Escolar Documentos

Profissional Documentos

Cultura Documentos

Symbols of Oil Gas Piping

Enviado por

Delvin Davis MDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Symbols of Oil Gas Piping

Enviado por

Delvin Davis MDireitos autorais:

Formatos disponíveis

Line Identification

70 - P 53 - C2 1.5" Ih Insulation Type (1) Line Size Piping Specification Line Number Service Identification Letter Plant Number

Line Mounted Equipment

Blind Flange Line Mixer Flexible Hose Hose Connection Gate Flanged/Screwed/ Socket Welded GateButt Welding Ends Gate with Screwed Plug (Vent or Drain) Globe Flame Arrester Needle Check Paddle Blank Silencer Stop Check Ball Paddle Spacer Ring head Butterfly Plug Quick Acting Blind

Valves

(2)

Spring Loaded

Reducer - Concentric Reducer - Eccentric Cap

Thermal Link Angle

Air Intake Filter Figure 8 Blank (Open)

Three Way

A IA Ac Am B BFW C Ca CHW CW CWS D FG

Utiliity Air Instrument Air Acid Ammonia Blowdown Water Boiler Feed Water Condensate Caustic Chilled Water Cooling Water (fresh) Cooling Water (Salt) Drinking Water Fuel Gas

FO FL H K LO N P R S SO V WF

Fuel Oil Fire Water (regardless of source) Hydrogen Catalyst Lube Oil Nitrogen Process Line Carrying Hydrocarbons Refrigerant Steam - (Prefix H,M or L to Denote Pressure) Seal Oil Vent, Relief & Flare Lines Foul Water

Figure 8 Blank (Closed)

Four Way

Double Block & Bleed

Three Way Plug Four Way Plug Float

O

Lines

Process Line - Primary (0,7mm thickness) Process Line - Secondary (0,5mm thickness) (indicate direction of flow)

Ih

Spray Nozzles

Diaphragm Orbit (4) Globe Y-Pattern Slide Steam Jacketed Plug ***

Drip Ring Assembly

PE

Normally Open (3) Intermittently Open (3) Normally Closed (3) TSO CSO CSC LC LO

F

Injection Nozzle

O C

Insulated line (1)

RS

Ist

Insulated Line - Heat Traced (1)

Removable Spool

Flexible Coupling

Steam Jacketed Line Line Identification reference block at plot limit

Flange with Insulating Gasket

Lever Operated Expansion Joint

Tight Shut-Off Car Sealed Open Car Sealed Closed Locked Closed Locked Open Flushed

Line Identification continuation reference block - within plot limits

-------

Line Strainer (Y-Type)

Steam Desuperheater

Piping Identification change (spec or insulation) Line number change

General Notes

Strainer

Miscellaneous Connections

AS

B - Basket C - Cone P - Plate

Steam Separator

and

References

Air Station

HC PC PO QS S SC

Hose Connection Purge Connection Pump Out Quench Steam Sample Connection

L

SC LB SL SO SL US VC

Sample Cooler with by-pass (Light Oils) Steam Lance

F

Ejector or Eductor Tee-Type Strainer Steam Exhaust Head

This drawing is to be read in conjunction with GPS-A4. Symbols shown are drawn with flow from left to right, unless otherwise indicated. All flanged connections to equipment shall be shown. ( ) Refer to notes on sheet 3. GPS-A1, -A17, -L1, -L16, -N1

Cooling Water CW P (Purge)

DC EP FC GC GS

Sources

Drain Connection Expansion Plate Flush Connection Gland Condenser Gas Seal

Steam Out Steam Trap Utility Station Vent Connection

F

Sample Cooler (Light Oils) Sample Cooler SC H (Heavy Oils)

Filter

Trap Vacuum Booster (Lift)

Symbols for Process Flow Piping & Instrument Diagrams

Approvals Jan95 Standard Drawing Sheet No. Rev.

SD-A-10271

1 of 3

CES 98

Heaters (Schematic Only)

Pressure Vessels

Pressure Vessel Details

Flue Damper Waste Heat Recovery (One Pass typical of four shown) Convection Section (Two Passes shown)

BASIC VESSEL - HORIZONTAL

Blank Vessel Nozzle

MW MW

Manways (indicate size)

Demister Pad Hand Hole (Indicate Size)

HH

Flanged Connection

BASIC VESSEL - VERTICAL

Screwed Connection Internal Lining

8

Internal Pipe with Distribution Header Tray & Downcomer Tray Number

Radiant Section (Two Passes combining shown)

VESSEL WITH BOOT

Ih

External Lining Coalescing Medium

Where more than two Passes exist one Typical Pass shall be shown Air Inlet Heat Exchanger Fuel Burner Air Outlet

Inlet Diffuser

Heating Coil

KNOCK OUT POT

External Lining with Electric Trace Vortex Breaker with Strainer

Iet

AIR HEATER

Internal Wall (Weir)

Vortex Breaker

PULSATION DAMPER

Tanks

CONE ROOF COOLING TOWER

Internal Floating Deck (when used)

Heat Exchangers

IMMERSION HEATER

AIRCOOLER OR CONDENSER

Indicate Induced Draft Forced Draft Fan (Fixed) Fan (Variable Pitch) Louvre Controlled ID FD FF FVP LC

FLOATING ROOF

T

BASIC SHELL & TUBE HEAT EXCHANGER

KETTLE TYPE REBOILER

SPHERICAL DOUBLE PIPE HEAT EXCHANGER THERMOSYPHON REBOILER

Approvals Jan95

Symbols for Process Flow Piping & Instrument Diagrams

Standard Drawing Sheet No. Rev.

SD-A-10271

2 of 3

Pumps

(5)

Drivers

(Other than Electric Motors)

Notes

1. Insulation types (refer to GPS-N1)

Horizontal Centrifugal - Motor Driven

Turbine

Steam

Ih Iph Ipp Iaa, Iab, Iac Ist Iet

Vertical Centrifugal - Motor Driven

A

Full Heat Conservation Partial Heat Conservation Personnel Protection Acoustic Insulation, Type A, B or C (refer GPS-L16) Steam Trace Electrical Trace

Air

Engine

2. Valve symbols shown are applicable to flanged, socket weld and screwed end connections. Use a modified symbol (similar to that shown for a gate valve) only in the case of butt welding end connections. 3. Valves should be designated normally open or normally closed only where there are special operating reasons. 4. For "Orbit" valves use the letters PE to show which end is the pressure end. 5. Either apply a convention of symbols indicating any utility connections to pump and compressor seals, or crossreference the pump or compressor diagram which show these.

Rotary - Motor Driven

Hand

Reciprocating - Motor Driven

NOTE: Driver Symbols to be Placed Immediately Above and Touching the Driven Equipment

Compressors

(5)

Miscellaneous

Centrifugal - Motor Driven

Agitator or Mixer - Motor Driven

Rotary - Motor Driven ***

Drain to Sewer *** OWS - Oily Water Sewer FWS - Foul Water Sewer

Reciprocating - Motor Driven

Symbols for Process Flow Piping & Instrument Diagrams

Approvals Jan95 Standard Drawing Sheet No. Rev.

SD-A-10271

3 of 3

Você também pode gostar

- Material Selection and SpecificationDocumento50 páginasMaterial Selection and SpecificationbashirAinda não há avaliações

- Piping SpecificationDocumento5 páginasPiping SpecificationShandi Hasnul FarizalAinda não há avaliações

- Check List - Basic Engineering Package (BEP) Information Input/ ReviewDocumento4 páginasCheck List - Basic Engineering Package (BEP) Information Input/ ReviewssgentisAinda não há avaliações

- Piping Spec: CS150 TFS 1021: Engineering StandardDocumento4 páginasPiping Spec: CS150 TFS 1021: Engineering Standardbmanojkumar16Ainda não há avaliações

- Piping and Valve Specifications Rev. A PDFDocumento28 páginasPiping and Valve Specifications Rev. A PDFYessine RebaiAinda não há avaliações

- Symbols of Chemical Apparatus and Instrumentation: Packing Column Tray ColumnDocumento2 páginasSymbols of Chemical Apparatus and Instrumentation: Packing Column Tray ColumnSamik MukherjeeAinda não há avaliações

- Piping SystemsDocumento73 páginasPiping SystemsSebin MathewsAinda não há avaliações

- A1a PMSDocumento5 páginasA1a PMSS.selvakumarAinda não há avaliações

- Piping Material EquivalentsDocumento1 páginaPiping Material EquivalentspejnorozyAinda não há avaliações

- Annexure To SOW 10 Standard Specification For Steam TracingDocumento9 páginasAnnexure To SOW 10 Standard Specification For Steam TracingASHISH GORDEAinda não há avaliações

- AL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCDocumento5 páginasAL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCCaptainToniesAinda não há avaliações

- Sec.6 - Class C Heat ExchangerDocumento33 páginasSec.6 - Class C Heat ExchangerAgung Dewandaru MahatmantoAinda não há avaliações

- Piping Wall Sizing and Thickness CalculationDocumento16 páginasPiping Wall Sizing and Thickness CalculationAriAinda não há avaliações

- PipingDocumento4 páginasPipingmshkAinda não há avaliações

- ASHRAE HVAC 2001 Fundamentals HandbookDocumento6 páginasASHRAE HVAC 2001 Fundamentals HandbookJosé A. Ramírez100% (1)

- Pressure Test For Piping According To Asme B31.4Documento13 páginasPressure Test For Piping According To Asme B31.4ahmed088394940% (1)

- Control Valve - EN 1349Documento5 páginasControl Valve - EN 1349Nemanja PapricaAinda não há avaliações

- API Standard Storage Tank Data SheetDocumento3 páginasAPI Standard Storage Tank Data Sheetjuanchocazon78Ainda não há avaliações

- PMS PDFDocumento215 páginasPMS PDFAlvin Smith100% (4)

- Piping ChecklistDocumento1 páginaPiping Checklistsiva8000Ainda não há avaliações

- Pipe CodeDocumento113 páginasPipe CodeVikas Kumar PathakAinda não há avaliações

- MIS-M-DS-04053 50m3 Slop Tank Data Sheet-BDocumento2 páginasMIS-M-DS-04053 50m3 Slop Tank Data Sheet-Bhappale2002Ainda não há avaliações

- PIPING Engineering Interview Questions:-: Isolation, Regulation, Non-Return and Special PurposesDocumento21 páginasPIPING Engineering Interview Questions:-: Isolation, Regulation, Non-Return and Special PurposesAdil KhawajaAinda não há avaliações

- Pipe Routing InstructionsDocumento37 páginasPipe Routing InstructionsDANLIN ENGINEERS100% (1)

- Test Pack Table of ContentsDocumento1 páginaTest Pack Table of ContentsRavindra S. JivaniAinda não há avaliações

- Material ComparisonDocumento10 páginasMaterial ComparisonMardeOpamenAinda não há avaliações

- Piping Material Service IndexDocumento3 páginasPiping Material Service IndexOghenekevwe OrumahAinda não há avaliações

- Vessel Module Sans RH GoodDocumento24 páginasVessel Module Sans RH GoodThaksenAinda não há avaliações

- Aviation Refuelling Equipment CatalogueDocumento180 páginasAviation Refuelling Equipment Catalogueviktor_gligorovAinda não há avaliações

- P - ID Drawing StandardsDocumento8 páginasP - ID Drawing StandardsObaid AliAinda não há avaliações

- Comparison Between ASME B31.1 & 31.3 & 31.8Documento10 páginasComparison Between ASME B31.1 & 31.3 & 31.8karuna346100% (2)

- Sa-516 70 TDCDocumento2 páginasSa-516 70 TDCshazan100% (1)

- Piping Isometric Check ListDocumento2 páginasPiping Isometric Check ListPaulo SousaAinda não há avaliações

- Piping ConstructionDocumento31 páginasPiping ConstructionAnonymous dSFbLxc9Ainda não há avaliações

- Check List For Piping GADDocumento3 páginasCheck List For Piping GADkaruna100% (2)

- Cti Code Tover Standard Specifi CationsDocumento10 páginasCti Code Tover Standard Specifi CationsSanjeev GulatyAinda não há avaliações

- Piping & Instrumentation DiagramDocumento20 páginasPiping & Instrumentation DiagramOladayo Siyanbola100% (2)

- Model Review Process X5axp5bsDocumento8 páginasModel Review Process X5axp5bsNadi Jothidan KLAinda não há avaliações

- Rocess LOW Iagram: An OverviewDocumento20 páginasRocess LOW Iagram: An OverviewRajkumar AAinda não há avaliações

- 345 Testing THDocumento6 páginas345 Testing THDjeisonSeccoAinda não há avaliações

- Reciprocating CompressorDocumento6 páginasReciprocating CompressorEDUARDOAinda não há avaliações

- d6t PDFDocumento2 páginasd6t PDFaeylxdAinda não há avaliações

- Legend Sheet ModelDocumento1 páginaLegend Sheet ModelĐỗ Thiện100% (1)

- Plano Tren de Fuerza d11tDocumento2 páginasPlano Tren de Fuerza d11talexander_1985Ainda não há avaliações

- Backhoe 420E y 430E Interactivo - SISDocumento15 páginasBackhoe 420E y 430E Interactivo - SISIvanZavaleta100% (10)

- Plano de Implementos d11tDocumento2 páginasPlano de Implementos d11talexander_1985Ainda não há avaliações

- 092 M-002 Mechanical Symbols and LegendsDocumento1 página092 M-002 Mechanical Symbols and Legendseuri08Ainda não há avaliações

- Chapter 3 P&idDocumento101 páginasChapter 3 P&idLim Leong100% (1)

- D 8 TDocumento2 páginasD 8 TAlberjose Sanchez RuizAinda não há avaliações

- PFD P ID InstrumentationDocumento101 páginasPFD P ID InstrumentationBadrian Badbad67% (3)

- Chapter 1.1 PFD & PIDDocumento103 páginasChapter 1.1 PFD & PIDS JAinda não há avaliações

- Graphical Symbols For Piping Systems and Plant: BASED ON BS 1553: PART 1: 1977Documento9 páginasGraphical Symbols For Piping Systems and Plant: BASED ON BS 1553: PART 1: 1977Bruce QuareAinda não há avaliações

- Valvulas SporlanDocumento8 páginasValvulas SporlanEduardo Sanchez LopezAinda não há avaliações

- Chemical Process DiagramDocumento43 páginasChemical Process DiagramMark GuevarraAinda não há avaliações

- D8R Track-Type Tractor Hydraulic System: 7XM1-UP 9EM1-UPDocumento2 páginasD8R Track-Type Tractor Hydraulic System: 7XM1-UP 9EM1-UPLuis Eduardo Corzo Enriquez100% (4)

- 2015-Xii. P&id PDFDocumento71 páginas2015-Xii. P&id PDFFitria Nur HayatiAinda não há avaliações

- Architectural AbbreviationsDocumento15 páginasArchitectural AbbreviationsMohamed AjeemusshaanAinda não há avaliações

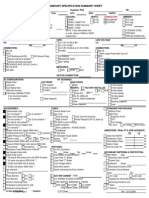

- Padmount Specification Summary Sheet: Fluid: Temp: ConductorDocumento2 páginasPadmount Specification Summary Sheet: Fluid: Temp: Conductorpeloquin1349391Ainda não há avaliações

- Sensors & Gauges Legend: C175-16 Genset Skid LimitDocumento5 páginasSensors & Gauges Legend: C175-16 Genset Skid LimitTrungSon NguyenAinda não há avaliações

- XX-XXX: Sub-Plant Number Stream Number (From 01)Documento2 páginasXX-XXX: Sub-Plant Number Stream Number (From 01)Xiyao RenAinda não há avaliações

- Final Submittal For Butterfly Valve - Dairy Farm Revised 20-8-2017Documento95 páginasFinal Submittal For Butterfly Valve - Dairy Farm Revised 20-8-2017Unni CyriacAinda não há avaliações

- Dosing Equipments PDF Document Aqua Middle East FZCDocumento40 páginasDosing Equipments PDF Document Aqua Middle East FZCAdolfsmith69Ainda não há avaliações

- GRP - GRE - GRV Pipes and FittingDocumento6 páginasGRP - GRE - GRV Pipes and FittingrajaAinda não há avaliações

- US Manual EnglishDocumento101 páginasUS Manual EnglishFernando ChavezAinda não há avaliações

- EP FA IN 01 PH Philosophy For Instrumentation and Instrument Air - Rev-2 - 2009-09-01.doDocumento45 páginasEP FA IN 01 PH Philosophy For Instrumentation and Instrument Air - Rev-2 - 2009-09-01.doVasile MadalinAinda não há avaliações

- Camshaft Vibration Damper ''D 63''Documento36 páginasCamshaft Vibration Damper ''D 63''AlexDor100% (1)

- 2Documento14 páginas2WormInchAinda não há avaliações

- MEC-SPE - Air Cooled Heat ExchangersDocumento30 páginasMEC-SPE - Air Cooled Heat Exchangershasan_676489616Ainda não há avaliações

- Internal Gear PumpDocumento24 páginasInternal Gear Pumparisqi wahyuAinda não há avaliações

- Standard Specification For Waste Water MaterialsDocumento25 páginasStandard Specification For Waste Water Materialspopperoo00Ainda não há avaliações

- SPEC For Chilled Water Pipework and FittingsDocumento4 páginasSPEC For Chilled Water Pipework and FittingsonspsnonsAinda não há avaliações

- World Flange StandardsDocumento10 páginasWorld Flange StandardsIsaac KendallAinda não há avaliações

- Sabre Instrument Mounting Systeme BrochureDocumento12 páginasSabre Instrument Mounting Systeme Brochurehafizi07Ainda não há avaliações

- Atlas Copco: DryersDocumento90 páginasAtlas Copco: DryersMarko StojanovicAinda não há avaliações

- 3051Documento84 páginas3051Tamy AlexAinda não há avaliações

- Fisher Control Valve HanbookDocumento116 páginasFisher Control Valve HanbookDebb RsAinda não há avaliações

- 1D83 (1C1D8450E2) T105SE Crypton RDocumento56 páginas1D83 (1C1D8450E2) T105SE Crypton RRenAinda não há avaliações

- Electronic Parts Catalog - Option DetailDocumento3 páginasElectronic Parts Catalog - Option Detailnaya aninditaAinda não há avaliações

- Fe800 Installation Manual PDFDocumento56 páginasFe800 Installation Manual PDFJose Mata RamcharanAinda não há avaliações

- OISD STD 2015 OISD STD 132 Pressure Relieving DevicesDocumento60 páginasOISD STD 2015 OISD STD 132 Pressure Relieving DevicesÏÂm ÂvïRâjAinda não há avaliações

- PB 4D88E 6 S N 14803 UP For PC55MDocumento48 páginasPB 4D88E 6 S N 14803 UP For PC55MAnderson OlsenAinda não há avaliações

- IMI TRUFLO RONA Fully Welded Ball ValvesDocumento12 páginasIMI TRUFLO RONA Fully Welded Ball ValvesAlexandra HarperAinda não há avaliações

- 18 Heat ExchangersDocumento6 páginas18 Heat ExchangersJoshua EvansAinda não há avaliações

- J54-100 Parte1Documento45 páginasJ54-100 Parte1angel gabriel perez valdezAinda não há avaliações

- Annex "A" - Schedule of Prices Schedule of Prices Point A Pierre Refinery Gasoline Optimisation ProgramDocumento11 páginasAnnex "A" - Schedule of Prices Schedule of Prices Point A Pierre Refinery Gasoline Optimisation ProgramToapanta FredyAinda não há avaliações

- Basket Strainers: ApplicationsDocumento15 páginasBasket Strainers: ApplicationsTu PhamAinda não há avaliações

- Data Sheet - Angus OM-80 Oscillating MonitorDocumento2 páginasData Sheet - Angus OM-80 Oscillating Monitorzelda1022Ainda não há avaliações

- Carbon Steel Strainer Fig 34 HP-Technical InformationDocumento3 páginasCarbon Steel Strainer Fig 34 HP-Technical InformationSouljah KhifferAinda não há avaliações

- Service Manual: Hammermaster RockbreakersDocumento423 páginasService Manual: Hammermaster RockbreakersredAinda não há avaliações

- 6.1 Data Sheet For Pipeline Ball ValveDocumento3 páginas6.1 Data Sheet For Pipeline Ball ValveDeepak PalAinda não há avaliações