Escolar Documentos

Profissional Documentos

Cultura Documentos

Piping and Pipe Support Systems

Enviado por

gateauxboyDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Piping and Pipe Support Systems

Enviado por

gateauxboyDireitos autorais:

Formatos disponíveis

type excitation frequencies sources determined from the, speed, the number of cylinders for actIOn and twice

the for double-action stages, The natural frequencies should avoided in restraining systems are ~Illf of the rpm, d all up to 5 times the rpm of the equipment. If these an d ', reuuencies annroacn the natural frequencies of the connecte prpmg sysreSOi1lU1CC the form of in pressure sources can appear_ The surge loads can affect the supports, and adjastructures, way to control vibration lind its undesirable effects is to elirnor isolate the source of vibration, elimination and isolation in numerous applications these methods are not possible, so vibration effects should be considered in the system design,

N>,rin.1ic pressure

of the

For most the coefficient of thermal expansion varies the temperature, so (5.22) is not Because of the thermal ill inches per foot between an ambient temperature of 70"F (21°C) and various operating temperatures has been worked out materials, Values for some of these materials are thermal loads on supports is the system. This uf the axial runs lire absorbed

M '" 6E!~

We demonstrated

more most

are added 1.0 II system, the pipe restrained for and occasional loads, when increases in temperature and which is too well restrained will not be able to expand, forces will at the points of lockup, causing large stresses

that as more restraints

where M

developed

= developed

force. III (N) moment, of elasticity of inertia displacement, inJb (rnm-N} temperature, psi' N/mm'l

rl~"",llnn

in the

E '" modulus

moment

;l '" imposed

at installed in (rnm]

ideal restraint condition for thermal considerations is a total lack restraint. Since this is not feasible, other loads, some forces due will on restraints even in the most optimally supsystem. In this section we show how these loads can be calculated. we show how to determine thermal movements for selection and of clearances in restraints,

of pipe. in' (rnm") to direction of growth, in

L = length

of leg perpendicular

The amount of thermal growth absorbed (.~) is portional to the ratio of the stiffness of the to the sum the stiffnesses of all absorbing the thermal The moments and forces must be resisted the restraint system, whether it directly a force of two restraints.

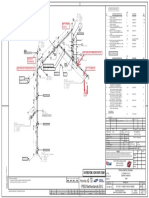

Problem 5.6 The system in Fig. ,,26 is made of carbon steel find operut es :!f)t)°F (177°C) It uses 12;n (:WO·mm) at andard schedule line with = 279 M (1.11; X 10 mm ' 8:,d = 27,7 X 10'; psi 0.91 X lU" N/m'i, From 5.4. the thermal expansion IS found to be 0,0226 in/I! (lilt!:! mm/rn). The system is restrained two anchors (at poillts A and G) and two vertical restraints (at points LJ E), The iirs! step III findillg the ther mul loads is to cah-uls te the pipe ex paus ions and determine the legs which will resist them, The resisting legs are all those perpendicular tu the growth, except in those cases where the pipe is restrained at illtermediate points. The summary of pipe movements and resisting le~, is shown in 'I'ahle f> 5. The stiffness of each pipe segnWll! is calculated as ",,,,"sectional and material p"'I,,'rlies of all II", pipes ill t hi- problem 'H"

direction}.

is of concern primarily to the pipe length axis Thermal expansion can be computed by the following

l?

" d'T ~ " thermal coettieient eapansion ill direction specified hjll~nKlh,

(;),22) in l mm]

pipe length

in dirert i..n of mlrrNlI, in tmrn] of thermal

pipe t e rnpe rat ure,

·.',·CI

ulllln®",n, in/hn ·.'Ilmm/lmm

·("11

-1110 -110

0

0.0180 0.IHS2 0.0121 0.0087 0.0051 0.0015 0.0000 0.0023 0.0042 0'()061 0.0080 0.0099 0.0120 0.0140 0.0161 0.0182 0.0209 0.0226 0.0248 0.0270 0.0293 0.0316 0.0339 0.0362 0.0387 0.0022 0.0000 0.0022 0.0040 0.0058 0.0076 0.0094 0.0113 0.0132 0.0152 0.0171 0.0191 0.0210 0.0230 0.0250 0.0271 0.0292 0.0314 0.0335 0.0357

0.0261 0.0236 0.01!!7 0.0134 0.0078 0.0022 0.0000 0.0034 0.0062 0.0090 O.OIlS 0.Gl4£ 0.0175 0.0203 0.0232 0.0261 0.0291 0.0321 0.0351 0.0380 0.0410 0.0440 0.0470 0.0501 0.0531

0.0275 0.0231 O.Ol!l3 0.0132 0.0079 0.0023 0.0000 0.0034 0.0063 0.0091 0.0121 O.OHil 0.0179 0.0208

0.0267 0.0241 O.O1!~() 0.0137 0.0081 0.0030 0.0000 0.0035

0.0373 1),0310

110

70 100

0.0000 0.0(Wi 0.0084 0.0123 0.0162 0.0200 0.0242 0.0283 0.0325 0.0366 0.0409 0.0452 0.0496 0.0539 0.0584 0.0028 0.0073 0.0717 0.0764

125 150

175 200

0.0064

0.0093 0.0123 0.0152 0.0183 0.0214 0.0245 0.0276 0.0308 0.0340 0.0372 0.0405 0.0438 0.0472 0.0506 0.0540 0.0575

225 2lIO 275

300 325 350 375 400 425

0.0238

0.0267 0.0297 0.0327 O.035S 0.0388 0.0419 0.0449 0.0481 0.0512 0.0543

4110 475

500

525

550 575 600 625

650

0.0411 0.0436 0046iJ 0.0486

0.0379 0.0402 0.0424 0.0447 0.04£9 0.0491 0.0514 0.0538 0.0562

0.0562 0.0593 0.0024 0.0056

0.0574 0.0607 0.0039 0.0071

0.0010 0.0645 0.0680 0.0717

0.0810 0.0857 0.0903

6i5

700'

725

750

775

800

0.0537 0.0563 0.0589 00016

0.0719 0.0750 0.0783 0.0815

0.0736 0.0768 0.0801 0.0834

0.0790 0.0826 0.0864 0.0902

825

850 875

900

925

0.0097 0.0725 0.0753

0.0634 0.0658 0.0683

0.0880 0.0913 0.0946 0.0979

0.0900 0.0934 0.096, 0.1002

0.0978 0.101~ 0.1056 0.1096 0.1135 0.1173 0.1216 0.1257 0.1298

950

975 1000 1005 1010 1015 1050

0.0808 0.0835 0.0862 0.0889 0.0895 0.0900 0.09(i€ 0.0946 0.1004 0.1057

0.0732 0.0756 0.0781 0.0806 0.0811 0.0816 0.0821 0.0855 0.0905

0.1046 0.1080 0.11l4 0.1148

0.1071 0.1105 0.1140 0.1175

1100

150 1200 1250 1300 1350

0.1162 168 0.1216 0.1284

O.UlO O.ll66

0.1222 0.1278

0.1420 0.1488 0.155£ 0.1624

the felolill~ .tilfne""

of lhe lobi d'.placement

of uch leI( i. ~iven hy ilL'. Therefore. absorbed by ..ny liven I"IJ " i. defined

the l''''l'orl'''''

80

.. n.ueu~.

eIi.placemont

.'_bood

by ~ n, in ,,,, .. I

......... "II opeci~ed '''''pl.cement,lIlml

100226)( iO U226 )( 100226 )( 10.0226 )(

151 ~ 0 ~4 ,WI ~ ()~ 601 - I :16 :~I) - U6i!

in I~ 6 m"'~ in 117 :1 rnm] in 1:14 5 men] in (17:1 IIl",1

II 1', ('

n,

r.

F·V

A It HC,

L. ~ 1"."lh H( lew ", fa ("" L, '<"lflh o( ch .,."". ~

{!AT w

tolal diapl

1 W be oi>enrbood,0" I...... '

rwm Eq. 15.231, ror se gmen'

;1Il •

A II,

Iorces

0""41 the di.pl.""ment llboao.be<i by the 11M momentll csn boa fooM by ."""'m'~l'''''''. m"m«ontll ,'" til4> , .. u.intll in FiJ· 6.26 cAn he fOl.lM:

now 11, the shear Lt.i... alf, the forces snd

M au ....--...IIj,C.....

AI

IUt

f" so

J5lt:lO'1:l(J' -_:J.6(:i.()-1,

6(277

x HtH~7Y)

~ nS,987 Th.,dore til" approumate thermal

10

III 125,6\19

011

In

N~

load.

the ... cnor ~. pomt A on' t II> 12~,H99

III

f \ ~6611>

nJO

NI

M, - 228,987

M, • •

NI

114,4!!:! on 11,019<1 on NI :189,096 'n II> (n .•~7 m NI ;

r, Sim,j,,,ly,

1172

tb 15<;61 NI

M,

the loed.

can he (ound

on the vert ns! re st r amt a a ,

1'''''''' lJ HI"j

Ii

The

15 ml

,.·,

n~omenh at J>i-pint& [) BlIHi ,.~' are rt"~'!ited ..... 18 The 1011,,1 r"r.· •• cell be round hy:

,,,. :1210 :tlll,liil, ;'47.411

} 1'.

""

4fWi7

::'!_4:_~~

:l40

f-

fl47.4:!.1 l4U

H4~11

ih U7,fi4.JH NI up (ul(uitbteo .!:It t he Hndwr

Similarly

Ih. - rHr Ce'Stifh I inUfHrul.'i •

nUl lIt'

pOint

s;

guided-cantilever method dues fully accurate result» the intersection free to rotate to some redistributing the rnurnent. In most CSIleS ,I; is conservative results: however, in many casea greater accuCharta have been developed for the the design ..,,'''''', ••••with accurate load celeulations for III range of contigurations. Table 5.6 presents III !leriell of chlllm by the I'IT Grinnell lind reprinted here with their permission. The full series lUI! IIvaillible in ITT Grinnell's De,ign and Sutli nro-vld.>d to the engmeer the configurations IIIfe of eapansicn Iocps. Through of and proper of aupports, escessive thermal stresses may be reduced. My support IOClllillll1l which direct the expansiun 10 areas of greater stresses can be CUIlsuch all those shown ill 5.27 are used to increase the flexibility of hot piping systems, Theile loops are designed to accommodate the thermal espanaion plpmg operation 5.270 illustrates the free thermal movement of the piping. wiLh terminal lucaliml!l of representing equipment nozzlee. The uncontrolled expansion of the can cause IOCllliHIlB A lind G to become overstressed or over loaded by eacesaive moments lind forces on the nozguides lit locatione C lind F and a limit slop or rigid restrain! 1111 location R. Il8 shown in 5.27 b. the thermal expansion can directed into the expansion Thus the III! the terminal COIlnections can be reduced 1I~:nllflciml

U!Ie

Over

<,

Ire~~ed

(UWlt."<t!On

or the Grinnell

Ib I

ht_iMlion

@, Thenmil MollltfMftlll

Poilll I'oi", t': Puim 9-':

PHill'

ment,

thermal movements may be estimated at intermediate pointa ill a a linear variatiufI between points of known displace. !,'or example. if the movement uf It point located [) fa (I _5 rn] fwm (toward Rl in Io'ig. 5.26 were desired, it could he computed by the ratioli the lit poinl Ii determined in Prob

/!;IiJ.:l4)

.1 Y

2 ill (5(U! rnrn] UP. cold '0 I... ,

iJill

4 ill 001.1; mm] down. cold I" hu' I rn C25A mm) 111'. cold to ho'

Uill

(I

1''';111 L CU I ill (~!.II mrn]

1'00111114:

ill

t!;W.:lO:';) ~ tWin ill 11.1 mml "' U.U:'!? in 10.69 mm)

lither sources or vertical movement lire the r isere fj·D d!.J . uillUl/ fr T hi < A L . II" -. WIHeh e<p."d . urn II e ".~ we see L".. I the UPIll1l8U"l i... IHJ1U7 ill/fl (0005 m), IKl the rsser up"nslOns Gre curnput ed .... (011" .. ,,: . :I ...ml

movements are most uften hunger selection. All '", .... '1''''' verticel di~;pll~cf:mjent.s

the y direction for use ill the method tor deter-

I..,.

L", =

,o.01071{151W()71l7H:101 10 070111101 -

1t16101269mmlull

212", I17UI 15:1 ~ mml d .. wn

on 11M II mm l

TUUS.6

ElIPIlnllUml

IItmlllMllI

(Expansoon

filetOf'

C·moly and Low

Temperature. Carbon

T. of 70

100

:5

steel, 0.30'(. 0

Carbon steel, C > 0.30'(. 0

Cr.vmoly

Cr. :s; 3r~

0 40 106

Cr.vmoly sec .5 Cr.

Mo

S;

Austenitic

Cr. 1It4inI ess steell! 12

atainl ess

steele 0

9r;

Cr., 17 Cr., and 27 Cr.

0 34 90 145

25 Cr.-20 0

Ni

Wrougb iron 0 44

15(1

200

37 98

16<l 228 294

40

106 171 244 315 391

0 35

5.04

143 232

92 149 212

271 335

47 125 204

287

120 195 273 352

434

25(1

300

35(1

400

305

436 510

315 391

z«

17!

323

414 509 6<l3

204

264

368

455 54] 629

326

389

467

547

450

5(I(J

584

664

550

626 711

467 547 626 711

396

465 531

699 794

893

455 520

590

514 598

6ill

716

809

603

768

600 650 700

?is

BOO 875

850

75(1

743 084' 909

996

796

8S6 974 1068 113

796 886

974 1068

,~ 6"°

714 815 89J 929

989

1089 1189 1292 1395 1448 1500

1038

1113

1159

659 730 799 874 009

946 983

901

995

1088 1186 1235

855

946

nzs

1171 1216

1035

120B

1256

967

1005 1043

1284

1335

875 900

925

1303 1351 1398

1445 1492 1538

1081 1121 1161

1200 1240 1278

1552

1605

1022

1061 1097 1134 1174

1384 1435

1484 1533

950

975 1000

1659

1713

1766

1820

1212

1585

1634 1681 1781

1050

1100

1639

1737

1928

1150

l ; "" moment of

Você também pode gostar

- The Art of Designing Pipe Support SystemsDocumento6 páginasThe Art of Designing Pipe Support Systemsguluu100% (1)

- CAESAR II Software BasicsDocumento28 páginasCAESAR II Software Basicsanishsr100% (1)

- A Literature On "Cold Springing (Cold Pull) in Piping Systems"Documento5 páginasA Literature On "Cold Springing (Cold Pull) in Piping Systems"iaftAinda não há avaliações

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionAinda não há avaliações

- Taller3 Modeling Concepts in Buried Pipe AnalysisDocumento29 páginasTaller3 Modeling Concepts in Buried Pipe AnalysisFSAAVEDRAF100% (1)

- Featools Intro Webinar Scripted For IntergraphDocumento58 páginasFeatools Intro Webinar Scripted For IntergraphJimmy Alexander Avila100% (1)

- AFT Evaluating Pipe Dynamic Loads Caused by WaterhammerDocumento24 páginasAFT Evaluating Pipe Dynamic Loads Caused by WaterhammerroyalcomAinda não há avaliações

- Piping Stress Handbook - by Victor Helguero - Part 2Documento121 páginasPiping Stress Handbook - by Victor Helguero - Part 2namdq-1100% (1)

- AISC - Buckling DesignDocumento9 páginasAISC - Buckling Designmelvin_leongAinda não há avaliações

- Determine-The-Optimal-Span-Between-Pipe Supports-For-Thin-Walled-Piping-Systems PDFDocumento10 páginasDetermine-The-Optimal-Span-Between-Pipe Supports-For-Thin-Walled-Piping-Systems PDFLuis Pereira PeñaAinda não há avaliações

- StressISO TroubleshootingDocumento31 páginasStressISO TroubleshootingDarren Kam100% (1)

- Stress Combination Load CasesDocumento3 páginasStress Combination Load CasesLcm Tnl100% (1)

- Basics For Stress Analysis of Underground Piping Using Caesar II-20150924Documento4 páginasBasics For Stress Analysis of Underground Piping Using Caesar II-20150924iaftAinda não há avaliações

- Slug Flow Analysis Using Dynamic Spectrum Method in Caesar IIDocumento7 páginasSlug Flow Analysis Using Dynamic Spectrum Method in Caesar IIJ A S JASAinda não há avaliações

- Piping Stress Analysis Pipeline System in Offshore PlatformDocumento2 páginasPiping Stress Analysis Pipeline System in Offshore Platformgpskumar22100% (1)

- Dorin Popescu FRP Allowable Stress - Intergraph CADWorx & AnalysisDocumento7 páginasDorin Popescu FRP Allowable Stress - Intergraph CADWorx & Analysisxaaabbb_550464353Ainda não há avaliações

- LIFT OFF ModuleDocumento28 páginasLIFT OFF ModulericardoAinda não há avaliações

- Fatigue Analysis Using CAESAR IIDocumento7 páginasFatigue Analysis Using CAESAR IIayounga100% (1)

- Fe Pipe TrainingDocumento5 páginasFe Pipe TrainingMuhammad Enam ul Haq0% (1)

- AutoPipe Sustained Stress Calc B31.3Documento2 páginasAutoPipe Sustained Stress Calc B31.3curvedbrainAinda não há avaliações

- Heat Loss in Pipe Support PDFDocumento60 páginasHeat Loss in Pipe Support PDFThaku KishorAinda não há avaliações

- FPSO - Automating Structural DeflectionsDocumento10 páginasFPSO - Automating Structural DeflectionsJP EDSAinda não há avaliações

- Load Cases in Pipe Stress AnalysisDocumento2 páginasLoad Cases in Pipe Stress Analysisrenji_danny100% (2)

- Allowable External Loads On Tank Shell Openings (API 650 APP.P)Documento2 páginasAllowable External Loads On Tank Shell Openings (API 650 APP.P)Geronimo ZamoraAinda não há avaliações

- Stress Analysis Report FormatDocumento9 páginasStress Analysis Report FormatPinak Projects100% (2)

- Remove Support: Issued For ConstructionDocumento1 páginaRemove Support: Issued For Construction86tejasAinda não há avaliações

- Stressman Engineering - Study - Stresses in Branch Connections at Different AnglesDocumento7 páginasStressman Engineering - Study - Stresses in Branch Connections at Different AnglesDesmond ChangAinda não há avaliações

- CAESAR II Shortcut KeyDocumento3 páginasCAESAR II Shortcut KeyTamil SelvanAinda não há avaliações

- Modal Analysis With Caesar II: Smart Questions Smart Answers Smart PeopleDocumento2 páginasModal Analysis With Caesar II: Smart Questions Smart Answers Smart Peopleyundtech974100% (1)

- Slug FlowDocumento8 páginasSlug FlowAndiAinda não há avaliações

- Sp6 - 6 Stral Hand BookDocumento220 páginasSp6 - 6 Stral Hand BookproxywarAinda não há avaliações

- SIF Pipe Stress Checklist PDFDocumento2 páginasSIF Pipe Stress Checklist PDFEsapermana Riyan100% (1)

- Flexmen: Register User Forum List Calendar Active Topics FaqDocumento19 páginasFlexmen: Register User Forum List Calendar Active Topics FaqParilla13Ainda não há avaliações

- Guideline For GRE Pipe Stress Analysis - T SrinivasanDocumento5 páginasGuideline For GRE Pipe Stress Analysis - T Srinivasansri06Ainda não há avaliações

- Acoustic Pipe SupportsDocumento6 páginasAcoustic Pipe Supportsnamdq-1Ainda não há avaliações

- Pipe Stress Analysis Case Study - Pump Discharge - Piping Technology & Products, IncDocumento10 páginasPipe Stress Analysis Case Study - Pump Discharge - Piping Technology & Products, Inckaliya12100% (1)

- Algebraic and ScalarDocumento4 páginasAlgebraic and Scalardtr17Ainda não há avaliações

- Piping Engineering - Tank Nozzle Loads 1Documento1 páginaPiping Engineering - Tank Nozzle Loads 1Nasrul Adli100% (1)

- Cold SpringingDocumento5 páginasCold SpringingYakulitoAinda não há avaliações

- Pipe Stress Analysis by Computer CAESAR II PDFDocumento11 páginasPipe Stress Analysis by Computer CAESAR II PDFAbhijeetAinda não há avaliações

- PSV Reaction Force - Closed SystemDocumento5 páginasPSV Reaction Force - Closed SystemWayne MonneryAinda não há avaliações

- SlugDocumento1 páginaSlugtibor121774_66173108100% (1)

- Nozzle Thermal Movement and Evaluation Sheet For VesselDocumento27 páginasNozzle Thermal Movement and Evaluation Sheet For VesselJ A S JASAinda não há avaliações

- 01 E02STB007-W146693-03-0 - BC - Stress UpdateDocumento1 página01 E02STB007-W146693-03-0 - BC - Stress Update86tejas100% (1)

- Piping Flexibility - A Detailed ApproachDocumento5 páginasPiping Flexibility - A Detailed ApproachRUDHRA DHANASEKARAinda não há avaliações

- Pipe Stress AnalysisDocumento15 páginasPipe Stress AnalysispvmssonAinda não há avaliações

- Nozzle ProDocumento3 páginasNozzle Projojo_323Ainda não há avaliações

- Pipeline Stress Analysis With Caesar IIDocumento16 páginasPipeline Stress Analysis With Caesar IIznikfarAinda não há avaliações

- Auto PipeDocumento39 páginasAuto PipesyedatifmalikAinda não há avaliações

- 01 - Chapter 1Documento37 páginas01 - Chapter 1Eko Idris Hutagaol100% (1)

- Pipe Stress Analysis and Layout of Hot and Cold PipingDocumento27 páginasPipe Stress Analysis and Layout of Hot and Cold PipingJosé Antonio Alarcón LeónAinda não há avaliações

- Sist. Electrico de Hi-LuxDocumento198 páginasSist. Electrico de Hi-Luxhenrrysma100% (19)

- Capillary TubeDocumento8 páginasCapillary Tubeziko23100% (2)

- Gasdinamica: Laurea Magistrale in Ingegneria AerospazialeDocumento4 páginasGasdinamica: Laurea Magistrale in Ingegneria AerospazialeDavid BrandãoAinda não há avaliações

- Appendix A: - .Sizing of Distillation ColumnsDocumento14 páginasAppendix A: - .Sizing of Distillation ColumnsBlack WidowAinda não há avaliações

- Chrome-Extension Mhjfbmdgcfjbbpaeojofohoefgiehjai IndexDocumento21 páginasChrome-Extension Mhjfbmdgcfjbbpaeojofohoefgiehjai IndexTONAinda não há avaliações

- Tif'Wl: Blo Jectl5R J, Vac PGMB Is ( H Jro D.1"Er:T FoDocumento6 páginasTif'Wl: Blo Jectl5R J, Vac PGMB Is ( H Jro D.1"Er:T FoRicardo Javier PlasenciaAinda não há avaliações

- Calculate Saturated-Gas Loads For Vacuum SystemsDocumento3 páginasCalculate Saturated-Gas Loads For Vacuum SystemsFred FaberAinda não há avaliações

- What Has Changed in API 521 6EDDocumento19 páginasWhat Has Changed in API 521 6EDgateauxboy100% (1)

- BMW Comparion 320d THDocumento1 páginaBMW Comparion 320d THgateauxboyAinda não há avaliações

- BMW Comparion 325d M THDocumento1 páginaBMW Comparion 325d M THgateauxboyAinda não há avaliações

- Vibration Signals of Reciprocating Compressor Valves: Paweł Białek, Piotr BielawskiDocumento7 páginasVibration Signals of Reciprocating Compressor Valves: Paweł Białek, Piotr BielawskigateauxboyAinda não há avaliações

- De Super HeaterDocumento2 páginasDe Super HeatergateauxboyAinda não há avaliações

- The Use of QRA To Inform The Design of A High-Pressure Onshore PipelineDocumento12 páginasThe Use of QRA To Inform The Design of A High-Pressure Onshore PipelinehpmonAinda não há avaliações

- DW144 Smacna 2005Documento32 páginasDW144 Smacna 2005Angel Daniel GarciajoyaAinda não há avaliações

- Overseas Business 1Documento2 páginasOverseas Business 1gateauxboyAinda não há avaliações

- ANSI B16.5 FlangesDocumento24 páginasANSI B16.5 Flangesgateauxboy100% (2)

- Annular VelocityDocumento2 páginasAnnular VelocitygateauxboyAinda não há avaliações

- Branch Reinforcement Per Asme B31.4 PipelineDocumento1 páginaBranch Reinforcement Per Asme B31.4 PipelinegateauxboyAinda não há avaliações

- Hit A ChiDocumento46 páginasHit A ChigateauxboyAinda não há avaliações

- Pipe Design Basic MaterialDocumento1 páginaPipe Design Basic MaterialpandiangvAinda não há avaliações

- Case Study-Steam Jet EjectorDocumento21 páginasCase Study-Steam Jet Ejectorgateauxboy60% (5)

- ASME Joint EfficiencyDocumento49 páginasASME Joint Efficiencygateauxboy95% (39)

- Equivalent Material List For Standards: Ref. No. EML-001Documento3 páginasEquivalent Material List For Standards: Ref. No. EML-001gateauxboy100% (5)

- Efficient Industrial Heat Exchangers - Seminar ReportDocumento67 páginasEfficient Industrial Heat Exchangers - Seminar ReportdaemonohAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)