.2.2.1 Discussion—Although shear is the dominant applied

loading in this test method, the internal stresses are complex

and a variety of failure modes can occur. Elasticity solutions by

Berg et al (1)3, Whitney (2), and Sullivan and Van Oene (3)

have all demonstrated inadequacies in classical beam theory in

defining the stress state in the short-beam configuration. These

solutions show that the parabolic shear-stress distribution as

predicted by Eq 1 only occurs, and then not exactly, on planes

midway between the loading nose and support points. Away

from these planes, the stress distributions become skewed, with

peak stresses occurring near the loading nose and support

points. Of particular significance is the stress state local to the

loading nose in which the severe shear-stress concentration

combined with transverse and in-plane compressive stresses

has been shown to initiate failure. However, for the more

ductile matrices, plastic yielding may alleviate the situation

under the loading nose (1) and allow other failure modes to

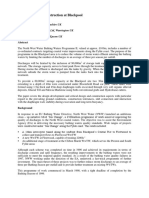

occur such as bottom surface fiber tension (2). Consequently, NOTE 1—Drawing interpretation per ANSI Y14.5-1982 and ANSI/

unless mid-plane interlaminar failure has been clearly ob- ASM B46.1-1986.

served, the short-beam strength determined from this test NOTE 2—Ply orientation tolerance 60.5° relative to –B–.

method cannot be attributed to a shear property, and the use of FIG. 1 Flat Specimen Configuration (SI)

Eq 1 will not yield an accurate value for shear strength.

5. Significance and Use

3.2.3 symmetric laminate, n—a continuous fiber-reinforced

laminate in which each ply above the mid-plane is identically 5.1 In most cases, because of the complexity of internal

matched (in terms of position, orientation, and mechanical stresses and the variety of failure modes that can occur in this

properties) with one below the mid-plane. specimen, it is not generally possible to relate the short-beam

3.3 Symbols: strength to any one material property. However, failures are

b—specimen width. normally dominated by resin and interlaminar properties, and

CV—sample coefficient of variation (in percent). the test results have been found to be repeatable for a given

specimen geometry, material system, and stacking sequence

Fsbs—short-beam strength.

(4).

h—specimen thickness.

5.2 Short-beam strength determined by this test method can

n—number of specimens.

be used for quality control and process specification purposes.

Pm—maximum load observed during the test. It can also be used for comparative testing of composite

xi—measured or derived property for an individual specimen materials, provided that failures occur consistently in the same

from the sample population. mode (5).

x̄—sample mean (average). 5.3 This test method is not limited to specimens within the

range specified in Section 8, but is limited to the use of a

4. Summary of Test Method loading span length-to-specimen thickness ratio of 4.0 and a

4.1 The short-beam test specimens (Figs. 1-4) are center- minimum specimen thickness of 2.0 mm [0.08 in.].

loaded as shown in Figs. 5 and 6. The specimen ends rest on

6. Interferences

two supports that allow lateral motion, the load being applied

--`,``,,,,,,,,`,```,,`,,,``,,-`-`,,`,,`,`,,`---

by means of a loading nose directly centered on the midpoint 6.1 Accurate reporting of observed failure modes is essen-

of the test specimen. tial for meaningful data interpretation, in particular, the detec-

tion of initial damage modes.

7. Apparatus

3

Boldface numbers in parentheses refer to the list of references at the end of this 7.1 Testing Machine, properly calibrated, which can be

standard. operated at a constant rate of crosshead motion, and which the

Copyright ASTM International 2

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Istanbul Teknik Universtesi/5956919001

No reproduction or networking permitted without license from IHS Not for Resale, 04/06/2011 08:00:28 MDT

Reproduction authorized per License Agreement with Monique Tyree (ASTMIHS Account); Mon Feb 6 14:08:00 EST 2006

D 2344/D 2344M – 00 (2006)

--`,``,,,,,,,,`,```,,`,,,``,,-`-`,,`,,`,`,,`---

within 63°C (65°F) and the required vapor level to within

63 %. Chamber conditions shall be monitored either on an

automated continuous basis or on a manual basis at regular

intervals.

7.5 Environmental Test Chamber, an environmental test

chamber is required for test environments other than ambient

testing laboratory conditions. This chamber shall be capable of

maintaining the test specimen at the required test environment

during the mechanical test method.

8. Sampling and Test Specimens

8.1 Sampling—Test at least five specimens per test condi-

tion unless valid results can be gained through the use of fewer

specimens, as in the case of a designed experiment. For

statistically significant data, consult the procedures outlined in

Practice E 122. Report the method of sampling.

8.2 Geometry:

8.2.1 Laminate Configurations—Both multidirectional and

pure unidirectional laminates can be tested, provided that there

are at least 10 % 0° fibers in the span direction of the beam

(preferably well distributed through the thickness), and that the

laminates are both balanced and symmetric with respect to the

span direction of the beam.

8.2.2 Specimen Configurations—Typical configurations for

the flat and curved specimens are shown in Figs. 1-4. For

NOTE 1—Drawing interpretation per ANSI Y14.5-1982 and ANSI/ specimen thicknesses other than those shown, the following

ASME B46.1-1986. geometries are recommended:

NOTE 2—Ply orientation tolerance 60.5° relative to –B–.

Specimen length = thickness 3 6

FIG. 2 Flat Specimen Configuration (Inch Pound)

Specimen width, b = thickness 3 2.0

error in the loading system shall not exceed 61 %. The NOTE 2—Analysis reported by Lewis and Adams (6) has shown that a

width-to-thickness ratio of greater than 2.0 can result in a significant

load-indicating mechanism shall be essentially free of inertia width-wise shear-stress variation.

lag at the crosshead rate used. Inertia lag may not exceed 1 %

of the measured load. The accuracy of the testing machine shall 8.2.2.1 For curved beam specimens, it is recommended that

be verified in accordance with Practices E 4. the arc should not exceed 30°. Also, for these specimens, the

7.2 Loading Nose and Supports, as shown in Figs. 5 and 6, specimen length is defined as the minimum chord length.

shall be 6.00-mm (0.250-in.) and 3.00-mm (0.125-in.) diameter 8.3 Specimen Preparation—Guide D 5687/D 5687M pro-

cylinders, respectively, with a hardness of 60 to 62 HRC, as vides recommended specimen preparation practices and should

specified in Test Methods E 18, and shall have finely ground be followed where practical.

surfaces free of indentation and burrs with all sharp edges 8.3.1 Laminate Fabrication—Laminates may be hand-laid,

relieved. filament-wound or tow-placed, and molded by any suitable

7.3 Micrometers—For width and thickness measurements, laminating means, such as press, bag, autoclave, or resin

the micrometers shall use a 4- to 5-mm (0.16- to 0.2-in.) transfer molding.

nominal diameter ball interface on an irregular surface such as

the bag side of a laminate and a flat anvil interface on machined 8.3.2 Machining Methods—Specimen preparation is impor-

edges or very smooth tooled surfaces. A micrometer or caliper tant for these specimens. Take precautions when cutting

with flat anvil faces shall be used to measure the length of the specimens from the rings or plates to avoid notches, undercuts,

specimen. The accuracy of the instrument(s) shall be suitable rough or uneven surfaces, or delaminations as a result of

for reading to within 1 % of the sample dimensions. For typical inappropriate machining methods. Obtain final dimensions by

section geometries, an instrument with an accuracy of 60.002 water-lubricated precision sawing, milling, or grinding. The

mm (60.0001 in.) is desirable for thickness and width mea- use of diamond tooling has been found to be extremely

surement, while an instrument with an accuracy of 60.1 mm effective for many material systems. Edges should be flat and

(60.004 in.) is adequate for length measurement. parallel within the specified tolerances.

7.4 Conditioning Chamber, when conditioning materials at 8.3.3 Labeling—Label the specimens so that they will be

nonlaboratory environments, a temperature/vapor-level- distinct from each other and traceable back to the raw material,

controlled environmental conditioning chamber is required that in a manner that will both be unaffected by the test method and

shall be capable of maintaining the required temperature to not influence the test method.

Copyright ASTM International 3

Provided by IHS under license with ASTM Copyright by ASTM Int'l (all rights reserved); Licensee=Istanbul Teknik Universtesi/5956919001

No reproduction or networking permitted without license from IHS Not for Resale, 04/06/2011 08:00:28 MDT

Reproduction authorized per License Agreement with Monique Tyree (ASTMIHS Account); Mon Feb 6 14:08:00 EST 2006

D 2344/D 2344M – 00 (2006)

NOTE 1—Drawing interpretation per ANSI Y14.5-1982 and ANSI/ASM B46.1-1986.

NOTE 2—Ply orientation tolerance 60.5° relative to –A–.

FIG. 3 Curved Specimen Configuration (SI)

9. Calibration 11.1.1 The specimen sampling method and coupon geom-

9.1 The accuracy of all measuring equipment shall have etry.

certified calibrations that are current at the time of use of the 11.1.2 The material properties and data-reporting format

equipment. desired.

10. Conditioning NOTE 3—Determine specific material property, accuracy, and data-

10.1 Standard Conditioning Procedure—Unless a different reporting requirements before test for proper selection of instrumentation

environment is specified as part of the test method, condition and data-recording equipment. Estimate operating stress levels to aid in

calibration of equipment and determination of equipment settings.

the test specimens in accordance with Procedure C of Test

Method D 5229/D 5229M, and store and test at standard 11.1.3 The environmental conditioning test parameters.

laboratory atmosphere (23 6 3°C (73 6 5°F) and 50 6 10 % 11.1.4 If performed, the sampling test method, coupon

relative humidity). geometry, and test parameters used to determine density and

11. Procedure reinforcement volume.

11.1 Parameters to Be Specified Before Test: 11.2 General Instructions:

--`,``,,,,,,,,`,```,,`,,,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International 4

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Istanbul Teknik Universtesi/5956919001

No reproduction or networking permitted without license from IHS Not for Resale, 04/06/2011 08:00:28 MDT

Reproduction authorized per License Agreement with Monique Tyree (ASTMIHS Account); Mon Feb 6 14:08:00 EST 2006

D 2344/D 2344M – 00 (2006)

NOTE 1—Drawing interpretation per ANSI Y14.5-1982 and ANSI/ASME B46.1-1986.

NOTE 2—Ply orientation tolerance 60.5° relative to –A–.

FIG. 4 Curved Specimen Configuration (Inch Pound)

11.2.1 Report any deviations from this test method, whether 11.2.3 Condition the specimens as required. Store the speci-

intentional or inadvertent. mens in the conditioned environment until test time, if the test

11.2.2 If specific gravity, density, reinforcement volume, or environment is different from the conditioning environment.

void volume are to be reported, then obtain these samples from 11.2.4 Following final specimen machining and any condi-

the same panels as the test samples. Specific gravity and tioning, but before testing, measure and record the specimen

density may be evaluated by means of Test Methods D 792. width and thickness at the specimen midsection and the

Volume percent of the constituents may be evaluated by one of specimen length to the accuracy specified in 7.3.

the matrix digestion procedures of Test Method D 3171, or for 11.3 Speed of Testing—Set the speed of testing at a rate of

certain reinforcement materials such as glass and ceramics, by crosshead movement of 1.0 mm (0.05 in.)/min.

the matrix burn-off technique of Test Method D 2584. Void 11.4 Test Environment—If possible, test the specimen under

--`,``,,,,,,,,`,```,,`,,,``,,-`-`,,`,,`,`,,`---

content may be evaluated from the equations of Test Method the same fluid exposure level as that used for conditioning.

D 2734 and are applicable to both Test Methods D 2584 and However, if the test temperature places too severe requirements

D 3171. upon the testing machine environmental chamber, test at a

Copyright ASTM International 5

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Istanbul Teknik Universtesi/5956919001

No reproduction or networking permitted without license from IHS Not for Resale, 04/06/2011 08:00:28 MDT

Reproduction authorized per License Agreement with Monique Tyree (ASTMIHS Account); Mon Feb 6 14:08:00 EST 2006

D 2344/D 2344M – 00 (2006)

FIG. 5 Horizontal Shear Load Diagram (Curved Beam)

FIG. 6 Horizontal Shear Load Diagram (Flat Laminate)

temperature with no fluid exposure control. In this case, a 11.6 Loading—Apply load to the specimen at the specified

restriction must be placed upon the time from removal of the rate while recording data. Continue loading until either of the

specimen from the conditioning chamber until test completion following occurs:

to inhibit nonrepresentative fluid loss from the specimen. 11.6.1 A load drop-off of 30 %,

Record any modifications to the test environment and specimen 11.6.2 Two-piece specimen failure, or

weight change after removal from conditioning until test 11.6.3 The head travel exceeds the specimen nominal thick-

completion. ness.

11.4.1 Monitor the test temperature by placing an appropri- 11.7 Data Recording—Record load versus crosshead dis-

ate thermocouple at specimen mid-length to be located on the placement data throughout the test method. Record the maxi-

underside of the beam. mum load, final load, and the load at any obvious discontinui-

11.5 Specimen Insertion—Insert the specimen into the test ties in the load-displacement data.

fixture, with the toolside resting on the reaction supports as 11.8 Failure Mode—Typical failure modes that can be

shown in Fig. 5 or Fig. 6. Align and center the specimen such identified visually are shown in Fig. 7. However, these may be

that its longitudinal axis is perpendicular to the loading nose preceded by less obvious, local damage modes such as transply

and side supports. Adjust the span such that the span-to- cracking. Record the mode and location of failure, if possible

measured thickness ratio is 4.0 to an accuracy of 60.3 mm identifying one or a combination of the modes shown.

(0.012 in.). The loading nose should be located equidistant

between the side supports to within 60.3 mm (0.012 in.). Both

12. Calculation

the loading nose and side supports should overhang the

specimen width by at least 2 mm (0.08 in.) at each side. In the 12.1 Short-Beam Strength—Calculate the short-beam

case of the flat laminate test, each specimen end should strength using Eq 1 as follows:

overhang the side support centers by at least the specimen Pm

Fsbs 5 0.75 3 b 3 h (1)

thickness.

--`,``,,,,,,,,`,```,,`,,,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International 6

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Istanbul Teknik Universtesi/5956919001

No reproduction or networking permitted without license from IHS Not for Resale, 04/06/2011 08:00:28 MDT

Reproduction authorized per License Agreement with Monique Tyree (ASTMIHS Account); Mon Feb 6 14:08:00 EST 2006

D 2344/D 2344M – 00 (2006)

FIG. 7 Typical Failure Modes in the Short Beam Test

where: 13.1.2 Whether the coupon configuration was standard or

Fsbs = short-beam strength, MPa (psi); variant.

Pm = maximum load observed during the test, N (lbf); 13.1.3 The date and location of the test.

b = measured specimen width, mm (in.), and 13.1.4 The name of the test operator.

h = measured specimen thickness, mm (in.). 13.1.5 Any variations to this test method, anomalies noticed

12.2 Statistics—For each series of test methods, calculate during testing, or equipment problems occurring during testing.

the average value, standard deviation, and coefficient of varia- 13.1.6 Identification of the material tested including: mate-

tion (in percent) for each property determined as follows: rial specification, material type, material designation, manufac-

n turer, manufacturer’s batch or lot number, source (if not from

x 5 ~ ( xi!/n (2) manufacturer), date of certification, expiration of certification,

i–1

filament diameter, tow or yarn filament count and twist, sizing,

form or weave, fiber areal weight, matrix type, prepreg matrix

sn–1 5 Œ( ~

n

i51

xi2 – n~x!2 !/~n–1! (3) content, and prepreg volatiles content.

13.1.7 Description of the fabrication steps used to prepare

the laminate including: fabrication start date, fabrication end

CV 5 100 3 sn–1/x (4)

date, process specification, cure cycle, consolidation method,

where: and a description of the equipment used.

x̄ = sample mean (average); 13.1.8 Ply orientation and stacking sequence of the lami-

sn–1 = sample standard deviation; nate.

CV = sample coefficient of variation, %; 13.1.9 If requested, report density, volume percent rein-

n = number of specimens; and forcement, and void content test methods, specimen sampling

xi = measured or derived property. method and geometries, test parameters, and test results.

13.1.10 Average ply thickness of the material.

13. Report

13.1.11 Results of any nondestructive evaluation tests.

13.1 Report the following information, or references point- 13.1.12 Method of preparing the test specimen, including

ing to other documentation containing this information, to the specimen labeling scheme and method, specimen geometry,

maximum extent applicable (reporting of items beyond the sampling method, and coupon cutting method.

control of a given testing laboratory, such as might occur with 13.1.13 Calibration dates and methods for all measurements

material details or panel fabrication parameters, shall be the and test equipment.

responsibility of the requester): 13.1.14 Details of loading nose and side supports including

NOTE 4—Guides E 1309, E 1434, and E 1471 contain data reporting diameters and material used.

recommendations for composite materials and composite materials me- 13.1.15 Type of test machine, alignment results, and data

chanical testing. acquisition sampling rate and equipment type.

13.1.1 This test method and revision level or date of issue. 13.1.16 Dimensions of each test specimen.

--`,``,,,,,,,,`,```,,`,,,``,,-`-`,,`,,`,`,,`---

Copyright ASTM International 7

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Istanbul Teknik Universtesi/5956919001

No reproduction or networking permitted without license from IHS Not for Resale, 04/06/2011 08:00:28 MDT

Reproduction authorized per License Agreement with Monique Tyree (ASTMIHS Account); Mon Feb 6 14:08:00 EST 2006

D 2344/D 2344M – 00 (2006)

13.1.17 Conditioning parameters and results. 14. Precision and Bias

13.1.18 Relative humidity and temperature of the testing

14.1 Precision—The data required for the development of a

laboratory.

precision statement is not currently available for this test

13.1.19 Environment of the test machine environmental

method.

chamber (if used) and soak time at environment.

13.1.20 Number of specimens tested. 14.2 Bias—Bias cannot be determined for this test method

13.1.21 Speed of testing. as no acceptable reference standard exists.

--`,``,,,,,,,,`,```,,`,,,``,,-`-`,,`,,`,`,,`---

13.1.22 Maximum load observed during the test, for each

specimen. 15. Keywords

13.1.23 Load-displacement curves for each specimen. 15.1 composite materials; resin and interlaminar properties;

13.1.24 Failure mode of each specimen, identified if pos- short-beam strength

sible from Fig. 7.

REFERENCES

(1) Berg, C. A., Tirosh, J., and Israeli, M., “Analysis of Short Beam (4) U.S. Department of Transportation, Federal Aviation Administration,

Bending of Fiber Reinforced Composites,” in Composite Materials: “Test Methods for Composites a Status Report: Volume III Shear Test

Testing and Design (Second Conference), ASTM STP 497, ASTM, Methods,” Report No. DOT/FAA/CT-93/17, III, FAA Technical Cen-

1972, pp. 206-218. ter, Atlantic City, 1993.

(2) Whitney, J. M., and Browning, C. E., “On Short-Beam Shear Tests for (5) Cui, W., Wisnom, M. R., and Jones, M., “Effect of Specimen Size on

Composite Materials,” Experimental Mechanics, Vol 25, 1985, pp.

Interlaminar Shear Strength of Unidirectional Carbon Fibre-Epoxy,”

294-300.

Composites Engineering, Vol 4, No. 3, 1994, pp. 299-307.

(3) Sullivan, J. L., and Van Oene, H., “An Elasticity Analysis for the

Generally and Specially Orthotropic Beams Subjected to Concentrated (6) Adams, D. F. and Lewis, E. Q., “Current Status of Composite Material

Loads,” Composites Science and Technology, Vol 27, 1986, pp. Shear Test Methods,” SAMPE, Vol 31, No. 6, 1994, pp. 32-41.

182-191.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International 8

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Istanbul Teknik Universtesi/5956919001

No reproduction or networking permitted without license from IHS Not for Resale, 04/06/2011 08:00:28 MDT

Reproduction authorized per License Agreement with Monique Tyree (ASTMIHS Account); Mon Feb 6 14:08:00 EST 2006

Você também pode gostar

- DESIGN CALCULATIONS - GL-03 2509 - 4.0mDocumento17 páginasDESIGN CALCULATIONS - GL-03 2509 - 4.0mmsiddiq1Ainda não há avaliações

- Astm D3518-94Documento7 páginasAstm D3518-94Chris KořánAinda não há avaliações

- A Level PhysicsDocumento239 páginasA Level PhysicsDaniel O'Connell100% (2)

- Astm D 5961 (2013)Documento31 páginasAstm D 5961 (2013)martin_calmonAinda não há avaliações

- Astm C393 PDFDocumento8 páginasAstm C393 PDFTuswanAinda não há avaliações

- D7249Documento9 páginasD7249LAL KRISHAinda não há avaliações

- Astm D 695 - 02Documento10 páginasAstm D 695 - 02catarinaAinda não há avaliações

- F101 96Documento24 páginasF101 96naser712Ainda não há avaliações

- Technical Reference V8i PDFDocumento629 páginasTechnical Reference V8i PDFWWAinda não há avaliações

- ASTM Composite D3039 Tensile Properties of PMCDocumento13 páginasASTM Composite D3039 Tensile Properties of PMCArman Kusuma WijayaAinda não há avaliações

- Astm C 297Documento6 páginasAstm C 297hülyaAinda não há avaliações

- Astm D 3164 - 03Documento4 páginasAstm D 3164 - 03phaindikaAinda não há avaliações

- Design of Rigid Pile Caps Through An Iterative Strut-And-Tie ModelDocumento12 páginasDesign of Rigid Pile Caps Through An Iterative Strut-And-Tie ModeljjohnsoneAinda não há avaliações

- A Brief History of Dislocation Theory - HirthDocumento6 páginasA Brief History of Dislocation Theory - HirtharyamesaAinda não há avaliações

- C364C364M-07 (2012) Standard Test Method For Edgewise Compressive Strength of Sandwich ConstructionsDocumento8 páginasC364C364M-07 (2012) Standard Test Method For Edgewise Compressive Strength of Sandwich ConstructionsShico1983Ainda não há avaliações

- Astm E6Documento12 páginasAstm E6Nacer KisyAinda não há avaliações

- Shear Properties of Composite Materials by The V-Notched Beam MethodDocumento13 páginasShear Properties of Composite Materials by The V-Notched Beam MethodrsugarmanAinda não há avaliações

- D3039 3039MDocumento12 páginasD3039 3039MMariana CarvalhoAinda não há avaliações

- Mechanical Properties of Polymers PDFDocumento45 páginasMechanical Properties of Polymers PDFMONIRUZZAMAN MONIRAinda não há avaliações

- D 6742 - D 6742m - 02 Rdy3ndivrdy3ndjnDocumento7 páginasD 6742 - D 6742m - 02 Rdy3ndivrdy3ndjnJuanAinda não há avaliações

- Calculating Thermal Endurance of Materials From Thermogravimetric Decomposition DataDocumento6 páginasCalculating Thermal Endurance of Materials From Thermogravimetric Decomposition DataEric GozzerAinda não há avaliações

- Climbing Drum Peel For Adhesives: Standard Test Method ForDocumento4 páginasClimbing Drum Peel For Adhesives: Standard Test Method ForMarceloAinda não há avaliações

- D 7264 - D 7264M - 15Documento10 páginasD 7264 - D 7264M - 15AMAR SAI PRABHUAinda não há avaliações

- Astm D 648Documento14 páginasAstm D 648廖修賢Ainda não há avaliações

- M-506 Co2 Corrosion ModelDocumento18 páginasM-506 Co2 Corrosion ModelEdgar Enrique Diaz MarquinaAinda não há avaliações

- D 3164 - 03 - RDMXNJQ - PDFDocumento4 páginasD 3164 - 03 - RDMXNJQ - PDFJOHNAinda não há avaliações

- 14.7.6 Steel-Reinforced Elastomeric Bearings - Method A: AASHTO LRFD Bridge Design Specifications, 8th Edition (2017)Documento8 páginas14.7.6 Steel-Reinforced Elastomeric Bearings - Method A: AASHTO LRFD Bridge Design Specifications, 8th Edition (2017)jrjdengineersAinda não há avaliações

- ASTM D 6093 - 97Documento3 páginasASTM D 6093 - 97shgsuhermanAinda não há avaliações

- D 5656 - 01 - Rdu2ntytmdeDocumento6 páginasD 5656 - 01 - Rdu2ntytmdeJOHNAinda não há avaliações

- Astm D 3039 - D3039M - 2008Documento13 páginasAstm D 3039 - D3039M - 2008PAOLO GIANNELLI100% (1)

- C363C363M-09 (2015) Standard Test Method For Node Tensile Strength of Honeycomb Core MaterialsDocumento4 páginasC363C363M-09 (2015) Standard Test Method For Node Tensile Strength of Honeycomb Core MaterialsShico1983Ainda não há avaliações

- ASTM3039 Tensile Properties of Polymer Matrix Composite MaterialsDocumento13 páginasASTM3039 Tensile Properties of Polymer Matrix Composite MaterialsGyanendra GavelAinda não há avaliações

- D785 08Documento6 páginasD785 08Adam Chin100% (2)

- Flatwise Compressive Properties of Sandwich Cores: Standard Test Method ForDocumento8 páginasFlatwise Compressive Properties of Sandwich Cores: Standard Test Method ForSana AshfaqueAinda não há avaliações

- 7905D7905M 14Documento18 páginas7905D7905M 14Andrea LaudaniAinda não há avaliações

- Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperatureDocumento2 páginasLinear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated TemperaturePyone Ei ZinAinda não há avaliações

- Compressive Strength of Carbon and Graphite: Standard Test Method ForDocumento3 páginasCompressive Strength of Carbon and Graphite: Standard Test Method ForLabeed ShamilAinda não há avaliações

- 2e63037b0560189ce02b24efb100df07Documento6 páginas2e63037b0560189ce02b24efb100df07Hernando Andrés Ramírez GilAinda não há avaliações

- D 2512 Â " 95 - RDI1MTITOTUDocumento11 páginasD 2512 Â " 95 - RDI1MTITOTUhans ccAinda não há avaliações

- Astm C273 - C273M - 2011Documento7 páginasAstm C273 - C273M - 2011PAOLO GIANNELLI100% (1)

- Norme - Astm - D 3846 - 02Documento3 páginasNorme - Astm - D 3846 - 02Ryan DrakeAinda não há avaliações

- D 5528 - 01 Rdu1mjgDocumento12 páginasD 5528 - 01 Rdu1mjgJuanAinda não há avaliações

- ASTM D3479-D3479M - 2019 FatigaDocumento6 páginasASTM D3479-D3479M - 2019 FatigaPablo Ortega100% (1)

- Astm D3039 & D3479Documento15 páginasAstm D3039 & D3479Engr Khalil AkramAinda não há avaliações

- ASTM D4459.6249 Standard Practice For Xenon-Arc Exposure of Plastics Intended For Indoor Applications PDFDocumento4 páginasASTM D4459.6249 Standard Practice For Xenon-Arc Exposure of Plastics Intended For Indoor Applications PDFkkakosimAinda não há avaliações

- D7250D7250M 30432Documento7 páginasD7250D7250M 30432darebusi1Ainda não há avaliações

- C365 - CompresionDocumento3 páginasC365 - CompresionLucero Ponce de LeónAinda não há avaliações

- C 177 - 97 PDFDocumento22 páginasC 177 - 97 PDFingluisalejoAinda não há avaliações

- ASTM D638-02aDocumento13 páginasASTM D638-02amynor aldana100% (1)

- Astm D5961-D5961MDocumento26 páginasAstm D5961-D5961MJosé GomesAinda não há avaliações

- D5418Documento3 páginasD5418Nasos MasourasAinda não há avaliações

- Measuring The Damage Resistance of A Fiber-Reinforced Polymer Matrix Composite To A Drop-Weight Impact EventDocumento16 páginasMeasuring The Damage Resistance of A Fiber-Reinforced Polymer Matrix Composite To A Drop-Weight Impact EventThiago TanAinda não há avaliações

- Tear Strength of Conventional Vulcanized Rubber and Thermoplastic ElastomersDocumento9 páginasTear Strength of Conventional Vulcanized Rubber and Thermoplastic ElastomersPyone Ei ZinAinda não há avaliações

- Tensile Properties of Thin Plastic Sheeting: Standard Test Method ForDocumento11 páginasTensile Properties of Thin Plastic Sheeting: Standard Test Method ForAsyrof hibatullahAinda não há avaliações

- Astm D 3801Documento5 páginasAstm D 3801Boris AguilarAinda não há avaliações

- D6856 1166550-1Documento8 páginasD6856 1166550-1khudhayer1970Ainda não há avaliações

- D618 12087Documento4 páginasD618 12087xavicojmAinda não há avaliações

- Astm D2990 01 PDFDocumento20 páginasAstm D2990 01 PDFRodrigo Garcia100% (1)

- Designation: E2113 09Documento5 páginasDesignation: E2113 09Lupita RamirezAinda não há avaliações

- Compressive Properties of Polymer Matrix Composite Materials Using A Combined Loading Compression (CLC) Test FixtureDocumento13 páginasCompressive Properties of Polymer Matrix Composite Materials Using A Combined Loading Compression (CLC) Test Fixturemohammed karasnehAinda não há avaliações

- D3638-12 Standard Test Method For Comparative Tracking Index of Electrical Insulating MaterialsDocumento5 páginasD3638-12 Standard Test Method For Comparative Tracking Index of Electrical Insulating Materialsjose flores100% (1)

- ASTM C272 Water Absorption of Core Materials For Sandwich PDFDocumento4 páginasASTM C272 Water Absorption of Core Materials For Sandwich PDFSílvio Xavier SantosAinda não há avaliações

- Astm C 393 - 00Documento4 páginasAstm C 393 - 00AlexandreAinda não há avaliações

- ASTM D3163 For Determining Strength of Adhesively Bonded Rigid Plastic Lap-Shear Joints in Shear by Tension LoadingDocumento3 páginasASTM D3163 For Determining Strength of Adhesively Bonded Rigid Plastic Lap-Shear Joints in Shear by Tension LoadingSaavedra Aurel MarcAinda não há avaliações

- Astm C 907-2008Documento3 páginasAstm C 907-2008zeqs9Ainda não há avaliações

- Astm D3410 Testing Fixture PDFDocumento5 páginasAstm D3410 Testing Fixture PDFjiten5591Ainda não há avaliações

- D 5467 - D 5467m - 97 r04 Rdu0njcvrdu0njdnDocumento9 páginasD 5467 - D 5467m - 97 r04 Rdu0njcvrdu0njdnJuanAinda não há avaliações

- D2344 Standard Test Method For Short-Beam Strength of Polymer Matrix Composite Materials and Their LaminatesDocumento8 páginasD2344 Standard Test Method For Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminatesssassy113Ainda não há avaliações

- Fatigue Curve - S235JR ExperimantalDocumento9 páginasFatigue Curve - S235JR ExperimantalPrabath MadusankaAinda não há avaliações

- 2019 Summer Model Answer PaperDocumento21 páginas2019 Summer Model Answer Papermohiuddin sharifAinda não há avaliações

- Calculator Techniques For Solving Progression ProblemsDocumento5 páginasCalculator Techniques For Solving Progression ProblemsRichard RegidorAinda não há avaliações

- PCI Bearing Pad DesignDocumento6 páginasPCI Bearing Pad DesignMTCLSAinda não há avaliações

- Advanced Fluid and Heat Transfer (AE 6411) Lecture 1-1Documento49 páginasAdvanced Fluid and Heat Transfer (AE 6411) Lecture 1-1Just DearAinda não há avaliações

- Design and Fea Analysis of Vehicle Lifting Hydraulic Cylinder - Approach Using Cad and Cae-Ijaerdv04i1259897Documento9 páginasDesign and Fea Analysis of Vehicle Lifting Hydraulic Cylinder - Approach Using Cad and Cae-Ijaerdv04i1259897Krish KrishnaAinda não há avaliações

- A Multiple Choice Questions Bank Online GTU ExaminationDocumento28 páginasA Multiple Choice Questions Bank Online GTU ExaminationSuryadev Sinh SisodiyaAinda não há avaliações

- Design Difference Is Vs AISCDocumento2 páginasDesign Difference Is Vs AISCSaqlain AwanAinda não há avaliações

- Ground Response AnalysisDocumento19 páginasGround Response AnalysisBhaskar KumarAinda não há avaliações

- Yield Criteria Exercise Sheet SolutionsDocumento5 páginasYield Criteria Exercise Sheet Solutionssam joeAinda não há avaliações

- Original Citation:: Warwick - Ac.uk/lib-PublicationsDocumento46 páginasOriginal Citation:: Warwick - Ac.uk/lib-Publicationsroshansm1978Ainda não há avaliações

- Strength of Materials (Concepts) Flashcards - QuizletDocumento17 páginasStrength of Materials (Concepts) Flashcards - QuizletCalvin LabialAinda não há avaliações

- 2Documento60 páginas2Al-Amin RazakAinda não há avaliações

- Report TorsionDocumento17 páginasReport TorsionAhmad Haziq DanialAinda não há avaliações

- Transforming Pcomp To Pshell: Aersys Knowledge UnitDocumento6 páginasTransforming Pcomp To Pshell: Aersys Knowledge UnitSimon DelmasAinda não há avaliações

- Prestressed T-Beam PDFDocumento6 páginasPrestressed T-Beam PDFAbhilash KumarAinda não há avaliações

- Blackpool Tanks (Wharmby Et Al BGS-BTS 2001)Documento12 páginasBlackpool Tanks (Wharmby Et Al BGS-BTS 2001)Nick WharmbyAinda não há avaliações

- Strength of Materials (9024)Documento6 páginasStrength of Materials (9024)rajyamgarAinda não há avaliações

- Thin Film FlowDocumento50 páginasThin Film FlowSachin PandeyAinda não há avaliações

- Factors of Safety For The Design of BreakwatersDocumento10 páginasFactors of Safety For The Design of BreakwatersromeoremoAinda não há avaliações

- Uplift Capacity T-Z MethodDocumento5 páginasUplift Capacity T-Z MethodPalak ShivhareAinda não há avaliações

- Symmetrical Facing Wrinkling of Composite SandwichDocumento25 páginasSymmetrical Facing Wrinkling of Composite SandwichJoshua KarthikAinda não há avaliações